For this assignment as a group we made several project proposals:

- Orange juice machine

- A machine to water plant

- Robotic arm camera

After reviewing the different proposals, we decided to choose the machine to water the plants.

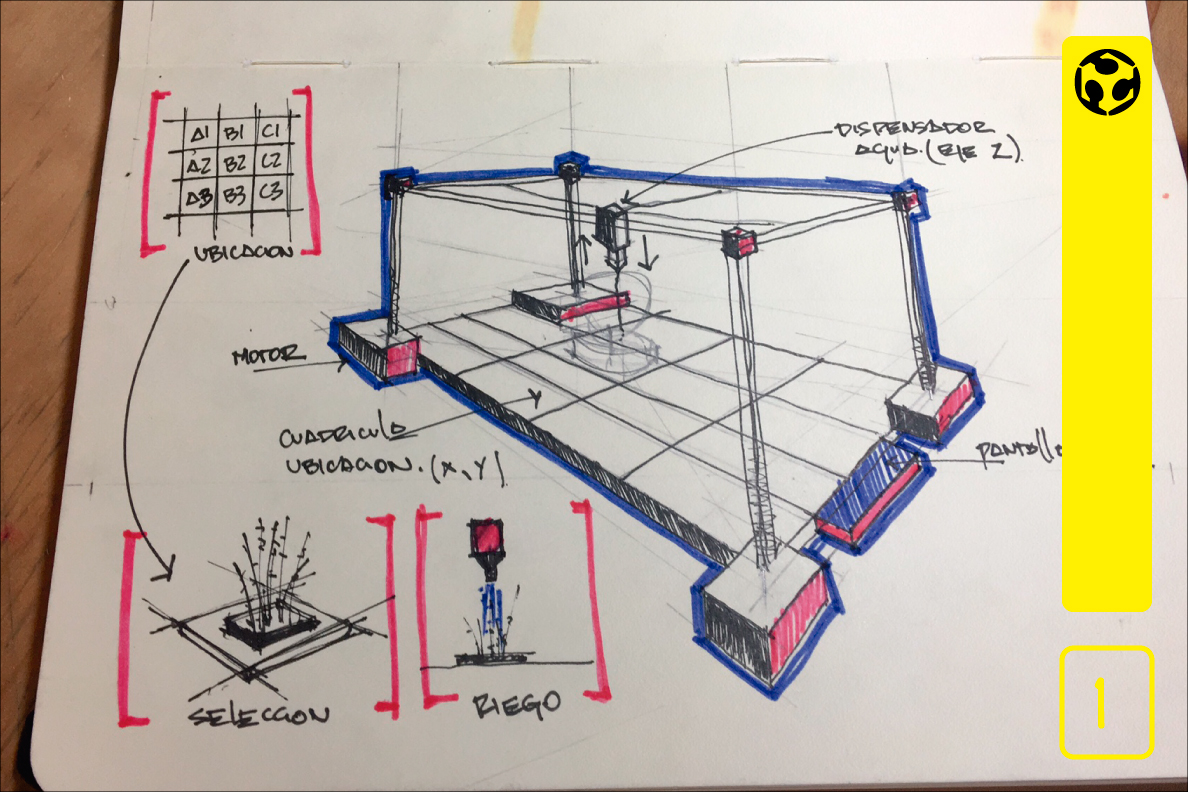

