Assembling the FabArm

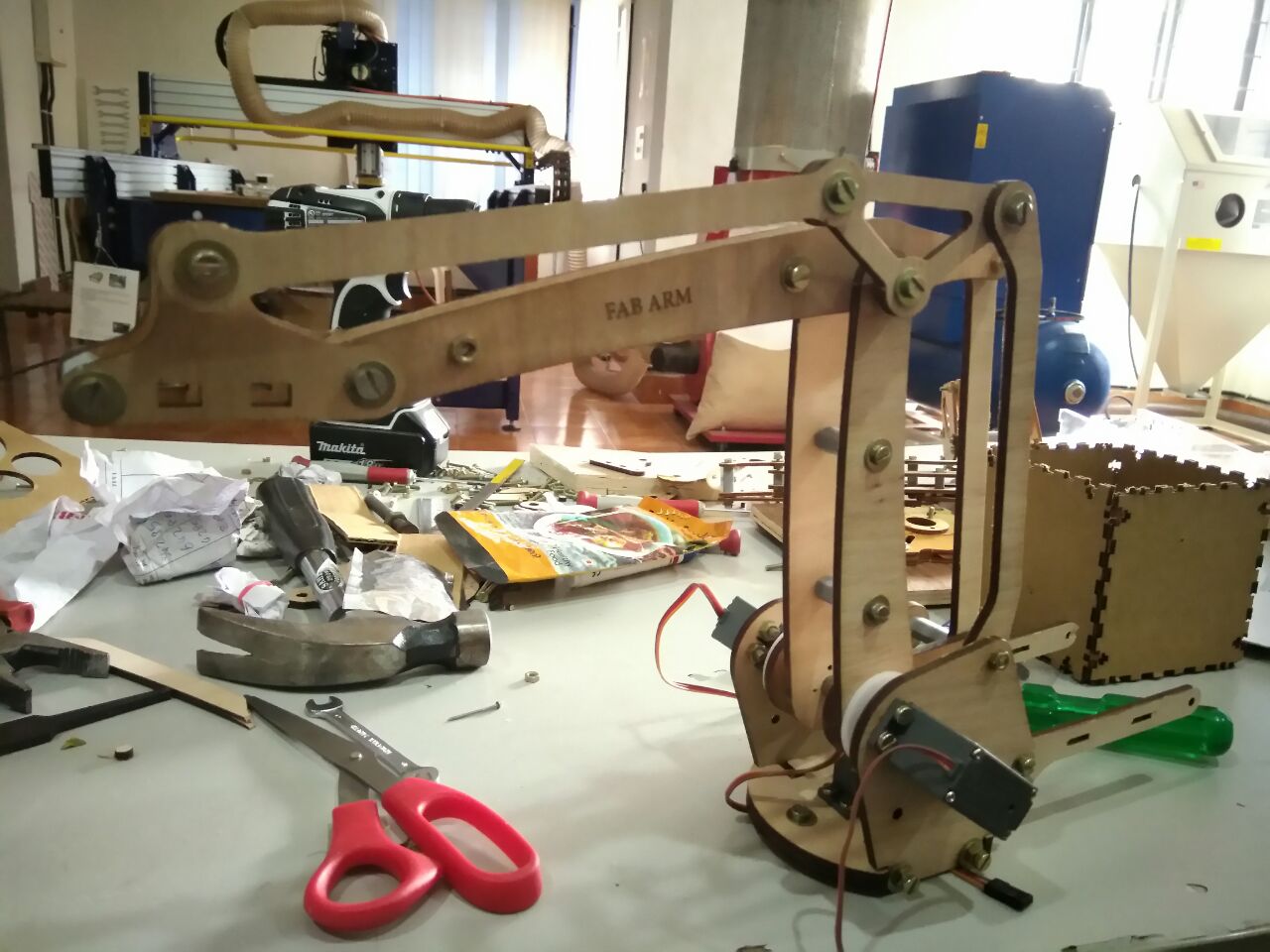

The FabArm we build on Mechanical Design week had some missing components and some fixtures also broke. So we decided to redo it once again.

