Make Something Big

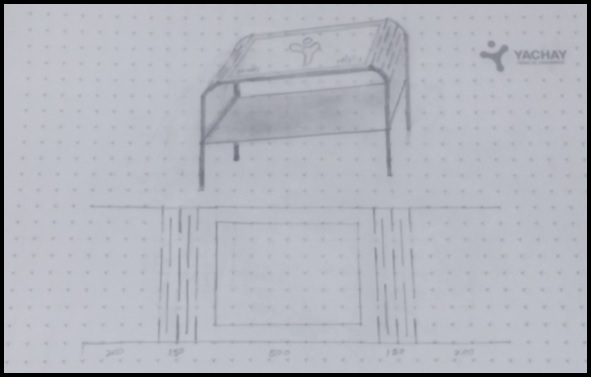

Making a sketch...

I make a decorative table for vases and this is its sketch.

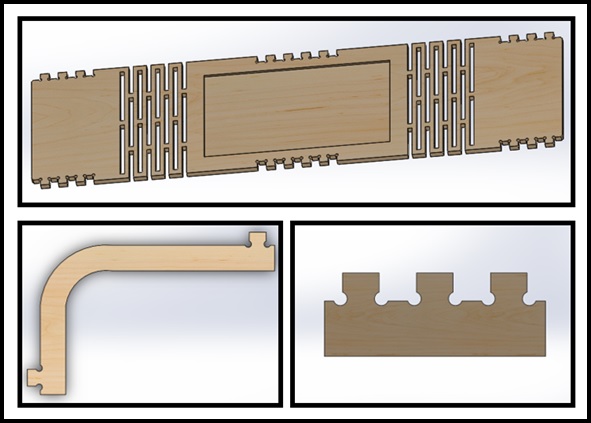

CAD...

First, I reviewed this task students last year and found an excellent documentation on Margrét Óskarsdóttir's page. This page helped me in the sizing of the hinges and the configuration of the Shopbot.

I designed the table on SolidWorks. You can download the files here: join1, join2, join3, top.

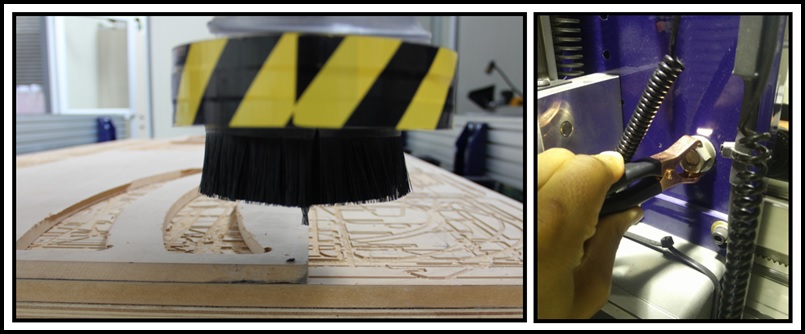

Setting machine

Is necessary to calibrate X, Y and zero values.

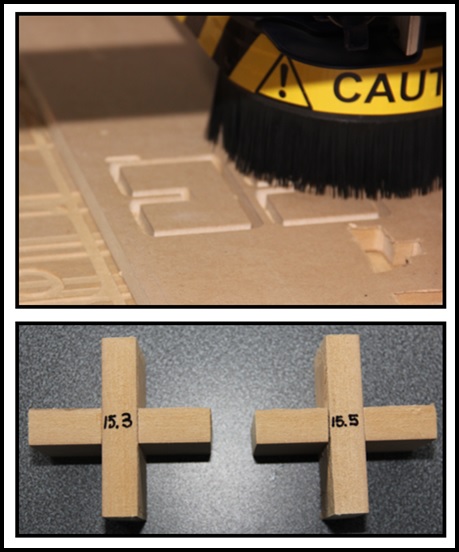

Is important to know the diameter of kerf of cut for designing a good press fit. In my case I need to consider 0.2mm.

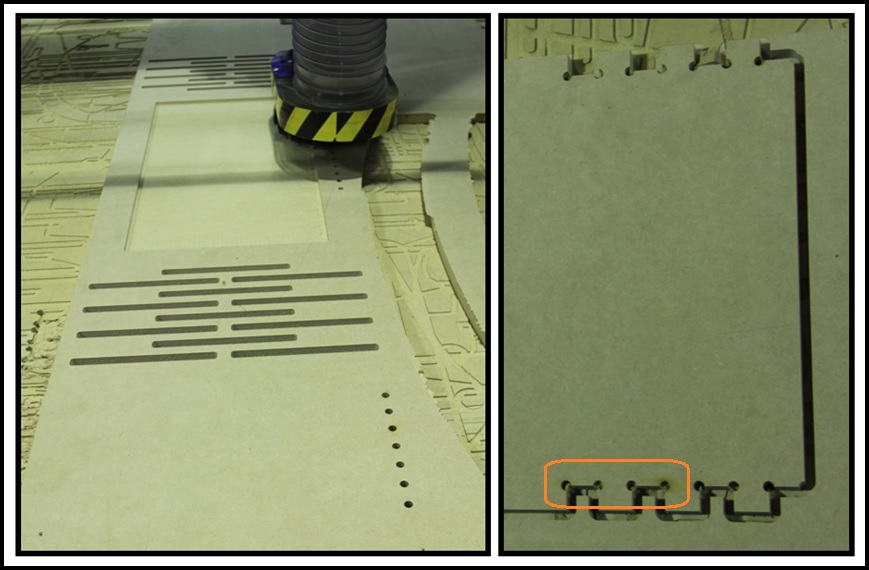

Cutting...

