Week 14 - Composites

Assignment:

read the material datasheet (MSDS) and technical datasheet (TDS) for the resin that you´re using. Design and fabricate a 3D mold (ft^2) and produce a fiber composite part in it

Theory:

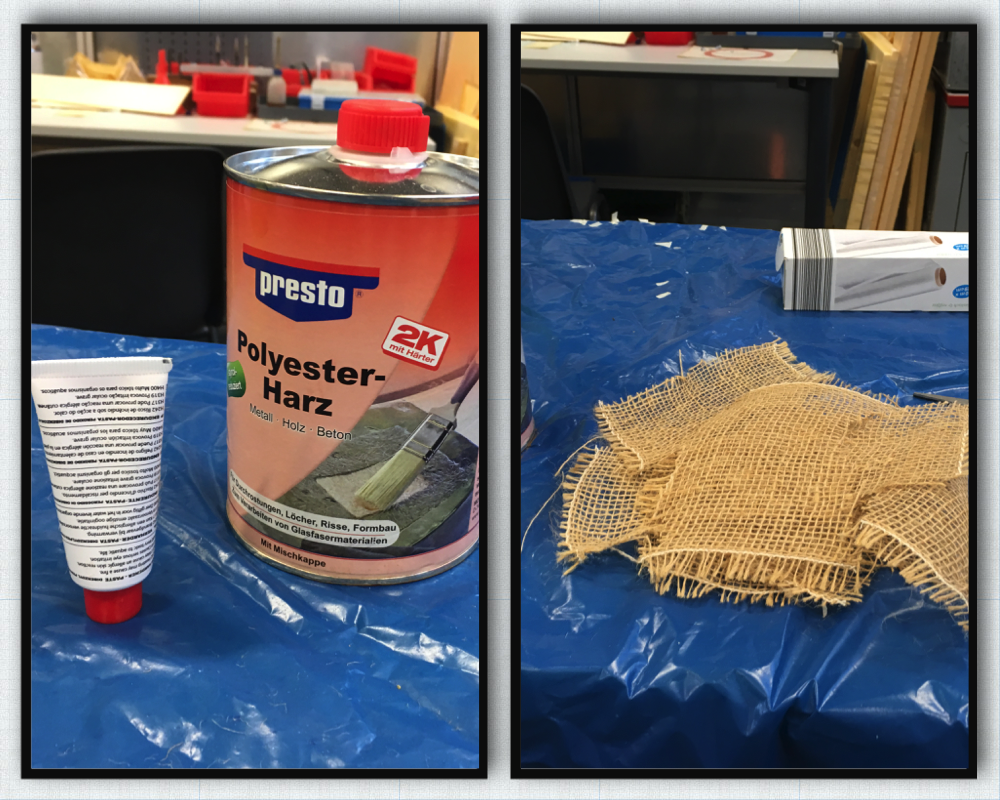

An composite or composite material is a material made of two or more materials that have different material properties than its individual components. For the properties of the composites, material properties and geometry of the components are important. In my example I have use a natural composite material (yute) in combination with polyesterresin

Composite materials are generally used for buildings, bridges, and structures such as boat hulls, swimming pool panels, race car bodies, shower stalls, bathtubs, storage tanks, imitation granite and cultured marble sinks and countertops. The most advanced examples perform routinely on spacecraft and aircraft in demanding environments.