Majority of the design for the fab arm were build on mechanical week. So I will not get to those details, but this week we had to make couple of flange shafts to hold up the fab arm. This part was missing when we build the fab arm first time, that is what we did this week.

We took apart a printer for a Aluminum Alloy Rod. We cut the rod for our specific need.

Ajith try to see if it fits, and it did..

I completed the rest of the assembly and the fab arm is complete.

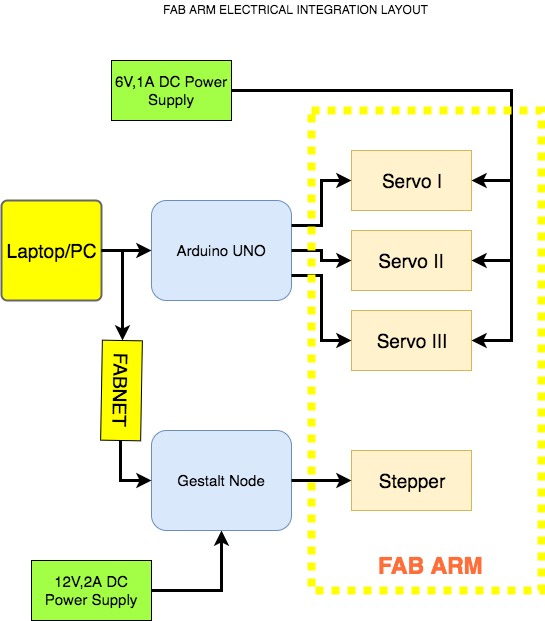

I also worked on the control integration and UI design. Pic Courtsey: Ajith

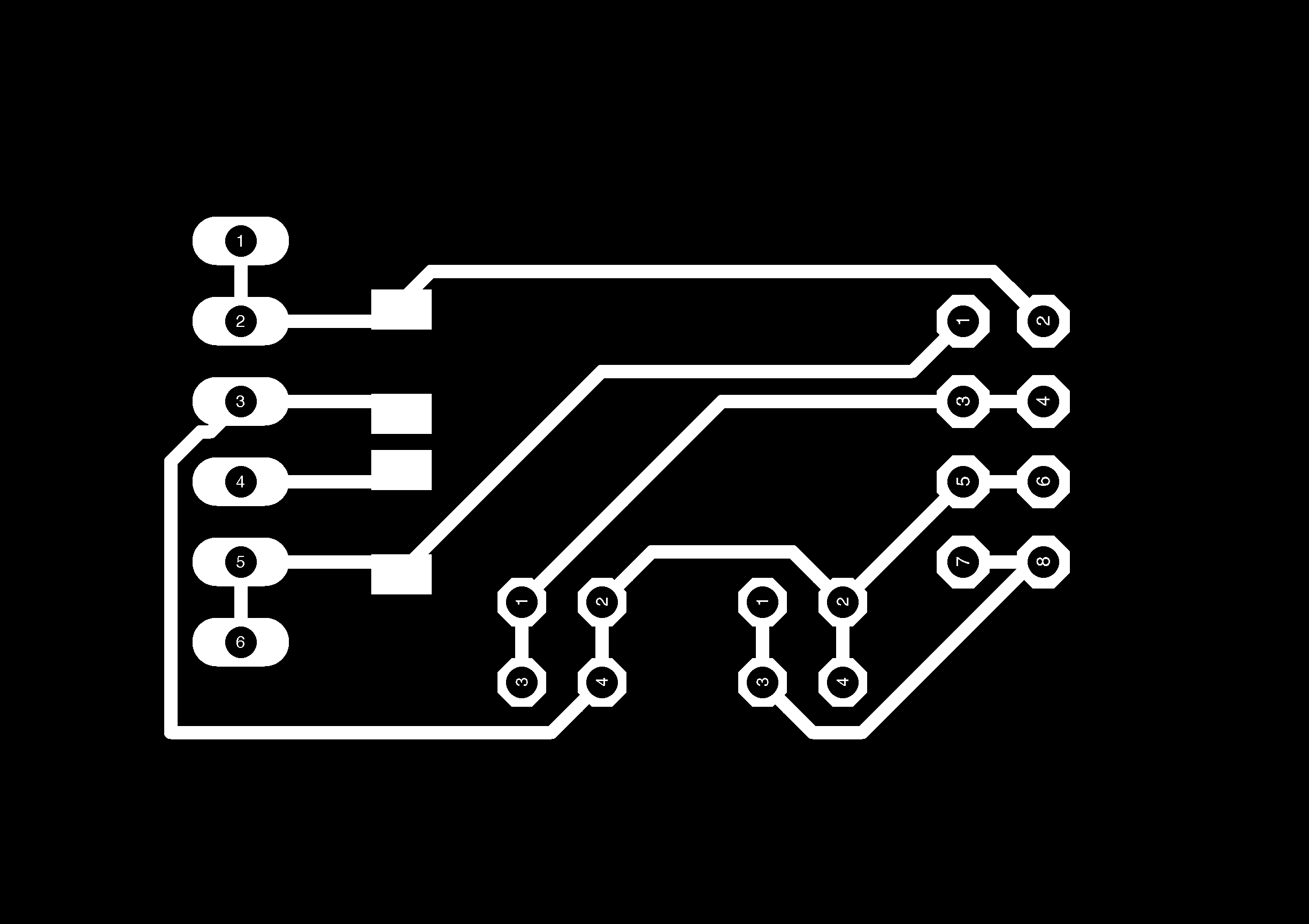

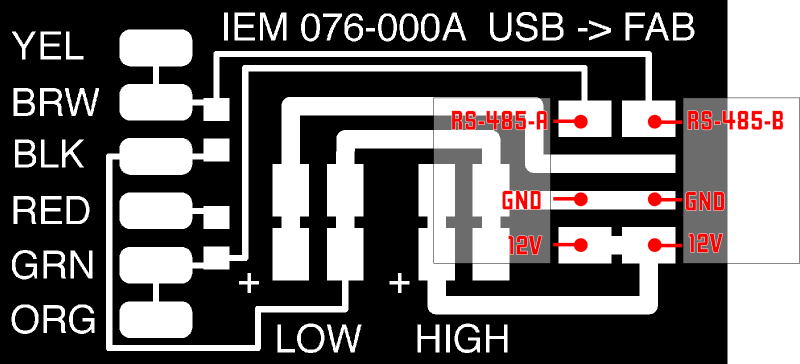

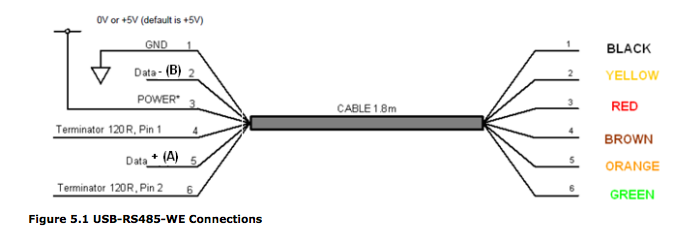

I started off with the fabnet usb design to power the fab arm and to communicate via ftdi.

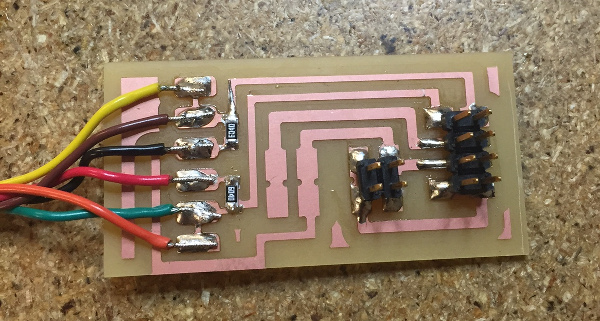

But my soldering wasn't quite good and the traces came off, and we had to desolder everything and do another board.

