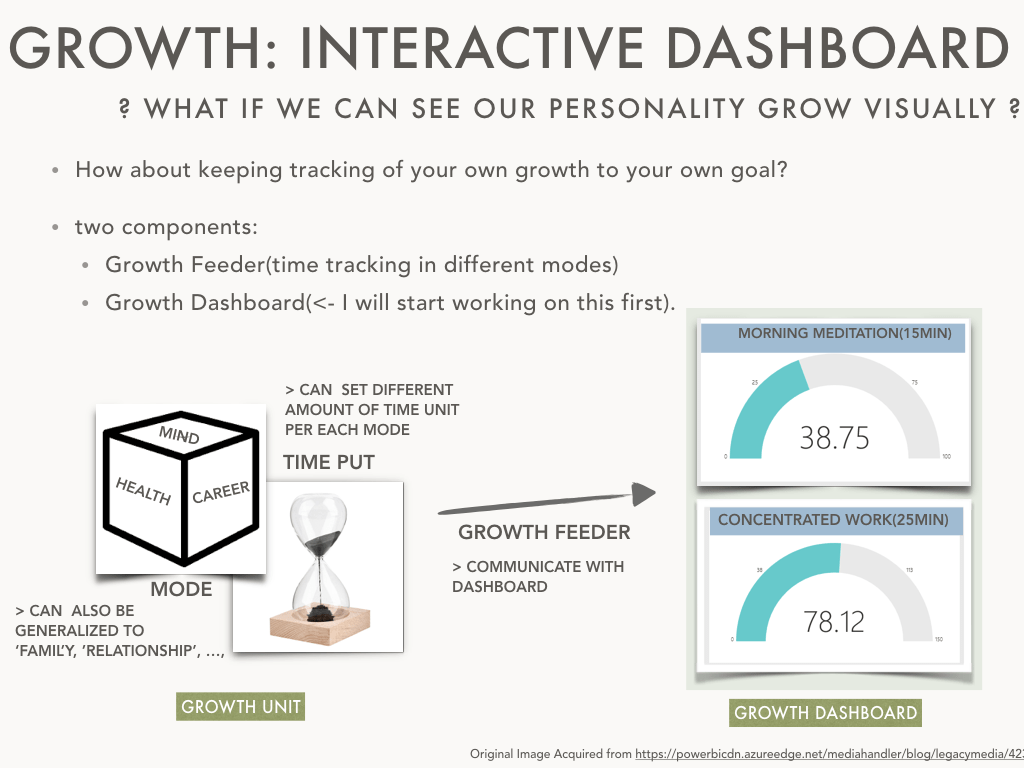

From my three ideas on my final project, I decided to go for the last one, Growth Dashboard. I'll work you through the process.

Final Presentation

Motivation & Idea

I would define 'human growth' as an amount of time put together, towards a goal one has

set.

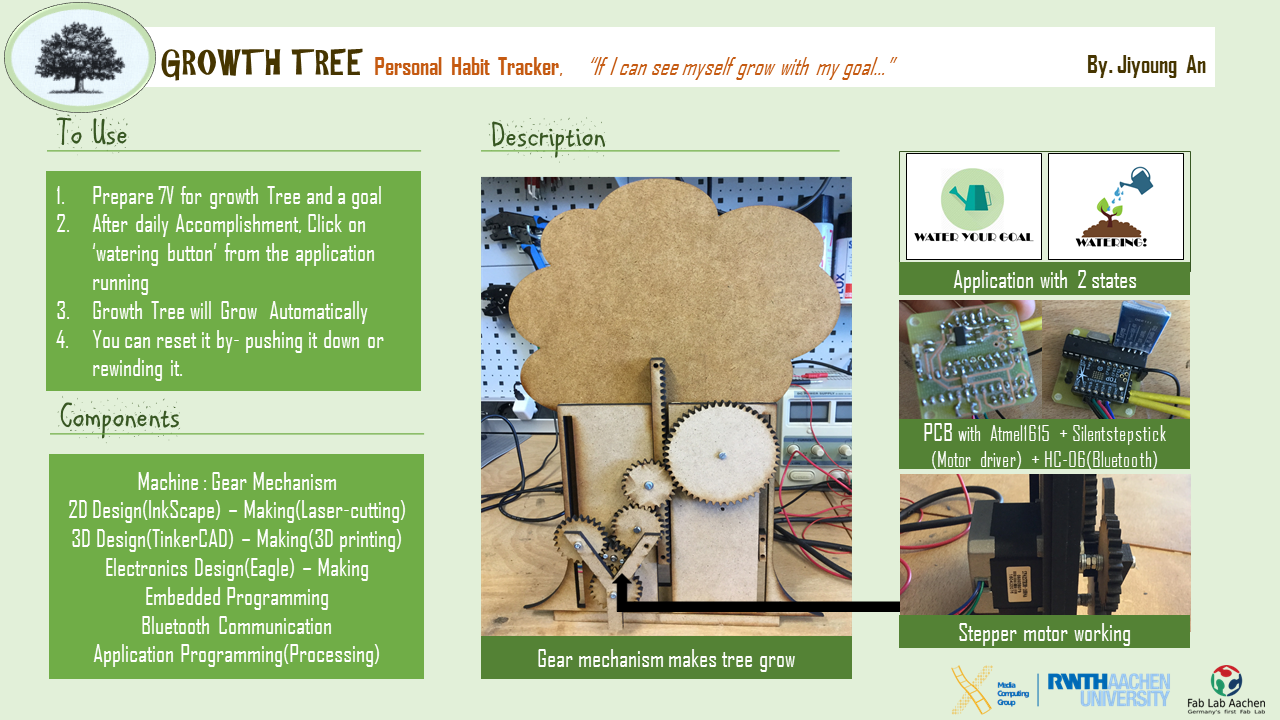

Let's imagine your goal is one tree. You will need to water them every day to grow them.

My application will aid this human-growing process by giving an immediate and persistent

feedback on how tall one's tree has grown, how big you have grown.

- Keep track of your personal growth

- Keep motivated

- Every time after you work for your own goal, you can 'water' the tree using Desktop application.

- As you don't forget about your goal, and you would like to grow it even taller.