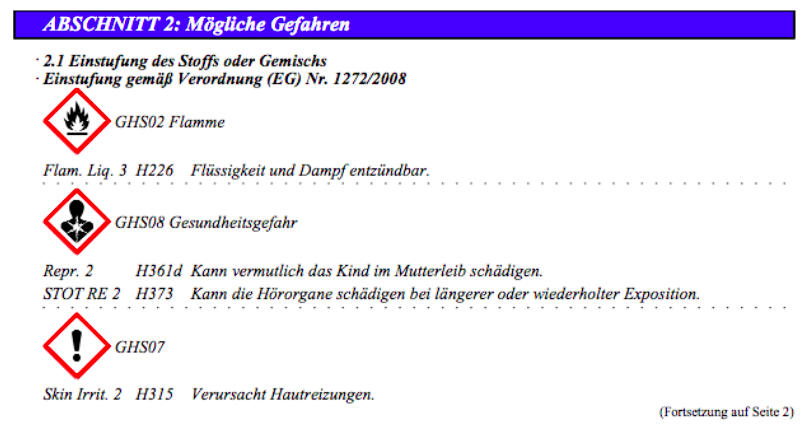

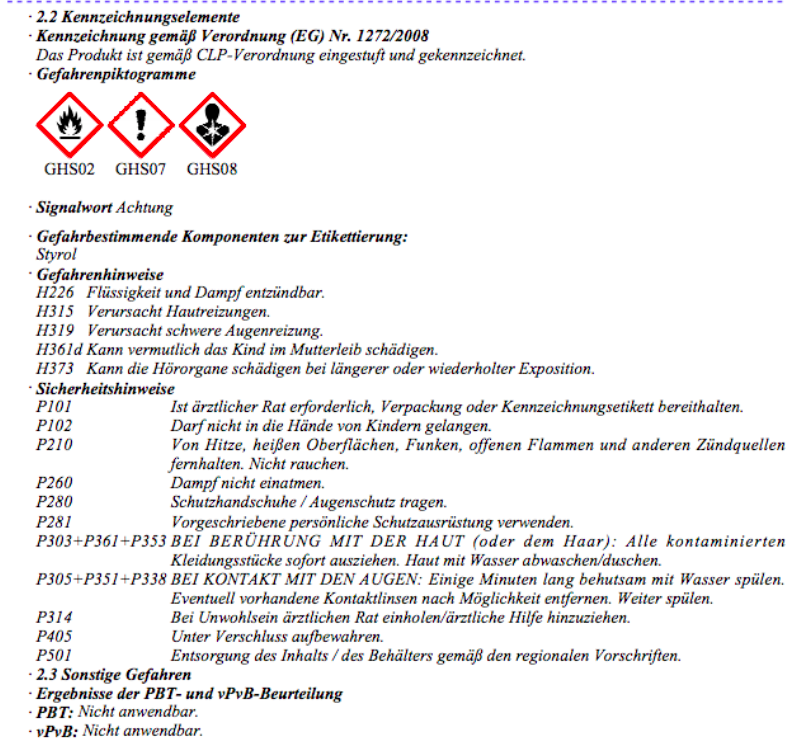

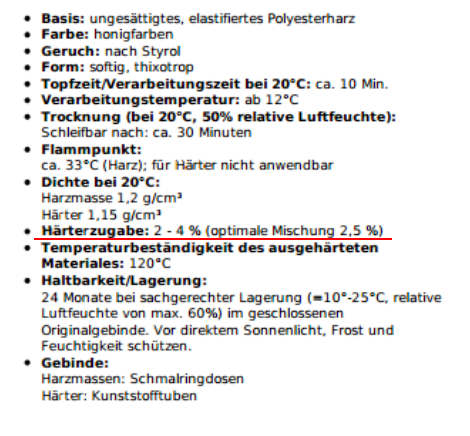

1. Read the material datasheet (MSDS) and technical datasheet (TDS) for the resin that you´re using.

Possible hazards

Disposal: Only recyclable containers should be recycled. Dispose of containers with residues to the problem disposal point.

