Composites

Introduction

Composites are two or more materials with markedly different physical or chemical properties – categorized as “matrix” or “reinforcement” – combined in a way that they act in concert, yet remain separate and distinct at some level because they don’t fully merge or dissolve into one another.

Plan

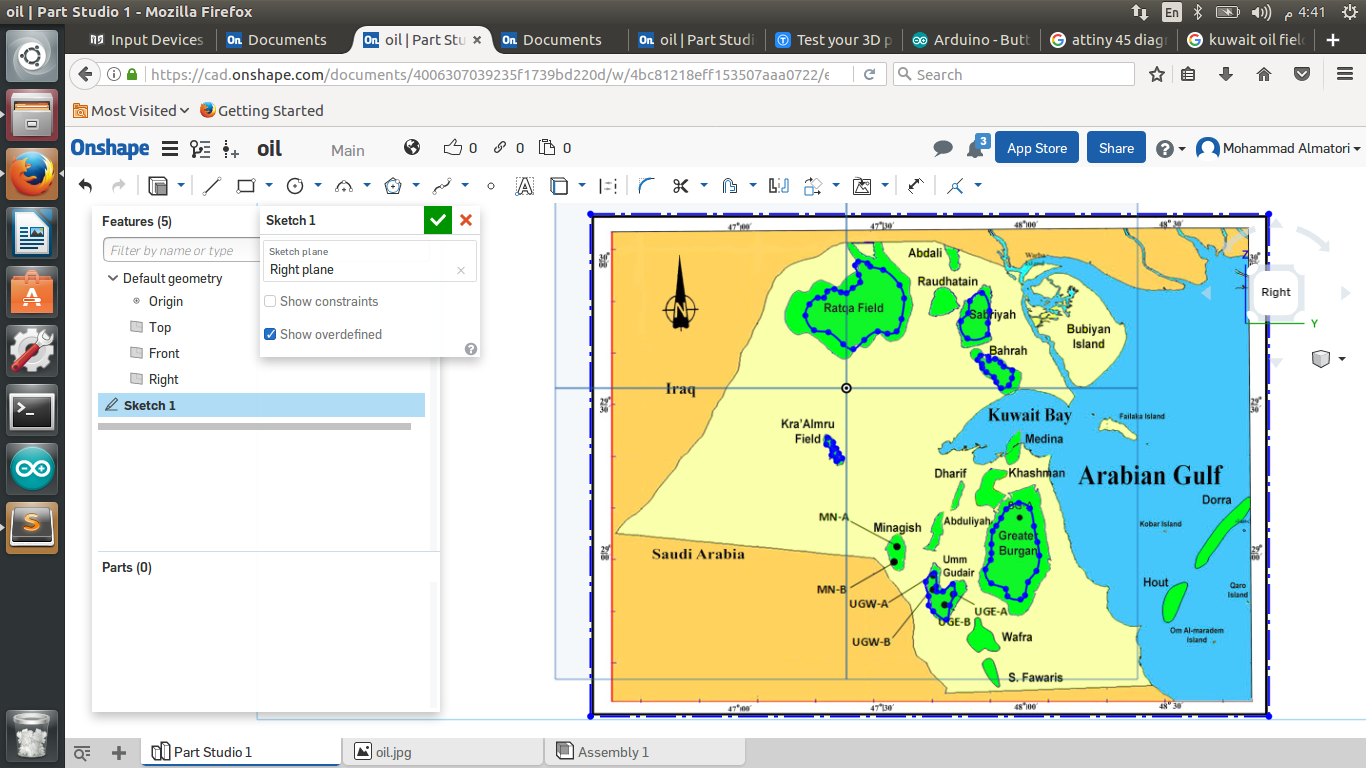

I plan to make my country map "Kuwait" in a 3D cmposite structure. I also added in the design later on some oil resuirvors.

Materials To Be used

listed below are the materials to be used for this week.