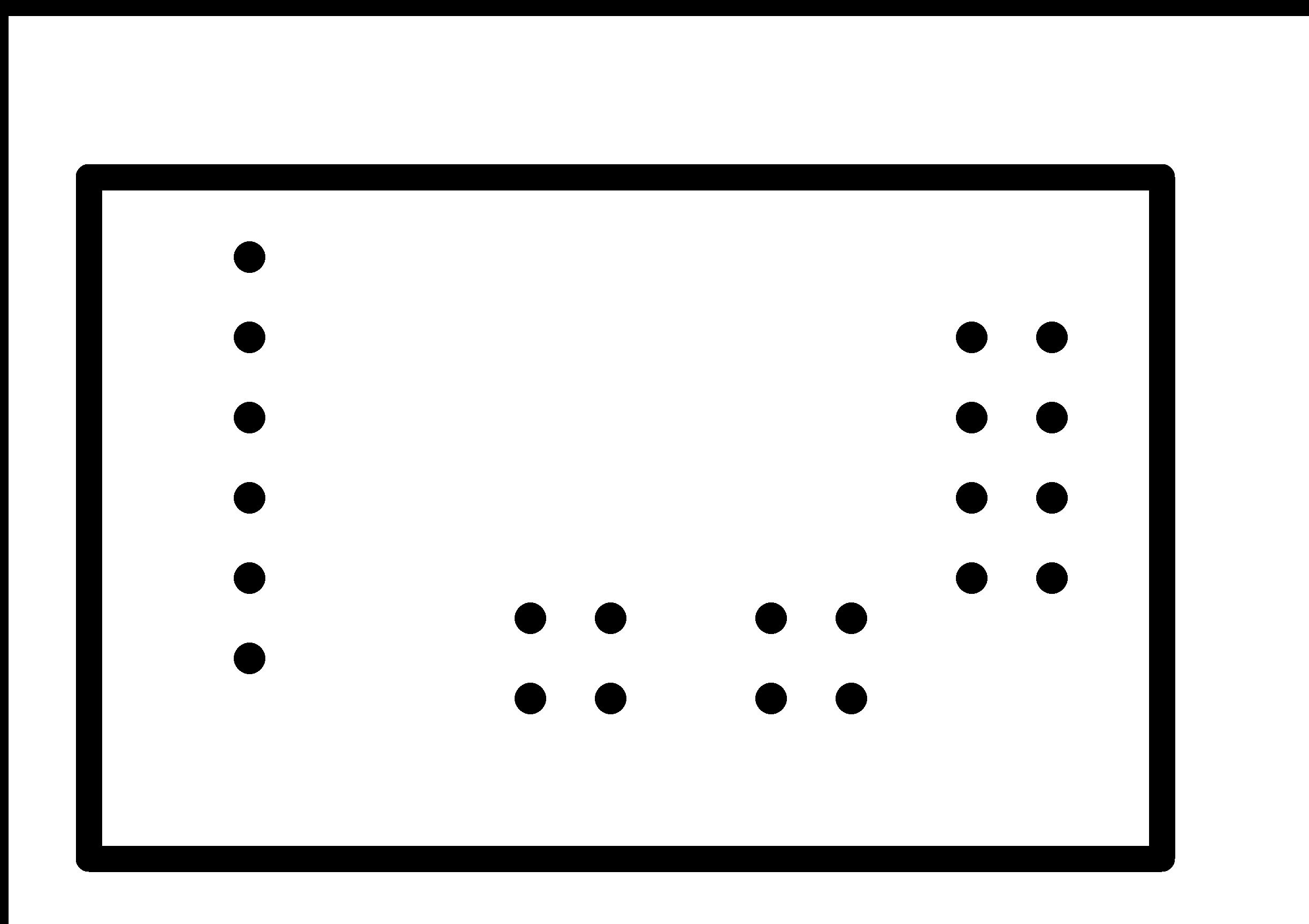

This time we did this board based on existing design,

The fabnet board we created,

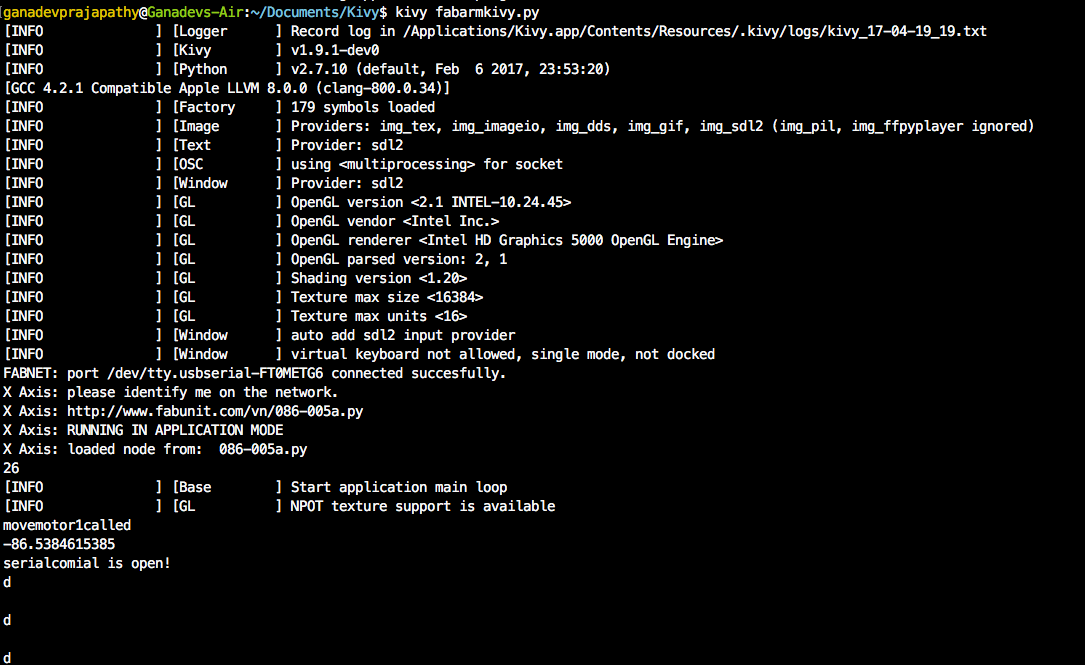

I used the fabnet to test the gestalt boards and worked towards integrating multiple stepper motors via gestalt.

We used the stepper motor to drive the fabarm through the guide rail that Rahul did using Jen's design,

With that done, I started with the arduino code to control the fabarm. We could not use the stepper motors to drive the fab arm elbows because the whole structure could not support the weight of the stepper motors. We used the arduino code to control the servo motors, which I had help from Renjith to get it properly communicating serially,

//add servo library

#include < Servo.h>

//define our servos

Servo servo1;

Servo servo2;

Servo servo3;

//Servo servo4;

//define our potentiometers

//int pot1 = A0;

//int pot2 = A1;

//int pot3 = A2;

//int pot4 = A3;

//variable to read the values from the analog pin (potentiometers)

int valPot1 = 120;

int valPot2 = 90;

int valPot3 = 90;

//int valPot4;

char inByte;

void setup()

{ Serial.begin(9600);

//attaches our servos on pins PWM 3-5-6-9 to the servos

servo1.attach(9);

servo1.write(valPot1); //define servo1 start position

servo2.attach(10);

servo2.write(valPot2); //define servo2 start position

servo3.attach(11);

servo3.write(valPot3); //define servo3 start position

// servo4.attach(6);

// servo4.write(70); //define servo4 start position

}

void loop()

{

//reads the value of potentiometers (value between 0 and 1023)

// while (1);

// valPot1 = analogRead(pot1);

// valPot1 = map (valPot1, 0, 1023, 100, 180); //scale it to use it with the servo (value between 0 and 180)

// servo1.write(valPot1); //set the servo position according to the scaled value

////-------------------------------------------------------------

// valPot2 = analogRead(pot2);

