#Exercise_10

13/04/2016

Assignment

Input DevicesMeasure something: add a sensor to a microcontroller board that you have designed and read it.

Design the controller board for the final project

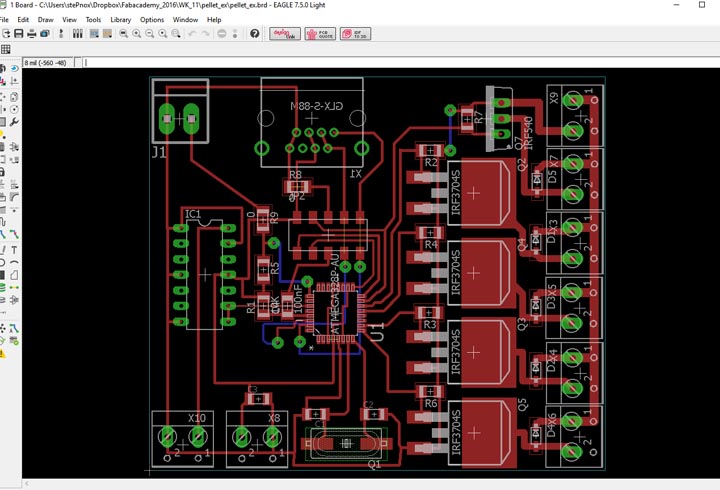

Source filesFor the assignment I decided to design the first prototype of the controller board that I will use for my final project. So I organized the two exercise, input and output devices together.

To control the pellet extruder I will need a ceramic heater cartridge in order to heat the noozle, a thermocouple to control the temperature, a thermistor or a temperature sensor to mesure the ambient temperature, a DC geared motor for the extrusion and a solenoid valve to cool the extruded material.