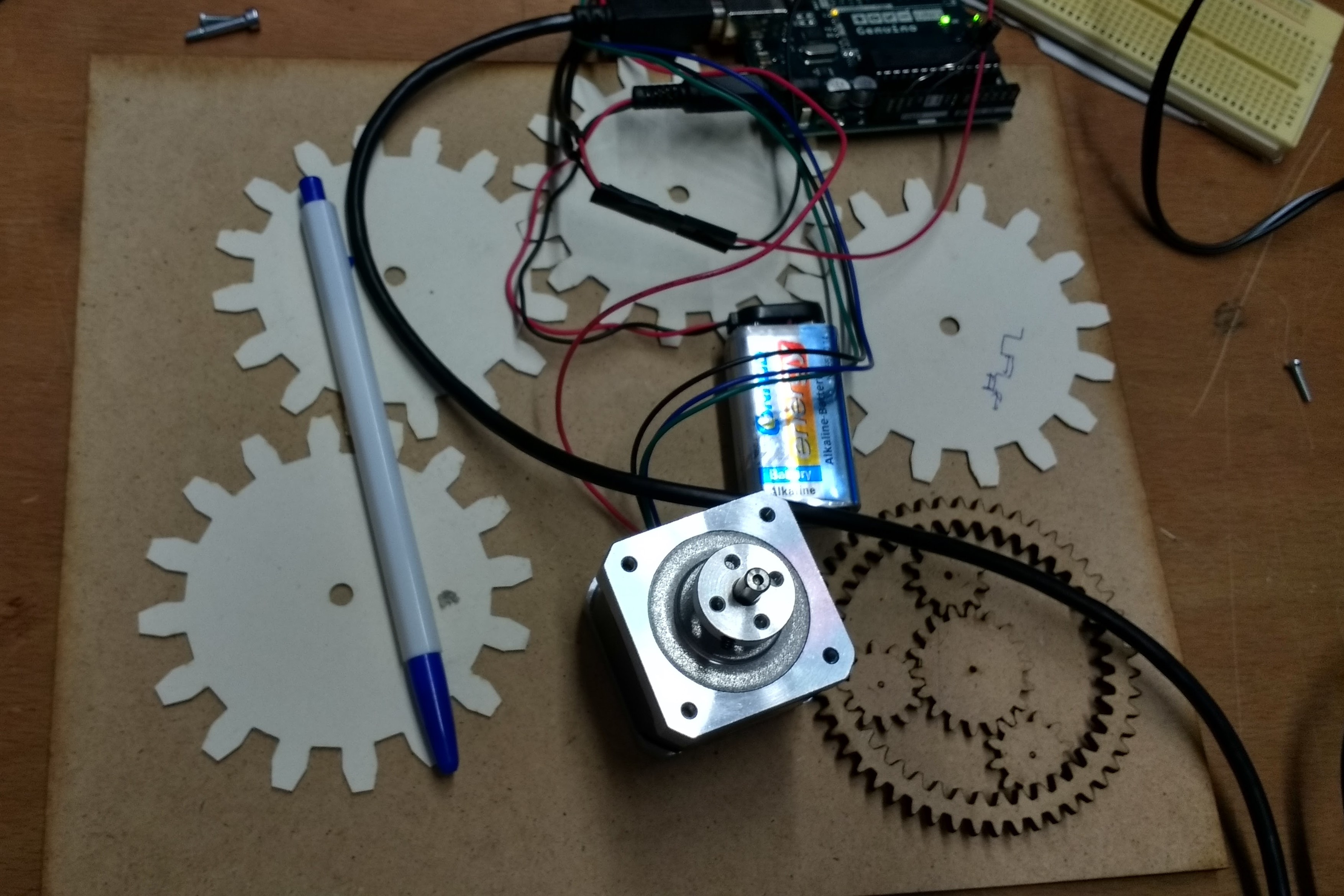

- Tree made with laser cut MDF panel

- PCB boards nestled in 3d printed casing

- Desktop Application to water your tree

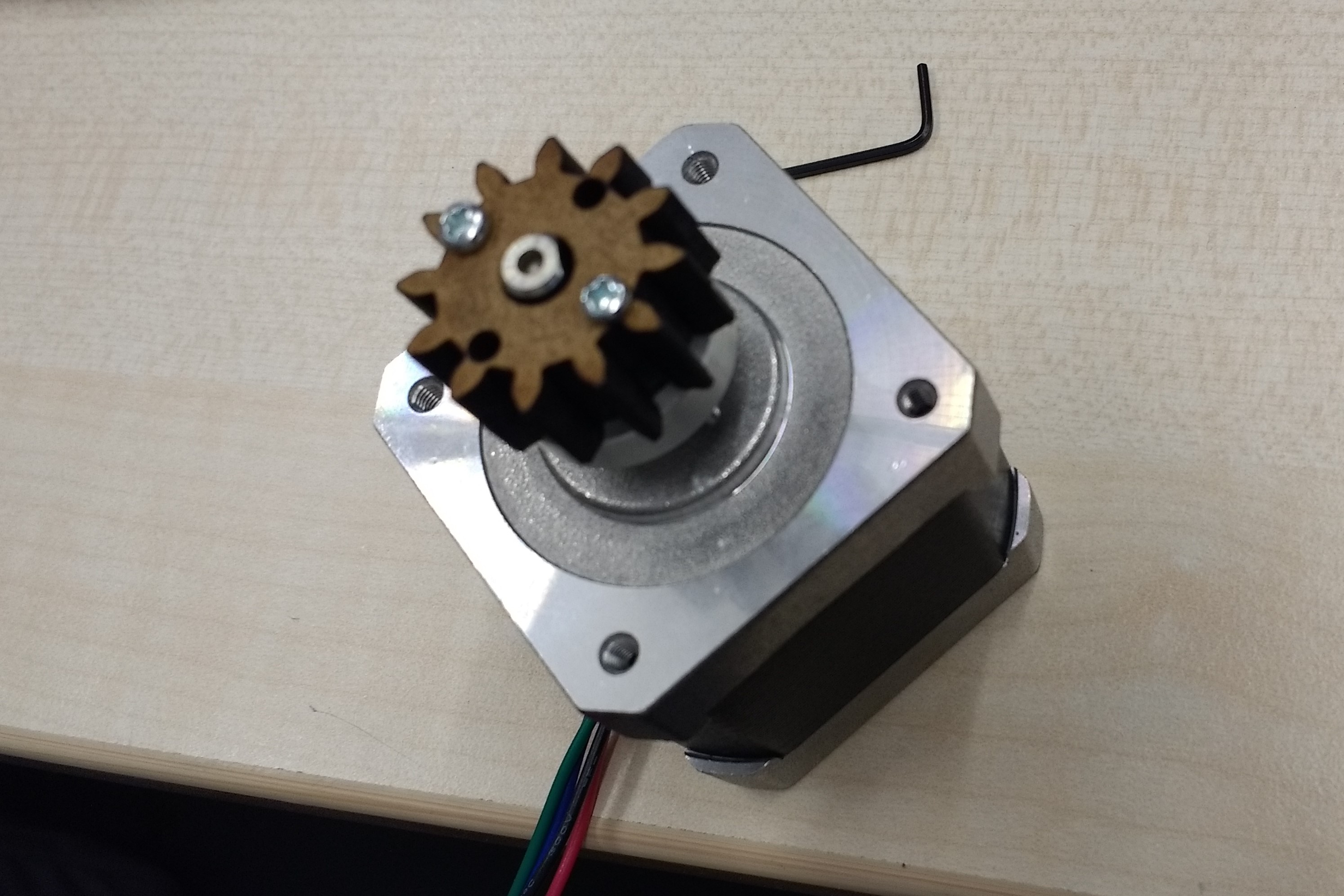

- Gear mechanism run by a stepper motor and silent step stick driver

- and Bluetooth channel communicates with your desktop application

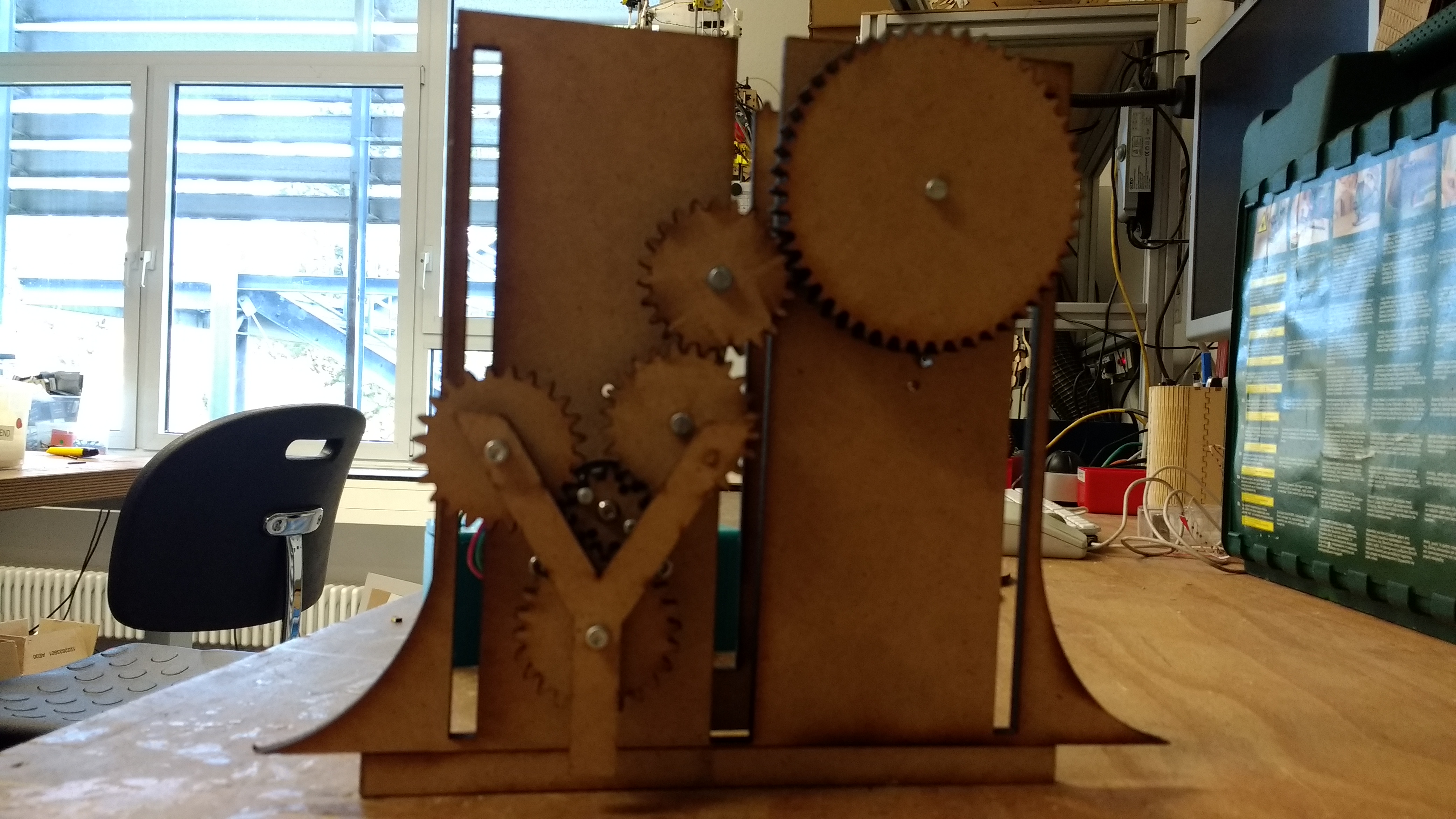

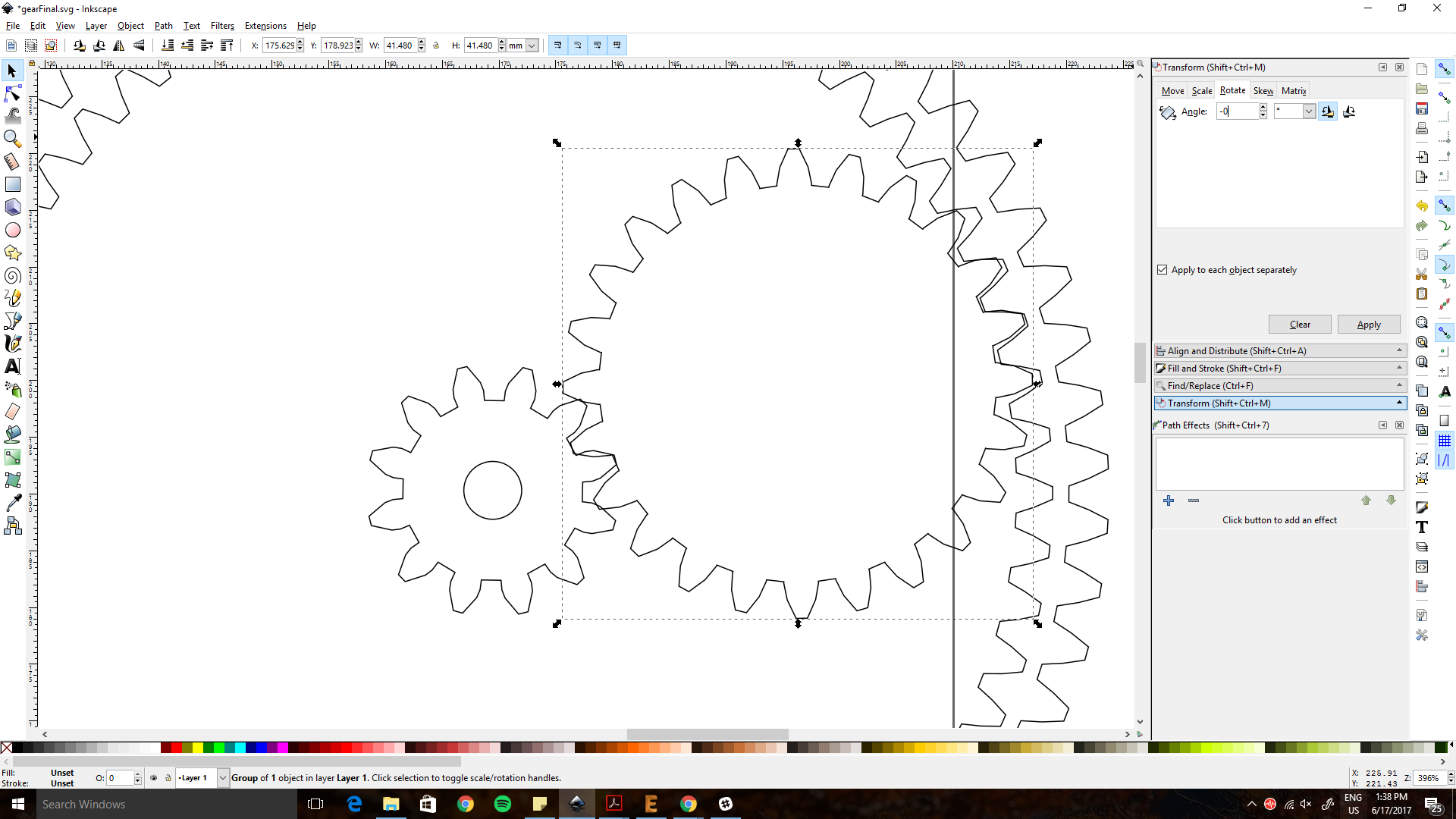

Mechanical: Designing of Gear System

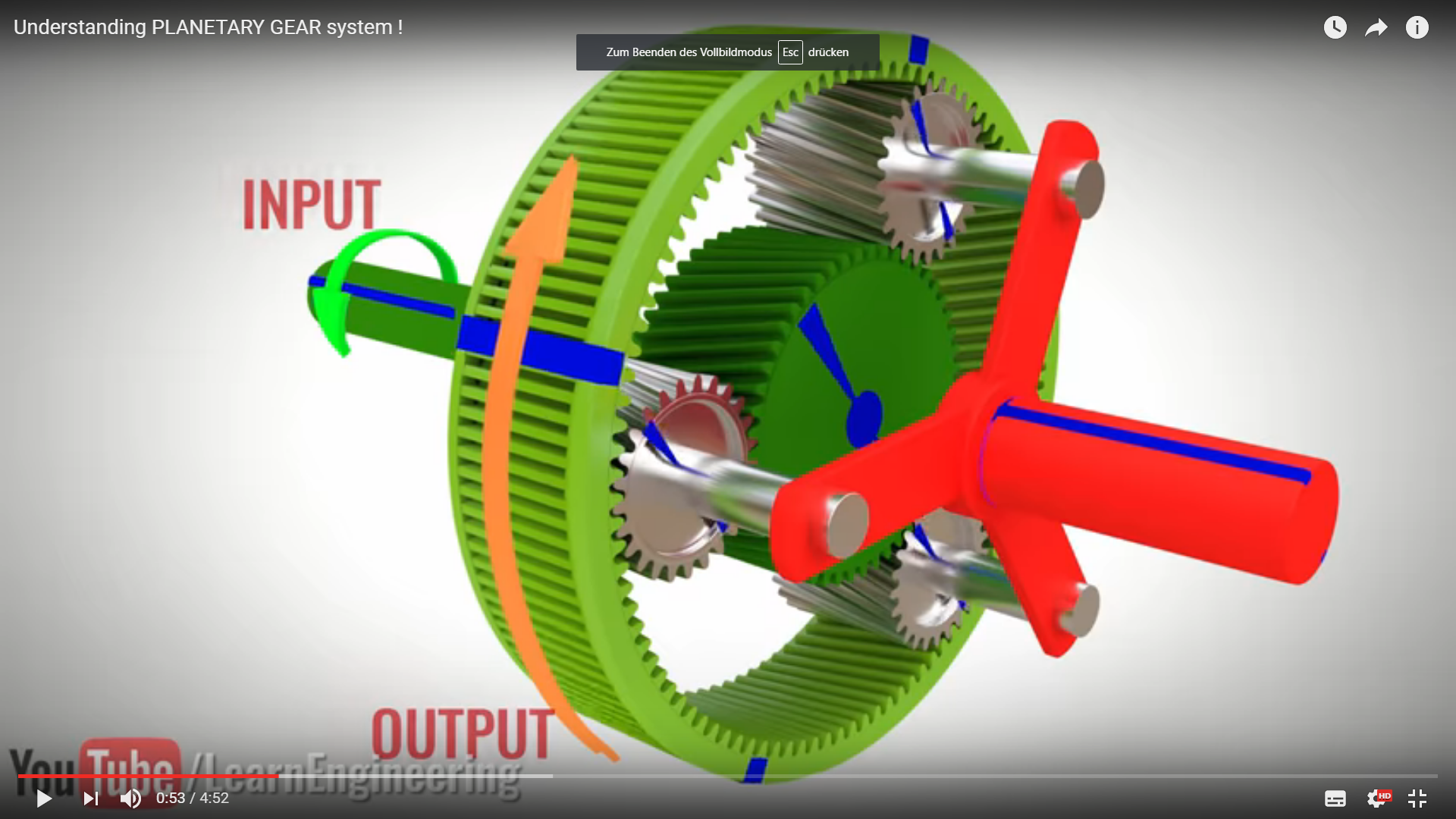

First I got intrigued by gear in general, and then I found planetary gear interesting.

I spent lot of time studying gear mechanism for and getting it to working as a living

organism.

Although creating gear itself was pretty easy using Inkscape gear extensions(It is even

native),

In deciding gear mechanism, making gear design, deciding the total dimension of it was

quite

tough, because as the number of tooth go up, the size of gear will also increase. and

most of the

time,

the total size was hard to imagine.

-so I have needed to study gear reduction with multiple layers and then printed them so

grab the

idea.

Quoting from Matthias Wandel's site on woodgear

making-tutorial which I find really

helpful, there are rules(it becomes simple as you keep looking at it) in designing gear system.

gear system calculation

R Number of teeth in ring gear

S Number of teeth in sun (middle) gear

P Number of teeth in planet gears

[1] all teeth have the same pitch/spacing.