// valPot2 = map (valPot2, 0, 1023, 0, 180);

// servo2.write(valPot2);

// //-----------------------------------------------------------------

// valPot3 = analogRead(pot3);

// valPot3 = map (valPot3, 0, 1023, 45, 130);

// servo3.write(valPot3);

//

// valPot4 = analogRead(pot4);

// valPot4 = map (valPot4, 0, 1023, 70, 150);

// servo4.write(valPot4);

if (Serial.available())

{

inByte = Serial.read();

switch (inByte) {

case 'a':

Serial.print("a");

valPot1 += 1;

servo1.write(valPot1);

Serial.println(" ");

break;

case 'b':

Serial.print("b");

valPot2 += 1;

servo2.write(valPot2);

Serial.println(" ");

break;

case 'c':

Serial.print("c");

valPot3 += 1;

servo3.write(valPot3);

Serial.println(" ");

break;

case 'd':

Serial.print("d");

valPot1 -= 1;

servo1.write(valPot1);

Serial.println(" ");

break;

case 'e':

Serial.print("e");

valPot2 -= 1;

servo2.write(valPot2);

Serial.println(" ");

break;

case 'f':

Serial.print("f");

valPot3 -= 1;

servo3.write(valPot3);

Serial.println(" ");

break;

case 's':

Serial.print(byte(valPot1));

Serial.print(" ");

Serial.print(byte(valPot2));

Serial.print(" ");

Serial.print(byte(valPot3));

Serial.println(" ");

break;

case '\n':

break;

default:

Serial.print("Wrong Input");

Serial.println(" ");

}

}

}

We used the arduino code to do a cleaning like action,

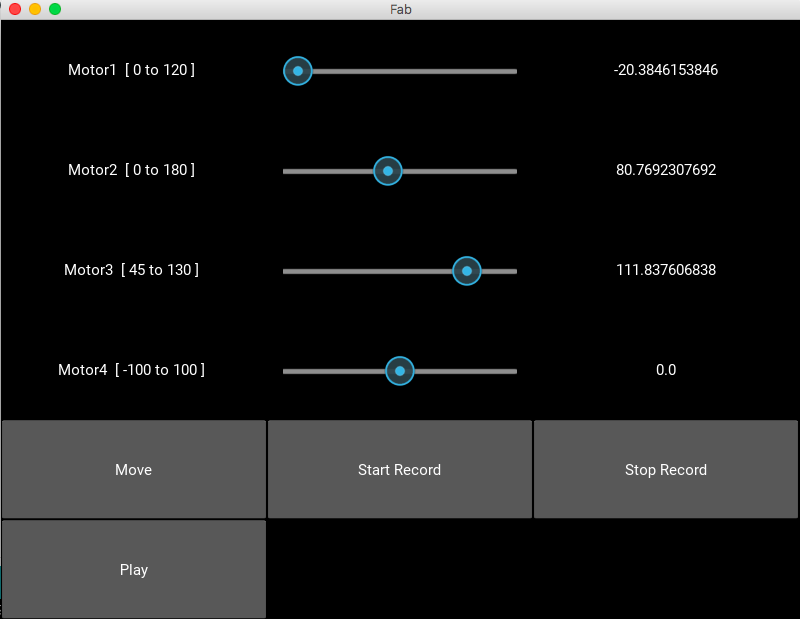

Along the same timeline, I worked on the GUI based on kivy. I used the sample code from Gestalt library to get started.

from kivy.uix.popup import Popup

from kivy.app import App

from kivy.uix.gridlayout import GridLayout

from kivy.uix.label import Label

from kivy.uix.textinput import TextInput

from kivy.uix.button import Button

from kivy.uix.boxlayout import BoxLayout

from kivy.uix.stacklayout import StackLayout

from kivy.uix.slider import Slider

from kivy.config import Config

Config.set('modules', 'serial', '')

