Project Development

About my project

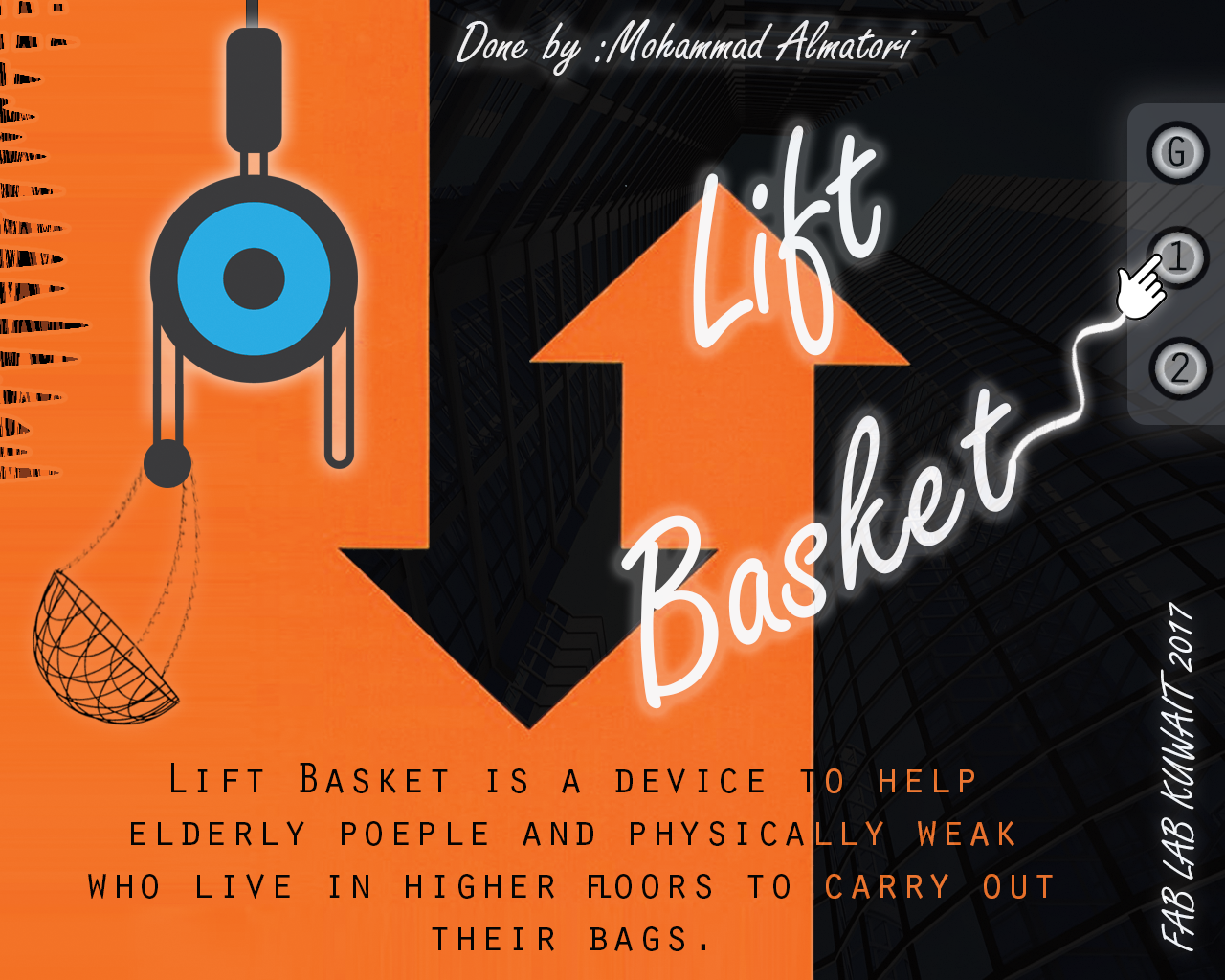

Is to develop a device that helps Elderly people and physical weak people to carry their bags to higher floors. lift basket, it carryout your bags right to your window. all you have to do is send your stuff to your floor.

What is the deadline? How much time do I have left?

The final project presentation date is 16-June 2017. I have one days to finish my project and complete my project presentation and final tuning.

What tasks have been completed, and what tasks remain?

Tasks Completed:

1- Designing and printing the pulley in 3D printer.

2- Designing and printing the Motor Holder in 3D printer.

3- Designing and cutting the hanging basket using Laser cutter.

4- Designing and cutting the Posters using Vinyl cutting.

5- Designing and cutting the base box using CNC.

6- Designing, Milling, Soldering and programming the circuit board.

7- Testing electronic components such as motors and stepper drives.

Tasks Remained:

Assemplying all components and testing.

How will I complete the remaining tasks in time?

All remaining is integrating all components together and tune the program to adjust the hight of the moving basket to reach certain floors. and by then i will match the following timing:

1- 3D design and printing.❬ 07/06/2017 ❭

2- Electronics board designing and manufacturing.❬ 08/06/2017 - 09/06/2017 ❭

3- programming.❬ 10/06/2017 ❭

4- Error fixes and Improvements. ❬ 11/06/2017 - 12/06/2017 ❭

What has worked?

The press-fit of my acrylic structure had a perfect fit by adding 0.3 mm on each side " a total of 0.6 mm" and 0.3 mm tolerance/allowance for the wooden structure.

Moreover, all mentioned above has worked.

What hasn't ?

I struggled a lot with motor. the original motor got malfunctioned therefore i had to replace it with smaller motor. this effected the size of the basket and the weight. Moreover, i tried the following to fix a pulley to the motor but all failed.

1- 3D printed the pulley with the same size of the motor shaft. but the shaft was slipping.

2- Added a hole for screw for the mentioned above pulley. still slipping.

3- Tried ready made pulley with screw. still slipping.

I de-assembled a small pulley with screws from old machine and used it. and it worked.

What questions still need to be resolved?

1- Is it a better option to use DC or Servo motor? what are related emplification?

2- Is there alternatives other than using threads or ropes?

3- Will relaying on stepper motor torque and speed sufficient enough?

4- What IP "Ingress Protection" rating will be required? Details Link... .

What have you learned?

I learned things that can be measured such as designing on new applications, using new hardware such as CNC, Laser cutter...etc. But, what i believe is a true gain is patience when working on a task, looking for a solution, thinking outside the box, creating an image before starting a work. these bast months experience was truly beneficial.

LINK HERE to FinalProject Page .