[2] Also use this equation to calculate the number of teeth required per gear so

everything fits

correctly:

R = 2 × P + S

Deciding Dimension and adjust size of other parts

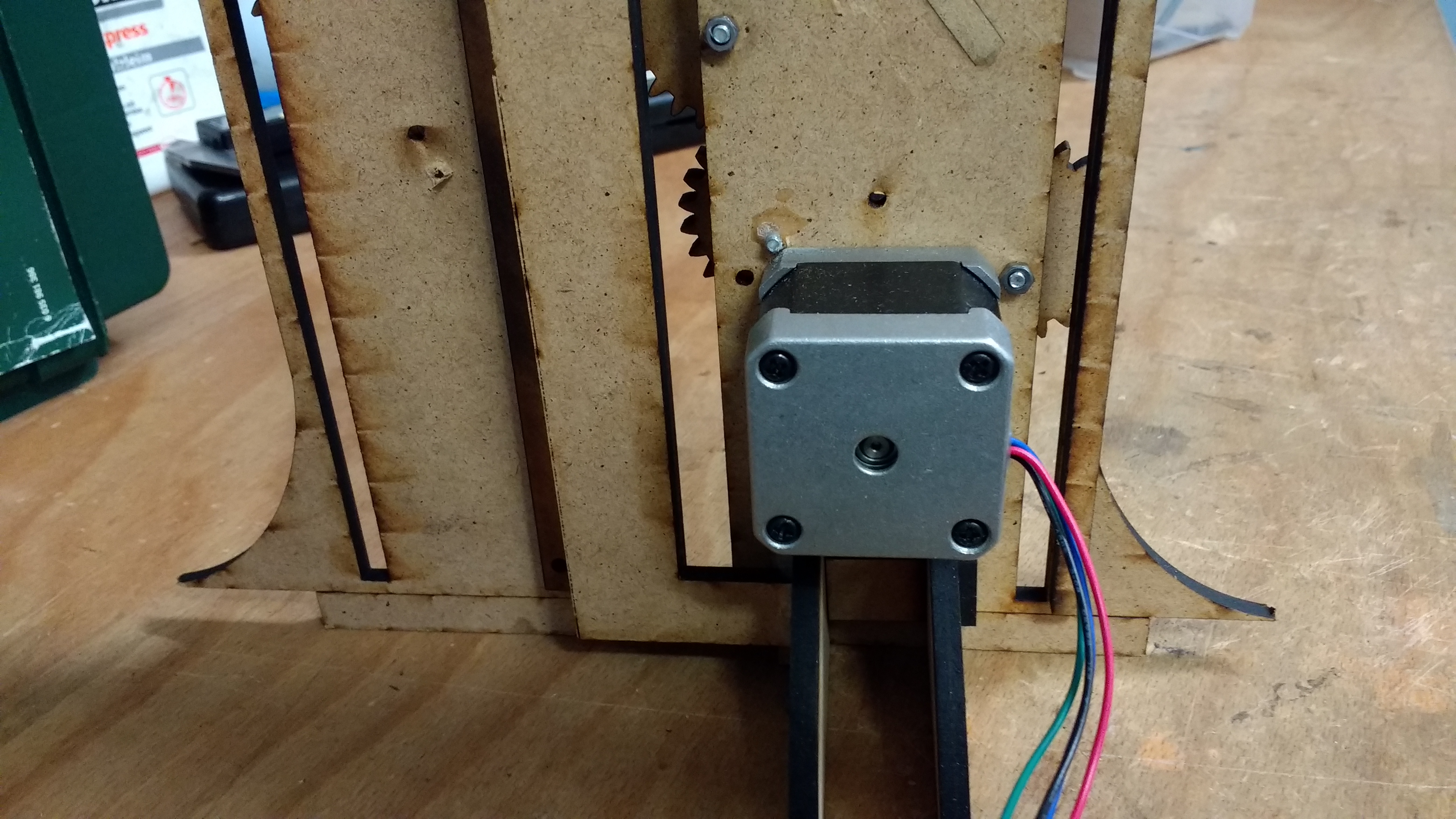

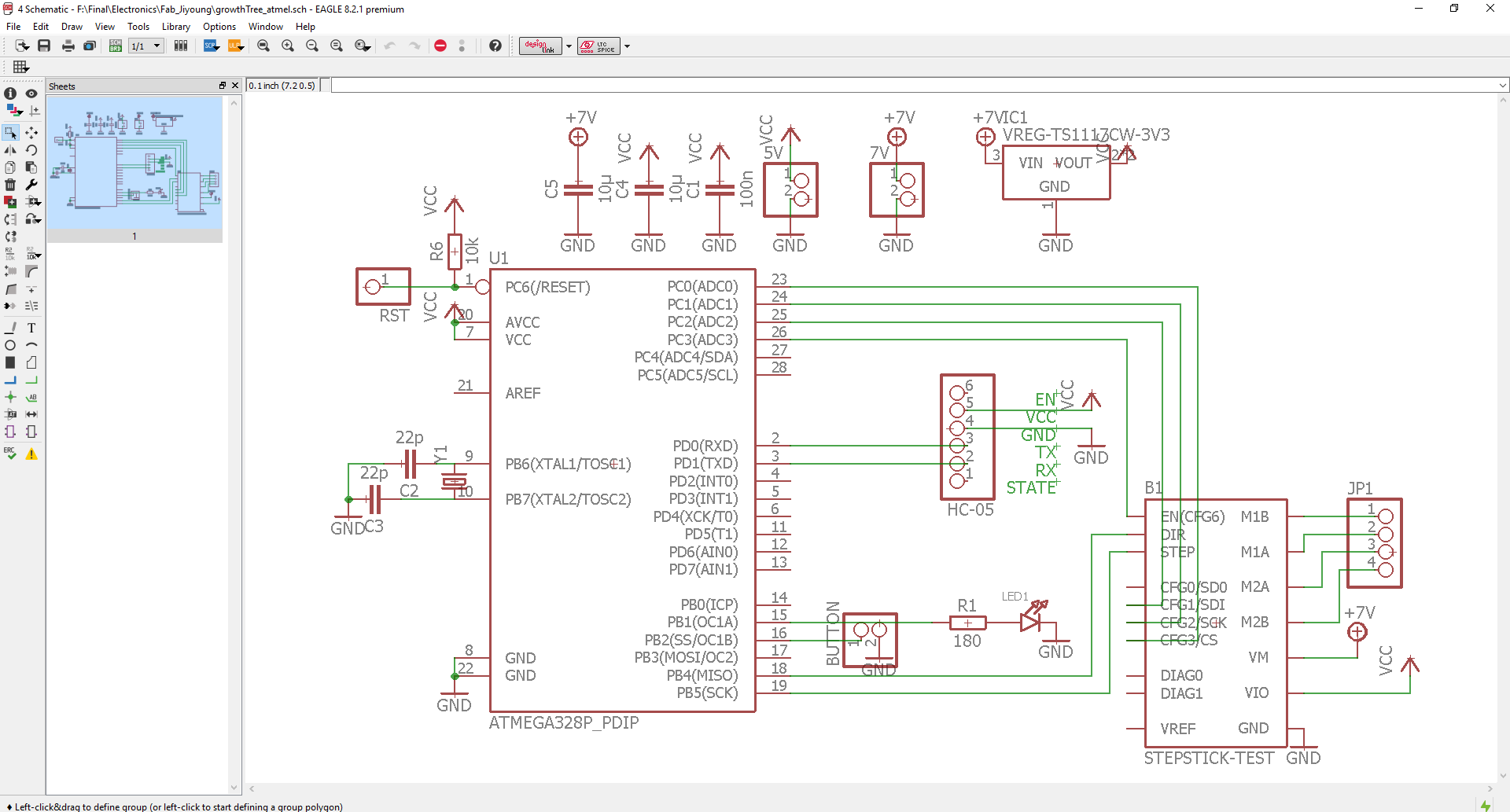

Electronics: Controlling of gear with Step Motor