BOM

- 1 X Thermocouple J type

- 1 X Thermistor

- 3 X Ceramic heater cartridge 24V 40W

- 1 X DC geared motor 24V 5Nm Torque

- 1 X Solenoid valve

- 1 X Power supply 24V 15A

- IC1 AD594 Amplifier

- MICRO ATMEGA328P-AU

- Q1 16Mhz Crystal

- C1, C2 18pF

- C3, C4 100nF

- R1-R8 10K

- R8, R9 0ohm

- Q2-Q5 IRF3710S N-FET 100V 57A

- Q7 IOR

- D1-D5 DIODE 1N4001

- 7 X Screw terminal

- 1 X MTA02-156 male connector

- 1 X RJ45 female connector

- 1 X SMD male header 5X2 connector

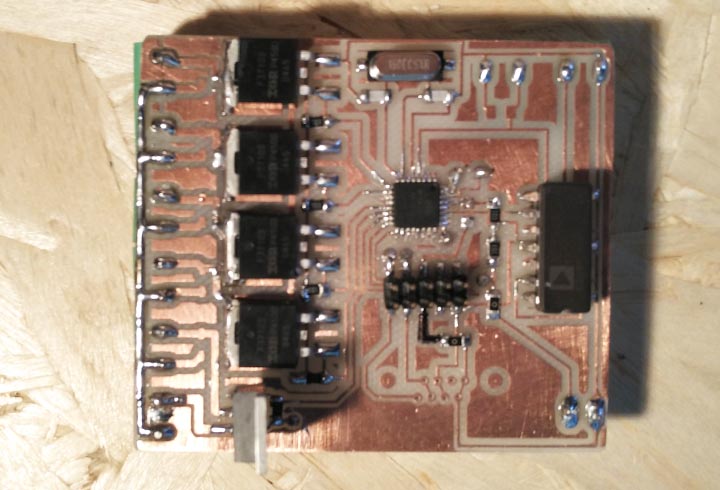

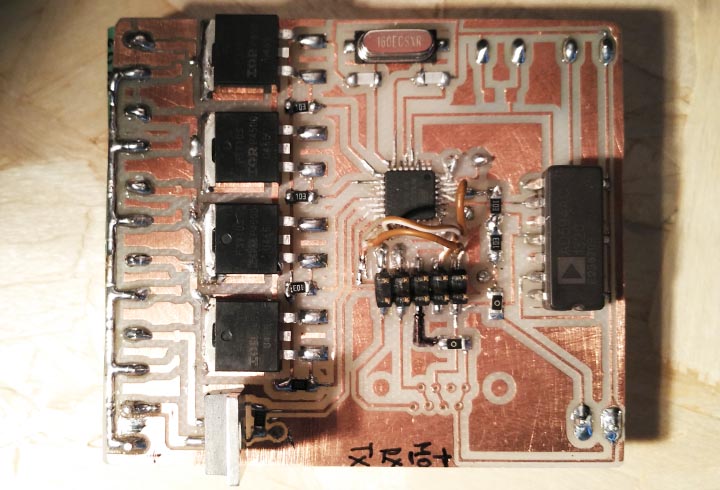

Board: on the board I have used a couple of through hole components, and soldered bending the feet.

The ISP connector have 10 pins becouse I have added the RX an TX in order to allow the serial communication, that will used to communicate with the robot, but to make easier the wiring I have installed an RJ45 connector too. The robot core and the extruder control board will be 7m distant.

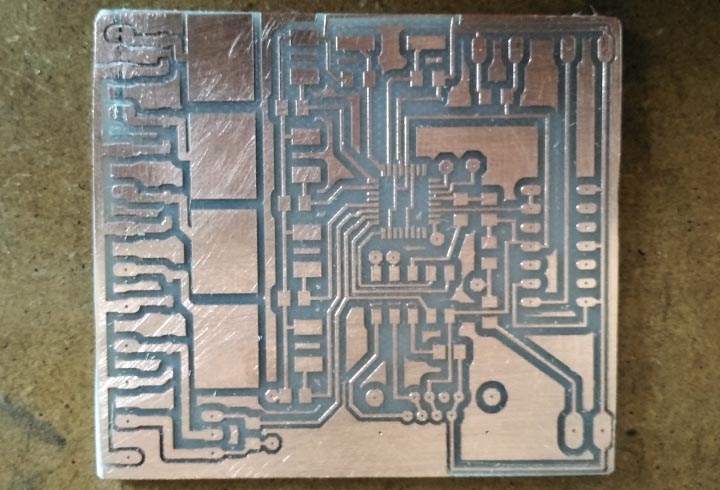

Milling: milling the board was pretty tricky, because the 328P-AU have a very tiny footprint, the pads are very close each oder (only 0,25mm). To mill the board I have used the same process described in the electronics production module.

Input testing usign the Arduino serial plotter, we can see the temperature increase on the chart using a lighter near the thermocouple.

Arduino Input code

//define the thermoc. pin

#define TC_1 A4

void setup() {

//initializa the serial port

Serial.begin(9600);

}

void loop() {

//read the analago pin

int sensorValue = analogRead(TC_1);

//convert the voltage to temperature

float voltage = sensorValue * (5.0 / 1023.0) * 100.0;

//print the temperature on the serial monitor

Serial.println(voltage);

//wait a second

delay(1000);

}

The code: this simple sketch read the temperature from a thermocouple. In this code I convert the analog read to a voltage and after print on the serial monitor the temperature.

Upload the code: as described in the Embedded Programming module to upload the code on the board I have used the Arduino IDE and the FabISP, the first time I have burned the bootloader in this way I can use the board like an Arduino UNO using only an FTDI converter to upload new sketch.

The code has worked well as expected.

Output Devices week

Board: I decided to usa an ATMEGA328P-AU insted of using the Attiny44, because I will need a lot of PWM ports and the hardware serial, in order to allow the comunication between the robot and the control board.

To control the nozzle temperature I will use a thermocouple to allow a very accurate measurement; so I have installed the AD594 in order to read the data from the thermocouple type J.

To heating the nozzle I use 3 Ceramic heater cartridge, so I will need 3 mosfet to allow the control of the heating and other two to control the DC geared motr and the Solenoid valve.