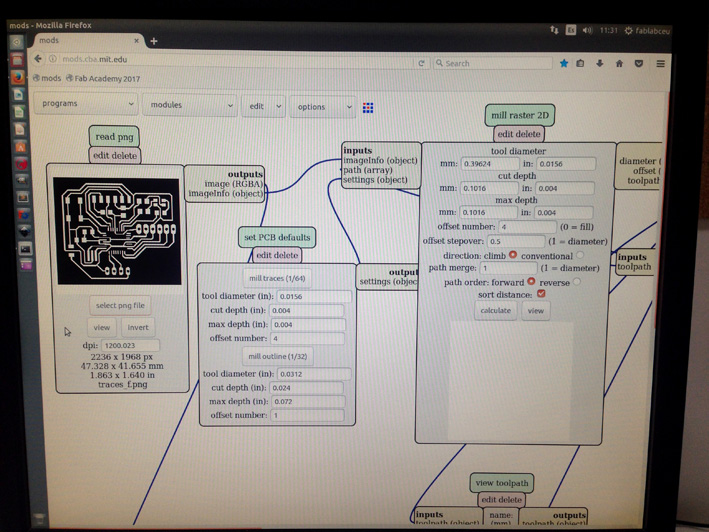

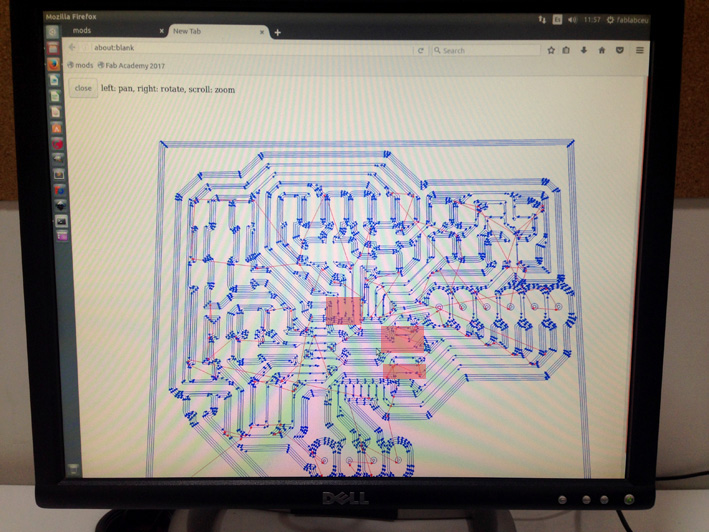

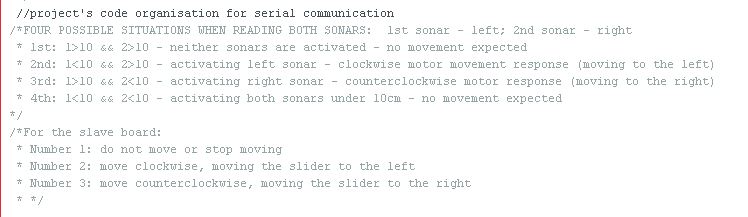

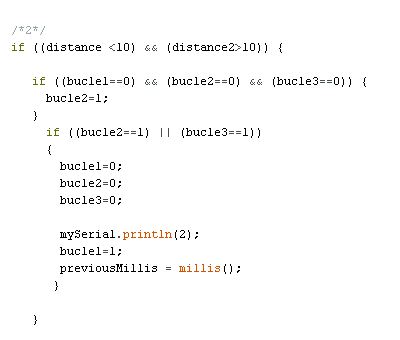

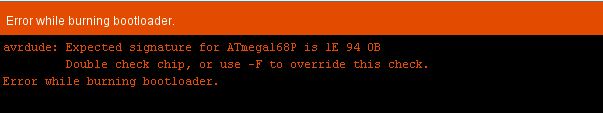

1. STRATEGY

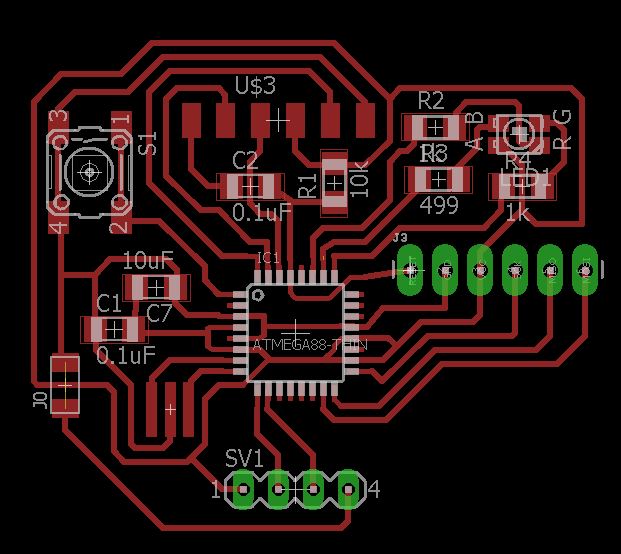

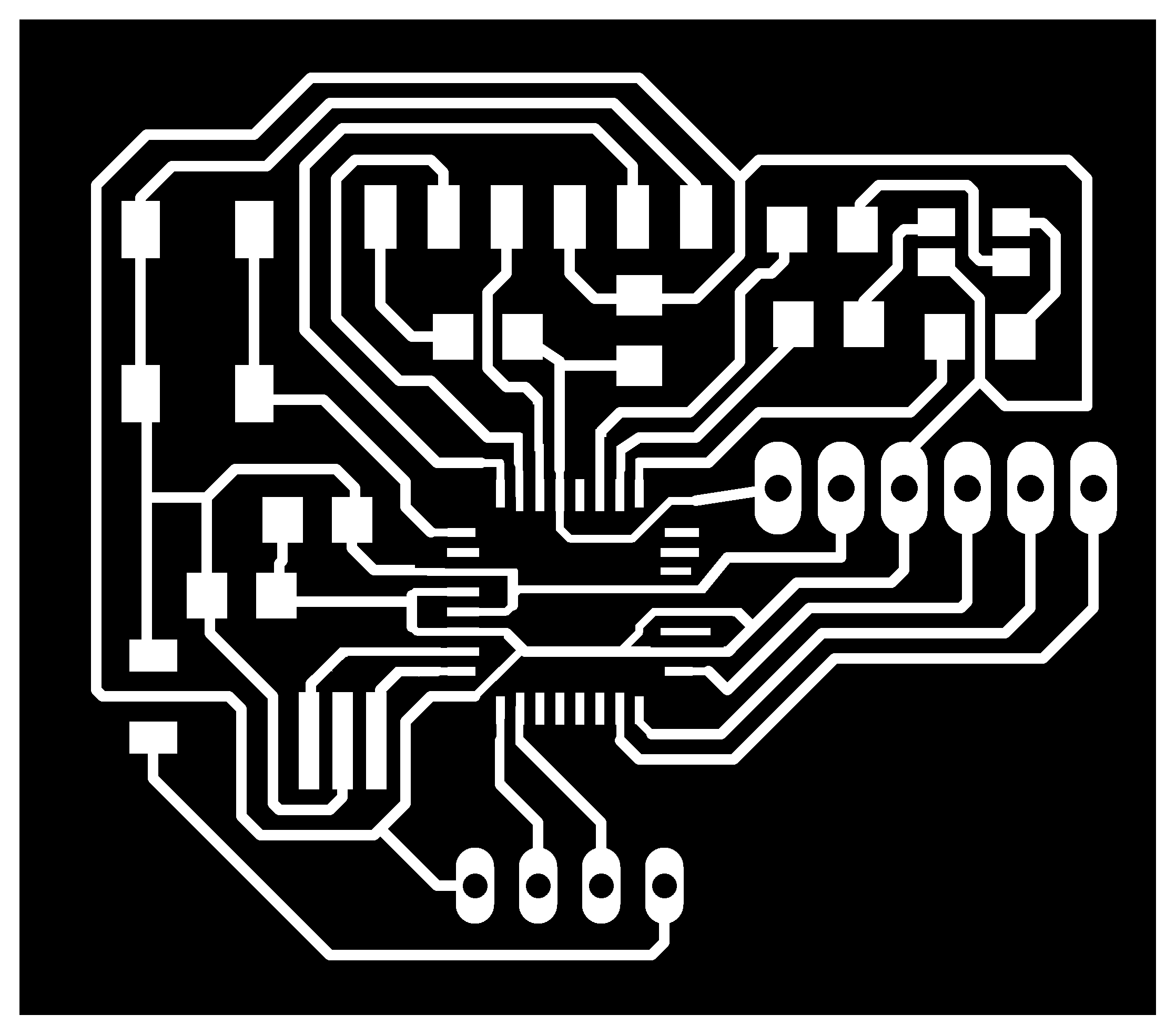

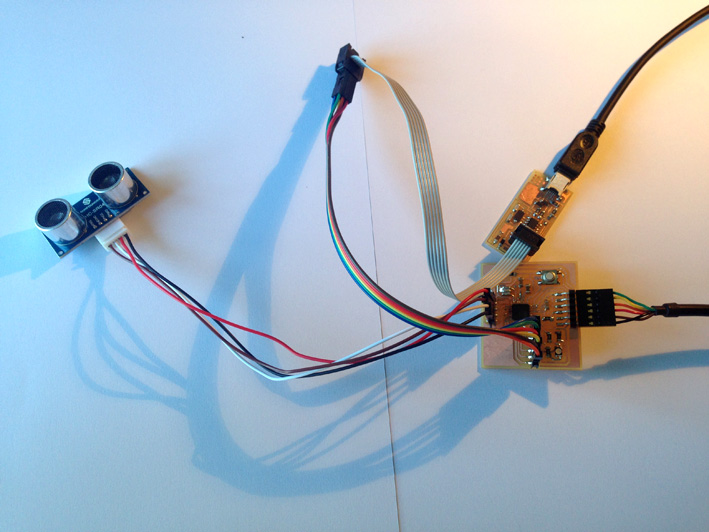

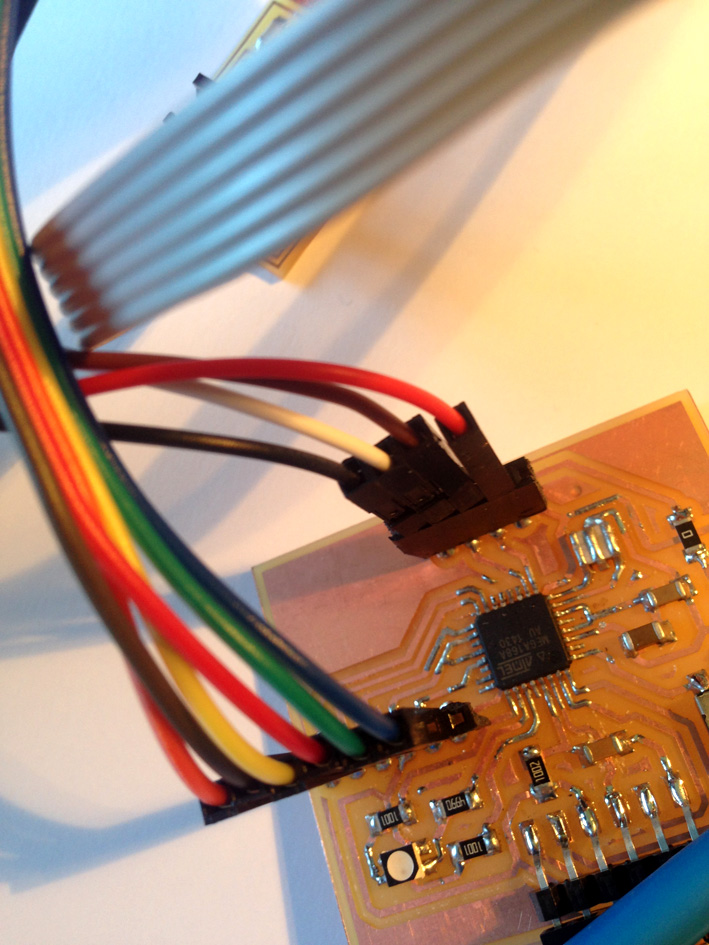

The goal this week is to continue developing my final project. As the project is to create a lightning device