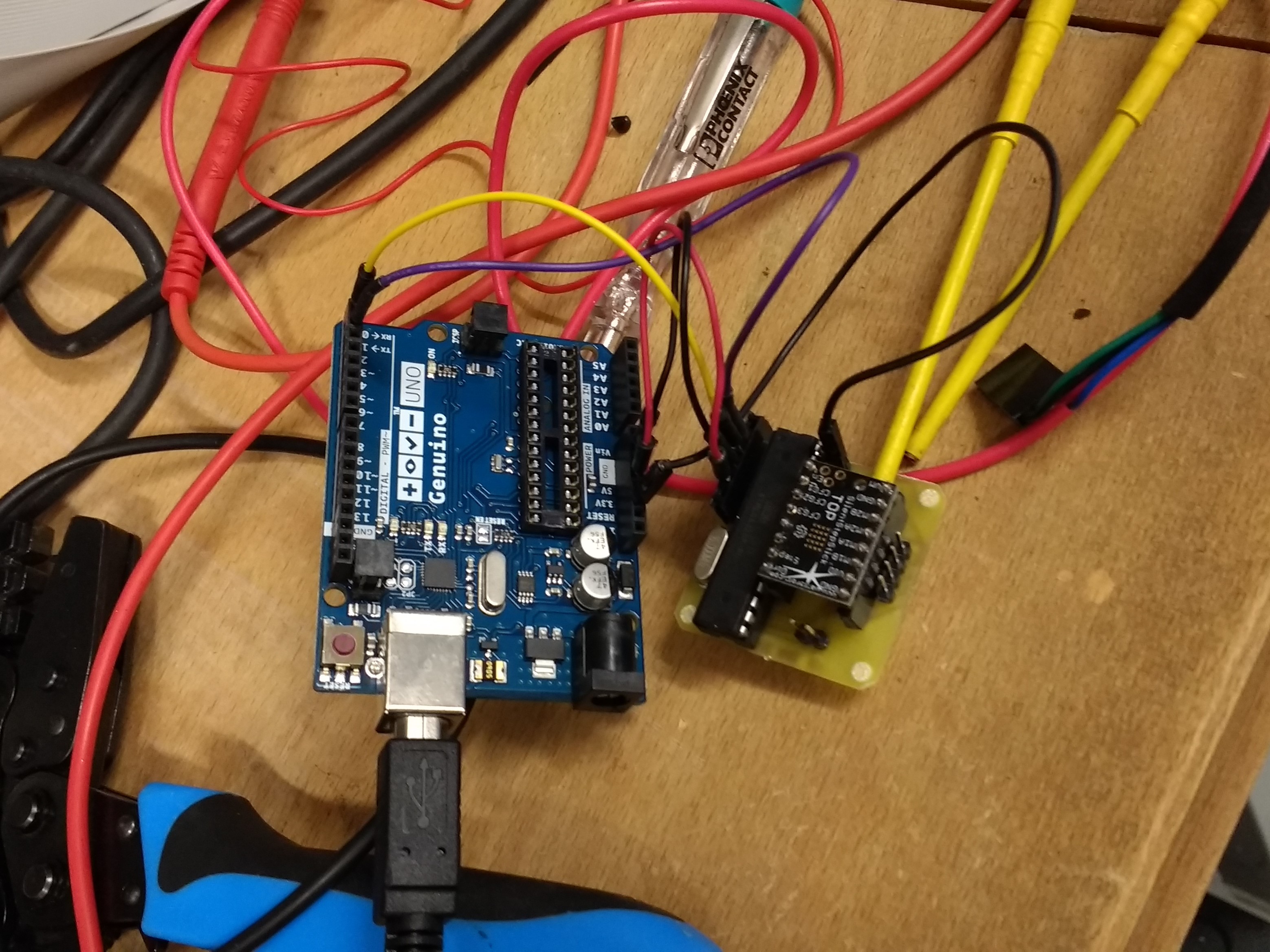

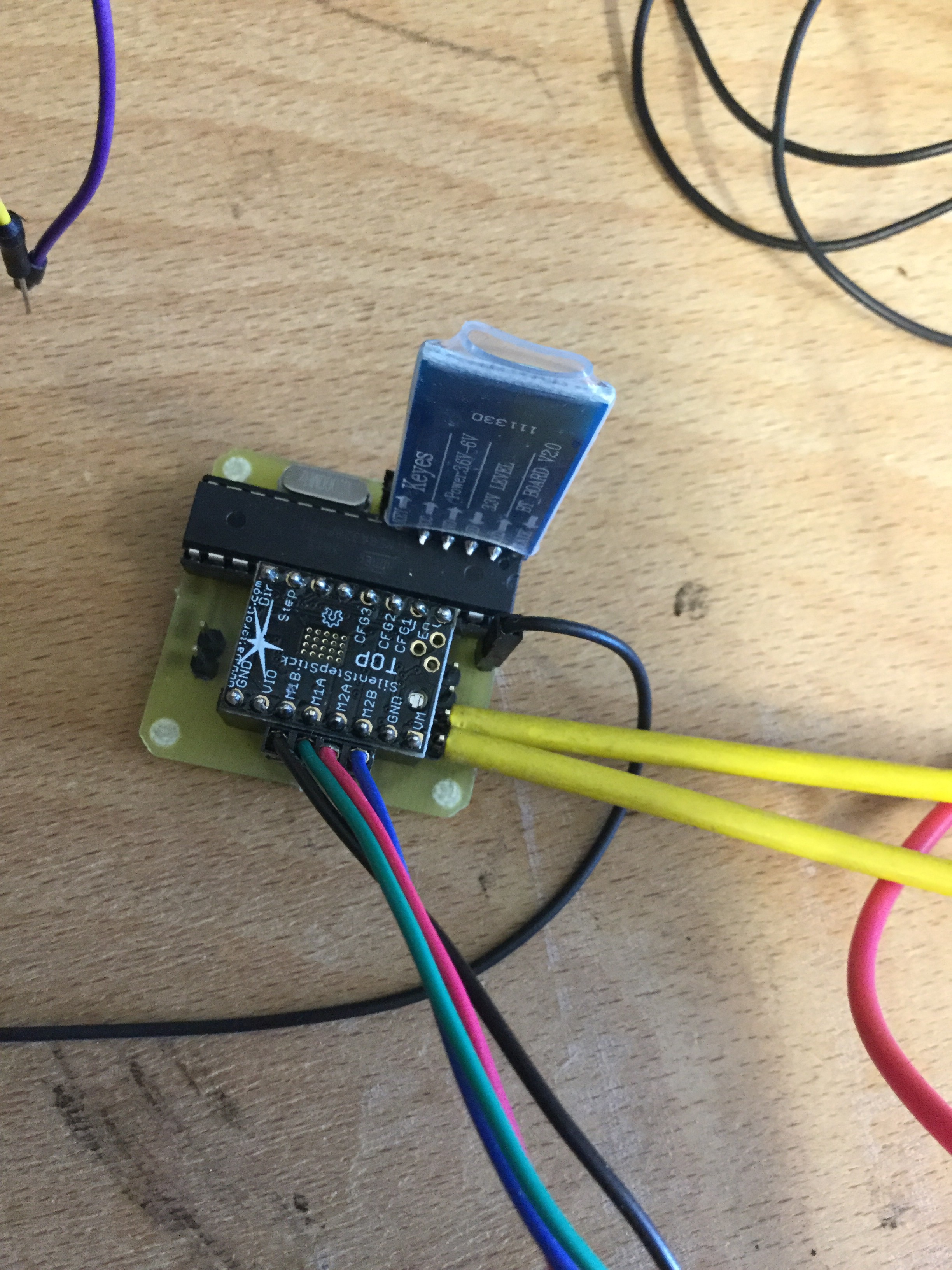

Before making a pcb, I decided to try out control of step motor movement first. I used 'silentstepstick(TMC2100)' driver for this and succeed to get it move, found out some variables to control the movement.

