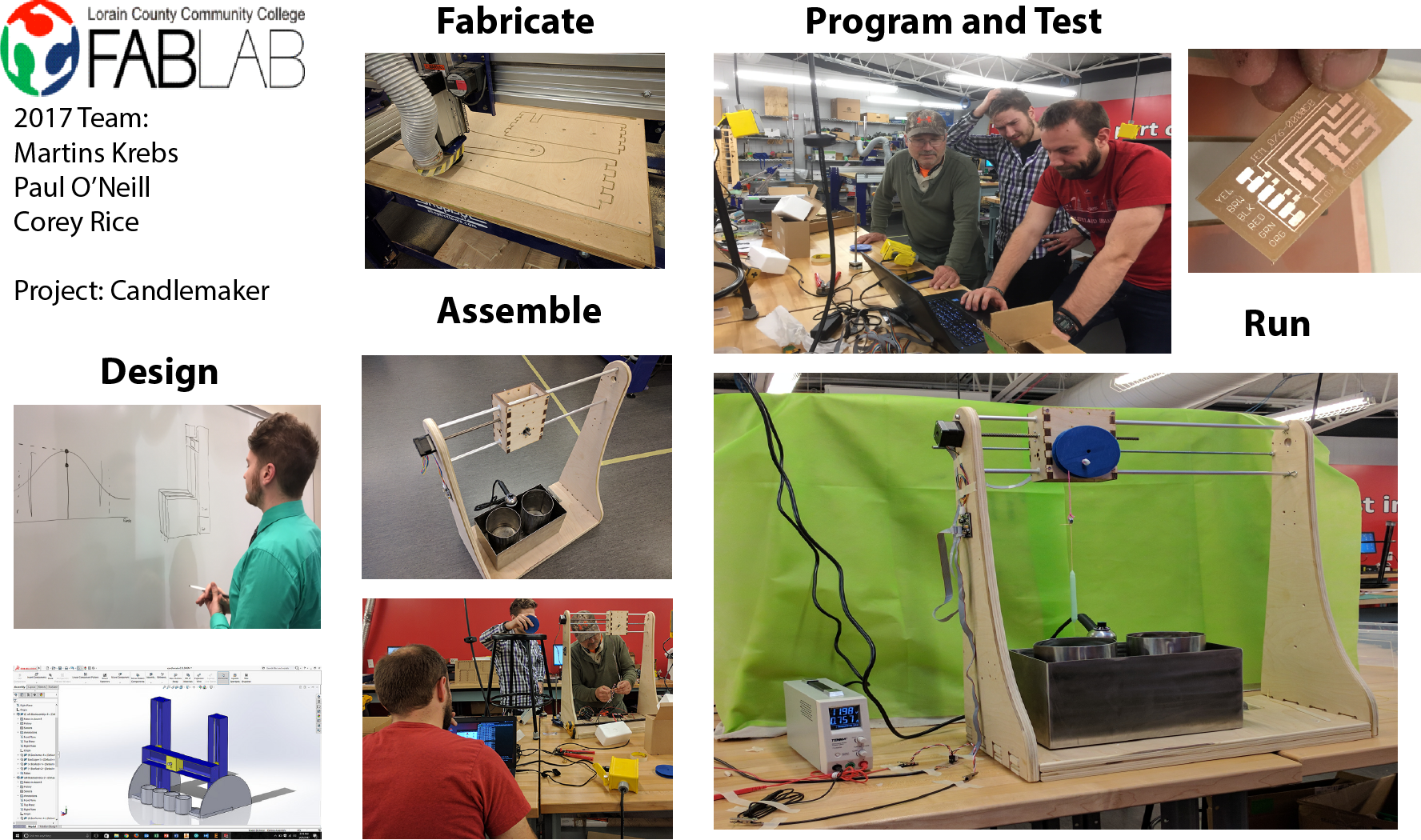

Early on in the course, our team decided that we would build a candle-making machine. The idea would be that we would dip wicks in colored wax to build up a candle. This way we could control the color of the candle or other properties from being able to control the types of wax used for each layer.