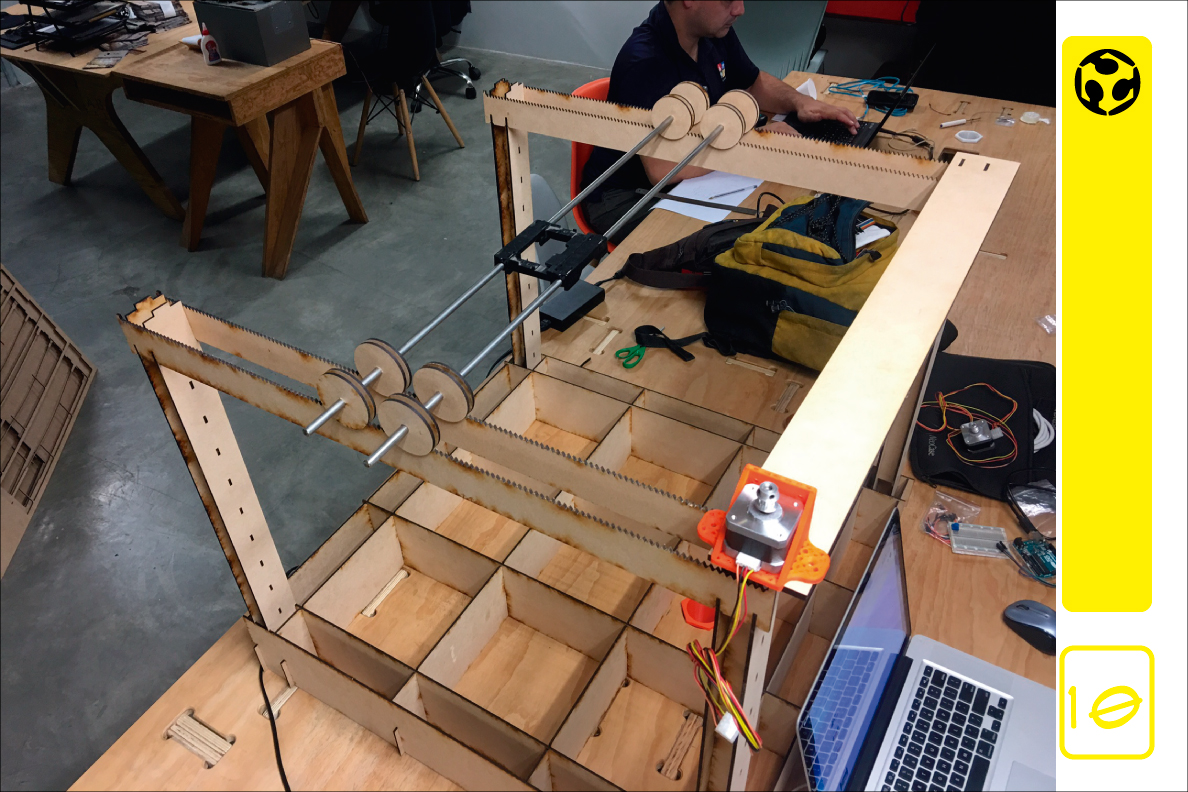

It must have a moveable head that runs on the x and y axes to position a hose over each plant and water it. The plants will be arranged in a grid of 3x3. under the machine head. Movement on the z axis is not necessary, so we will discuss to add it or not during the process.