# Forked from DFUnitVM Oct 2013

# set portname

# set location of hex file for bootloader

#

#------IMPORTS-------

from pygestalt import nodes

from pygestalt import interfaces

from pygestalt import machines

from pygestalt import functions

from pygestalt.machines import elements

from pygestalt.machines import kinematics

from pygestalt.machines import state

from pygestalt.utilities import notice

from pygestalt.publish import rpc #remote procedure call dispatcher

import time

import io

import threading

import serial

#------VIRTUAL MACHINE------

class virtualMachine(machines.virtualMachine):

def initInterfaces(self):

if self.providedInterface: self.fabnet = self.providedInterface #providedInterface is defined in the virtualMachine class.

else: self.fabnet = interfaces.gestaltInterface('FABNET', interfaces.serialInterface(baudRate = 115200, interfaceType = 'ftdi', portName = '/dev/tty.usbserial-FT0METG6'))

def initControllers(self):

self.xAxisNode = nodes.networkedGestaltNode('X Axis', self.fabnet, filename = '086-005a.py', persistence = self.persistence)

self.xNode = nodes.compoundNode(self.xAxisNode)

def initCoordinates(self):

self.position = state.coordinate(['mm'])

def initKinematics(self):

self.xAxis = elements.elementChain.forward([elements.microstep.forward(4), elements.stepper.forward(1.8), elements.leadscrew.forward(6.096), elements.invert.forward(True)])

self.stageKinematics = kinematics.direct(1) #direct drive on all axes

def initFunctions(self):

self.move = functions.move(virtualMachine = self, virtualNode = self.xNode, axes = [self.xAxis], kinematics = self.stageKinematics, machinePosition = self.position,planner = 'null')

self.jog = functions.jog(self.move) #an incremental wrapper for the move function

pass

def initLast(self):

# self.machineControl.setMotorCurrents(aCurrent = 0.8, bCurrent = 0.8, cCurrent = 0.8)

# self.xyzNode.setVelocityRequest(0) #clear velocity on nodes. Eventually this will be put in the motion planner on initialization to match state.

pass

def publish(self):

# self.publisher.addNodes(self.machineControl)

pass

def getPosition(self):

return {'position':self.position.future()}

def setPosition(self, position = [None]):

self.position.future.set(position)

def setSpindleSpeed(self, speedFraction):

# self.machineControl.pwmRequest(speedFraction)

pass

class FabControl(GridLayout):

def __init__(self, **kwargs):

super(FabControl, self).__init__(**kwargs)

self.cols = 3

self.row = 3

global serialcom, tempmotor1, tempmotor2, tempmotor3

tempmotor1 = 120

tempmotor2 = 90

tempmotor3 = 90

serialcom = serial.Serial()

serialcom.braudrate = 115200

serialcom.port = "/dev/tty.usbmodem1421"

serialcom.open()

self.add_widget(Label(text='Motor1 [ 0 to 120 ] '))

self.motor1 = Slider(min=-30, max=120, value=120)

self.motor1.bind(value=self.Motor1Change)

self.add_widget(self.motor1)

self.motor1value = Label(text=str(self.motor1.value))

self.add_widget(self.motor1value)

self.add_widget(Label(text='Motor2 [ 0 to 180 ] '))

self.motor2 = Slider(min=0, max=180, value=90)

self.motor2.bind(value=self.Motor2Change)

self.add_widget(self.motor2)

self.motor2value = Label(text=str(self.motor2.value))

self.add_widget(self.motor2value)

self.add_widget(Label(text='Motor3 [ 45 to 130 ] '))

self.motor3 = Slider(min=45, max=130, value=90)

self.motor3.bind(value=self.Motor3Change)

self.add_widget(self.motor3)

self.motor3value = Label(text=str(self.motor3.value))

self.add_widget(self.motor3value)

self.add_widget(Label(text='Motor4 [ -100 to 100 ] '))

self.motor4 = Slider(min=-100, max=100, value=0)

self.motor4.bind(value=self.Motor4Change)

self.add_widget(self.motor4)

self.motor4value = Label(text=str(self.motor4.value))

self.add_widget(self.motor4value)

self.move = Button(text="Move")

