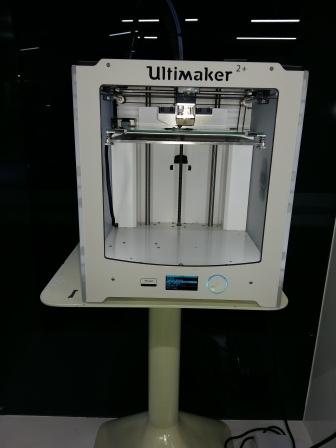

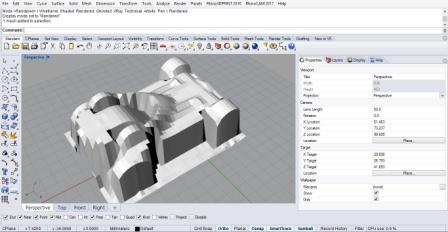

3D Printing - Introduction

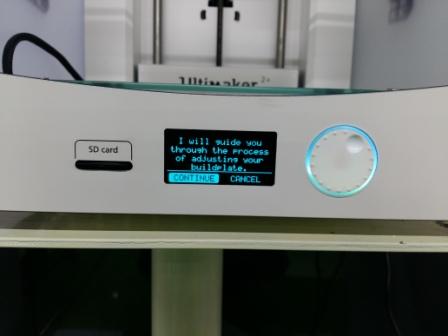

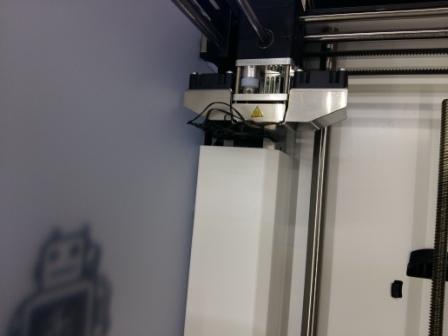

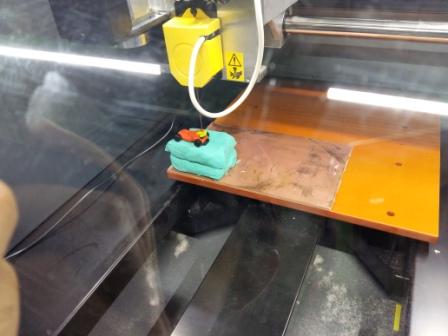

In our lab we are using ultimaker 2+ 3D printer. It has an open filament system and has easily swappable nozzles of different dia (0.25,0.4,0.6 and 0.8 mm) for detailed or faster print speed. For our testing we used 0.4 mm nozzle which is good compromize between speed and accuracy