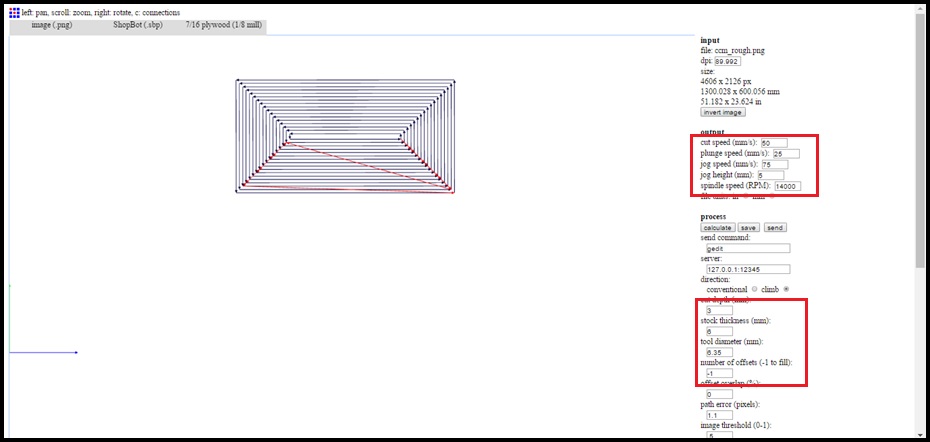

First I generate the top roughing CAM file for this I generate the CAM file in fabmodules.org. I use a 1/4 bit tool and I need to remove 6mm of material for this reazon the stock thickness is 6mm, you can see the parameters in next picture:

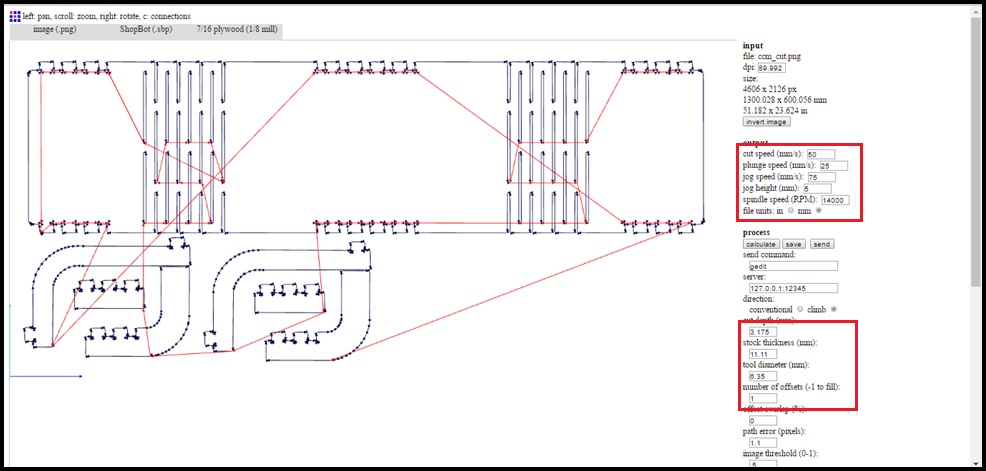

After I generated the cut CAM file, I use the same tool (1/4), in next picture you can see the parameters:

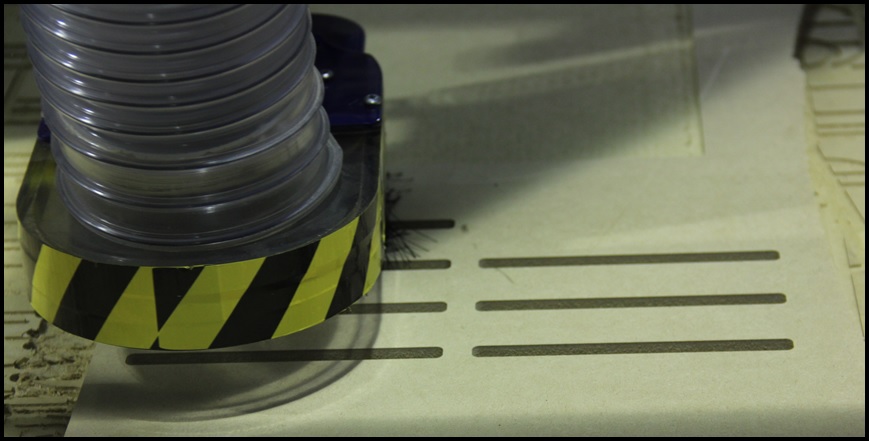

Finally y milling the plywood, first I milling the roughing and next I milling the cutting.