self.add_widget(self.move)

self.move.bind(on_press=self.initiatemove)

self.startrec = Button(text="Start Record")

self.add_widget(self.startrec)

self.stoprec = Button(text="Stop Record")

self.add_widget(self.stoprec)

self.play = Button(text="Play")

self.add_widget(self.play)

def Motor4Change(self, instance, value):

self.motor4value.text = str(value)

def Motor1Change(self, instance, value):

self.motor1value.text = str(value)

threading.Thread(target=self.movemotor1).start()

def Motor2Change(self, instance, value):

self.motor2value.text = str(value)

threading.Thread(target=self.movemotor2).start()

def Motor3Change(self, instance, value):

self.motor3value.text = str(value)

threading.Thread(target=self.movemotor3).start()

def initiatemove(self,instance):

# time.sleep(5)

threading.Thread(target=self.movemotor4).start()

threading.Thread(target=self.movemotor1).start()

threading.Thread(target=self.movemotor2).start()

threading.Thread(target=self.movemotor3).start()

def movemotor4(self):

print "movemotor4 called"

global stage

# print stage

# print self.motor4.value

# print self.motor1.value

# print self.motor2.value

# print self.motor3.value

#

movemotor4 = int(self.motor4.value)

supercoords = [[movemotor4]]

for coords in supercoords:

stage.move(coords, 0)

status = stage.xAxisNode.spinStatusRequest()

while status['stepsRemaining'] > 0:

time.sleep(0.001)

status = stage.xAxisNode.spinStatusRequest()

# ser = serial.Serial()

# ser.braudrate = 115200

# ser.port = "/dev/tty.usbmodem1411"

# ser.open()

def movemotor1(self):

print "movemotor1called"

global serialcom, tempmotor1

movemotor1 = self.motor1.value - tempmotor1

tempmotor1 = self.motor1.value

print movemotor1

# print movemotor2

# print movemotor3

if serialcom.isOpen():

print("serialcomial is open!")

# serialcom.write('a\n')

if movemotor1 > 0:

for i in range(int(movemotor1)):

print 'sending a'

serialcom.write('a\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

else:

for i in range(abs(int(movemotor1))):

serialcom.write('d\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

# serialcom.close()

def movemotor2(self):

print "movemotor2called"

global serialcom, tempmotor2

movemotor2 = self.motor2.value - tempmotor2

tempmotor2 = self.motor2.value

print movemotor2

if serialcom.isOpen():

print("serialcomial is open!")

# serialcom.write('a\n')

if movemotor2 > 0:

for i in range(int(movemotor2)):

print 'sending b'

serialcom.write('b\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

else:

for i in range(abs(int(movemotor2))):

serialcom.write('e\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

def movemotor3(self):

print "movemotor3called"

global serialcom, tempmotor3

movemotor3 = self.motor3.value - tempmotor3

tempmotor3 = self.motor3.value

print movemotor3

if serialcom.isOpen():

print("serialcomial is open!")

# serialcom.write('a\n')

if movemotor3 > 0:

for i in range(int(movemotor3)):

print 'sending c'

serialcom.write('c\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

else:

for i in range(abs(int(movemotor3))):

serialcom.write('f\n')

# time.sleep(.5)

# print serialcom.read()

print serialcom.readline()

class FabApp(App):

def build(self):

global stage

stage = virtualMachine()

# print dir(stage.xNode)

#stage.xNode.loadProgram('../../../086-005/086-005a.hex')

#stage.xNode.setMotorCurrent(1)

stage.xNode.setVelocityRequest(8)

return FabControl()

if __name__ == '__main__':

FabApp().run()

To run the python kivy program, kivy fabarmkivy.py

Screenshot of the UI,

It took me a while because it wasn't quite working as intended by the code, it was too jittery and random, sometimes it moves correct sometimes doesn't

Finally figure it was due to some loose connections and I replaced the servos as well during debugging,

Controlling via GUI

Download the files

fabarmkivy.py

fabarminterface.ino

FabNetTrace.png

FabNetCut.png