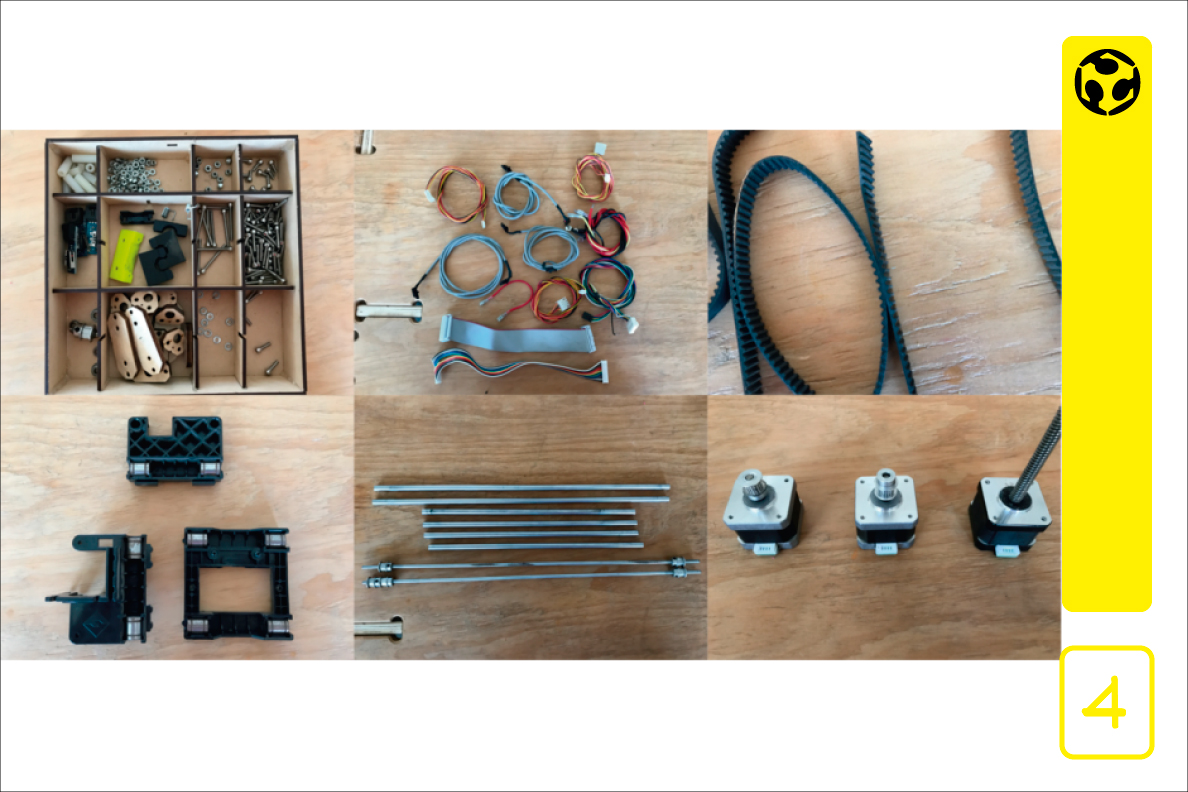

At the lab, we were offered an old broken 3d printer to salvage parts and reuse them in our machine. Salvaged parts include: stepper motors, metal bars, bearings, electronic components, and others.

1. I make a sketch of an initial idea that we take as a starting point to realize the design of the machine. (My sketch contribution)