Programming

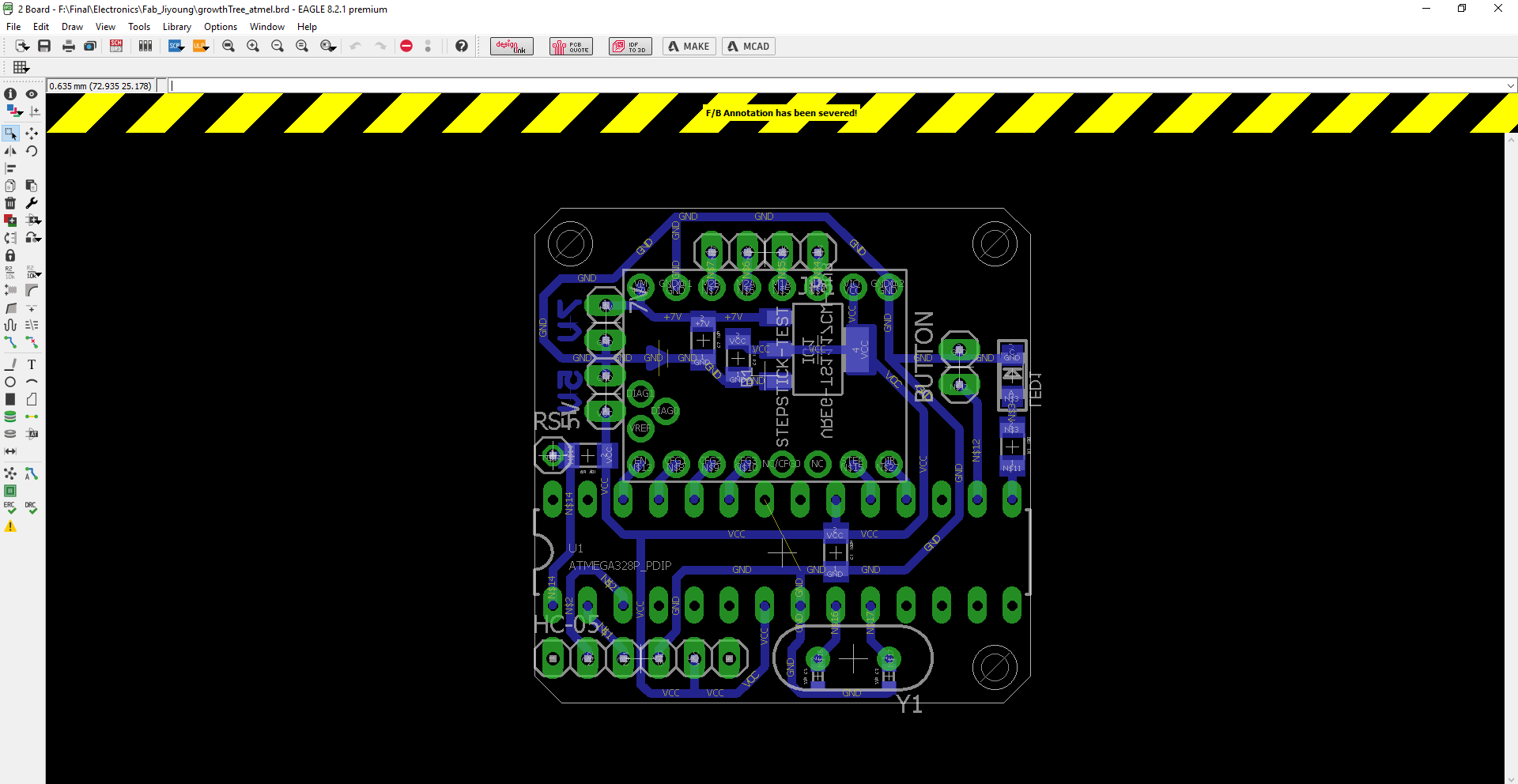

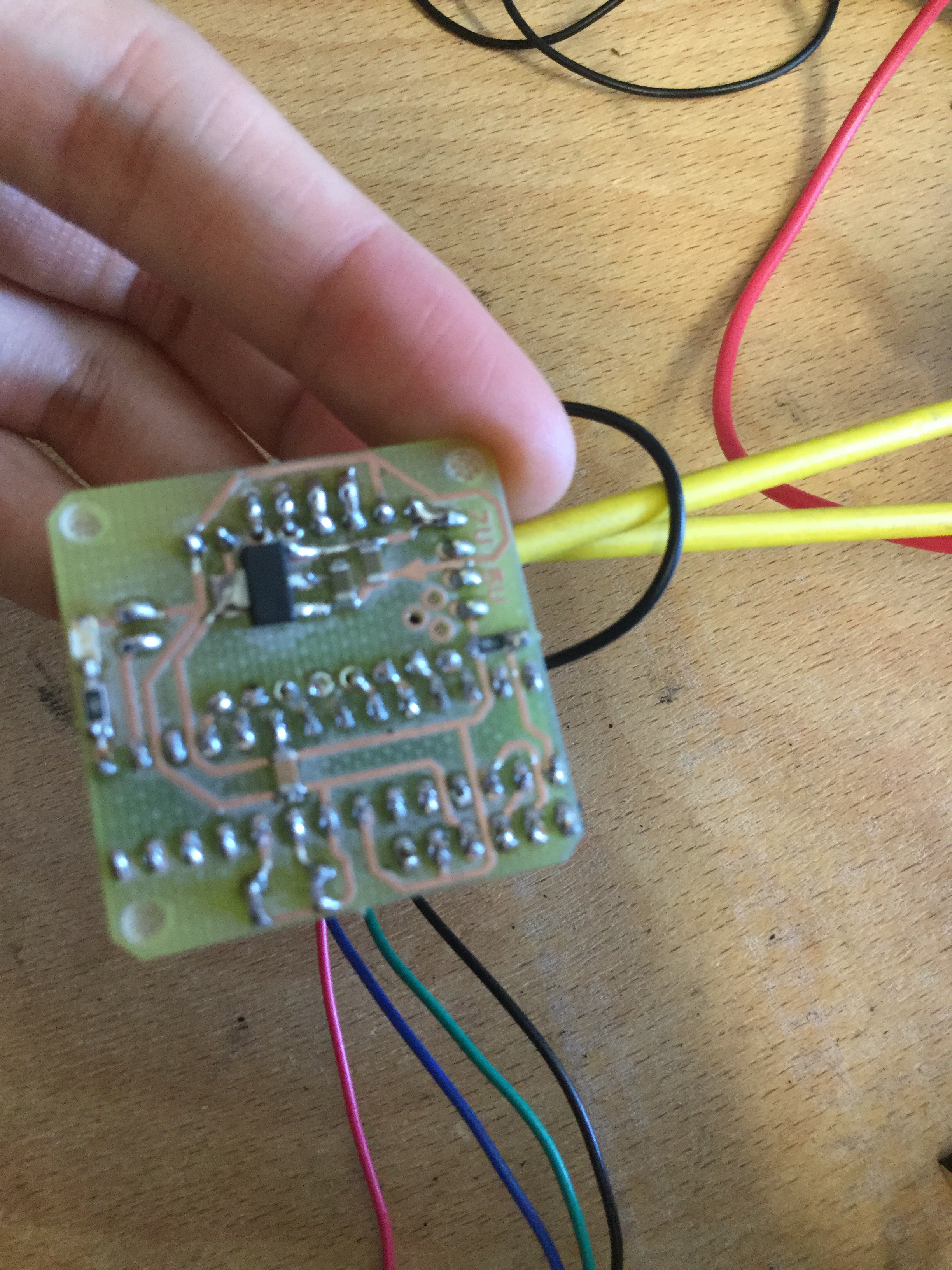

I reused PCB and program to run stepper motor from week8.

I reused Bluetooth module from week15.

Also, Desktop program that I used is from week16.

Application Programming

//handle mouse events

void mousePressed() {

if (toggle)

{

myPort.write("0");

image(LEDoffImage, 0, 0);

} else

{

myPort.write("1");

image(LEDonImage, 0, 0);

}

toggle = !toggle;

when moused pressed send a signal (0 or 1) to Bluetooth and change the image.

Embedded Programming - Network

//debugging, control

#define LED 9

#define BUTTON 10

//communication

#define TX 1

#define RX 0

SoftwareSerial mySerial(RX,TX);

boolean growthFlag = false; //to set false for initial movement

Variables for Bluetooth

void setup() {

//setting up bluetooth

mySerial.begin(9600);

//setting up led & buttion

pinMode(LED, OUTPUT);

digitalWrite(ENABLE, LOW); //off

pinMode(BUTTON, INPUT);

}

Setting up Bluetooth

void loop() {

while(mySerial.available() > 0) {

char receivedChar = mySerial.read();

int intReceivedChar = (int)receivedChar;

if (intReceivedChar == 48)

{

digitalWrite(LED, LOW);

growthFlag = false;

}

if (intReceivedChar == 49)

{

digitalWrite(LED, HIGH);

growthFlag = true;

}

}

Processing incoming chars