Shelf life / storage:

24 months with proper storage (= 10 ° -25 ° C, relative

Humidity of max. 60%) in the closed

Original container. Before direct sunlight, frost and

Protect the moisture

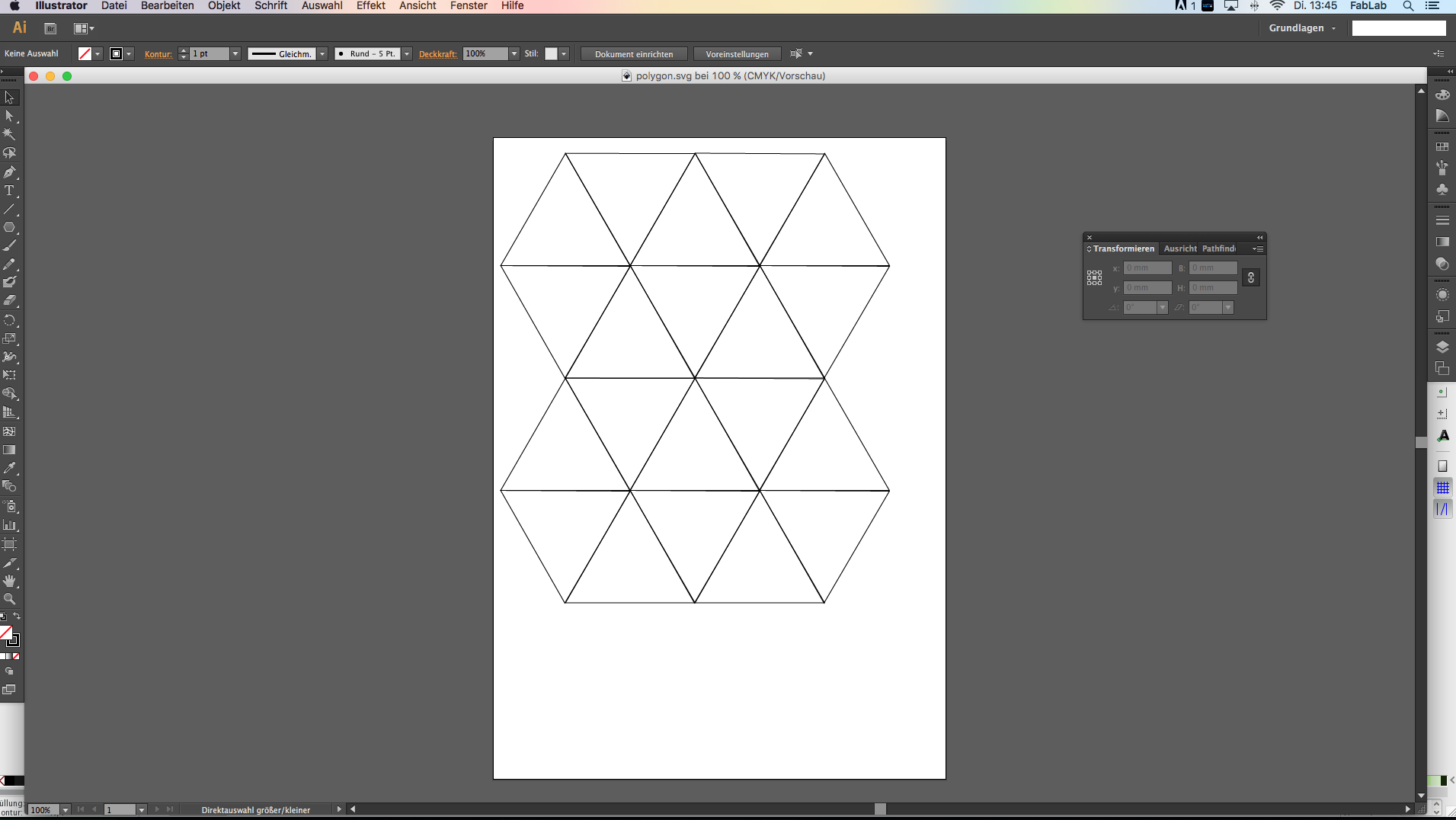

2. Preparing the 2D-design into a 3D-design