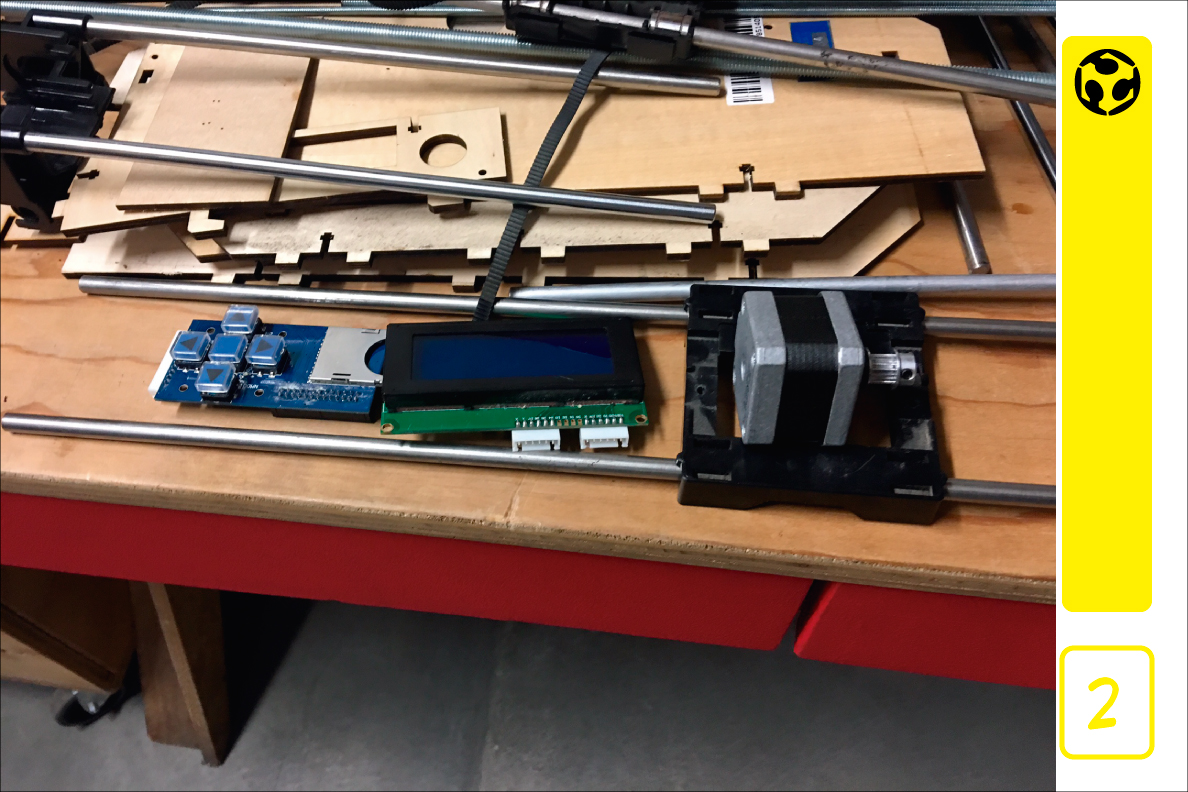

2. We proceeded to disarm a 3d printer that was out of use.

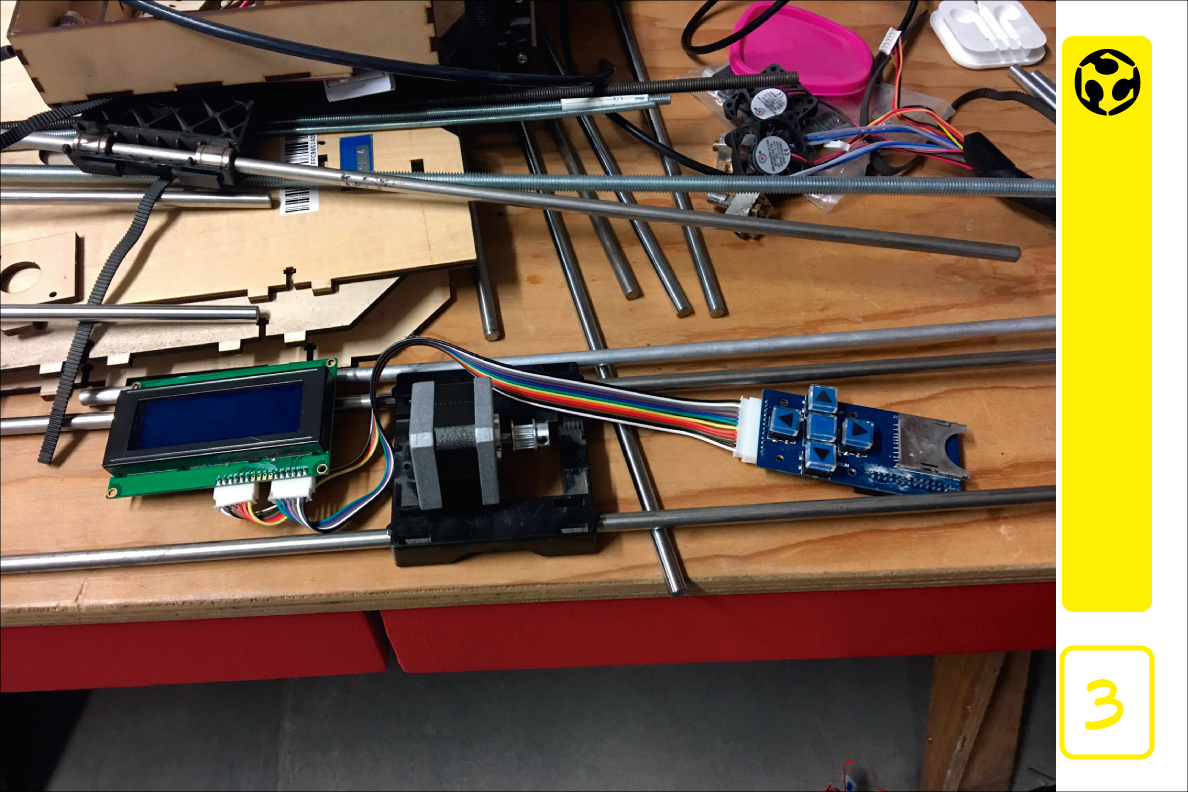

3. After disassembling the old machine, proceed to classify the components.