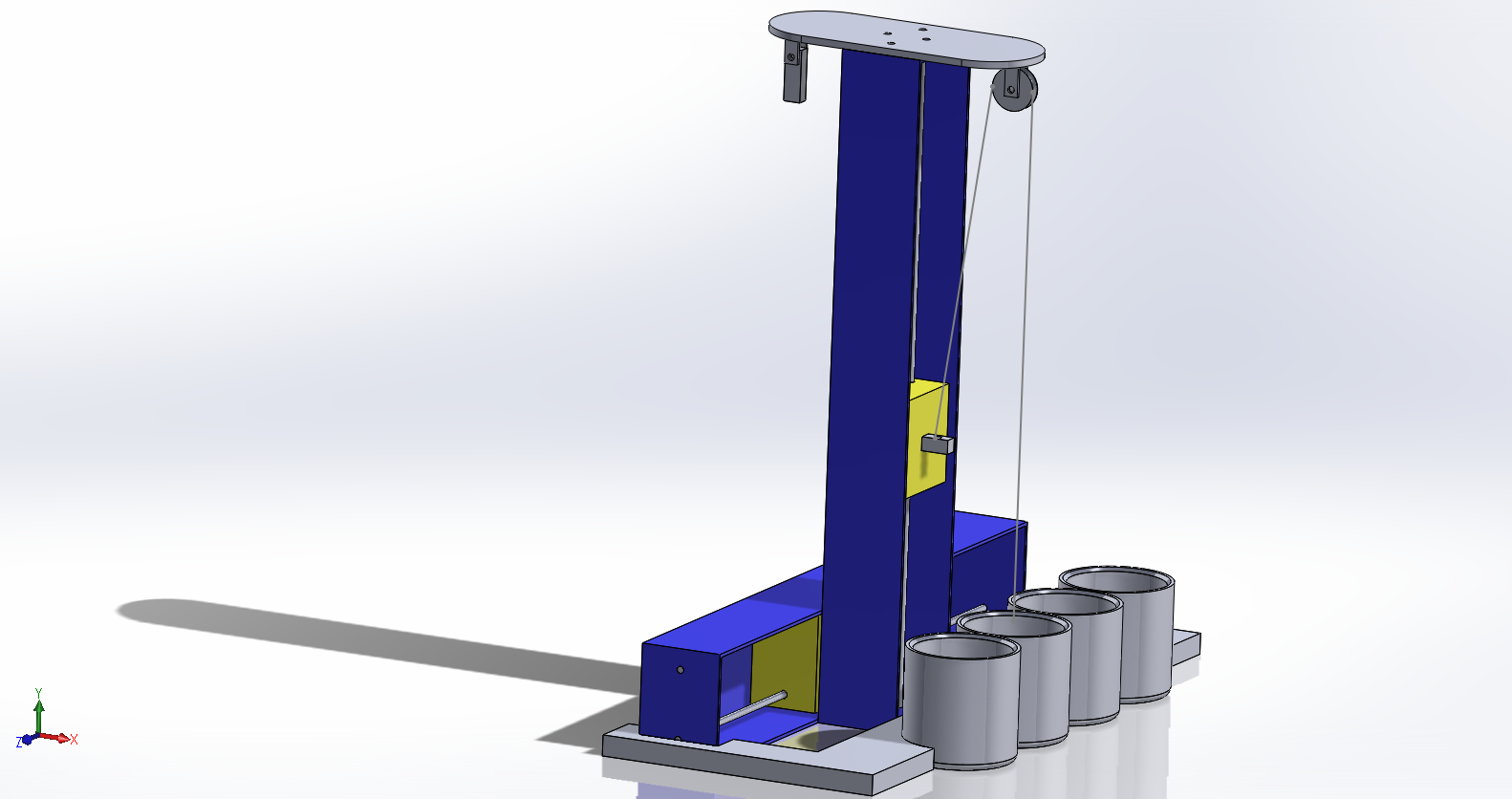

The design work started with using representative models from previous year's machines at LCCC. These allowed us to discuss concrete design plans, and outline exactly how the machine should be built. Marty Built a cardboard Stage. Paul and Corey met to discuss the progress and brainstorm further about the general design of the machine. A redesign was decided upon, to avoid struggles that were faced with the cardboard construction. The wood that was used was largely scrap that was available in the lab.