that can be moved without being touched, my idea is to create a new board connected to a sonar.

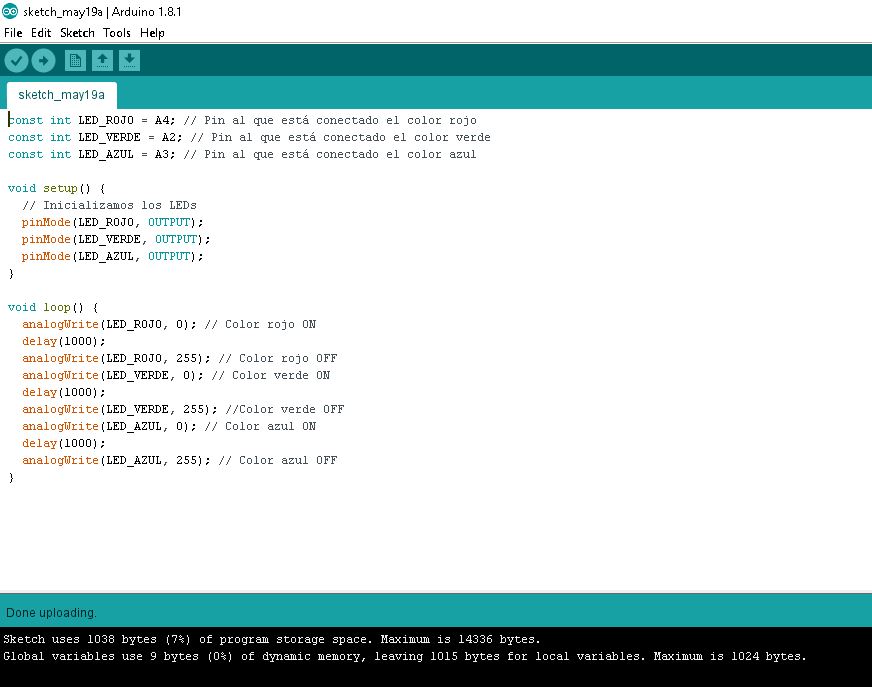

My idea is to create a program that changes the led's colour depending on the distance read by the sonar.

The reason why I have chosen a sonar and not other devices is because it can read distances. As this device is for my drawing table, at home, I will be moving around my room constantly and I need a device that can be activated at certain distances.