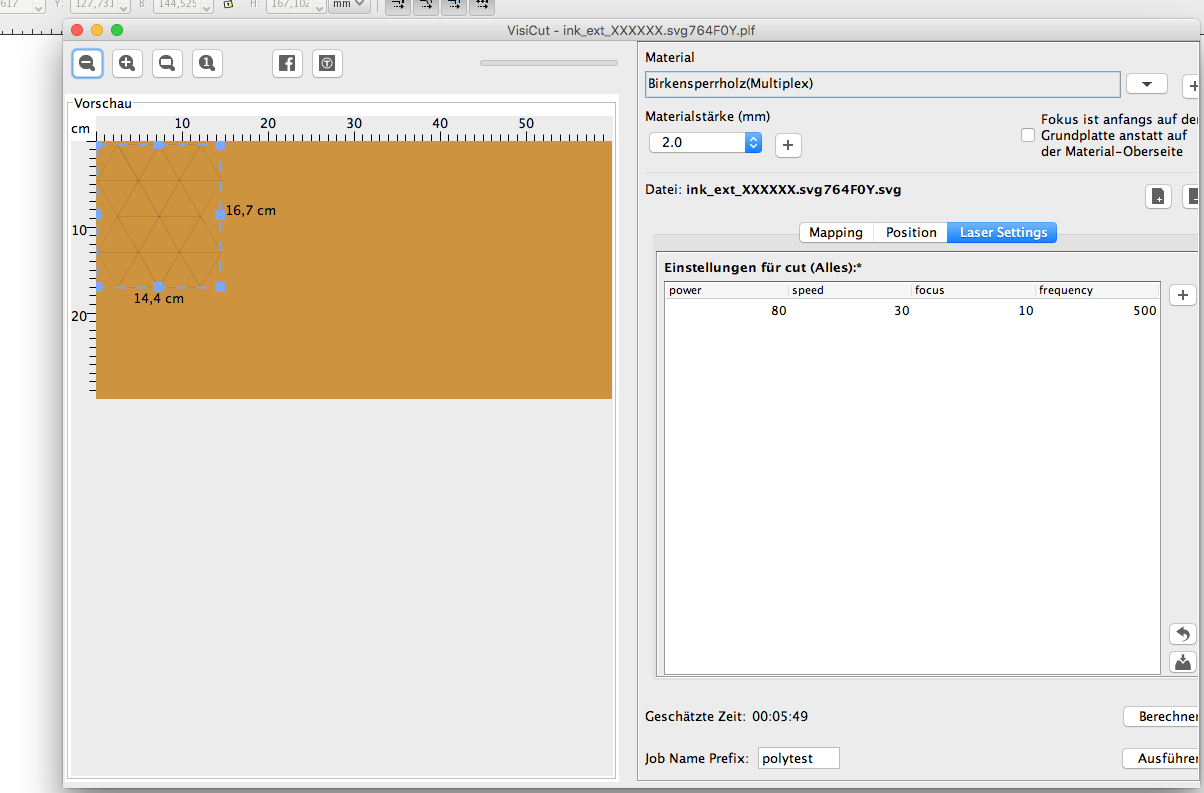

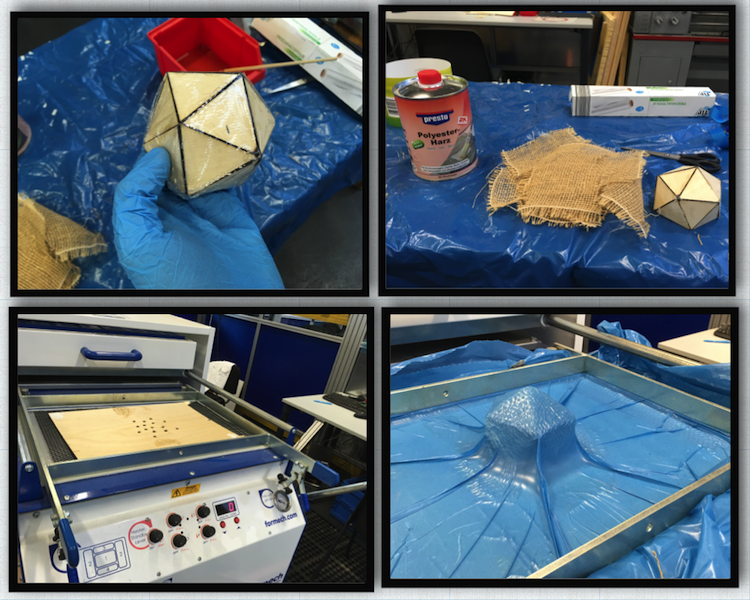

Lasercutter-settings

Power: 80%; speed 30%; fokus 10%; frequency 500 Hz:

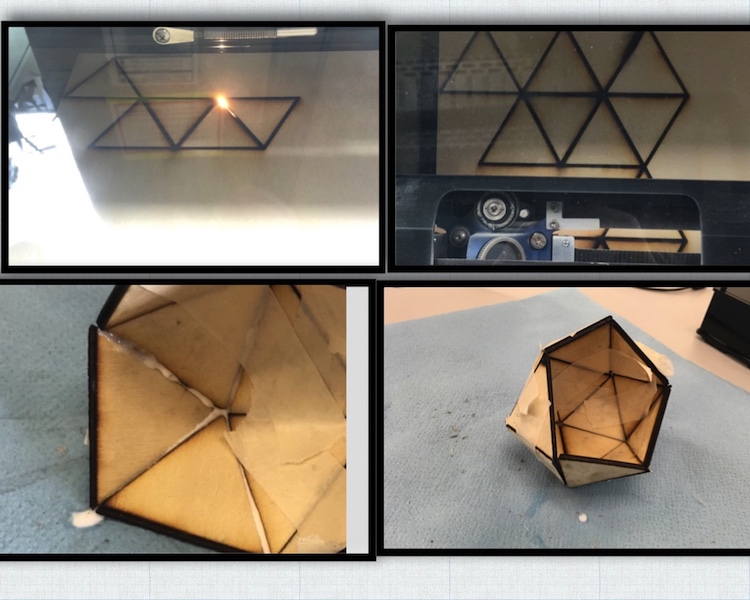

The individual triangles were glued together with the aid of wood glue. By changing from the focus I have the areas