4. We classify and separate the components.

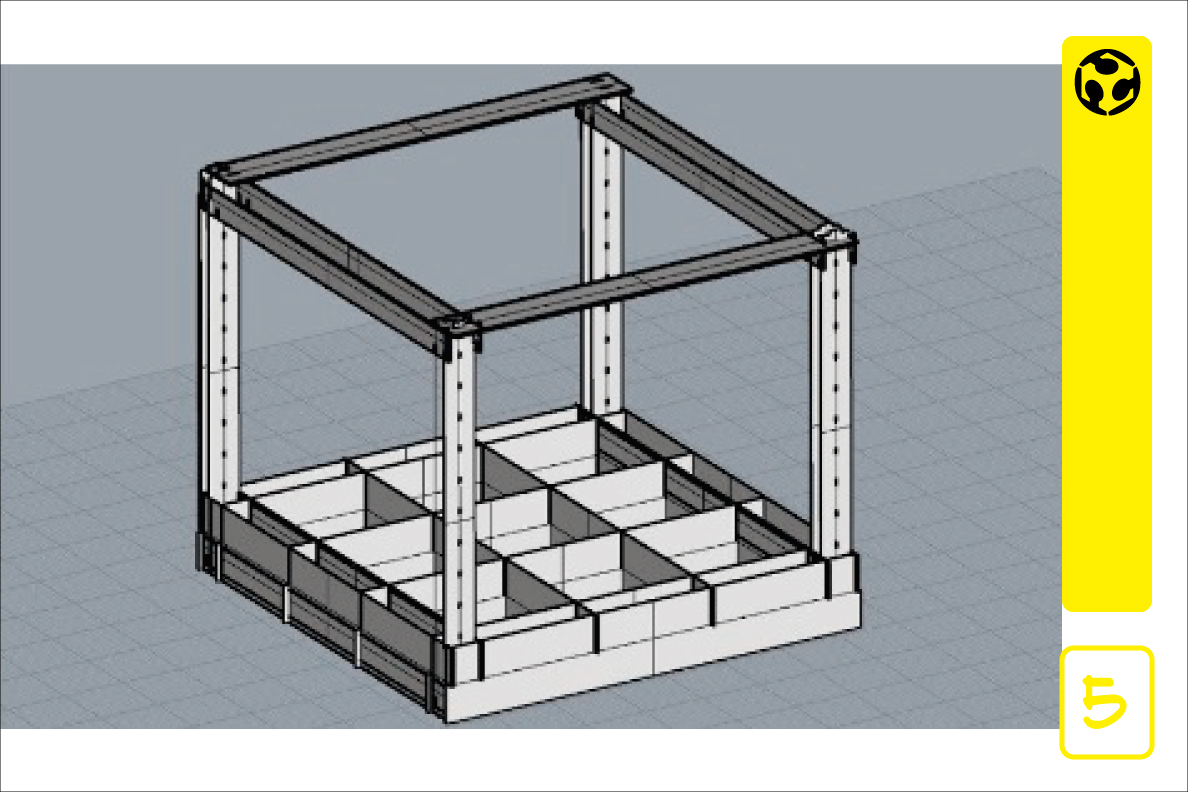

5. 3d model of the new machine.

I contribute to the preparation of the files in both modeling and laser cutting using the Rhino platform.