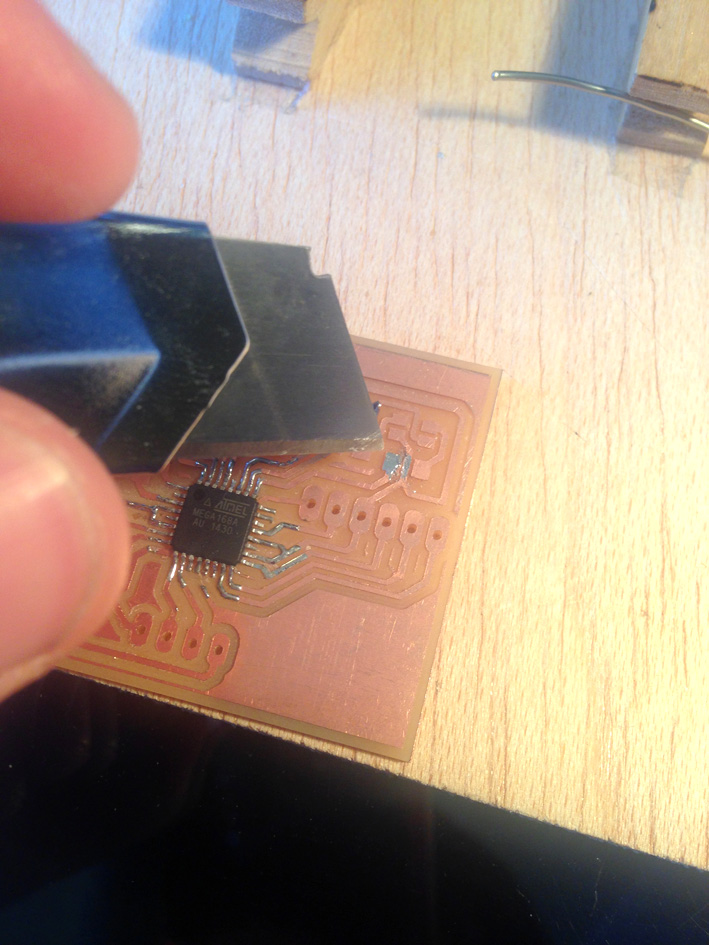

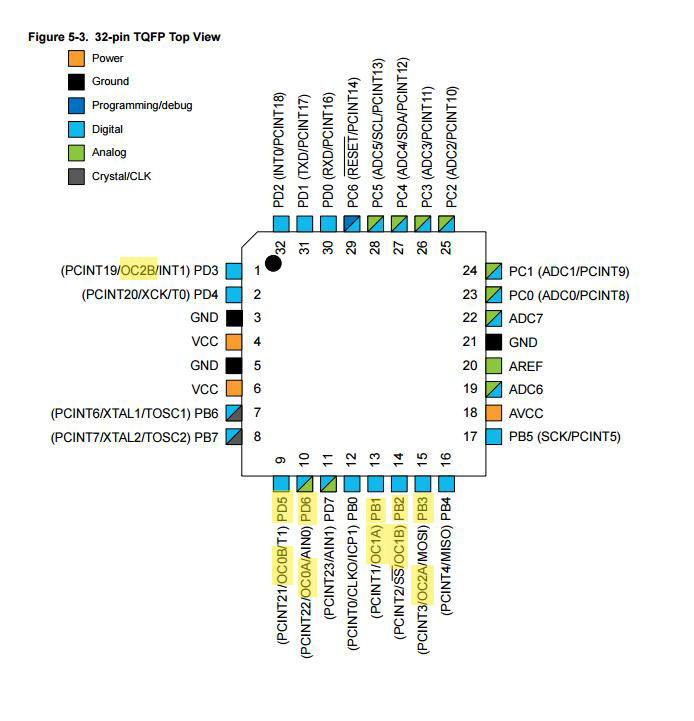

MCU I am going to use:

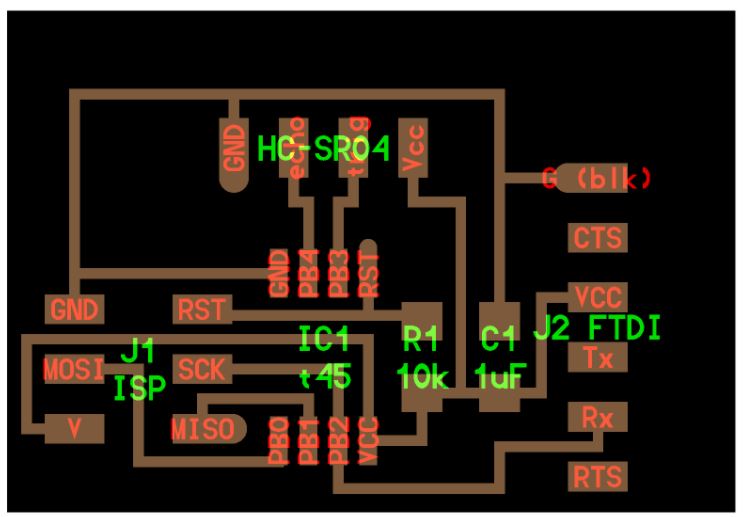

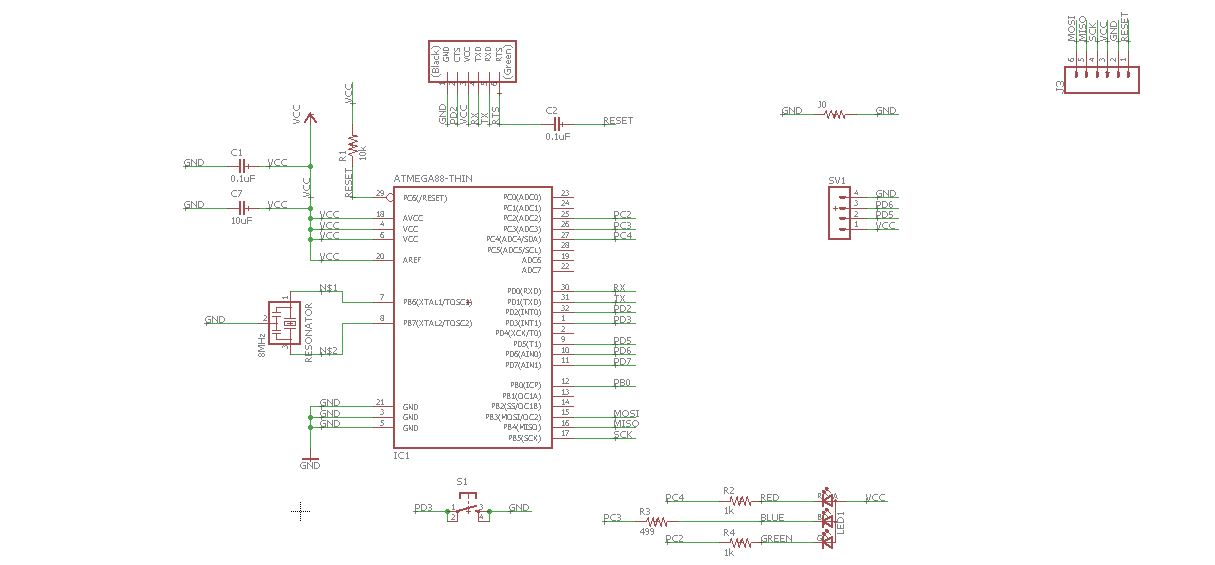

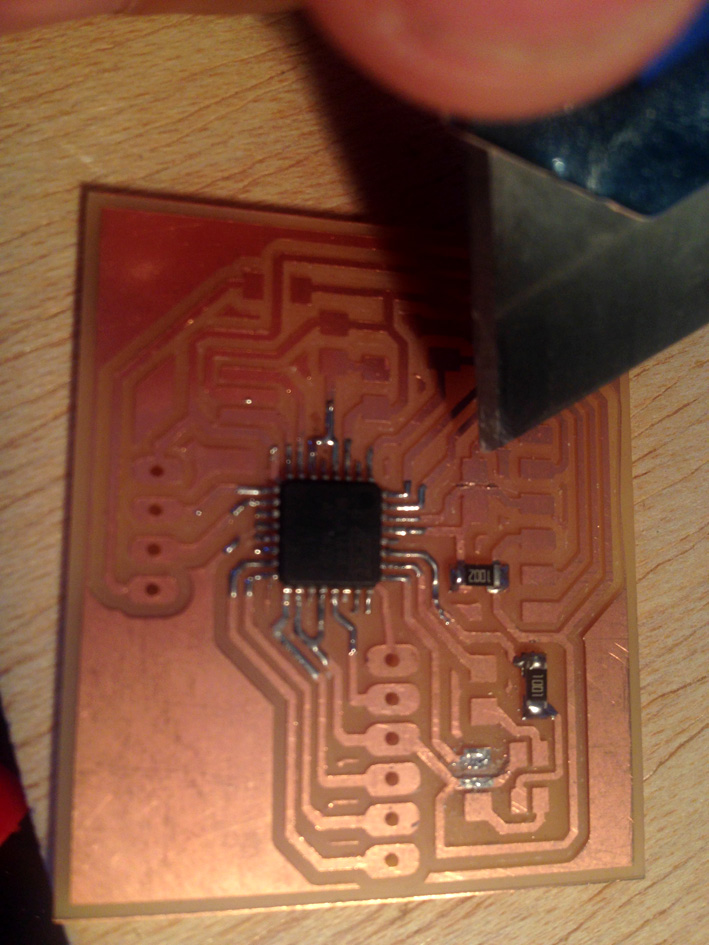

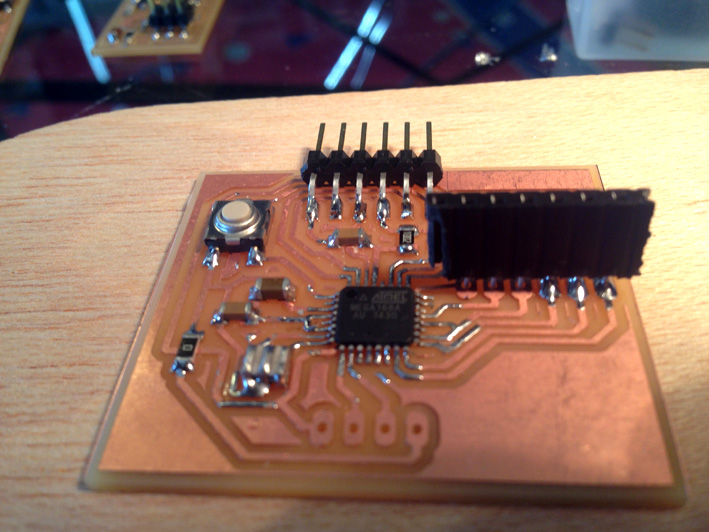

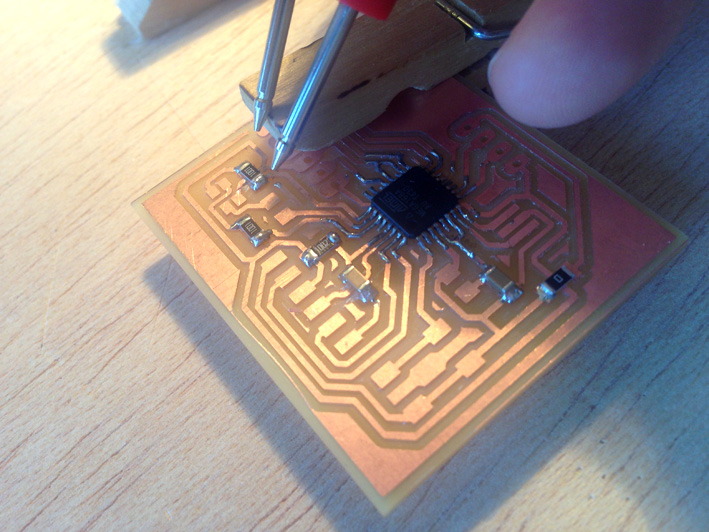

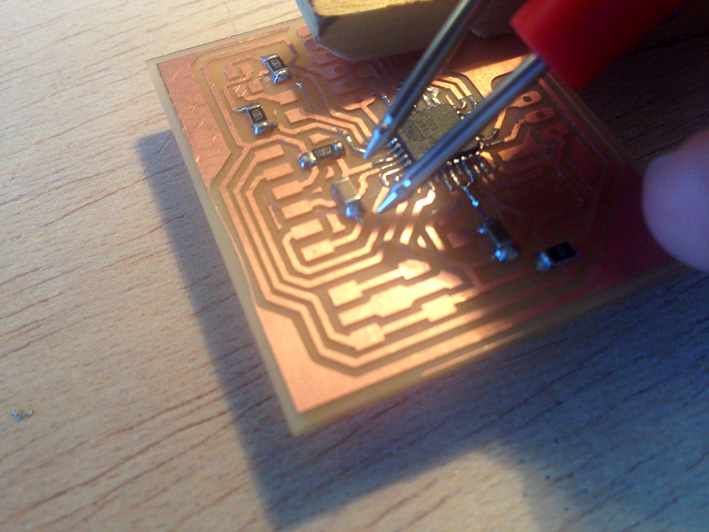

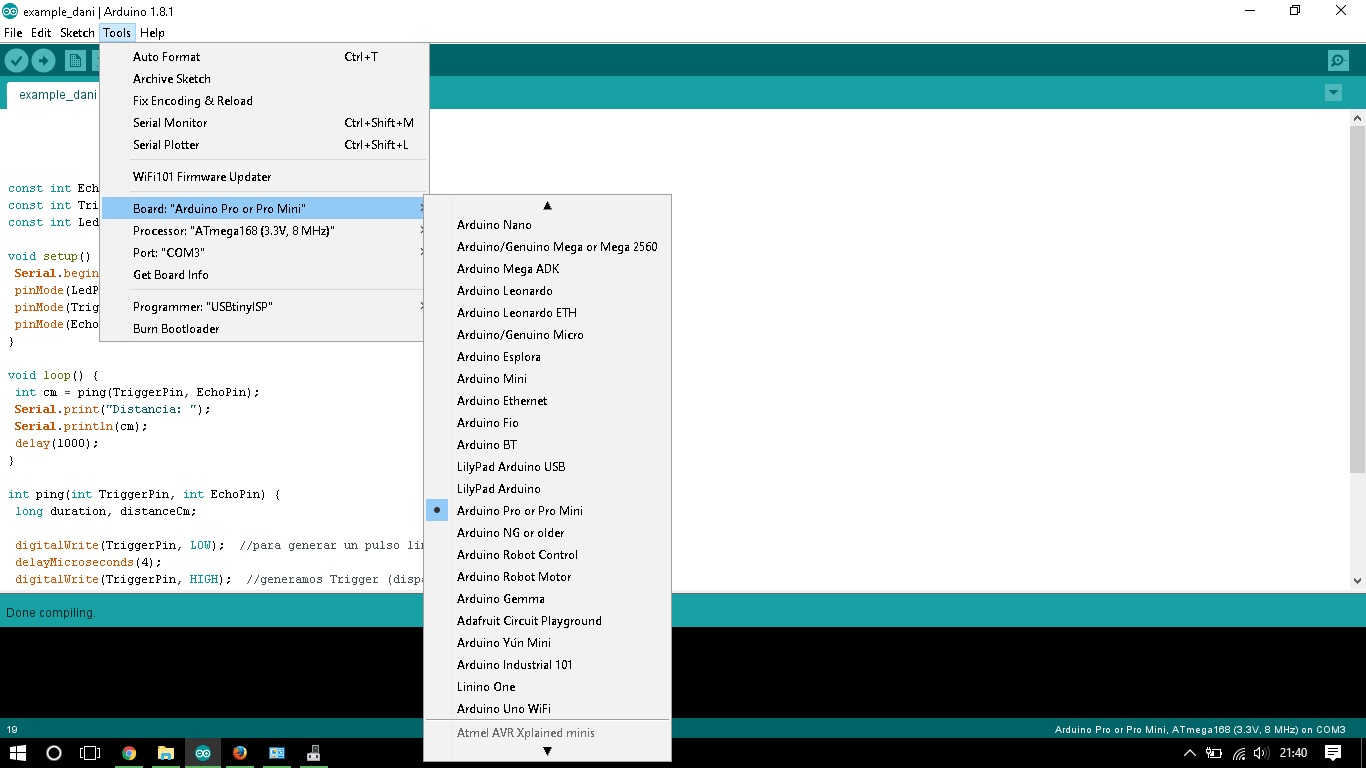

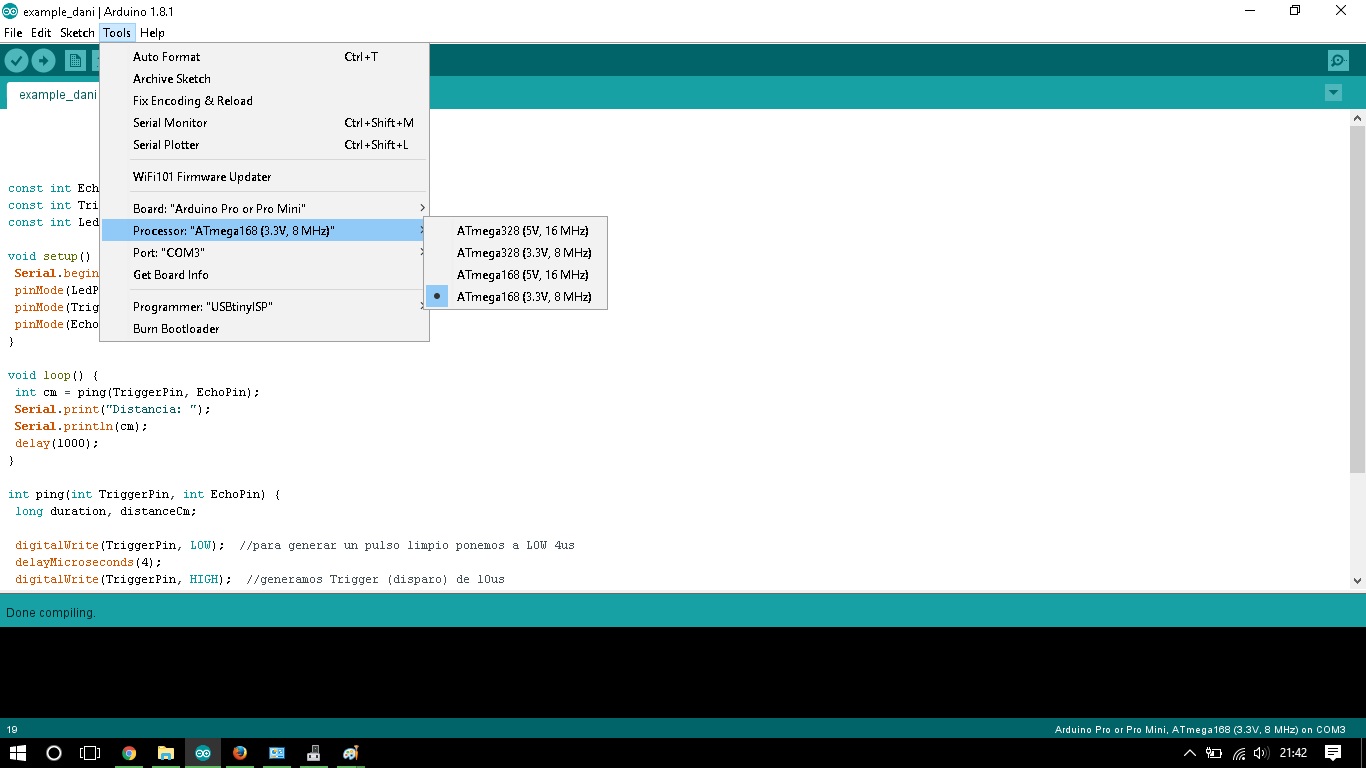

