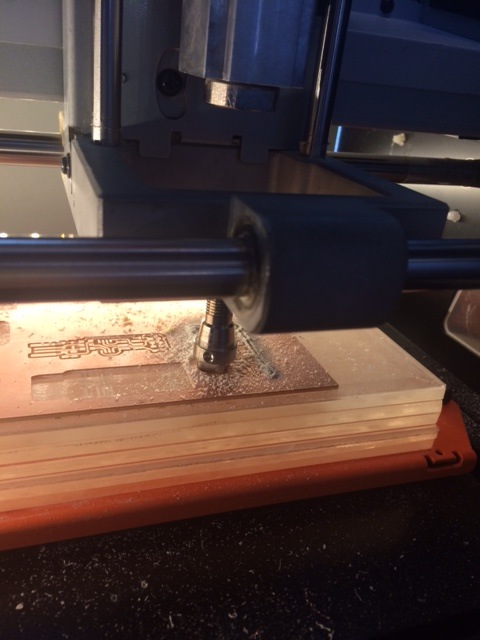

It means, the machine considered the current z=-1 as z=1 (which is lower by 2 now), and when it touched the surface thinking it's z=0, it was actually z=-2!!!!

So, the end mill was stuck and then the upper connecting part had to spin in reverse direction, unscrewing itself. I might have damaged the machine.

Go back