I had a problem, you can see in next image. This problem happened because I was cutting the board with a down-cut bit drill and for this job is neccesary to cut with up-cut bit drill. In Fab Lat meeting Mr Toshiro explain this. You can see the Toshiro's video here.

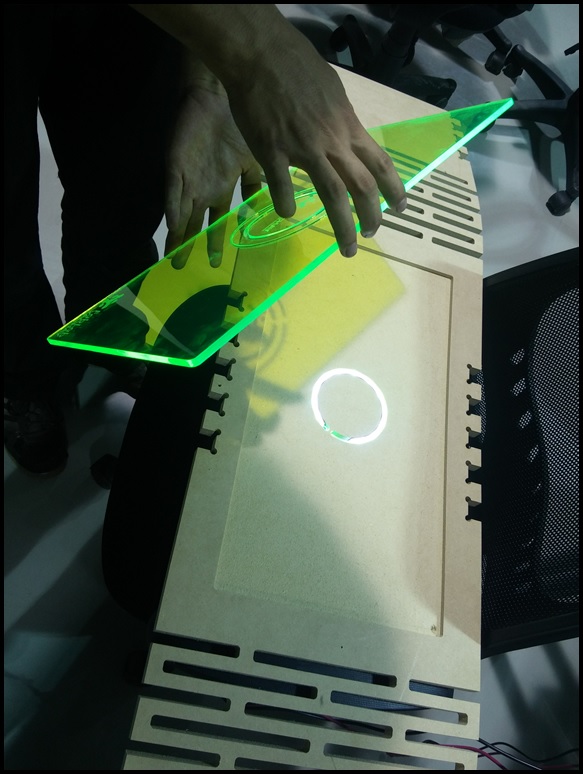

Assembling...

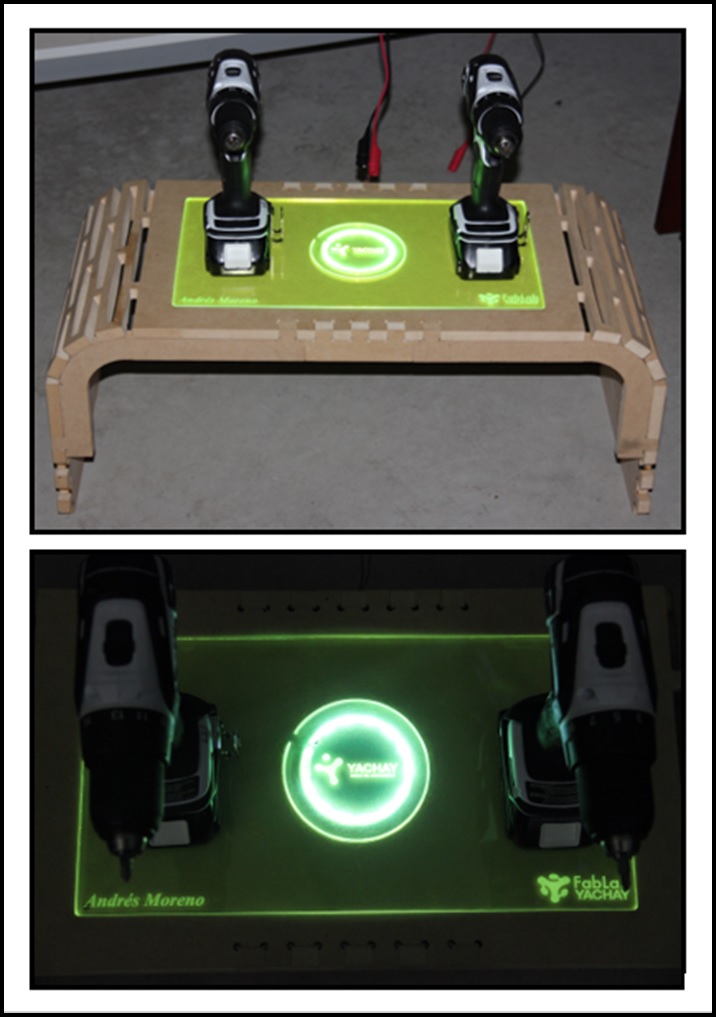

I cut acrilyc with lasser cutter for decorate the top and put leds for ilumination.

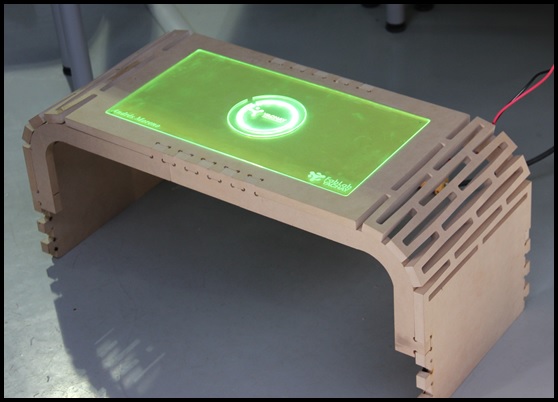

Final result.

Testing.