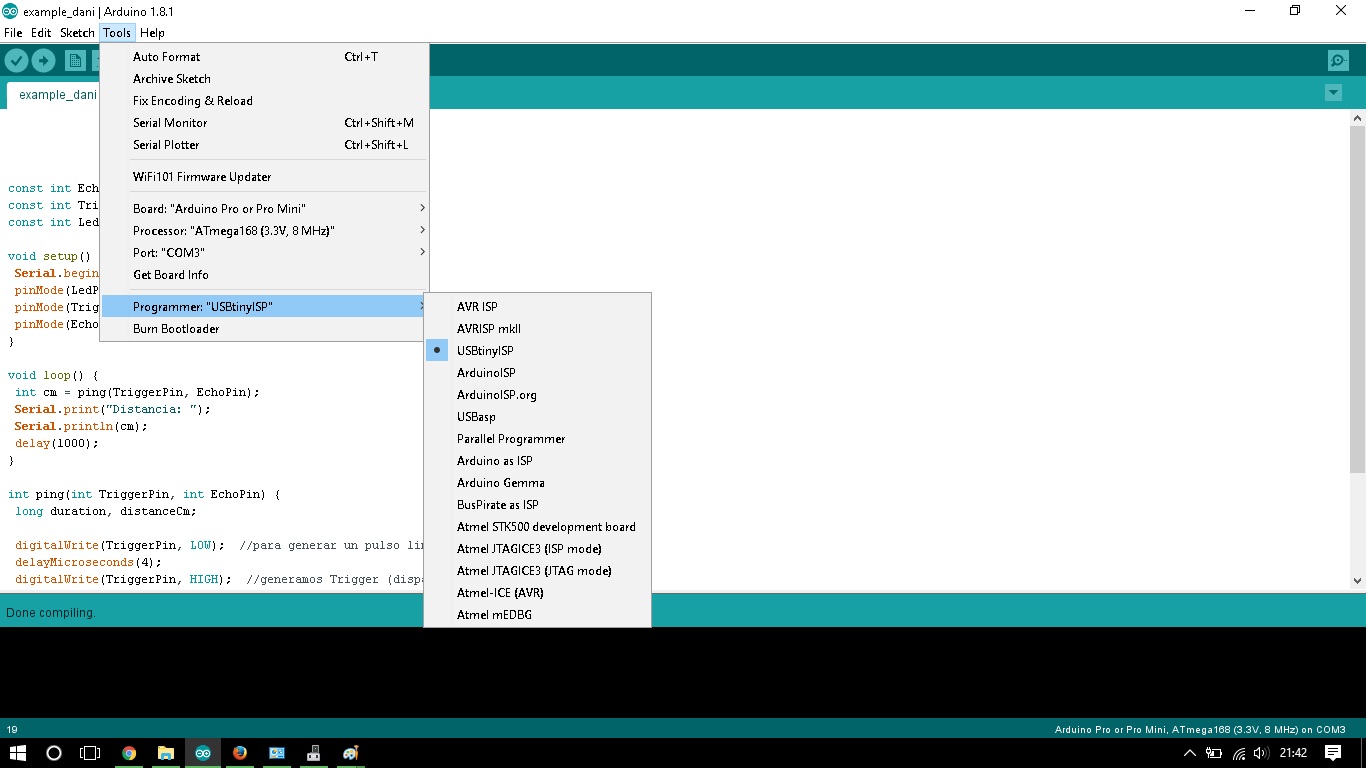

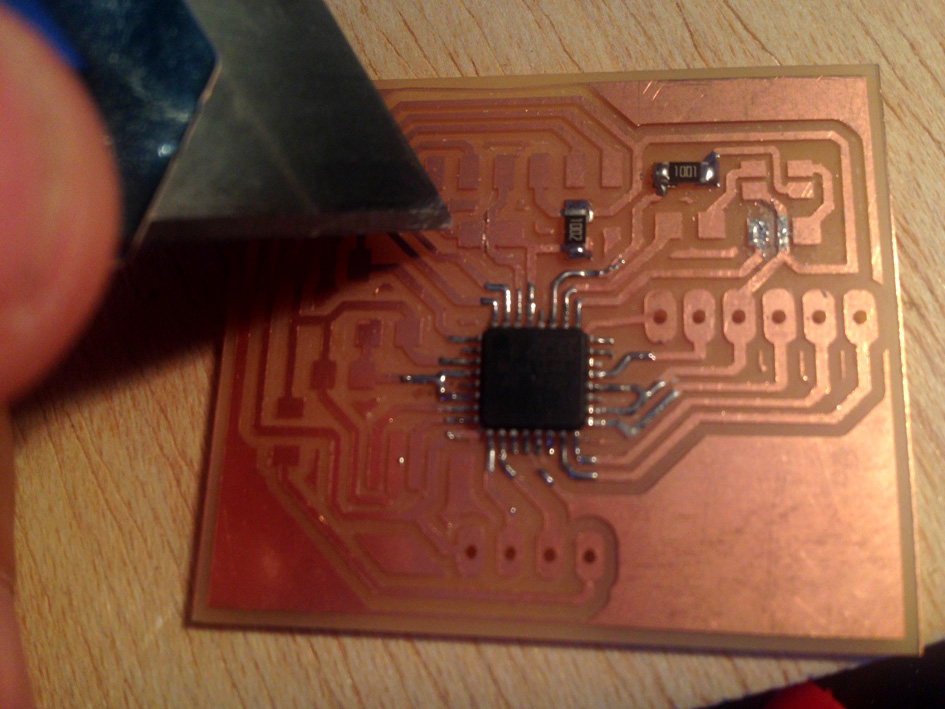

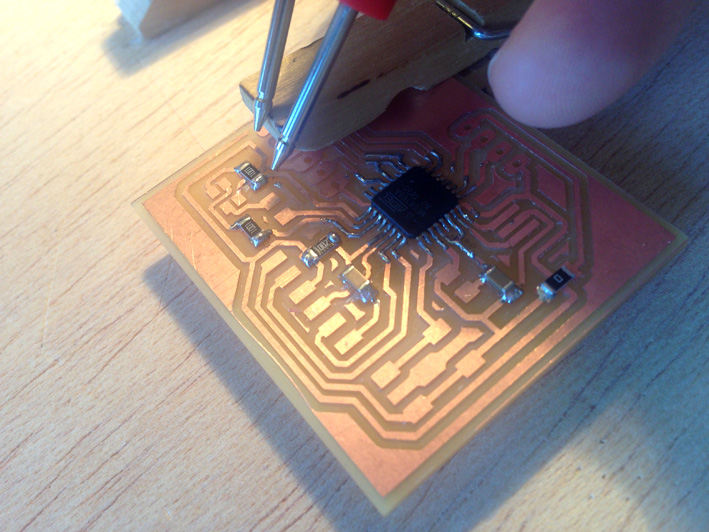

I will be using a Atmel AtMega 168 with 32 pins. The reason I chose this one is because it has more memory than the ATiny 45 that Neil uses. Plus, in order to have as well a RGB led, I need more pins to connect the led.

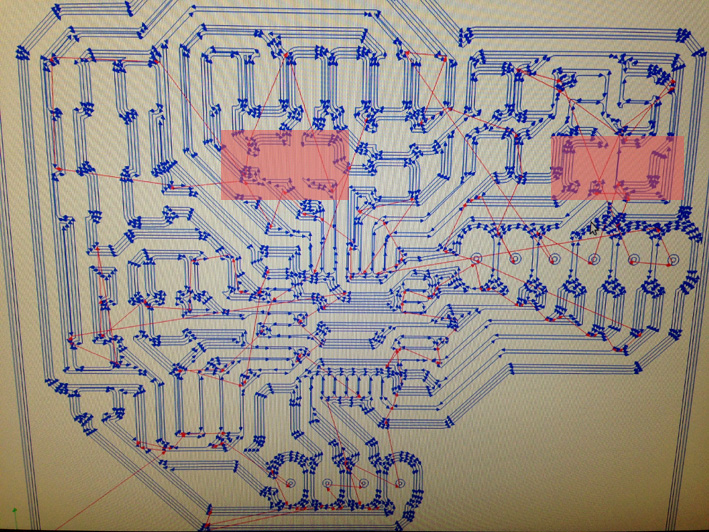

My first design was done with a ATiny 44. Later on, thinking more about the functionality of my board, I decided to change to the AtMega.

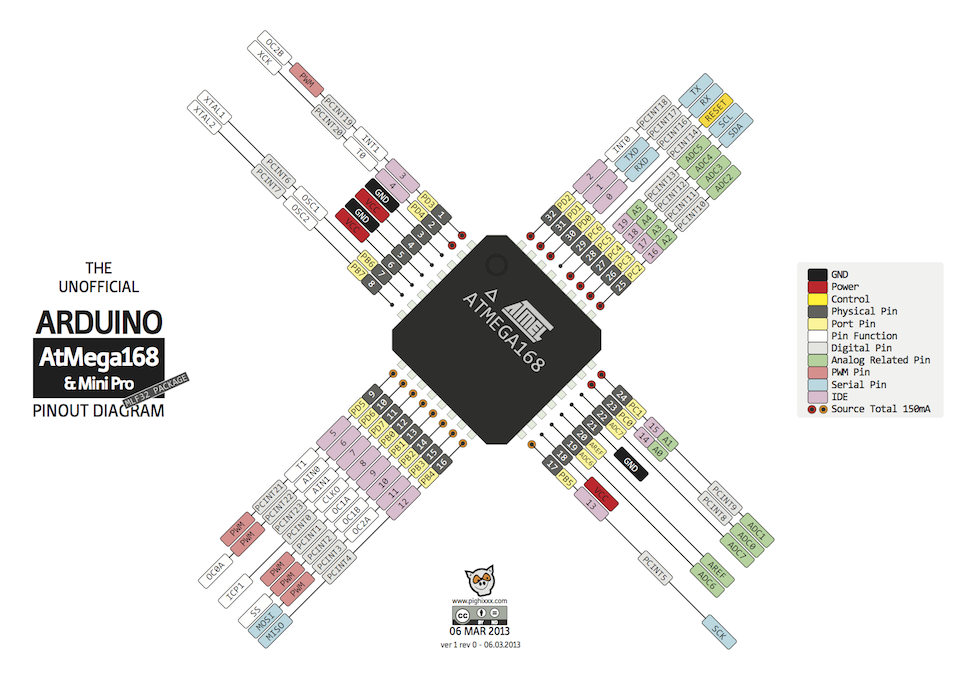

Here is the reference with arduino pins:

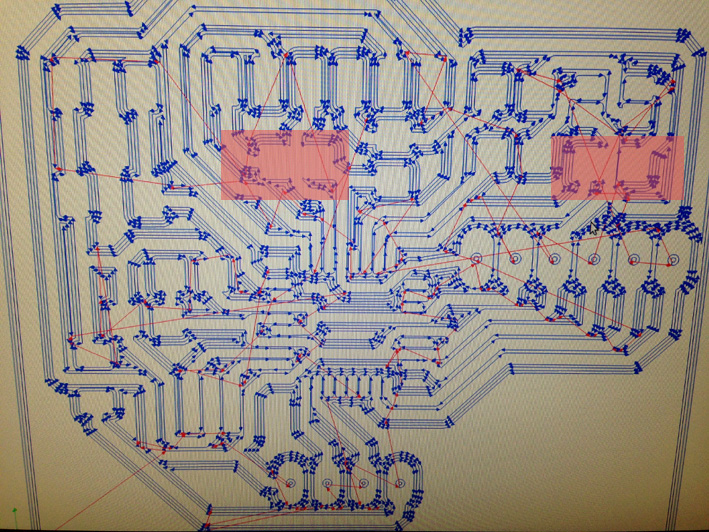

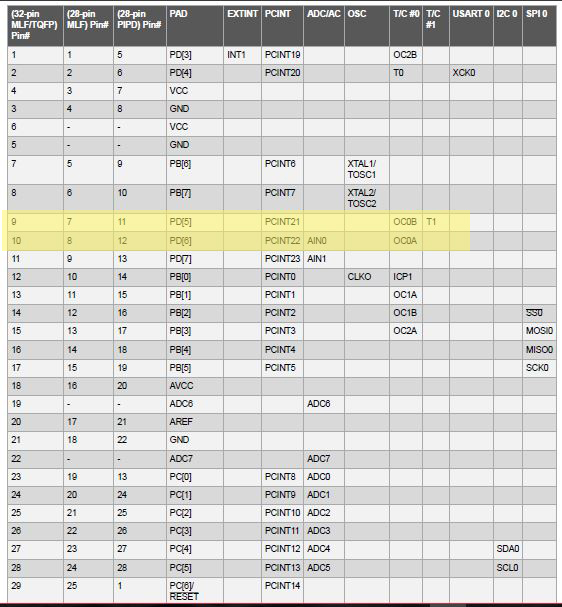

What pins I need to connect my ultrasonic device with my mcu?

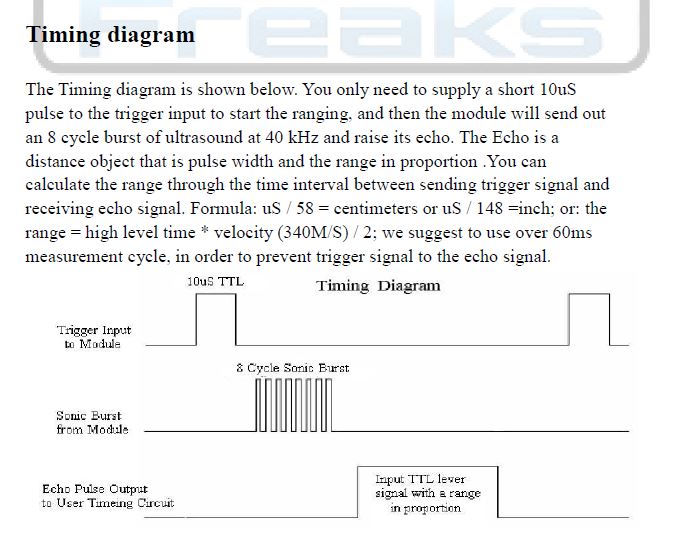

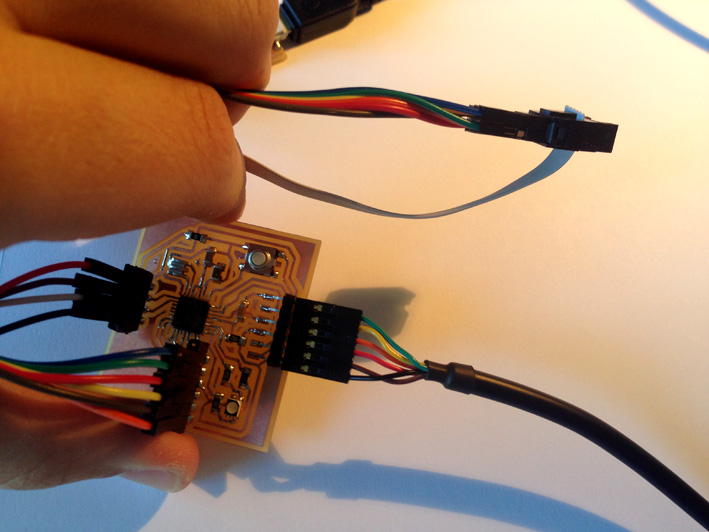

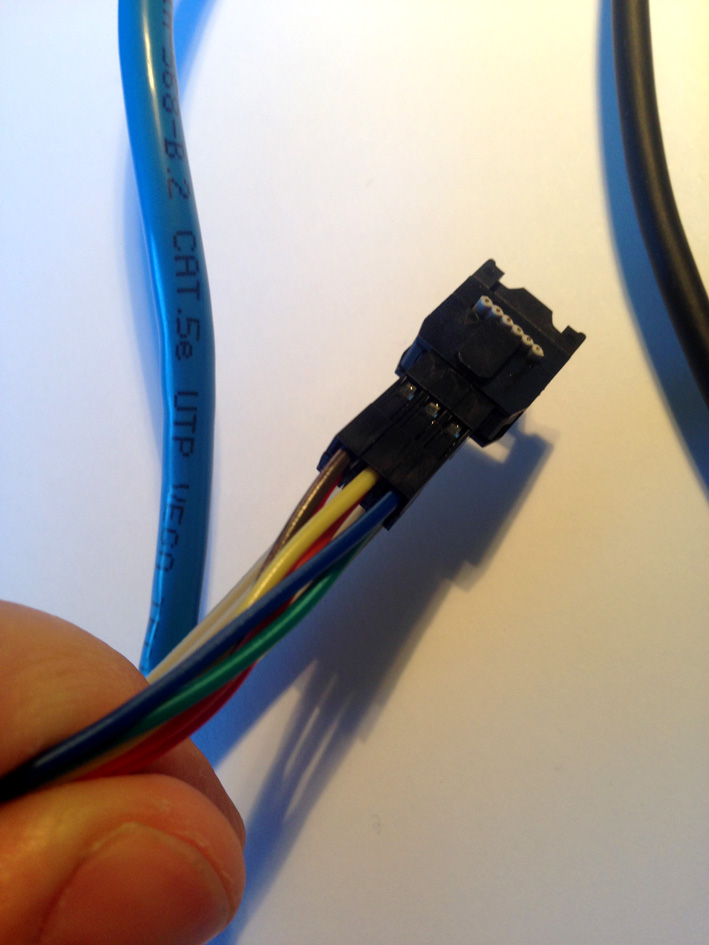

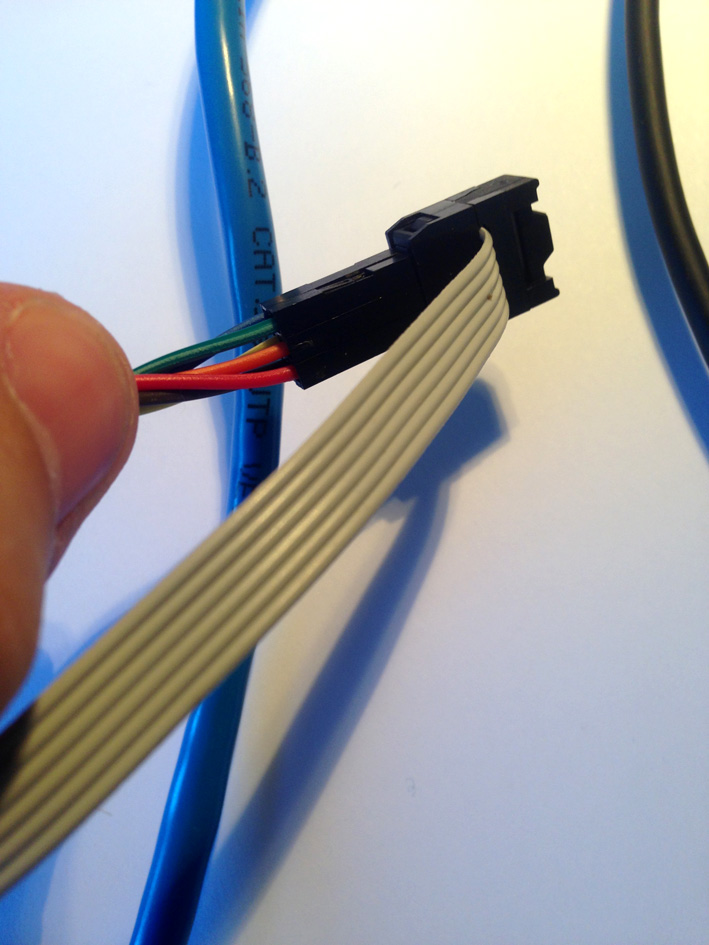

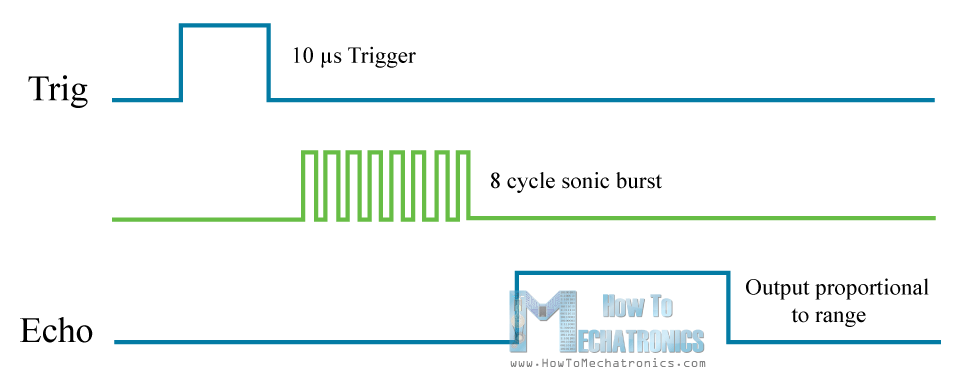

The ultrasonic sensor needs to be connected to my MCU with two connections: the 'Trigger Pin' and the 'Echo Pin'. The 'Trigger Pin' is connected to pin 'PD5' (or number 5) of my board, and the 'Echo Pin' is connected to 'PD6' (or number 6). On the table below it can be seen the different characteristics of each pin of my board:

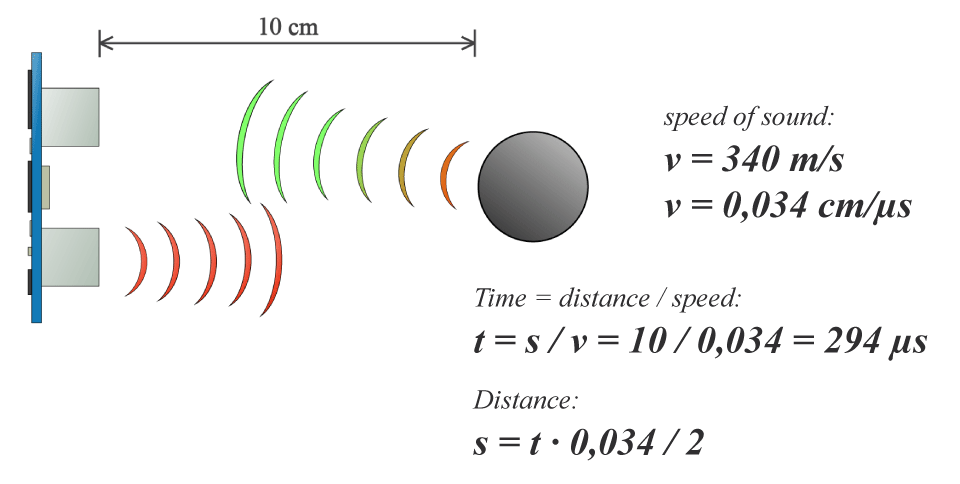

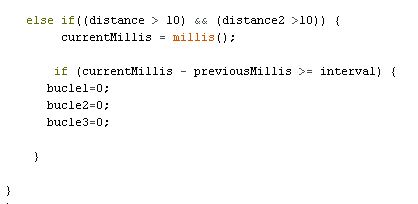

Both pins need to behave in a general way, as only one needs to be activated for a precise moment of time and the other pin listens to the reply. With the moment time, the mcu calculates the distance at which the nearest object is at. A further explanation is done later on in the

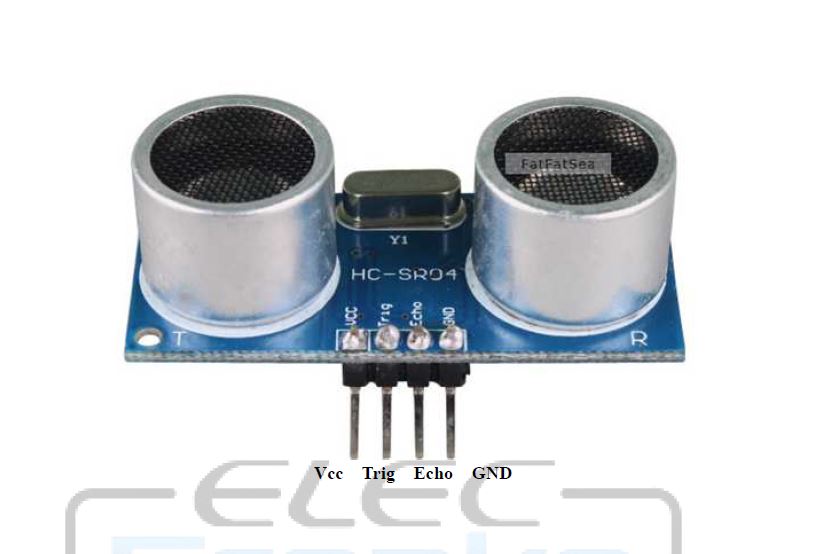

The device I will be using is the 'Ultrasonic Ranging Module HC-SR04', from Elec Freaks.

It has 4 pins: VCC, Trigger, Echo, Ground.

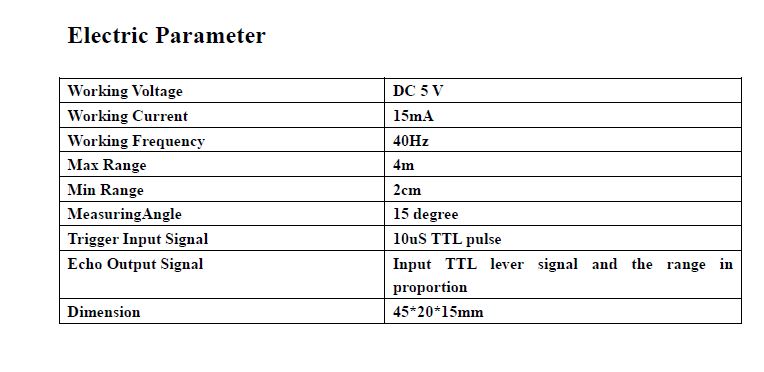

Technical Information: For this sonar, I do not need an extra supply as it works with a 5 volt circuit. It is perfect for me as I need to read distances within a short range (2cm up to 4 m).

Specifications

-Operating voltage: 5V

-Working current: 16mA.

-Weight: 90g;

-Dimensions: 46 x 20.5 x 19.5 mm (thickness of anti-reverse pin socket included)