Embedded Programming - Stepper Motor

const int stepsPerRevolution = 60;

unsigned long time;

int stepCount = 0; //; number of steps the motor has taken

int Speed = 10; //control how fast to 'step' the motor, 18 for roughly one minute per rotation

int NumSteps = 200; //angle 1.8degree

int MicroSteps =16; //microstep where stepperdriver set to - can be 1, 2, 4, 8, 16

int FullRotation = NumSteps * MicroSteps;

int Distance = 10; // how far we've carried

Variables for Stepper Motor

void setup() {

// CFG pins floating

pinMode(CFG1, INPUT);

pinMode(CFG2, INPUT);

pinMode(CFG3, INPUT);

pinMode(ENABLE, OUTPUT);

digitalWrite(ENABLE, LOW); //off -active

pinMode(DIR, OUTPUT);

digitalWrite(DIR, LOW);

pinMode(STEP, OUTPUT);

digitalWrite(STEP, LOW);

//peset

digitalWrite(DIR, LOW); //LOW or HIGH

digitalWrite(LED, LOW);

Setting up Silent step stick

void loop() {

digitalWrite(ENABLE, LOW); //actie

if(growthFlag == true){

digitalWrite(STEP, HIGH);

delayMicroseconds(Speed);

digitalWrite(STEP, LOW);

delay(Speed);

Distance = Distance +1; //record this step

digitalWrite(LED, HIGH);

}else{

digitalWrite(LED, LOW);

}

Distance = 0; //reset Distance count

growthFlag = false; //reset rotation flag

}

When flag is set to true, it runs full rotation

Putting Things Together