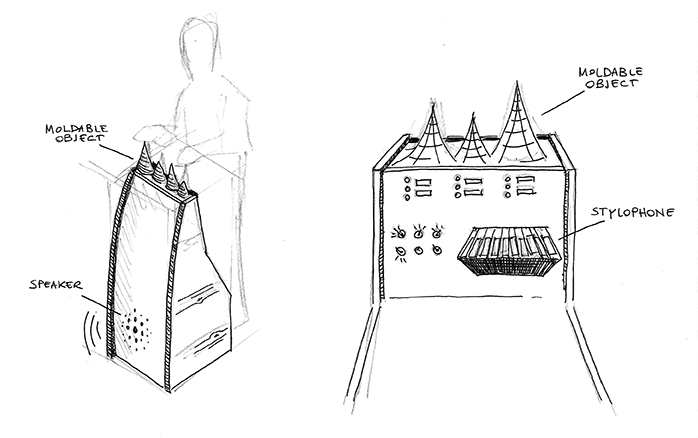

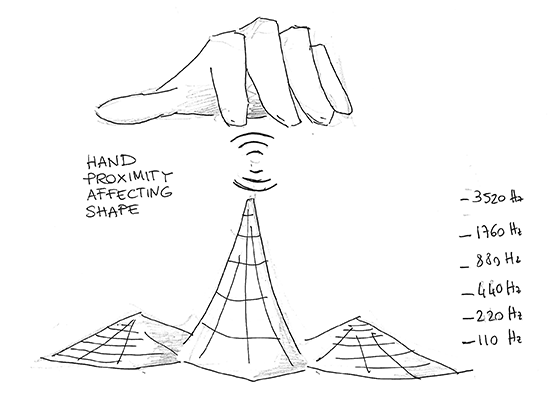

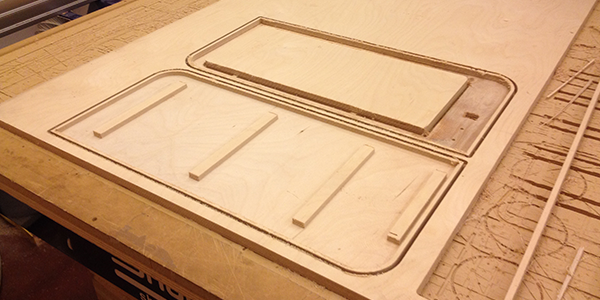

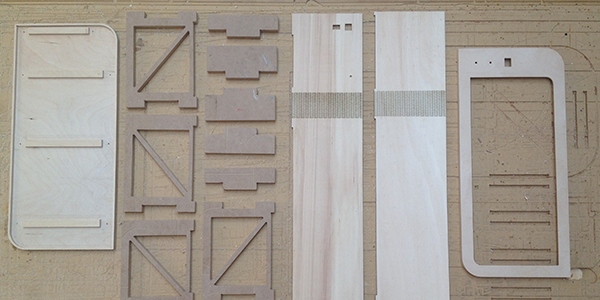

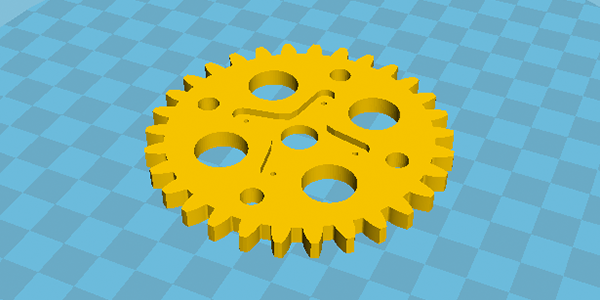

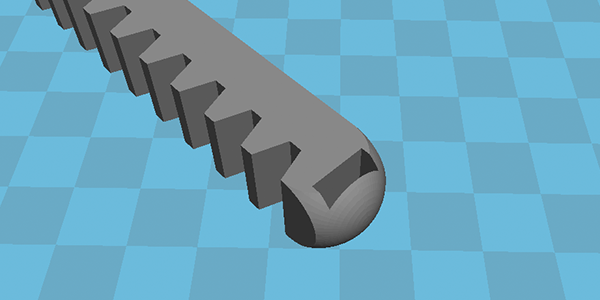

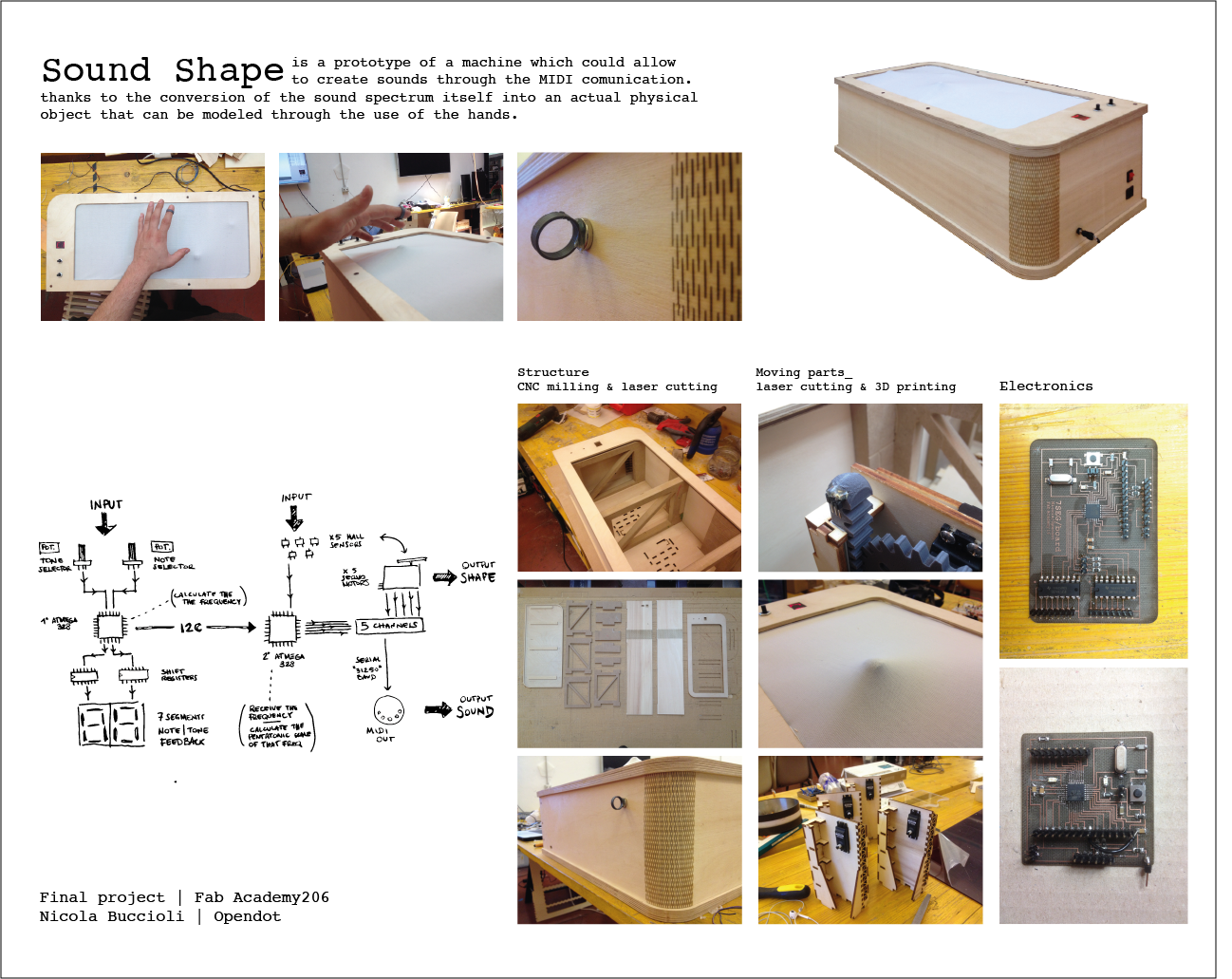

My aim during these months will be the prototyping of a machine which could allow to create sounds and alter their audio spectrum, thanks to the conversion of the sound spectrum itself into an actual physical object that can be modeled through the use of the hands. This machine will also incorporate a Stylophone for the generation of sound.