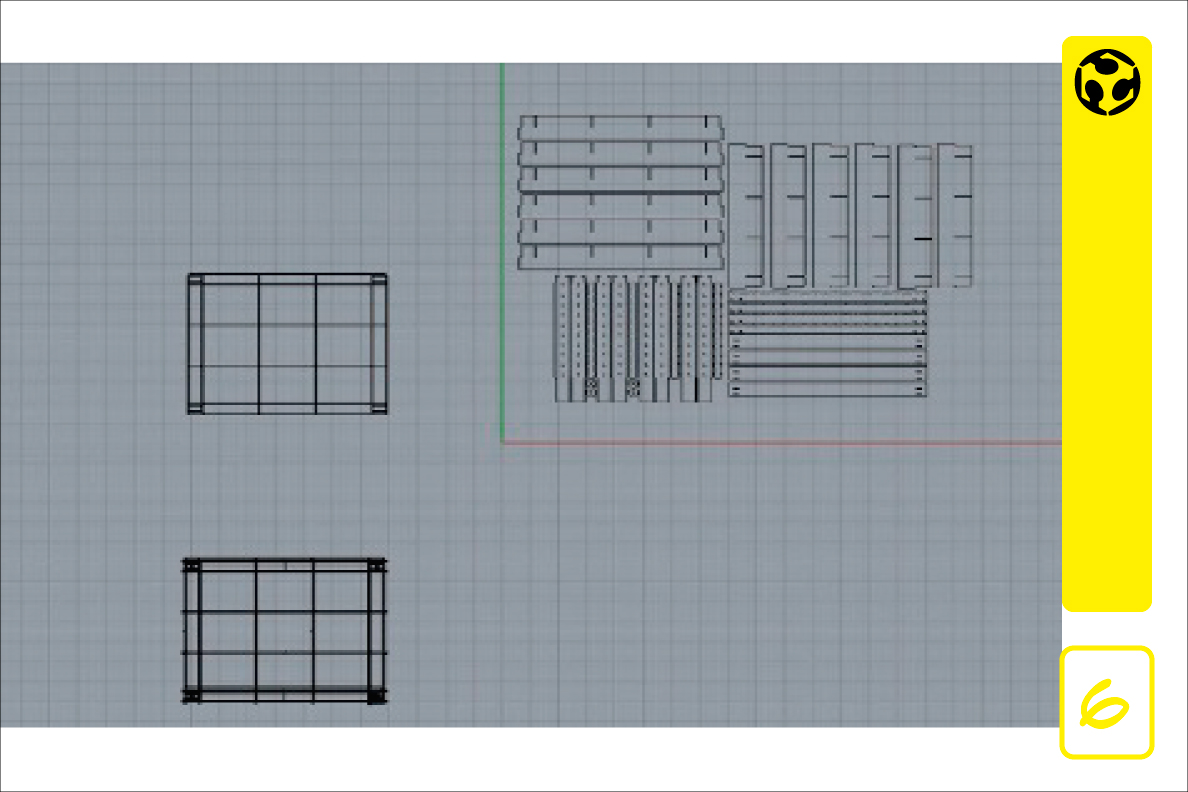

6. 2d parts for laser cut.

7. Assembly process.

I contribute in the assembly of the laser cut parts and establish the problems and improvements for the mechanism of movement.