The new design was cut out on a ShopBot and Epilog laser after a few iterative checks with cardboard to be sure it would fit together. The body cut out on the ShopBot was also given a once-over with a hand router to smooth out the edges and help the press-fit construction go together a bit more smoothly. (Perhaps a bit more tolerance should have been implemented in the design).

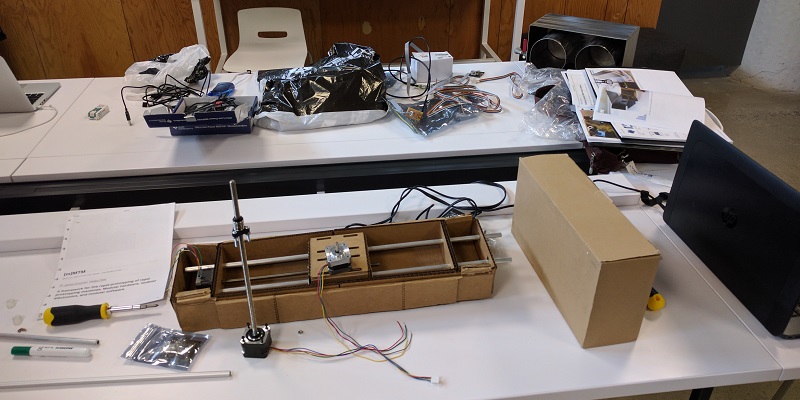

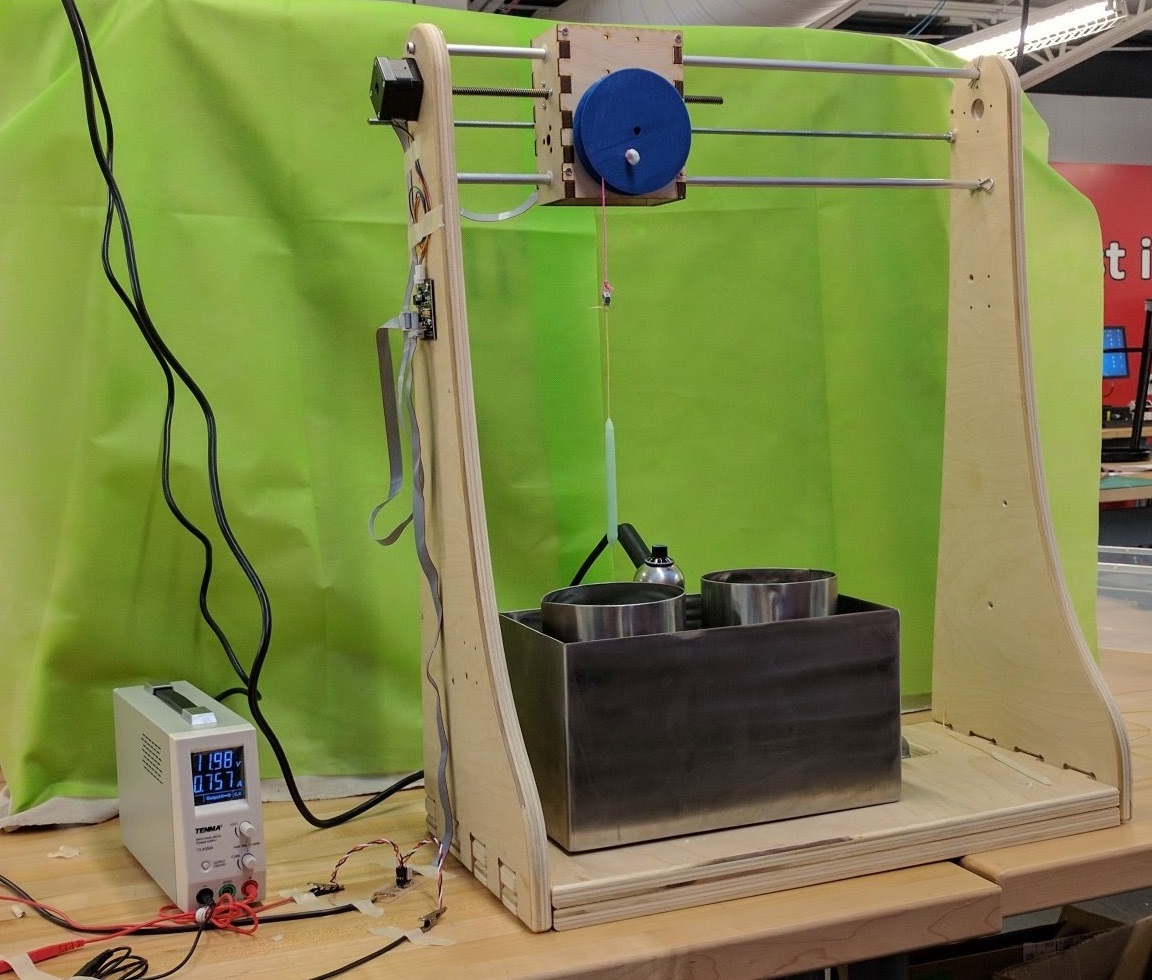

The body was constructed and both of the motors were screwed into place. The pulley body was 3D printed on a MakerGear M2 printer and attached to the vertical drive pulley to control the wick. The stainless steel hot water bath was set into place, and tested with the immersion heater. All of the construction fit well. This concluded the mechanical design portion of the building, and at this stage all of the components fit well and moved relatively freely.

The machine design took some work. It took several hours of playing with Python and the Gestalt library to get things up and running. Paul and Corey worked with three operating systems and a range of guidance from the internet to get things working. Paul had built a FabNet board, but we even tried out last year's to troubleshoot if that could have been the source of our problems. We later found that Paul's FabNet board worked great, and all of our struggles were with software conflicts. Eventually solving those conflicts, the team wrote the procedural code for the machine.

The choice was made to use an external CSV file to inform the motion of the machine. Since candle making involves cooling time, a three column CSV file was made, and the python program parses that information into x, y, and t parameters for motion. The x and y are for the default two-axis motion of the Gestalt's compound nodes. The time parameter of the CSV file informs how long the machine will wait after completing each motion step �€“ this feature is nearly always zero except for some cooling time after each dip in wax and for the final cool down.

Once all of these code elements were completed a few tests were run to determine the needed special and temporal positions and distances that would be needed. A CSV file was then built to guide the machine to dip the wick in the two colors of wax with appropriate wait times. [In truth, this is where the machine is most likely in need of more work. Ideally, the machine's operation would be more easily customizable, with auto-generated toolpaths based on just a few inputs such as the number of desired dips in wax and the desired color ratio.]

Finally, the machine was run several times to prove that it worked. In this testing it became clear that there were a few quirks to its operation. (1) First and foremost: the temperature of the wax is very important. Too hot, and it will melt wax off of the wick rather than build it up. Too cool and a film will form on the top of the wax bin, which will collapse on the candle and make for some lumpy candles. (2) Also, placing the wick directly on the pulley does not allow for the candles to be made without a nut at their bottom for weight. The wick comes pre-waxed and this means that you need a weight at the end so that it will hang straight as it unrolls from the pulley. In order to make straight candles, without a nut buried at their bottom a last-minute change was made. The wick was replaced on the pulley with some string that terminated with a quarter inch nut. The string moves freely on the pulley and the nut keeps it straight. With this arrangement, a wick can be tied on the nut and hung straight down over the wax without the need for a counterweight. This leads to nicer looking candles and avoid the stalactite wax build up that sometimes kept candles from completely submerging in the wax before.