Assignment 3

8.2.2017

Topic: Computer-Controlled Cutting

1. Laser

- make laser cutter test part(s), varying slot dimensions using

parametric functions, testing your laser kerf & cutting

settings (group project)

- design, make, and document a parametric press-fit construction

kit, accounting for the laser cutter kerf, which can be

assembled in multiple ways.

Learning outcomes

- demonstrate and describe parametric 2D modeling processes

- identify and explain processes

- develop, evaluate and construct the final project.

2. Vinyl Cutter

- cut something on the vinyl cutter.

Learning outcomes

- identify and explain processes

- design and create the final

project

Include your design files

and photos of your finished project

Picture note: At first, I increased the

picture size. I will use about 900 dots width and 72 or 96 dpi

resolution.

Lecture note: The Laser MicroJet

combines water jet and laser, and makes hot laser cold (http://www.synova.ch/technology/laser-microjet.html,

http://www.itw-chemnitz.de).

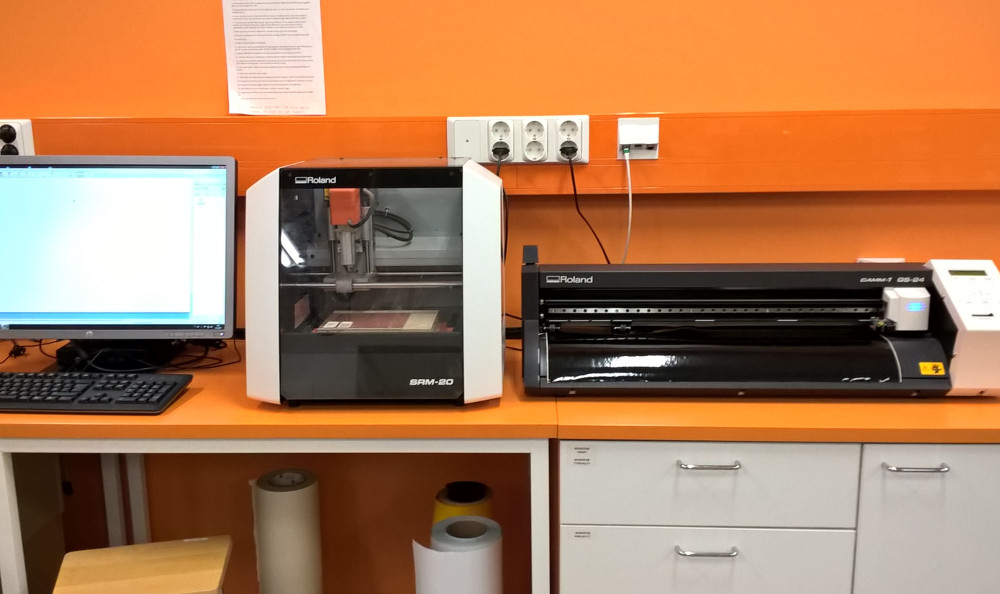

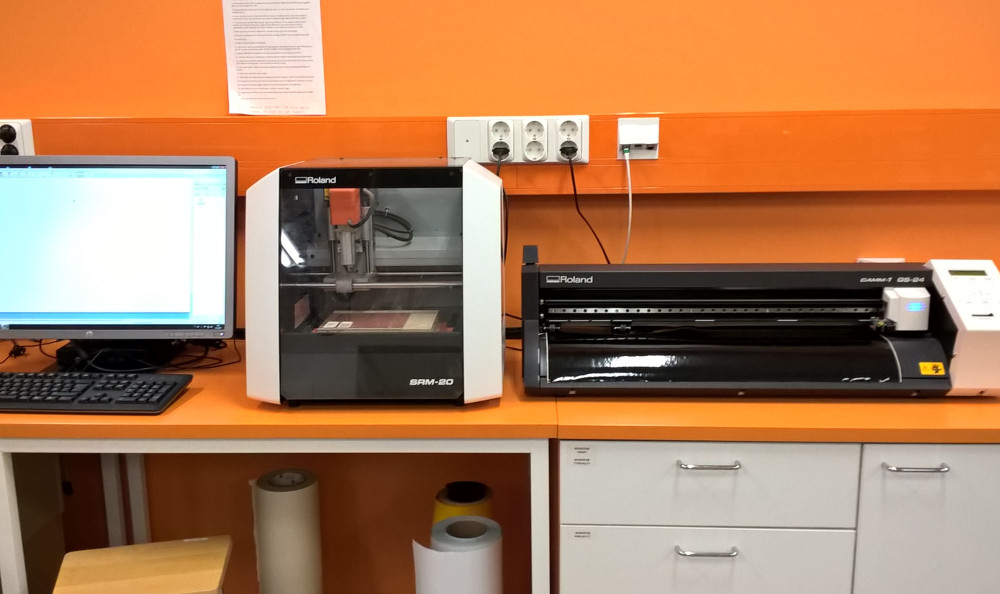

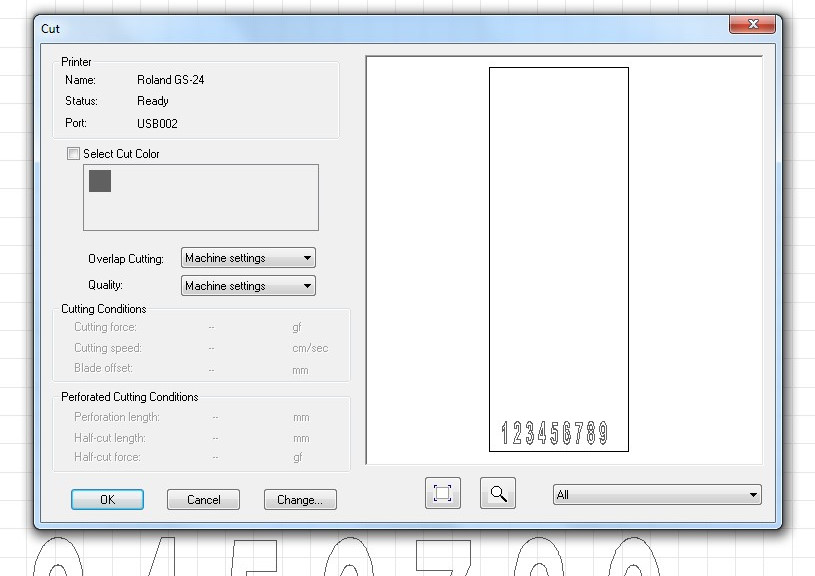

Vinyl cutter

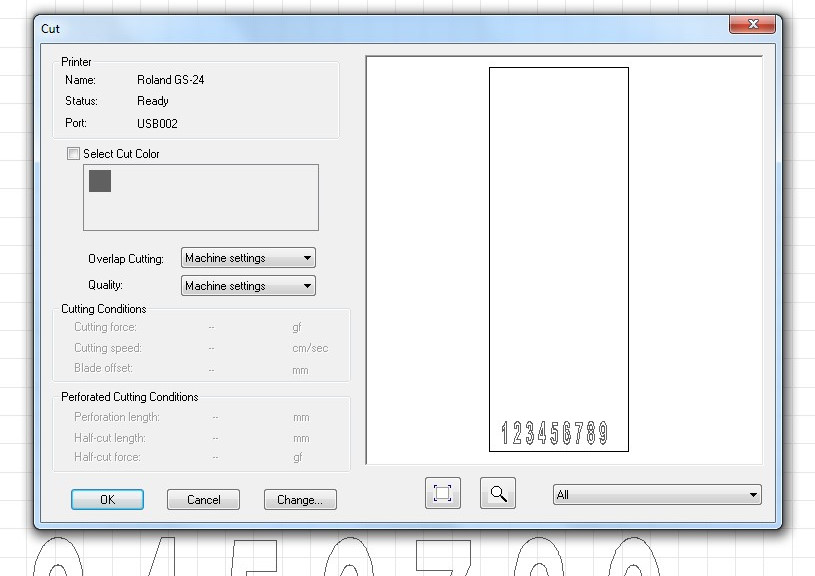

I use Roland GS-24 desktop cutter here. It is located right in

following picture. The control computer locates left, where the

cutter is connected by USB cable.

I lifted a black roll of paper to the back of cutter. It has stand

there. And, I loaded the paper in. Important thing is the lever in

left side of cutter, which locks the paper in place.

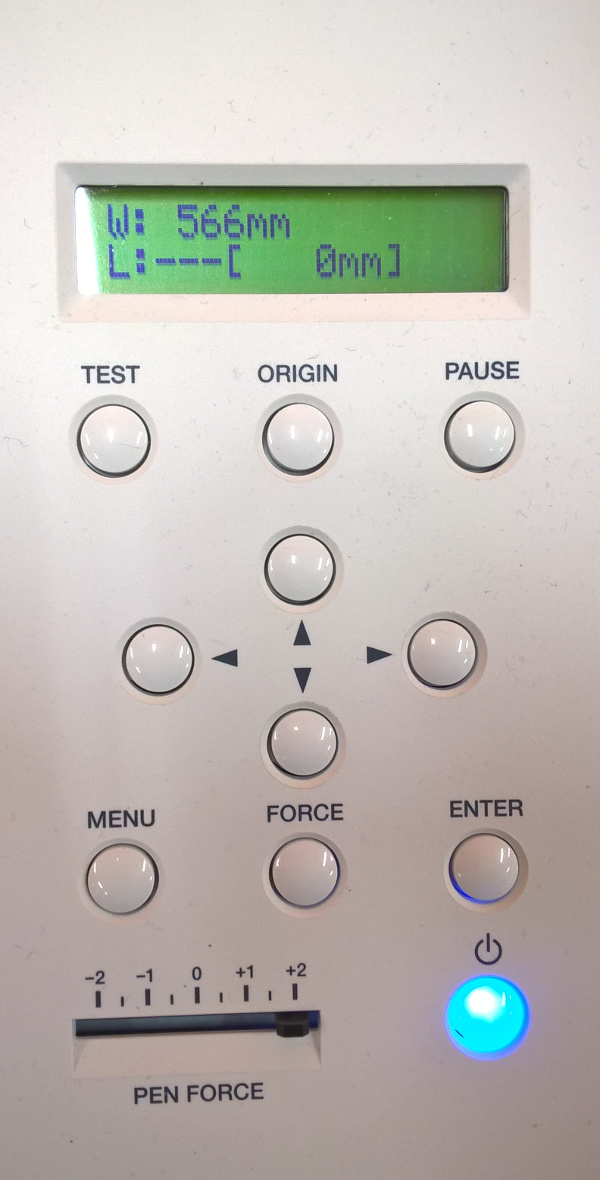

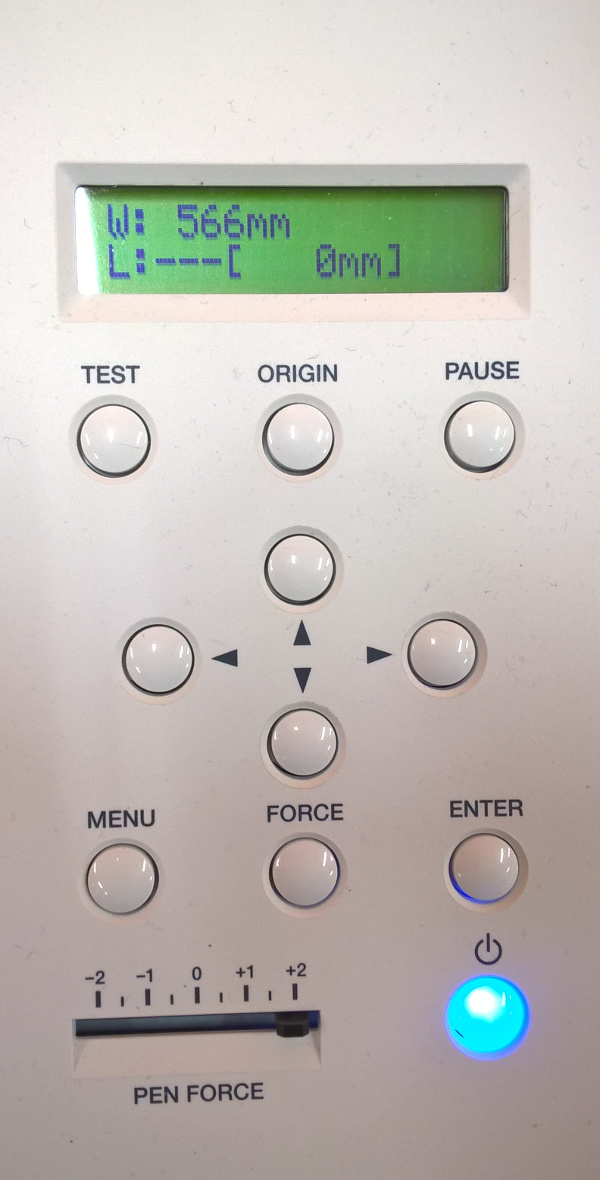

Then, I switched on the cutter. I selected sheet as roll and

control panel shows cutting area as in following picture.

The control panel is very easy to use. You can test cutting, set

origin and pause cutting.

Pen force setting controls the cutting depth. Blue button switch

cutter on and off.

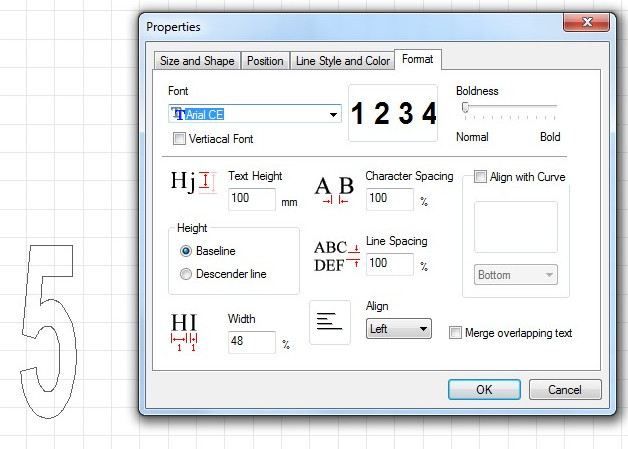

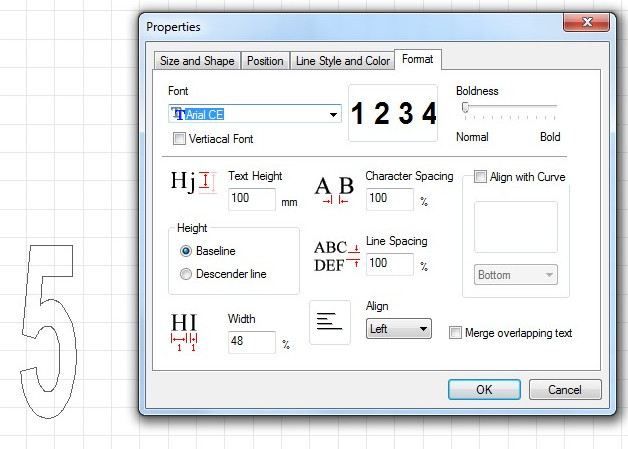

I used cutStudio program for my first cutting. My idea was big

numbers 1 to 9. I used text tool to write numbers 1 2 3 4 5 6 7 8 9

to the bottom of the sheet. Then, I selected them and changed the

text height to 100 mm as my plan. I selected font as Arial CE. Other

parameters were as default.

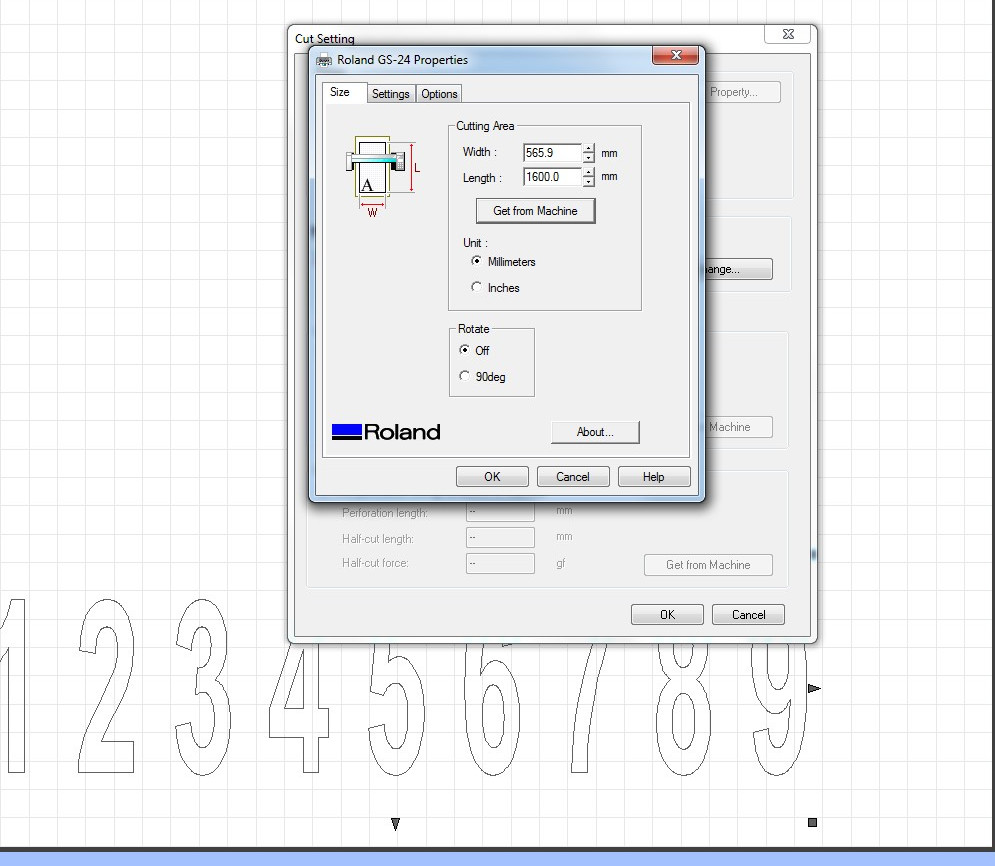

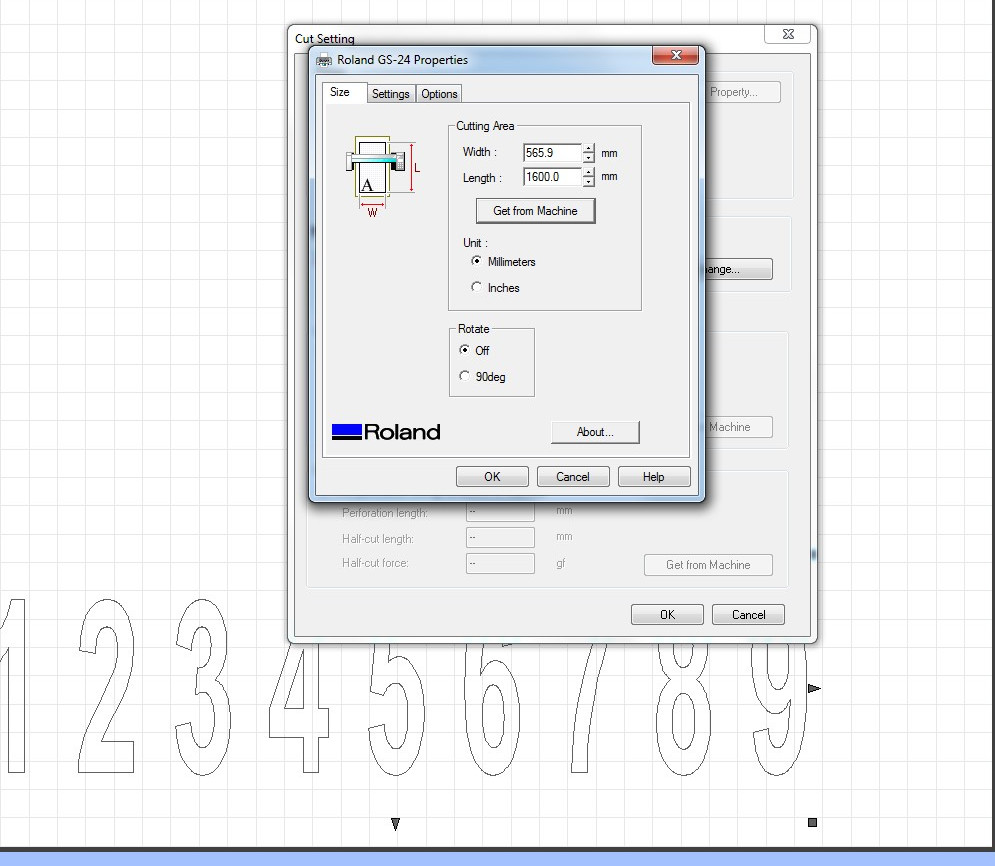

Then, I set cutting area by reading dimensions from machine.

Then, I selected cut command from menu, checked parameters, selected

OK and cutter started to work.

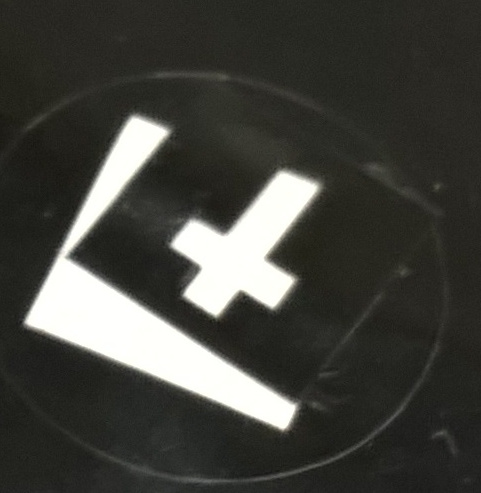

Cutting  gone too deep in sheet.

Therefore, I tuned the pen force to set the cut depth correctly.

gone too deep in sheet.

Therefore, I tuned the pen force to set the cut depth correctly.

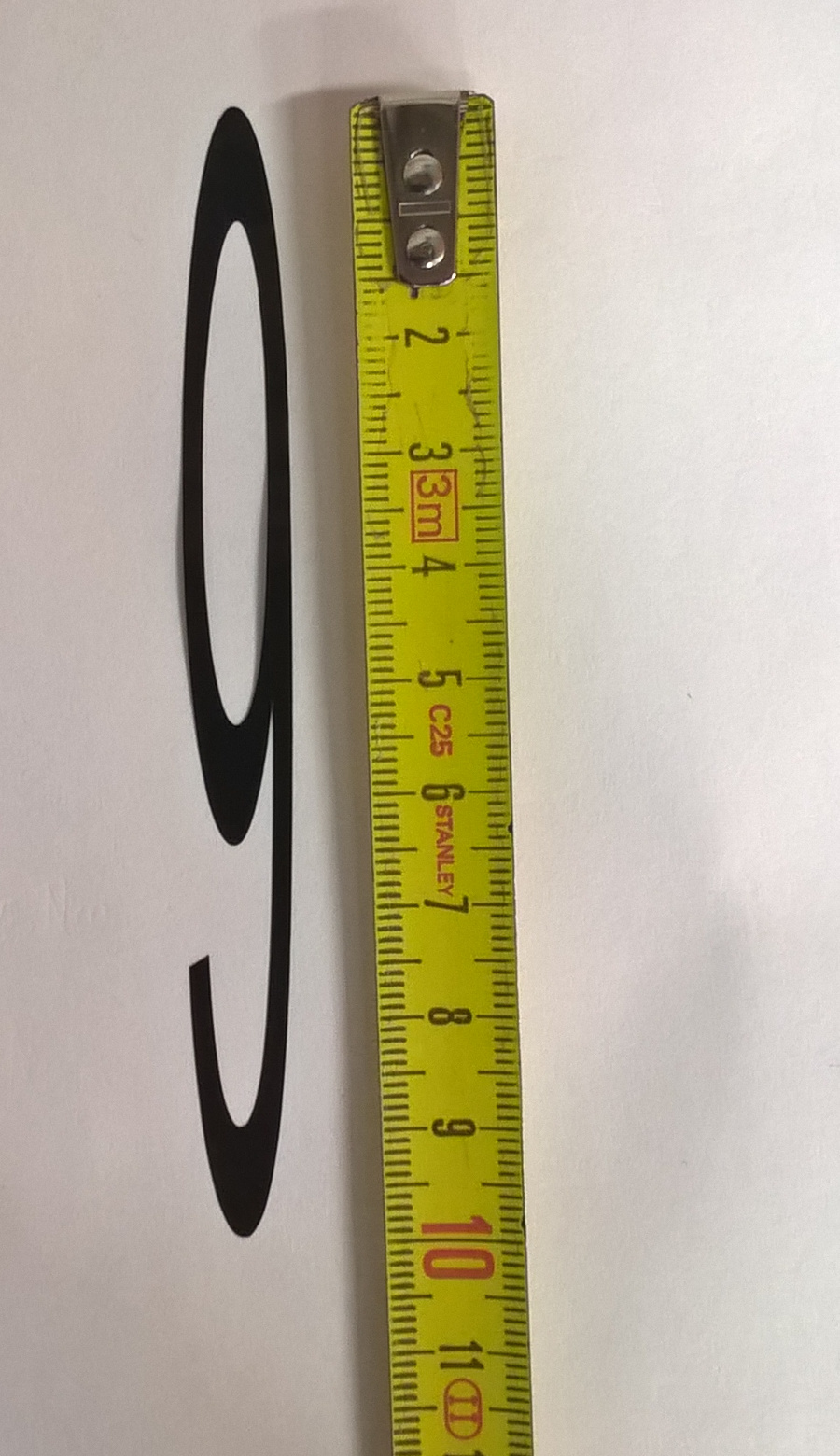

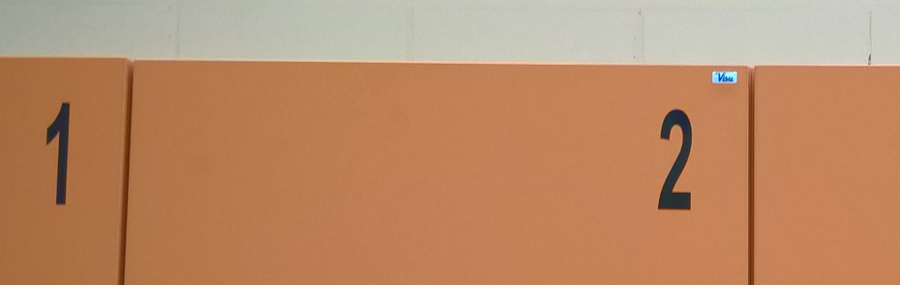

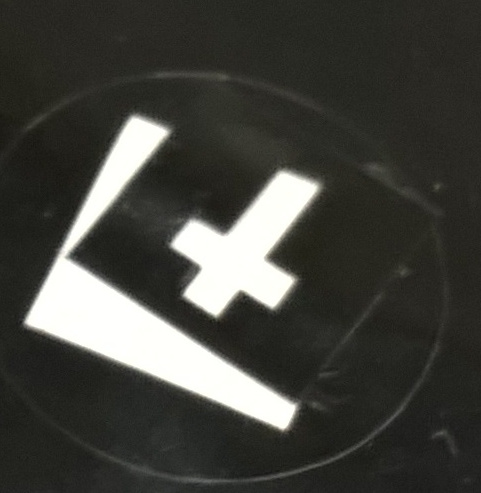

Following picture shows correct test results.

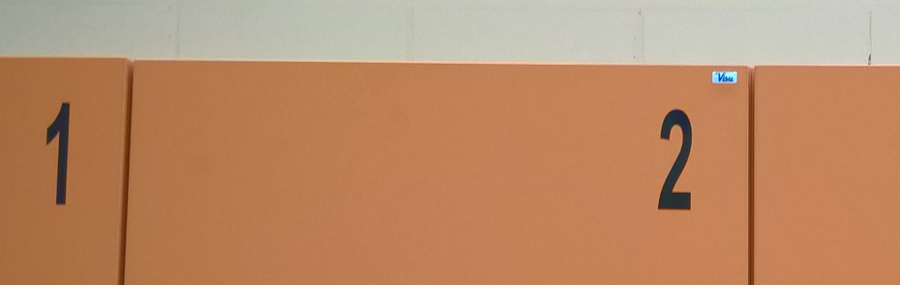

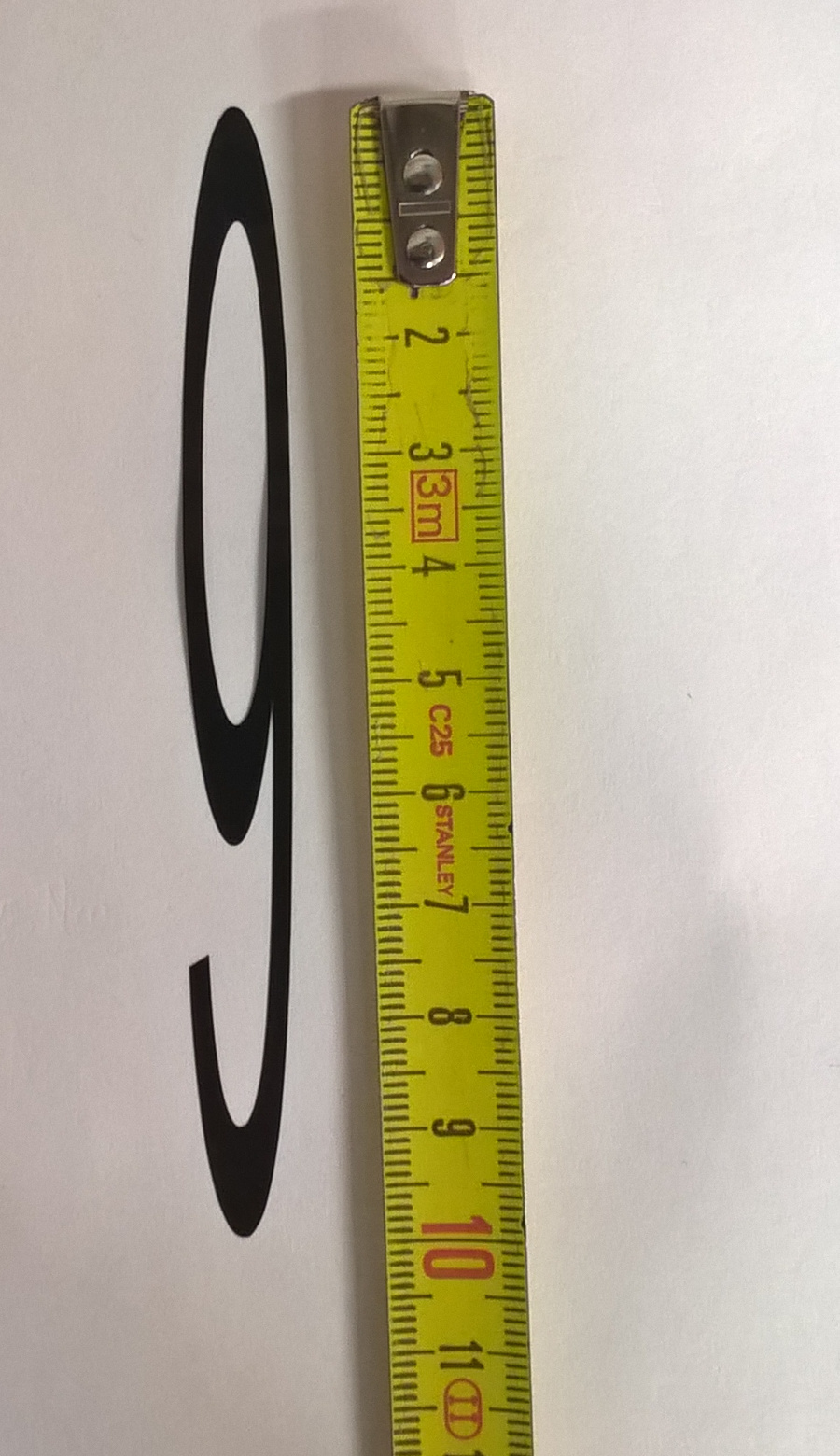

After all, my cuttings went well. I needed these numbers in our

laboratory as showed in the picture.

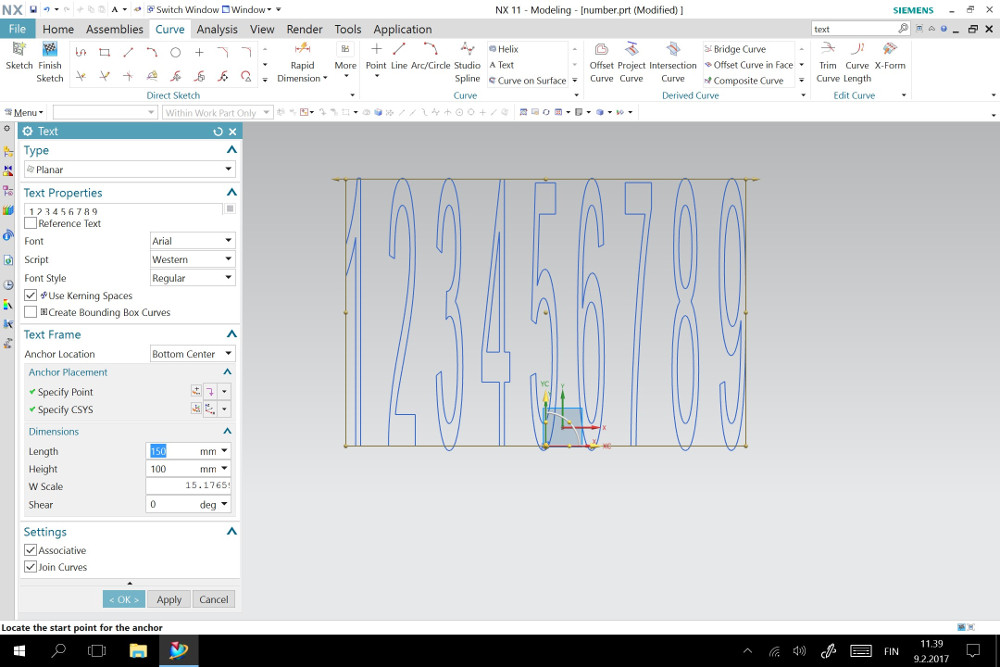

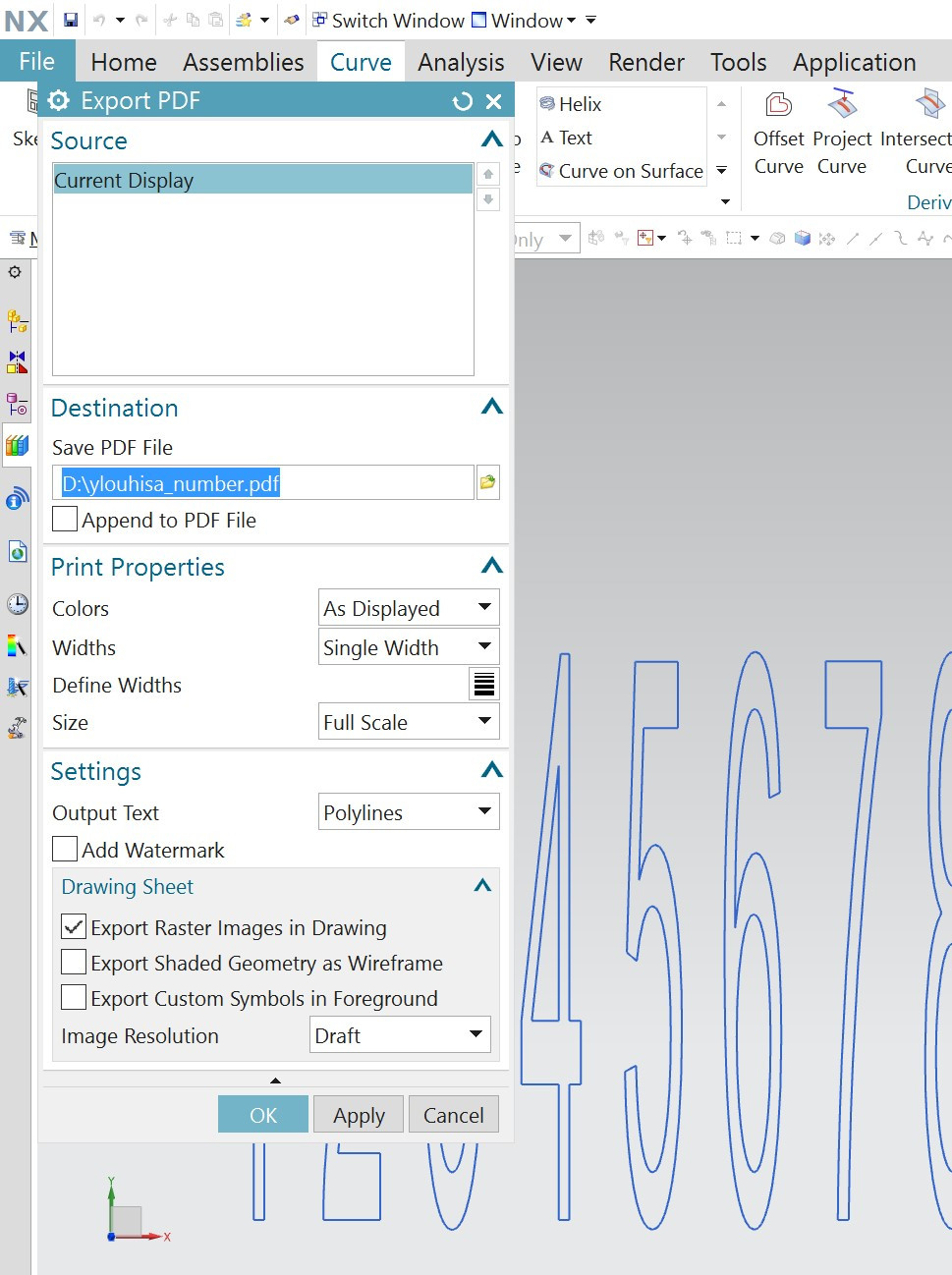

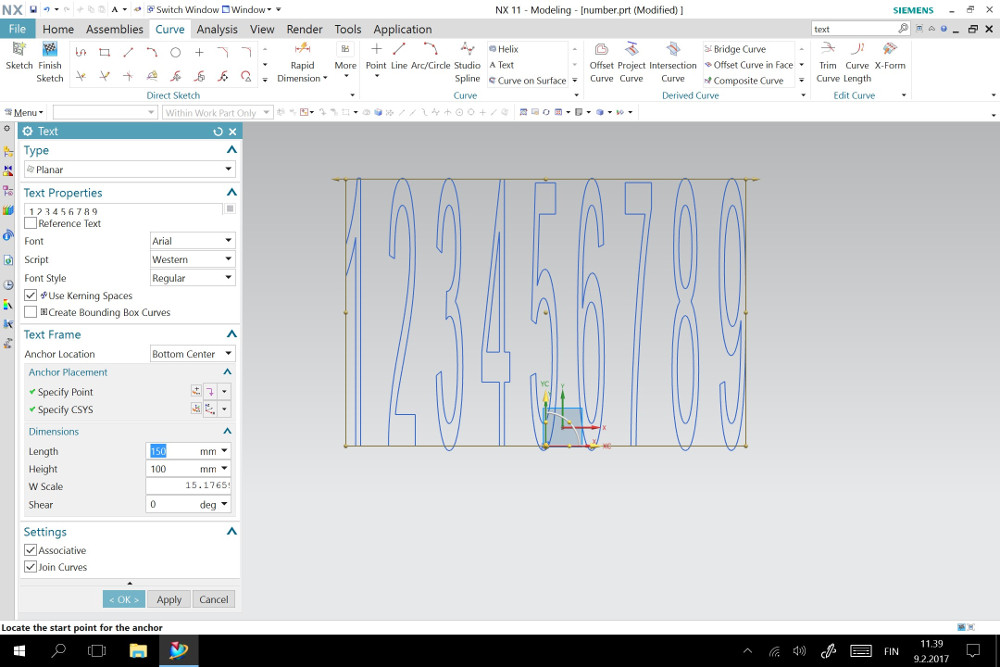

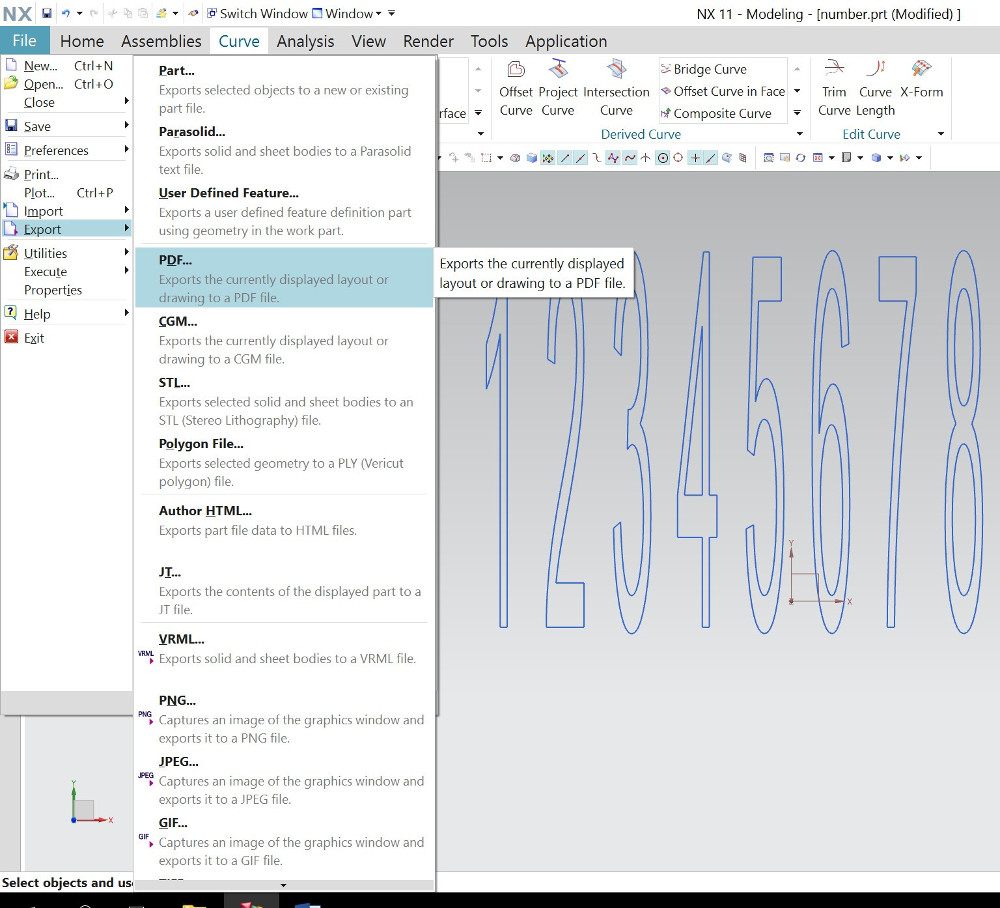

Also, I made the second cutting study using data from NX11 program.

I created new file, selected xy plain view as my work view, selected

curve and text from menus. And, I inserted numbers 1 2 3 4 5 6 7 8 9

in place with height of 100 mm and length of 150 mm. Other

parameters were as defaults.

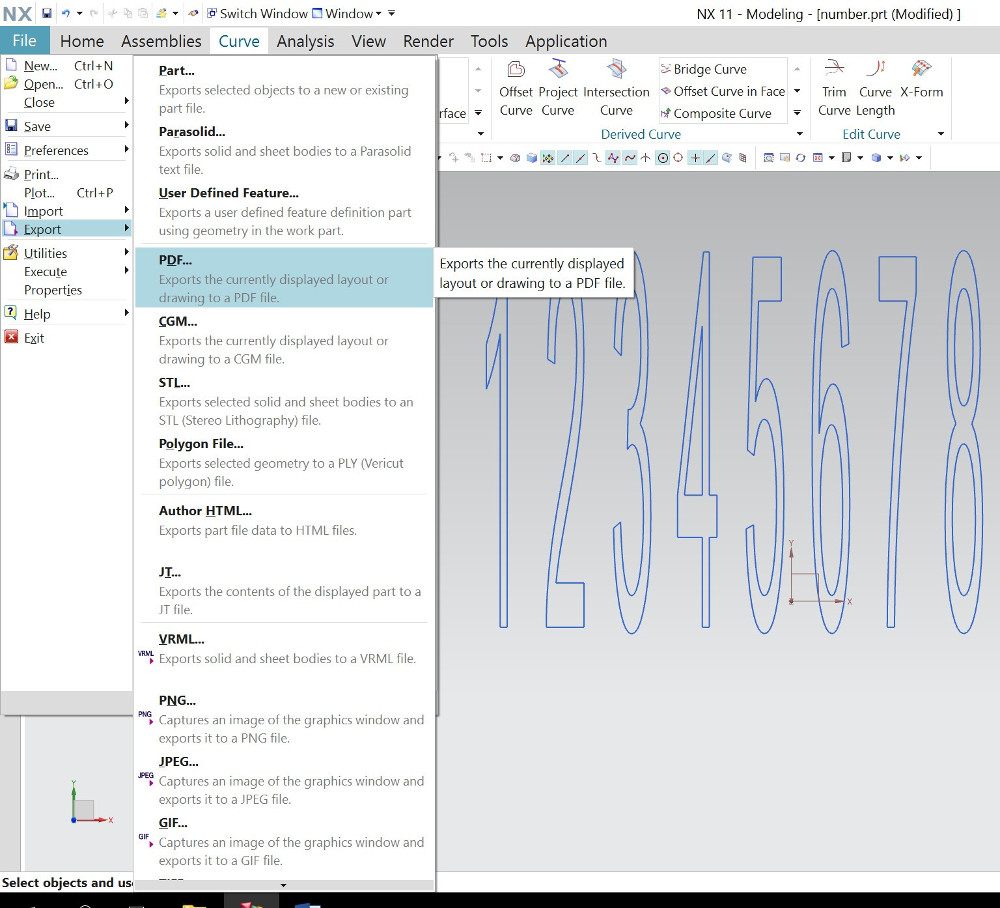

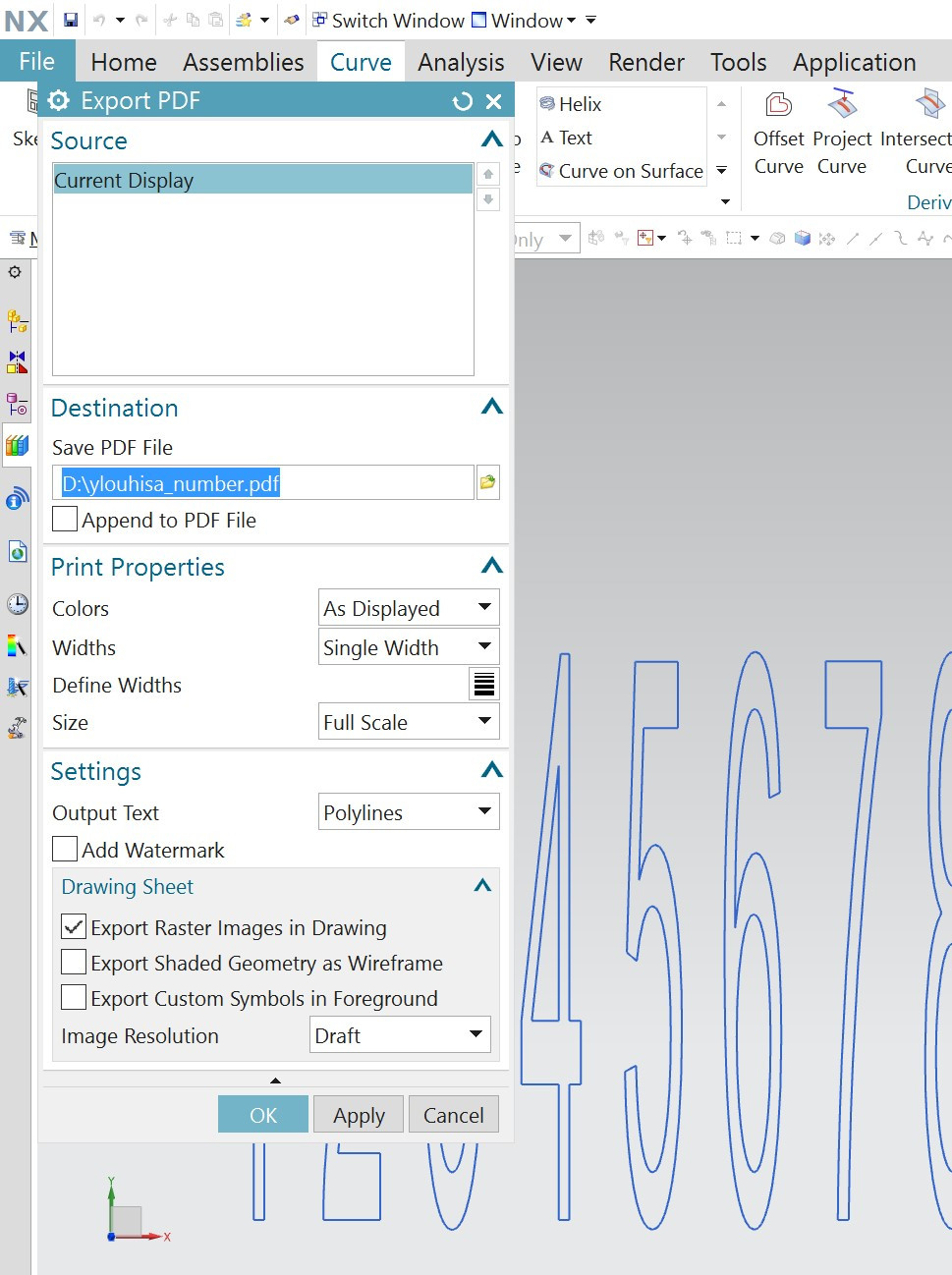

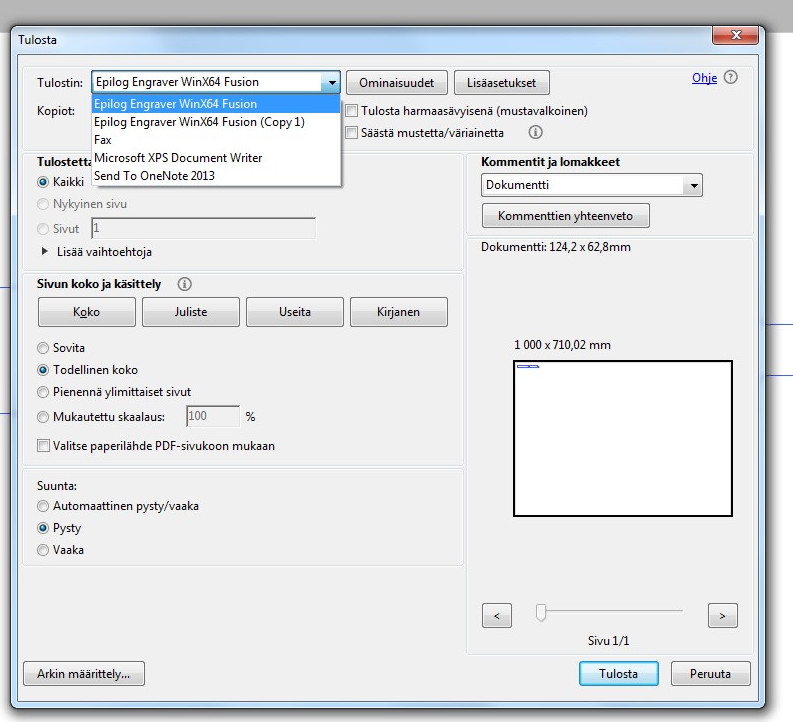

Then, I exported my drawing as PDF file.

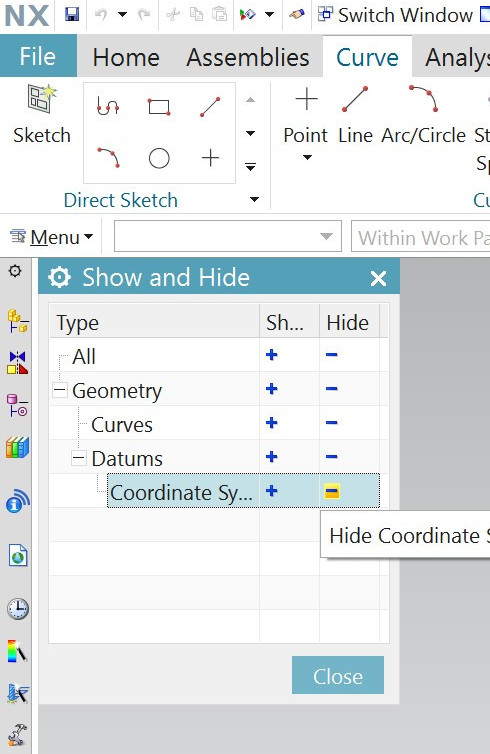

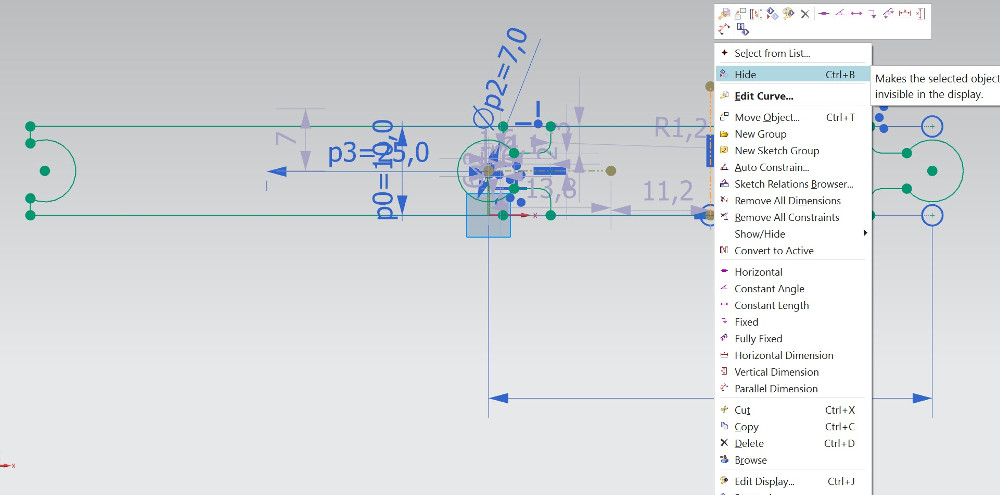

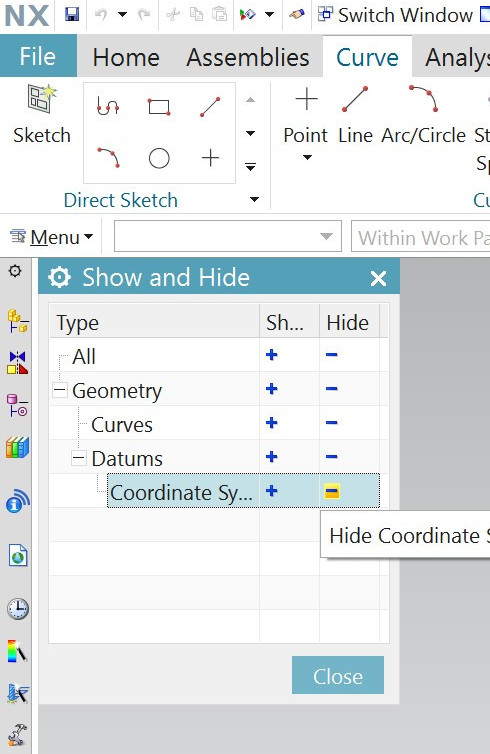

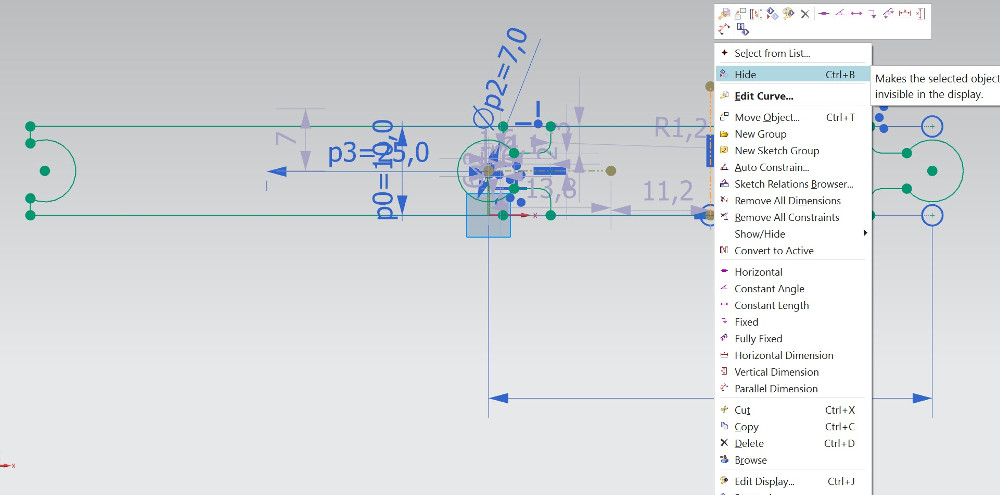

However, I must hide coordinate icon before exporting.

Here, I do export. Line thickness is same for all geometry and it's

value is 0.25 mm. It is not critical for vinyl cutting. Only vector

graphics is needed.

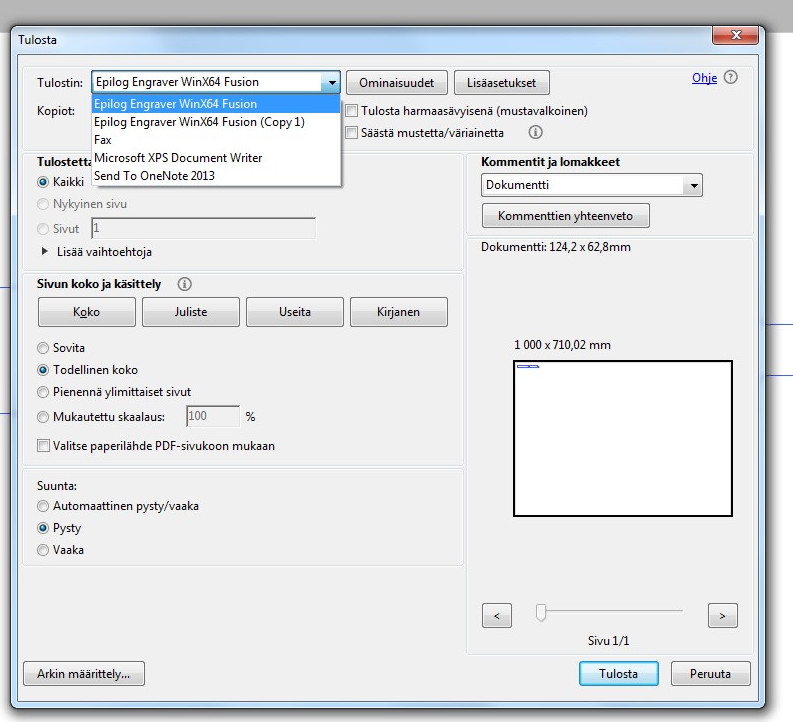

I opened the PDF file in control computer, selected print and again

the printer as Roland GS-24. I must change cutting length to 200 mm

in printer properties to ensure cutting to the bottom of the sheet.

Finally, I checked the size of my numbers. They are in order.

Laser cutting

I used Epilog Fusion laser with 75 Watts of power.

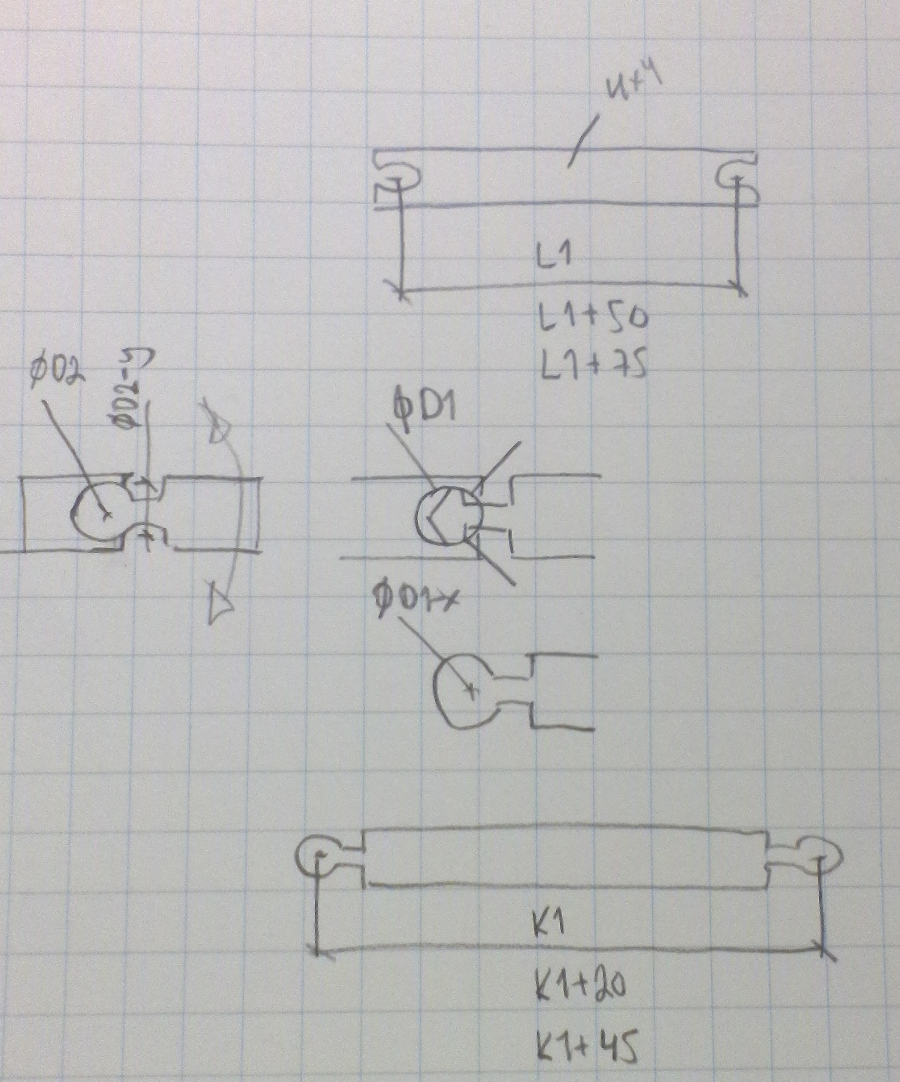

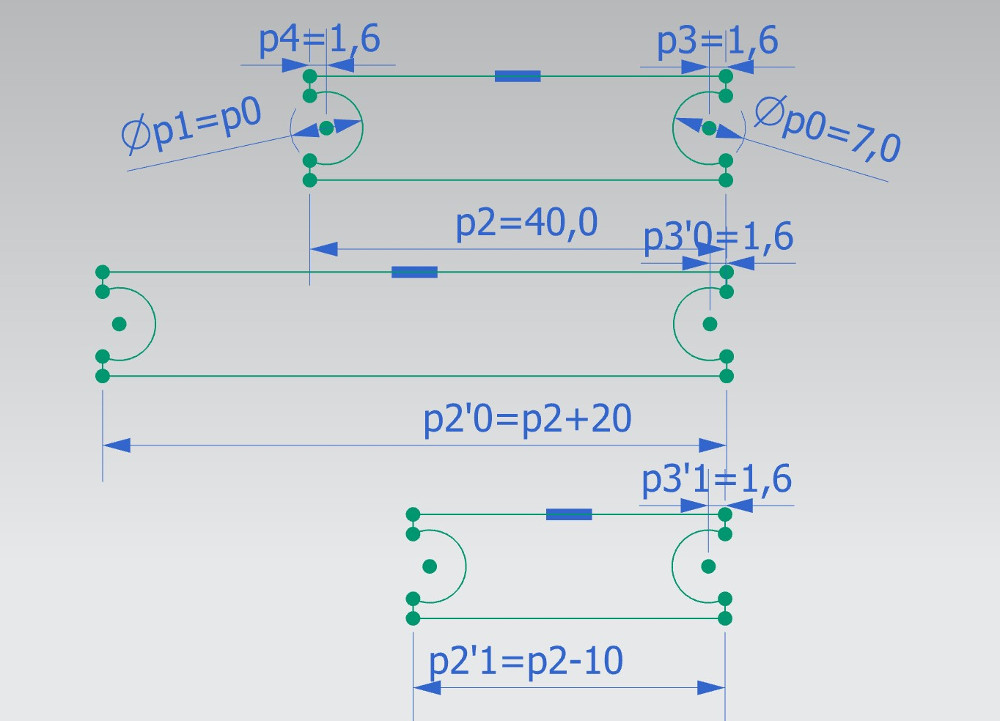

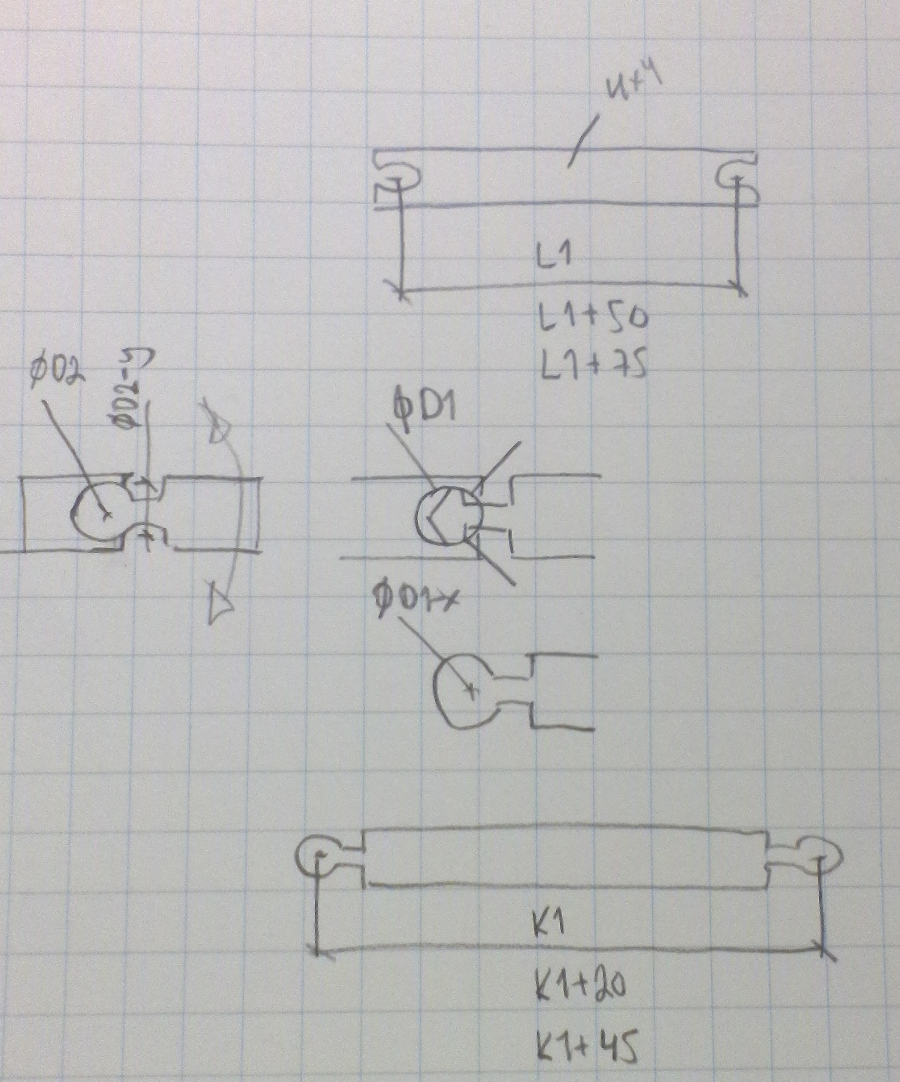

At first, I drew a sketch, what I would like to do. And, I decided

to cut a chain of bars which are connected together by snap-on

connectors. Also, I do them parametric by length series and

connection details.

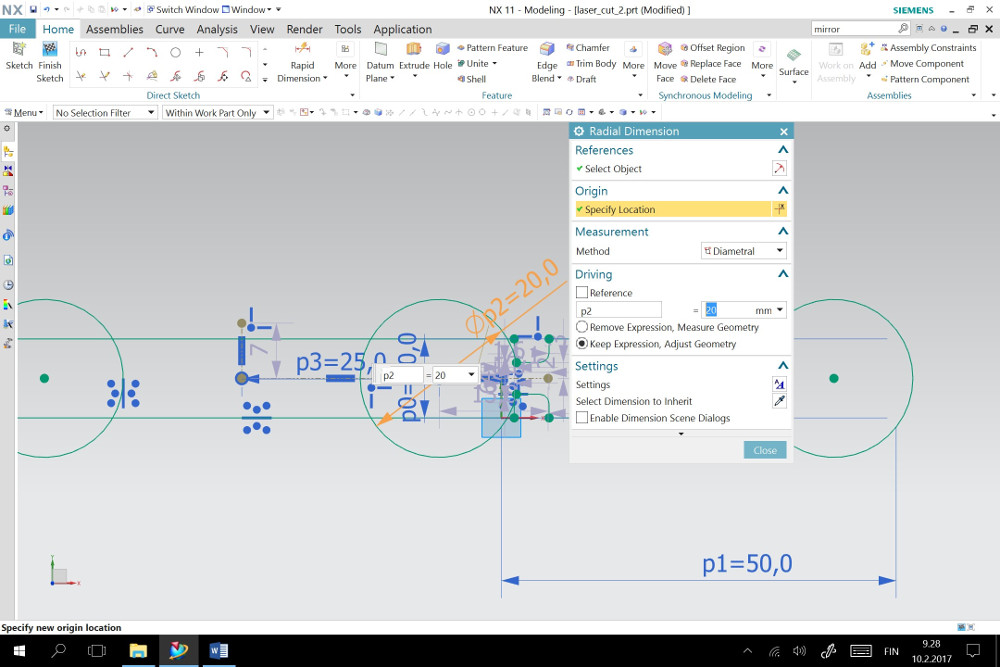

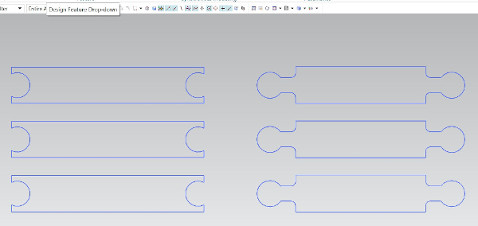

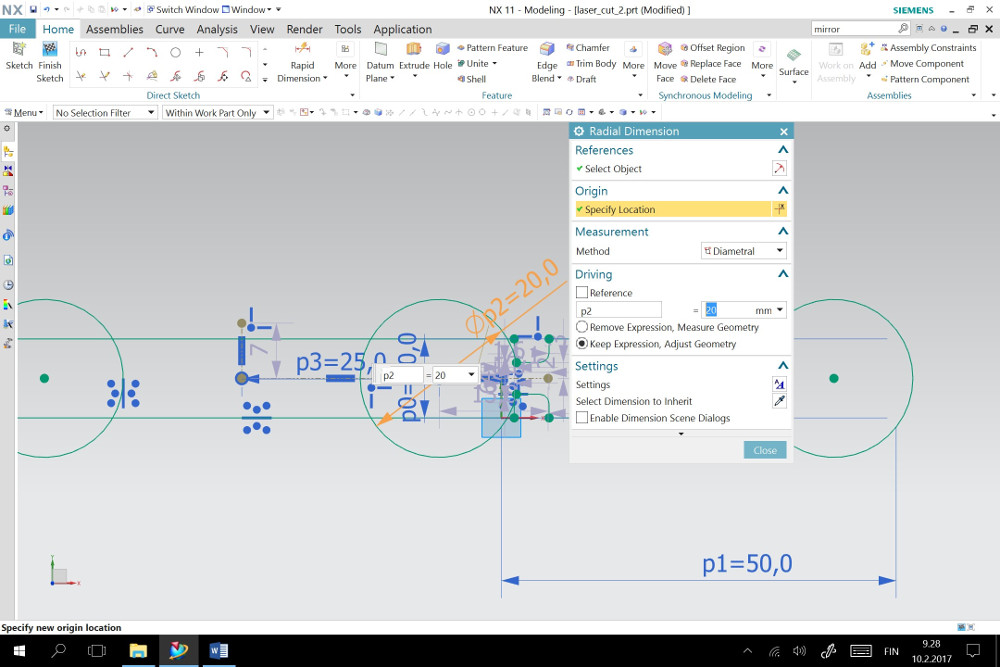

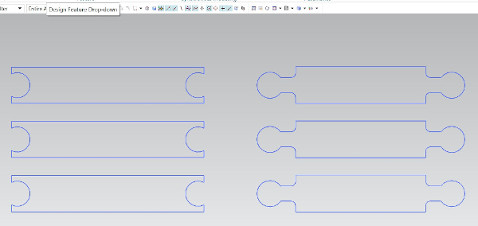

Here, I have a first computer sketch. I want draw all as one

assembly and develop my idea ready first. I want use 3 or 4 mm PMMA

sheet as my material.

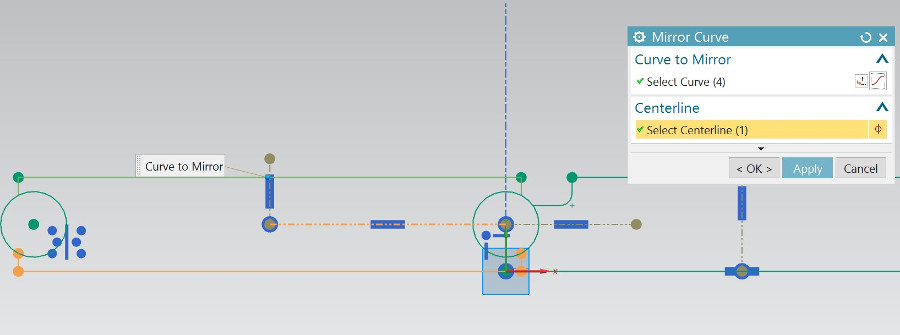

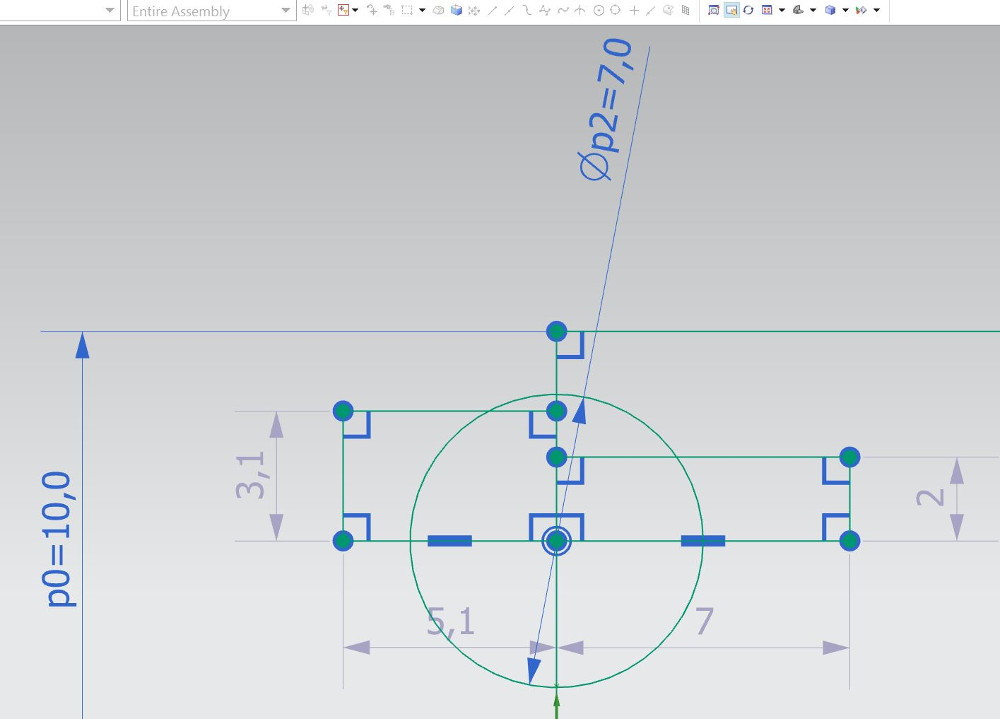

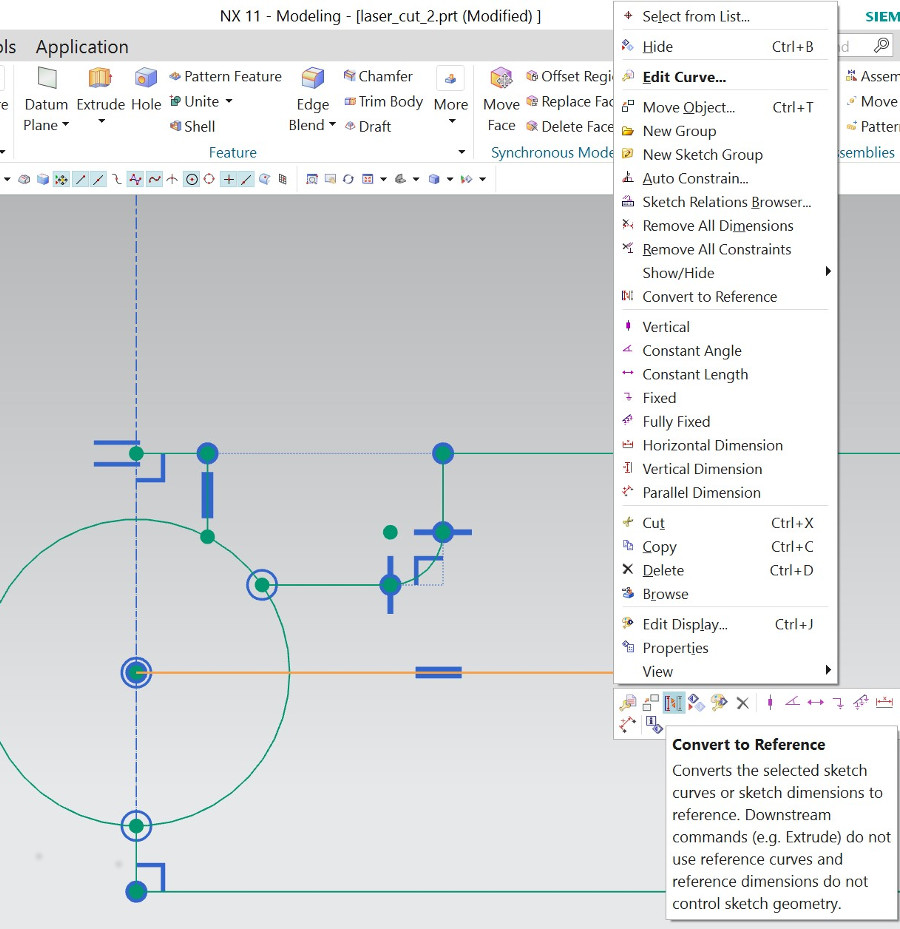

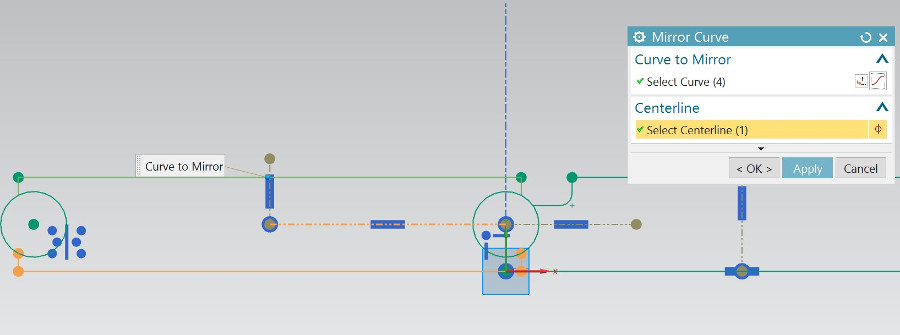

Then, I mirrored my geometry, but I needed two reference lines

to do it. Horizontal line mirrors the upper details down.

Vertical line mirrors the geometry right to left. Several mirror

operations got the geometry almost ready.

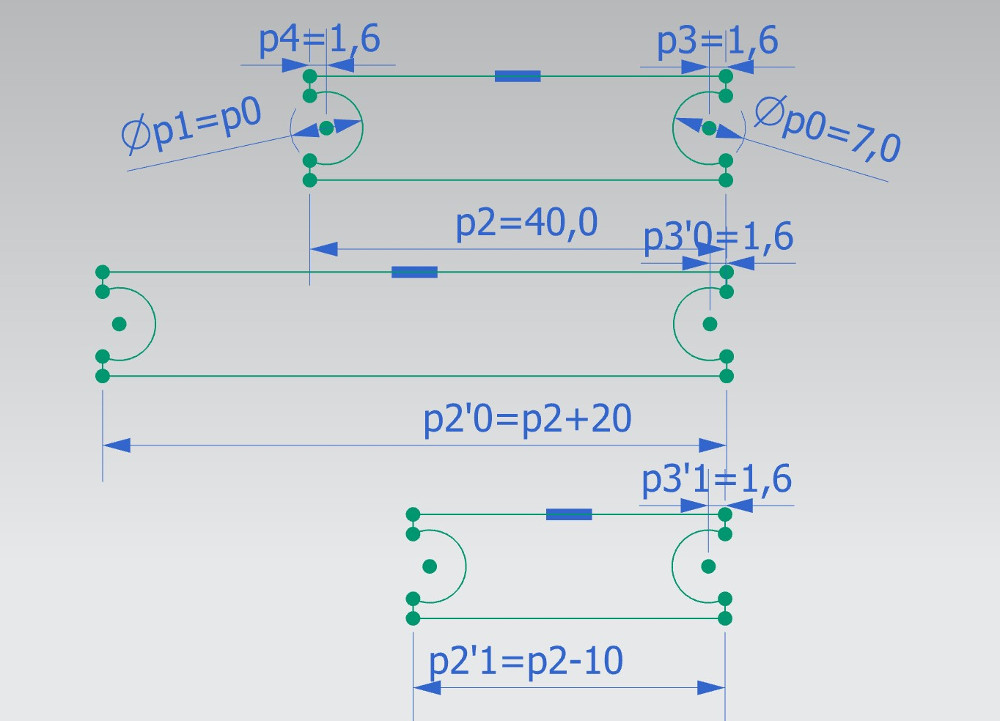

I tested the parametric features after mirroring. The middle and

left circles are mirrors of right circle and the size follows each

others.

Now, my first laser cut drawing is ready Only, I must hide

unwanted details, such as dimensions, dots and reference lines.

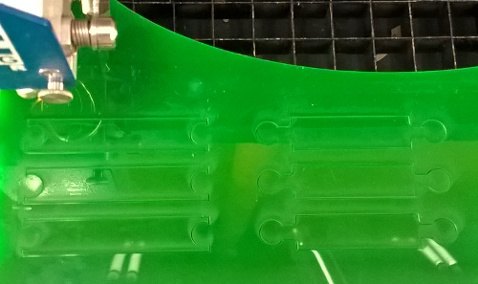

At first, I want test the snap feature, which are correct dimensions

there. Then, I made final drawings for my chain of bars. Therefore,

I made PDF file as earlier, but defined the line width as 0.02 mm. I

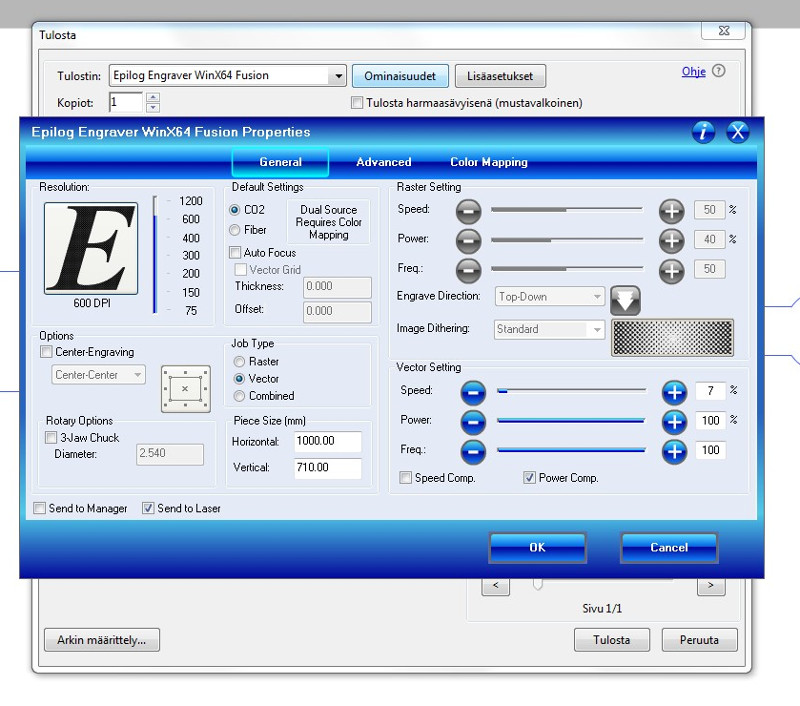

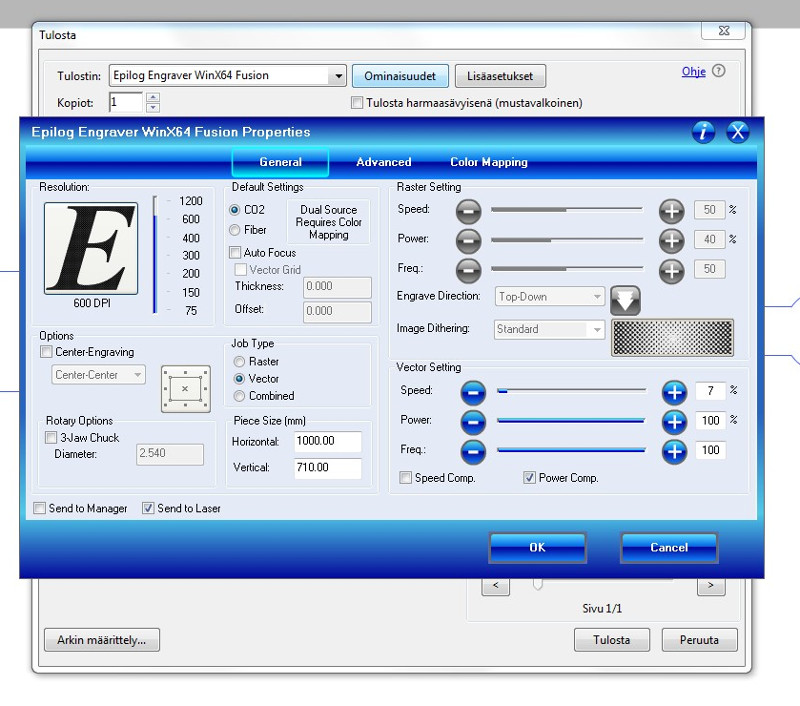

opened the file in laser control computer and selected printer as

Epilog Engraver WinX64 fusion.

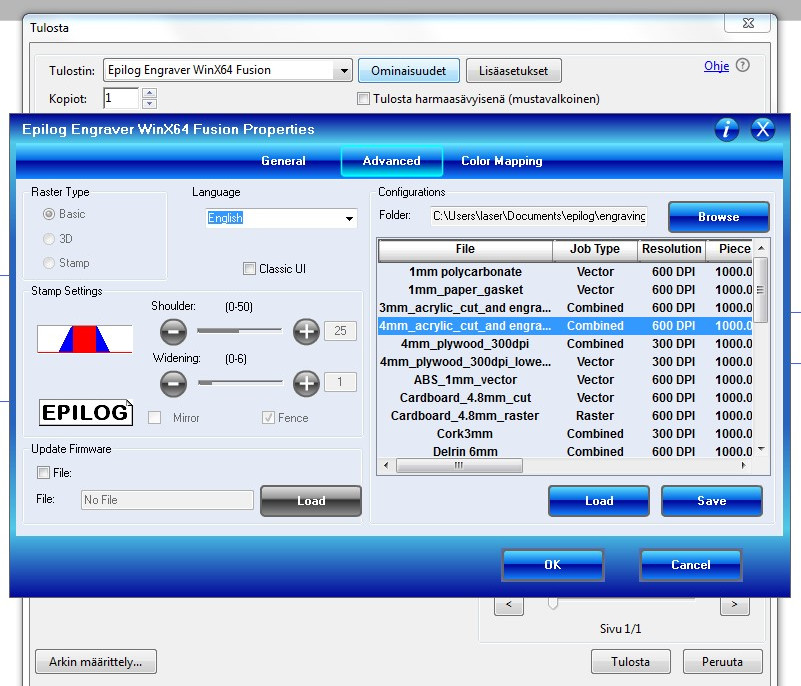

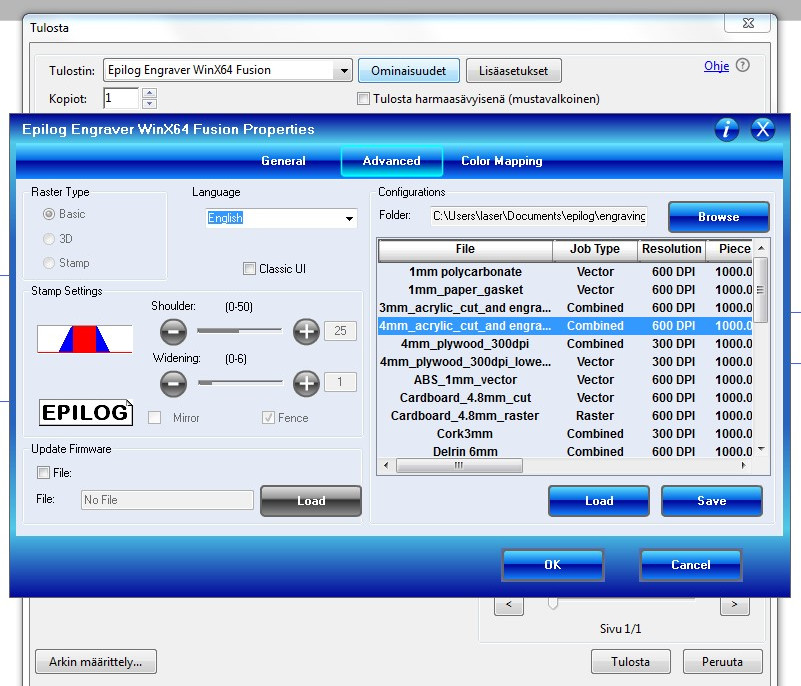

Then, I selected properties and from advanced tab I selected the

ready set parameters for 4 mm PMMA (Acrylic) material.

General tab shows all cutting and engraving parameters as following.

I can also tune them. I pressed ok here and print in next window.

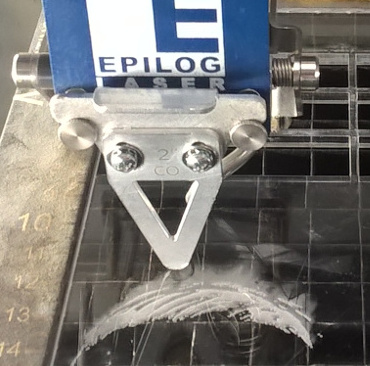

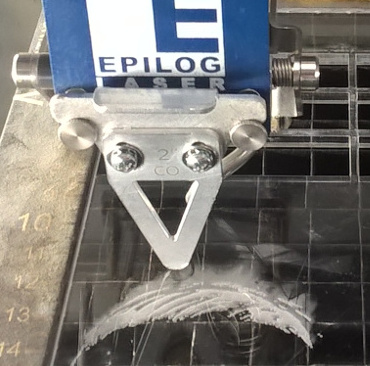

Then, I used laser control panel. I done final selections from right

menu by pressing up and down arrows. I used jog to move laser beam

there I want it to start. Jog confirmed by pressing the joystick.I

used focus to focus beam to the correct level as triangle tool

guided. And finally, I pressed GO.

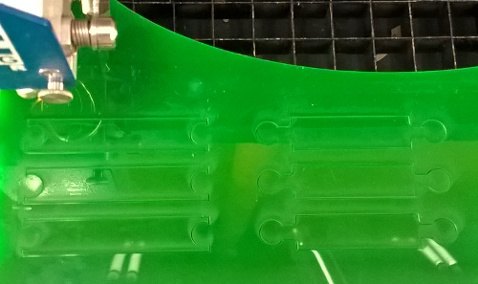

My first laser cutting is ready. I measured the snap joint details.

The hole diameter was 7.1 mm and the head diameter 6.9 mm. The

original (nominal) diameter was 7 mm in my drawings. Therefore, snap

nominal diameters must be 7 mm for the hole and 7.25 mm for the head

for tight connection. I can parametrize them and also bar

lengths as presented is following picture, diameter p1 = p0, length

p2'0 = p2+20 and length p2'1 = p2-10.

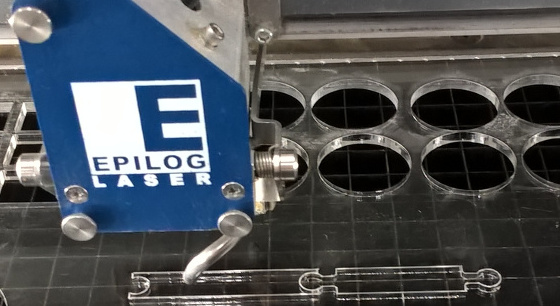

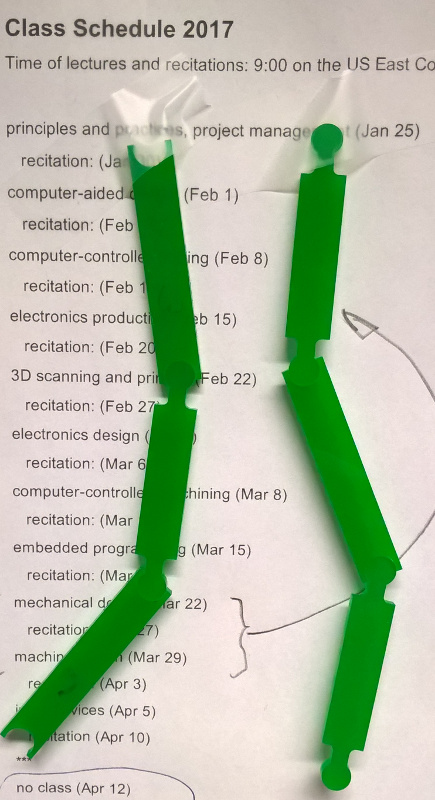

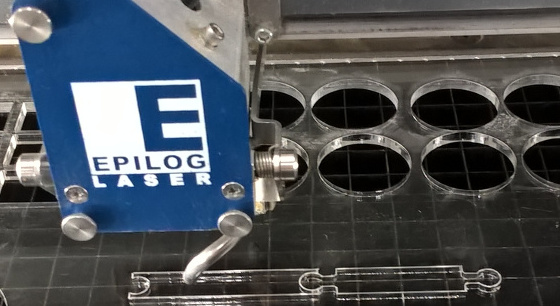

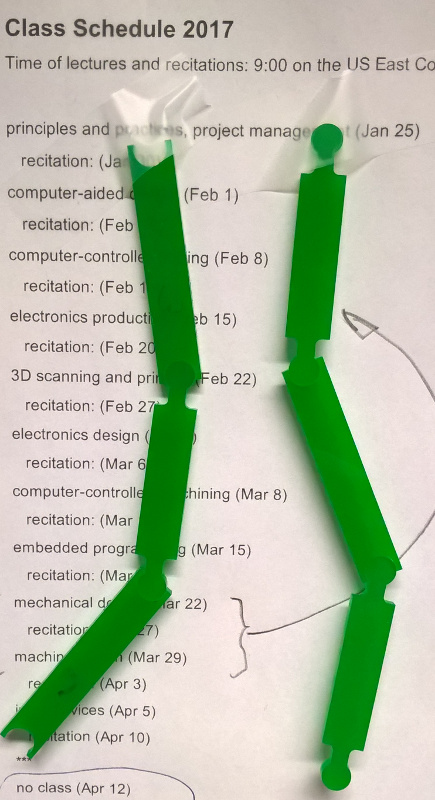

The final parts were drown as separate parts to the same sketch.

They was cut of green 3 mm PMMA material. The snap feature was

working well.

Group work

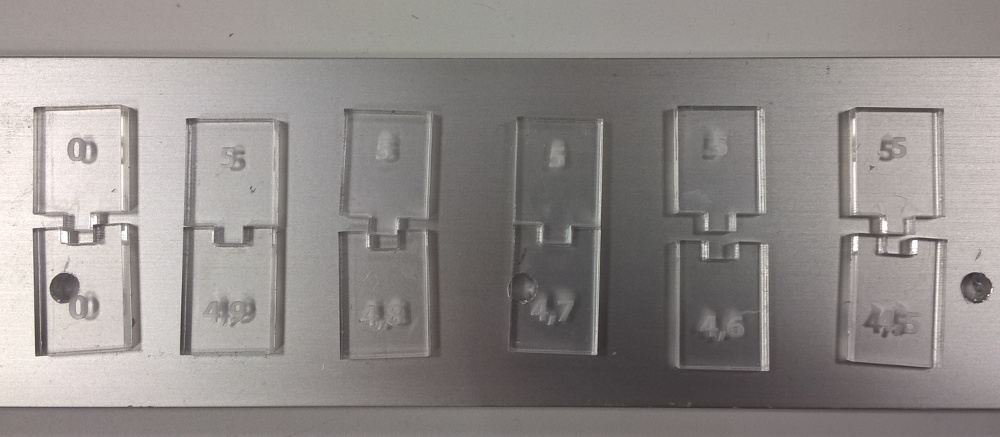

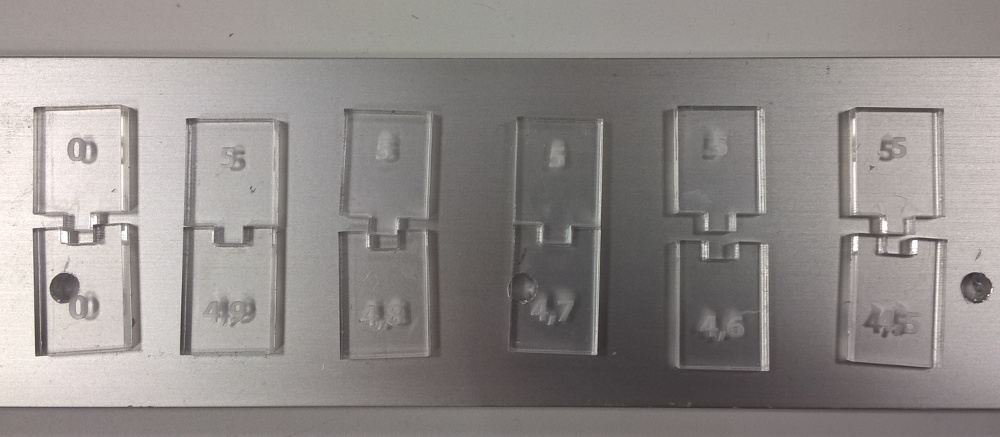

I made also a kerf study as group work with Eino.

We used 3 mm transparent PMMA. The most left parts were cut

together. Others separately. Numbers in parts mean nominal

dimensions in drawings. The best fitting pair was 5/4.8 mm. Kerf

diameter should be then 0.1 mm. This confirm also my earlier

studies. However, we found some tracks were not in right angle (90°)

as supposed and this may cause errors. Reason for that is unknown.

Maybe material had some defects. Eikka has documented also our

results in his page (http://archive.fabacademy.org/archives/2017/fablaboulu/students/73/FabAcademy_Eikka/Assignment_3.html).

Final project

In this case, I can not do any enhancements to my final project.

However, this study was useful. I seldom needed these parametric

features earlier. Now I can do them with NX.

My NX CAD files are here: vinyl cut and

laser cut.

These also in DXF format are here: vinyl

cut.dxf and laser cut.dxf.

CutStudio file is here: numbers_cut.cst.

gone too deep in sheet.

Therefore, I tuned the pen force to set the cut depth correctly.

gone too deep in sheet.

Therefore, I tuned the pen force to set the cut depth correctly.