slightly bevelled. As a result, the individual surfaces could be better adhered to one another.

With the help of wood glue and adhesive tape, the parts were now assembled:

3. Preparing the Composite

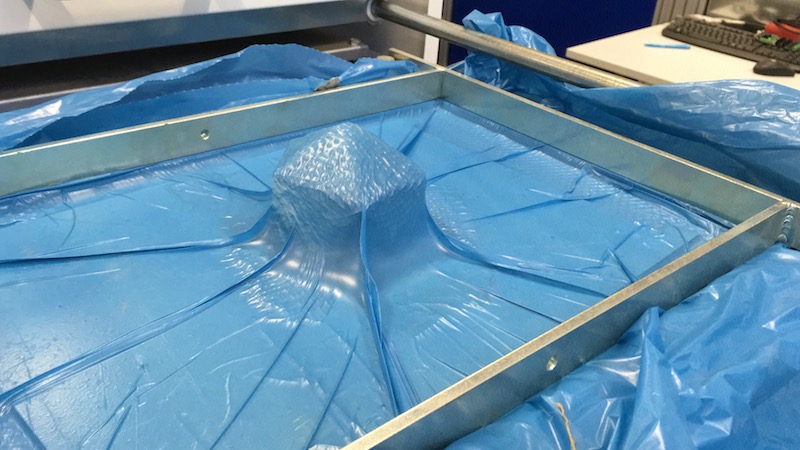

4. Preparing the Vacuummachine

Machine Information:

I used our 300XQ Formech vacuum thermoforming machine to press the composites together. It is a Sheet forming machine for the quick and easy creation of plastic molds by thermoforming. Simple operation, versatile tool use made of wood, gypsum, epoxy resin, 3D printer models, aluminum, etc. possible. For all thermoformable plastic plates and foils of approx. 100my to 6mm plate thickness. Plastics such as PS, ABS, PP, plexiglass, acrylic, PETG

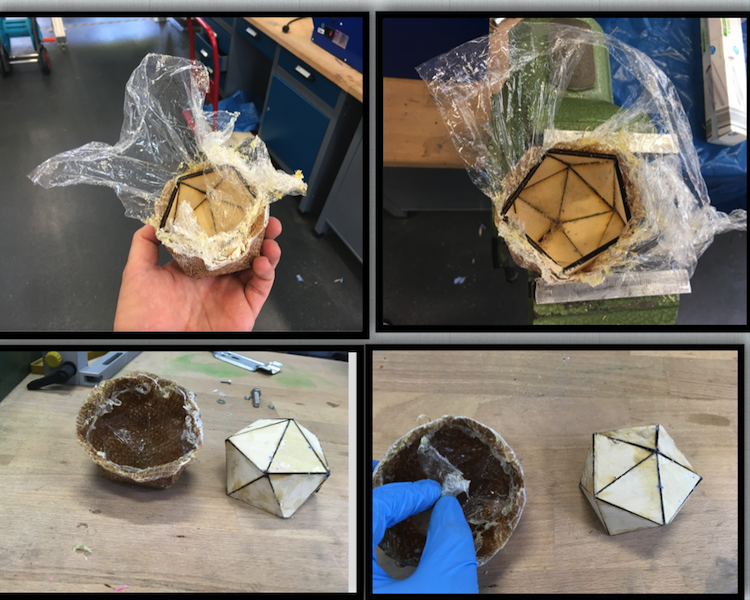

Here you can see the removed wood mold and the composite of the polygon plantpot:

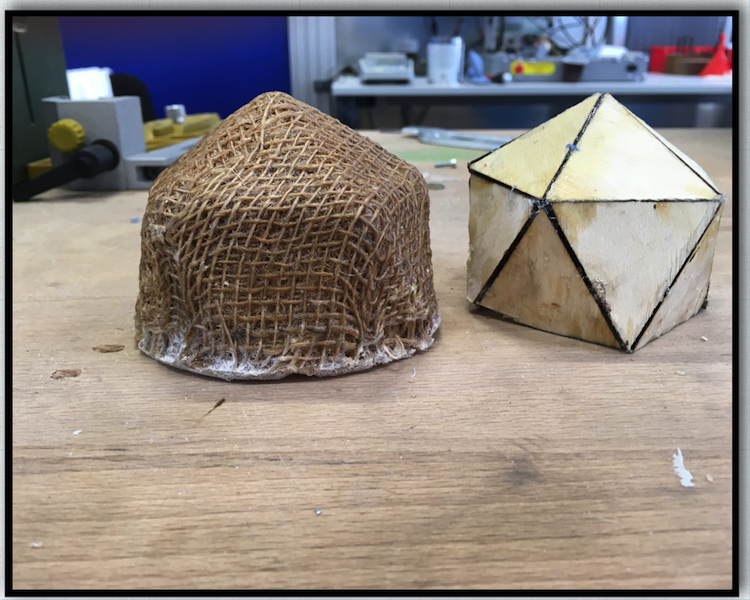

Lastly I have the surface with another layer of resin coated to have a nice finish:

After the hardening of the resin I could finally use the plantpot. The result is very hard and has a high strength:

With some hammer hits I demonstrate the hardness of the composite material:

It is amazing that the compounds between the polyester resin and the yute stripes have become so hard and strength. This week it was really exciting to see what you can create with this technic.

- Polygon Plantpot.svg

- Presto Resin safety Datahseet

- Presto Resin Datahseet

- http://academy.cba.mit.edu/classes/composites/index.html

- https://en.wikipedia.org/wiki/Composite_material

Download-Section:

Information-Source: