Assignment objectives

* Make something big.

Neil's class Summary

Design

After some basic learning of machine and tool rules followed by some file handling provided by Duncan Casal, our local guide for using the ShopBot router at

Sinergia Tech

i got the first glimpse of the real capabilities of bigger scale digital fabrication.

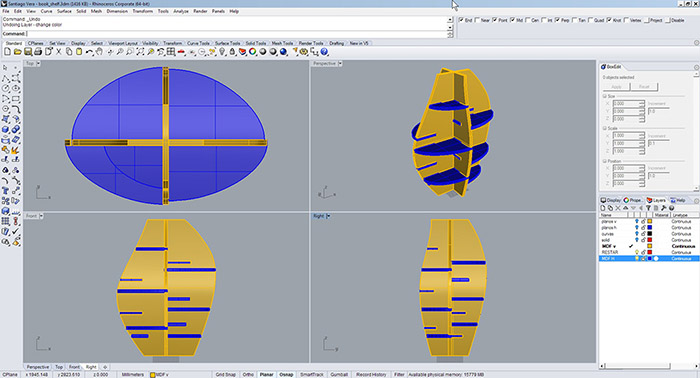

Some Rhino modeling ..

Some Rhino modeling ..

This is the final design.

This is the final design.

After performed the 3D to 2D operations, added the t-bones and nested parts for file printing in Autocad, i got a final usage of three boards of 740mm x 540mm.

After performed the 3D to 2D operations, added the t-bones and nested parts for file printing in Autocad, i got a final usage of three boards of 740mm x 540mm.

Download

the 3d model files.

Download

the 3d model files.

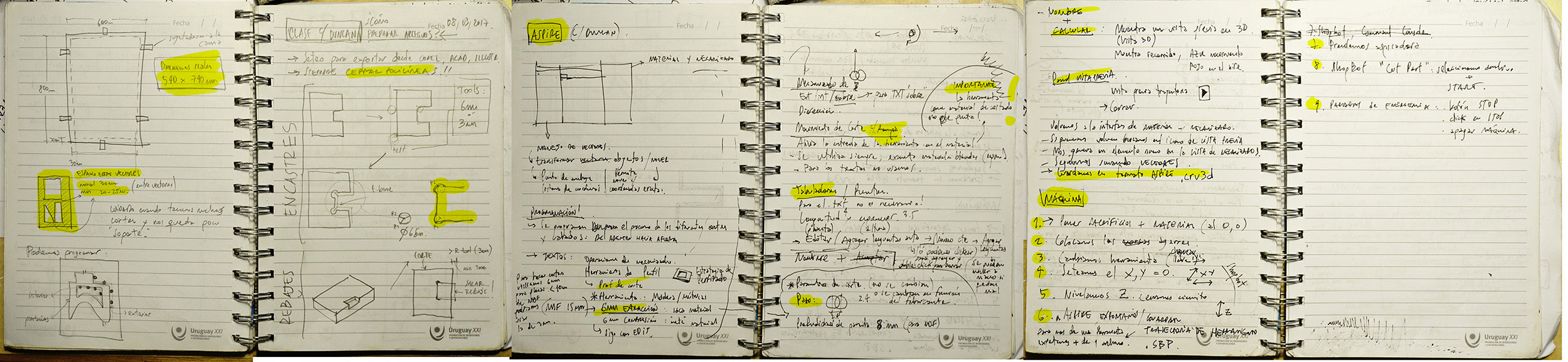

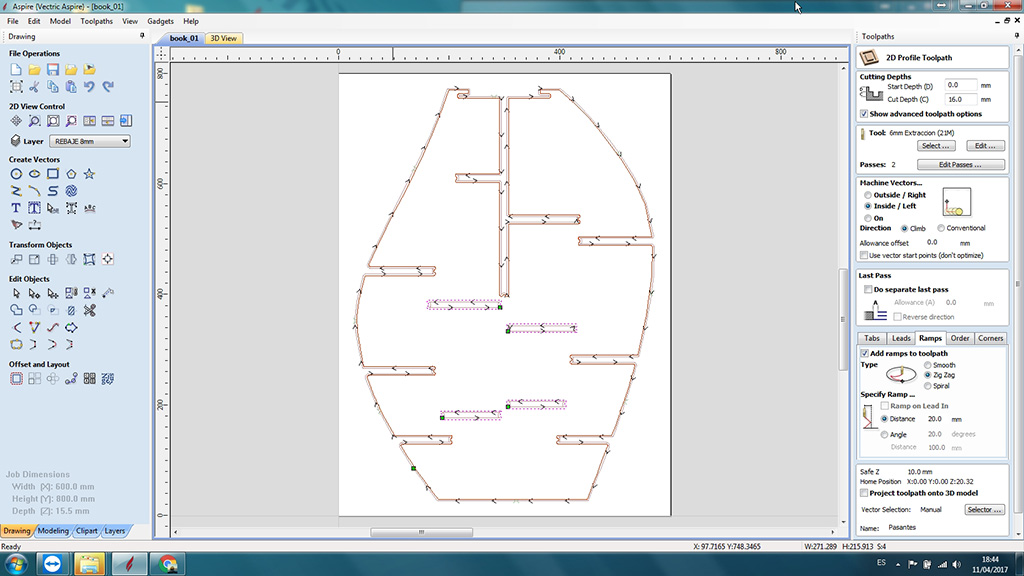

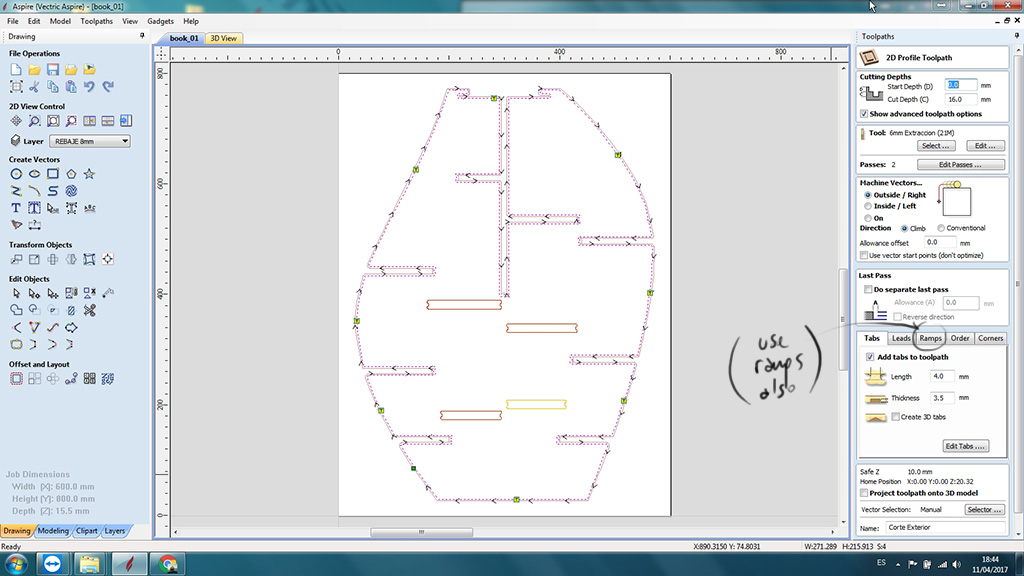

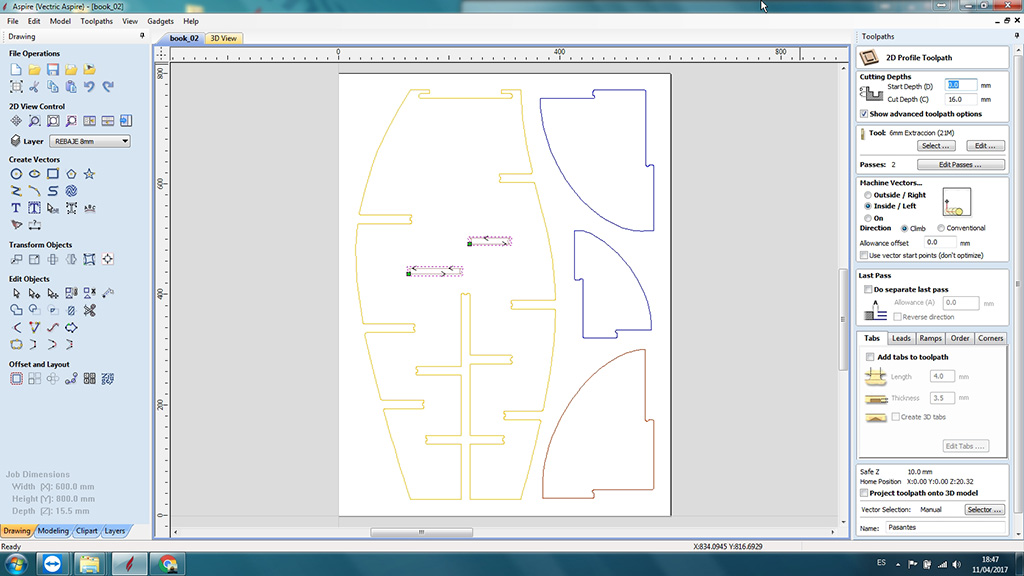

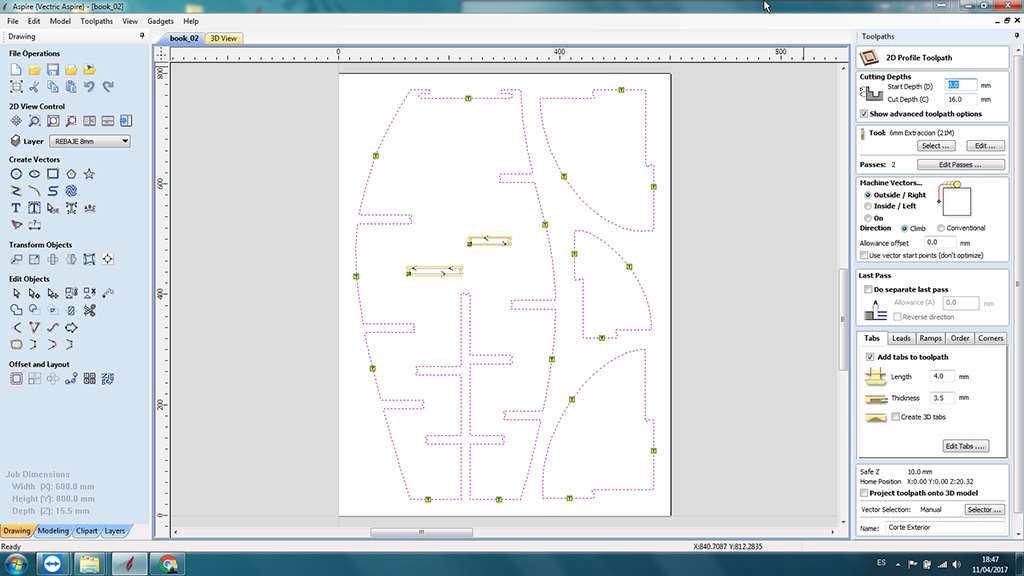

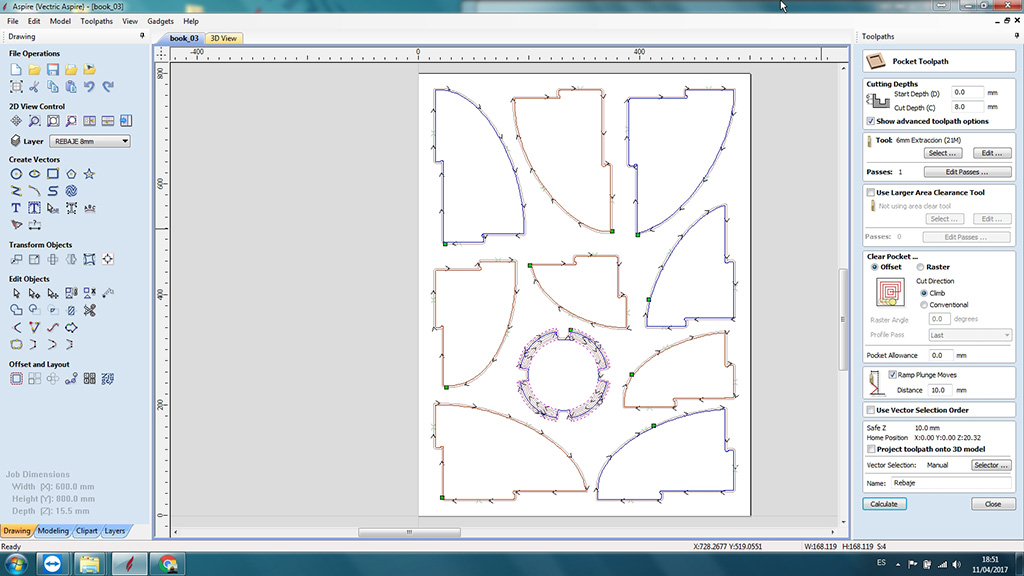

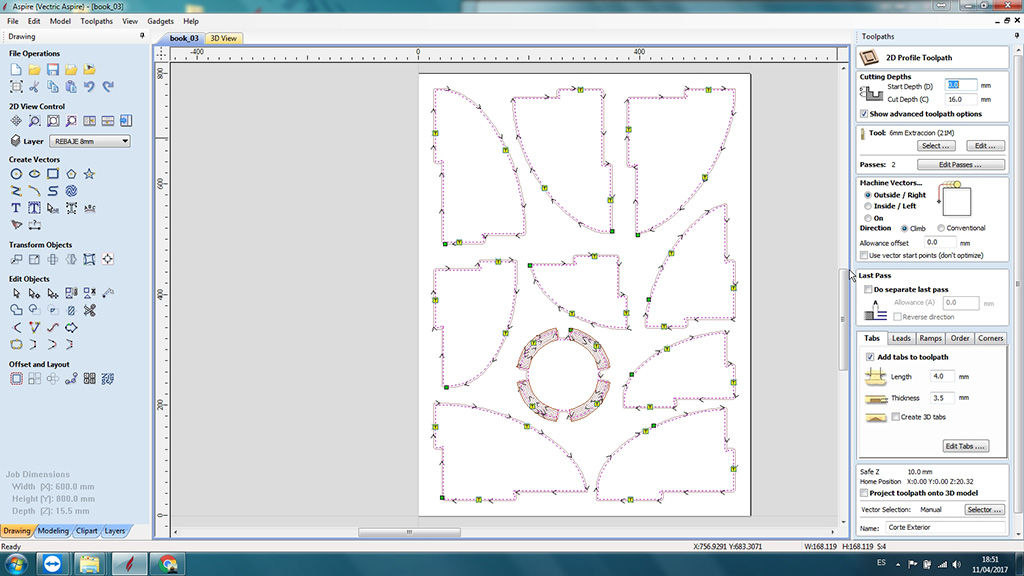

Programming with Vectric Aspire

To program the cuts in the ShopBot router we use Vectric Aspire 8.0. Here are the basic notes on how to use the program and some tutorials with a bit of extra help.

And here is the respective programming for each of the sheets.

And here is the respective programming for each of the sheets.

Sheet 1. Inside.

Sheet 1. Outside.

Sheet 1. Outside.

Sheet 1. Preview toolpath.

Sheet 1. Preview toolpath.

Sheet 2. Inside.

Sheet 2. Inside.

Sheet 2. Outside.

Sheet 2. Outside.

Sheet 2. Preview toolpath.

Sheet 2. Preview toolpath.

Sheet 3. Pocket.

Sheet 3. Pocket.

Sheet 3. Outside.

Sheet 3. Outside.

Sheet 3. Preview toolpath.

Sheet 3. Preview toolpath.

Finally i exported the files as .sbp format. Download

the Vectric Aspire programming files.

Finally i exported the files as .sbp format. Download

the Vectric Aspire programming files.

Machining

The first thing to know is the complete procedure to use the ShopBot router.

1.Turn on the machine.

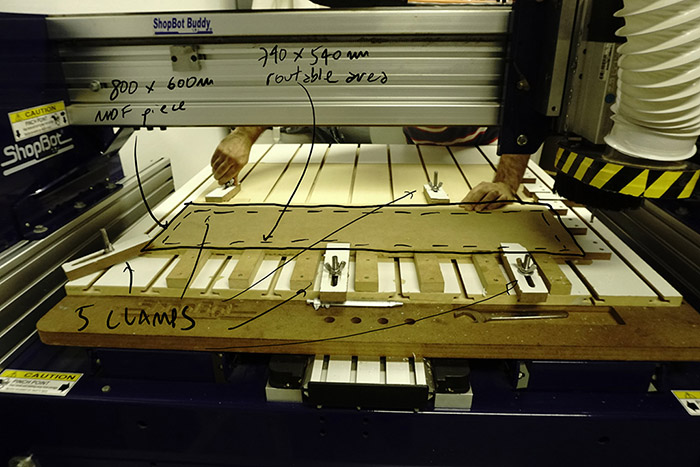

3. Place the clamps.

3. Place the clamps.

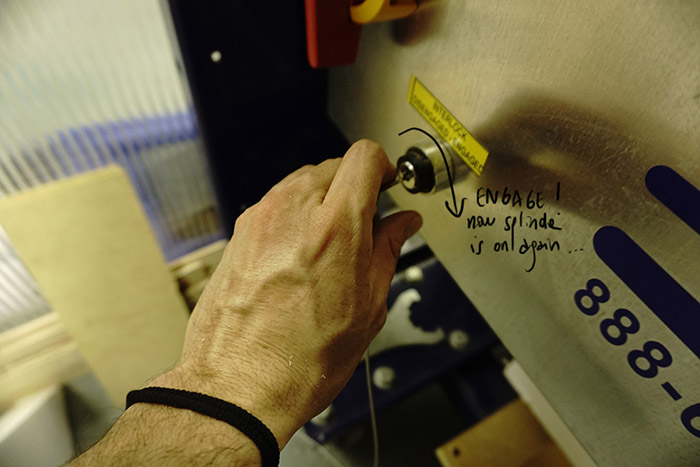

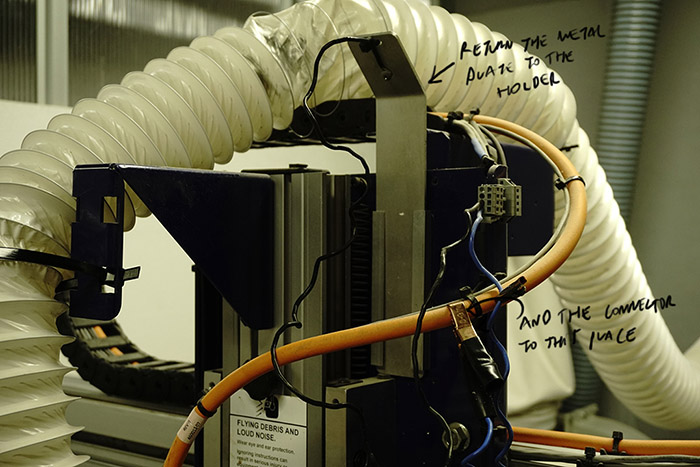

6. Then set Z to zero by placing the plate under the endmill, attaching the blue cable to the tool

6. Then set Z to zero by placing the plate under the endmill, attaching the blue cable to the tool

and finally return the metal plate to its holder and the connector to its place.

and finally return the metal plate to its holder and the connector to its place.

IMPORTANT! Before starting the work it essential to know the ways of stopping the machine in the event of any emergency or error.

IMPORTANT! Before starting the work it essential to know the ways of stopping the machine in the event of any emergency or error.

8. Now again in ShopBot Control Software, click on Cut Part, select your .sbp file and then click on Start button. The software will ask you if Z is set to zero, if the selected endmill is actually placed in the splindle and finally will ask you to confirm if start the job.

8. Now again in ShopBot Control Software, click on Cut Part, select your .sbp file and then click on Start button. The software will ask you if Z is set to zero, if the selected endmill is actually placed in the splindle and finally will ask you to confirm if start the job.

Machining process ..

Result.

Machining process ..

Result.

Final assembly.

Final assembly.