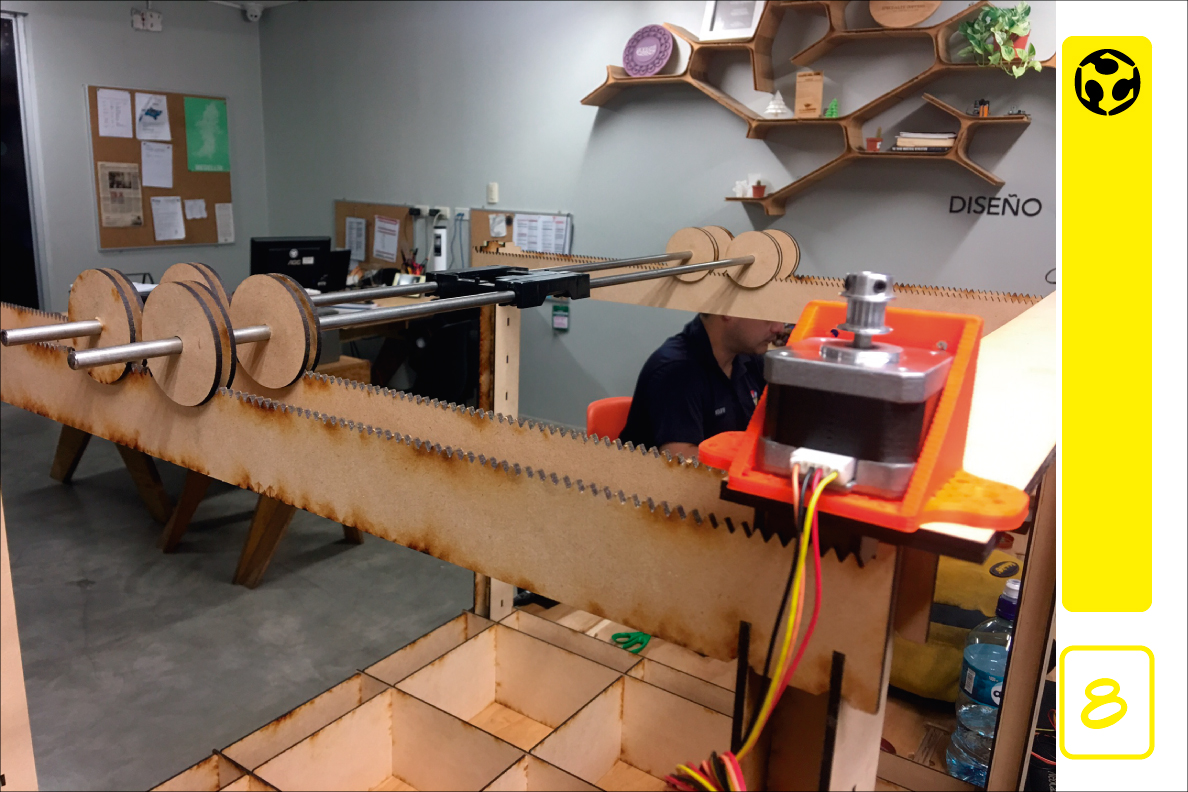

8. We place the servomotors.

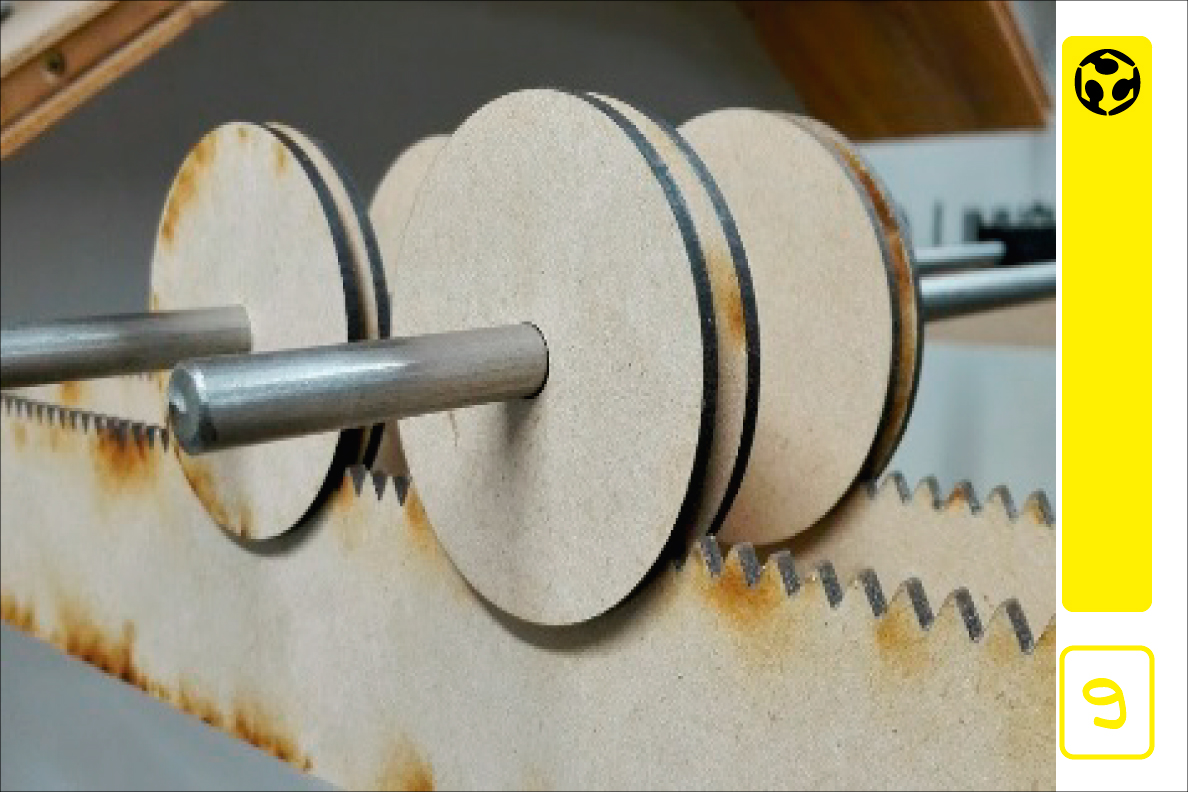

9. This step did not correspond to me, but I helped to mount the wheels. We had some discrepancies in how efficient this mechanism would be.

10. Top view of the machine.

To see the machine finished and working visit the page of the group, here.