Design

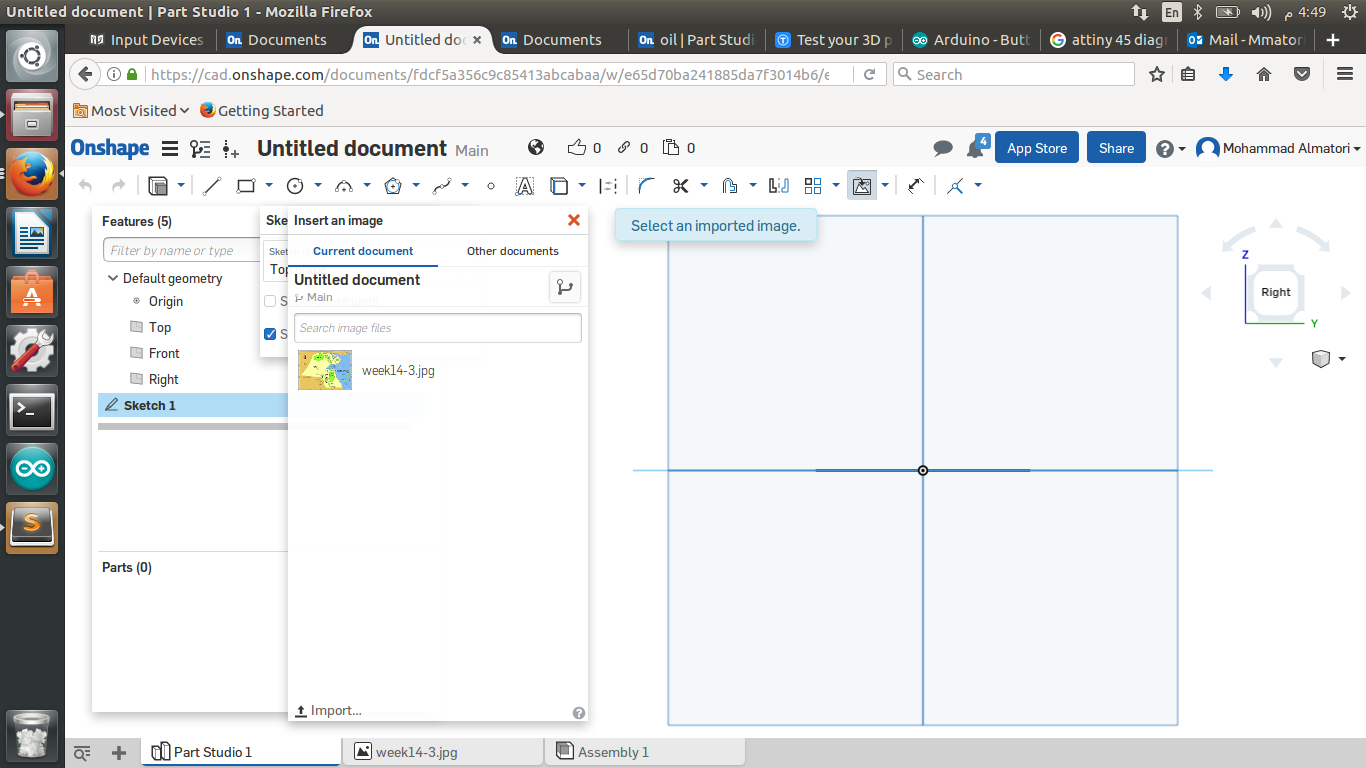

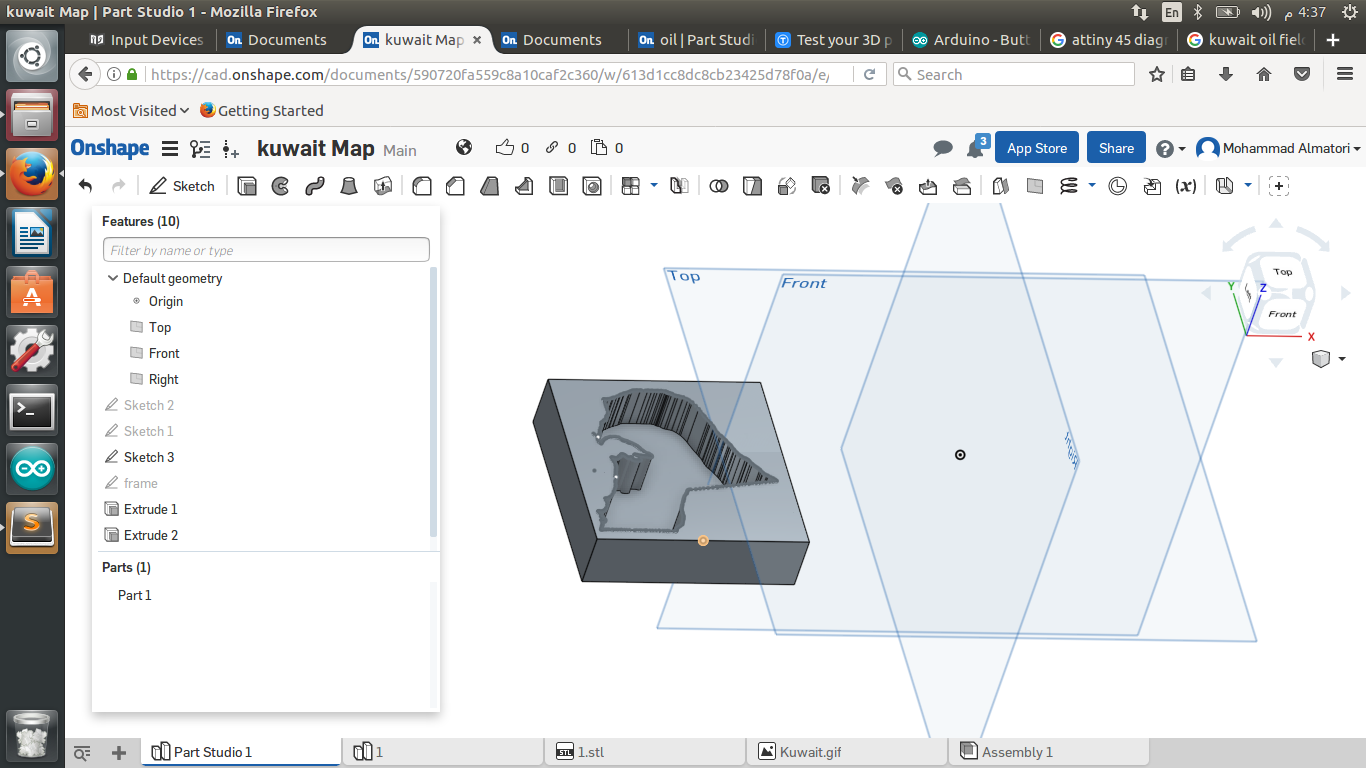

I am using Onshape to prepare my design. I used some new features to prepare my design, In order to drow Kuwait Map I imported an image and drew the map on top of it.

Afterward, i prepared my 3D shape by engraving Kuwait Map by 14 mm inside a frame of a width of 18 mm " whitch is the wood width"

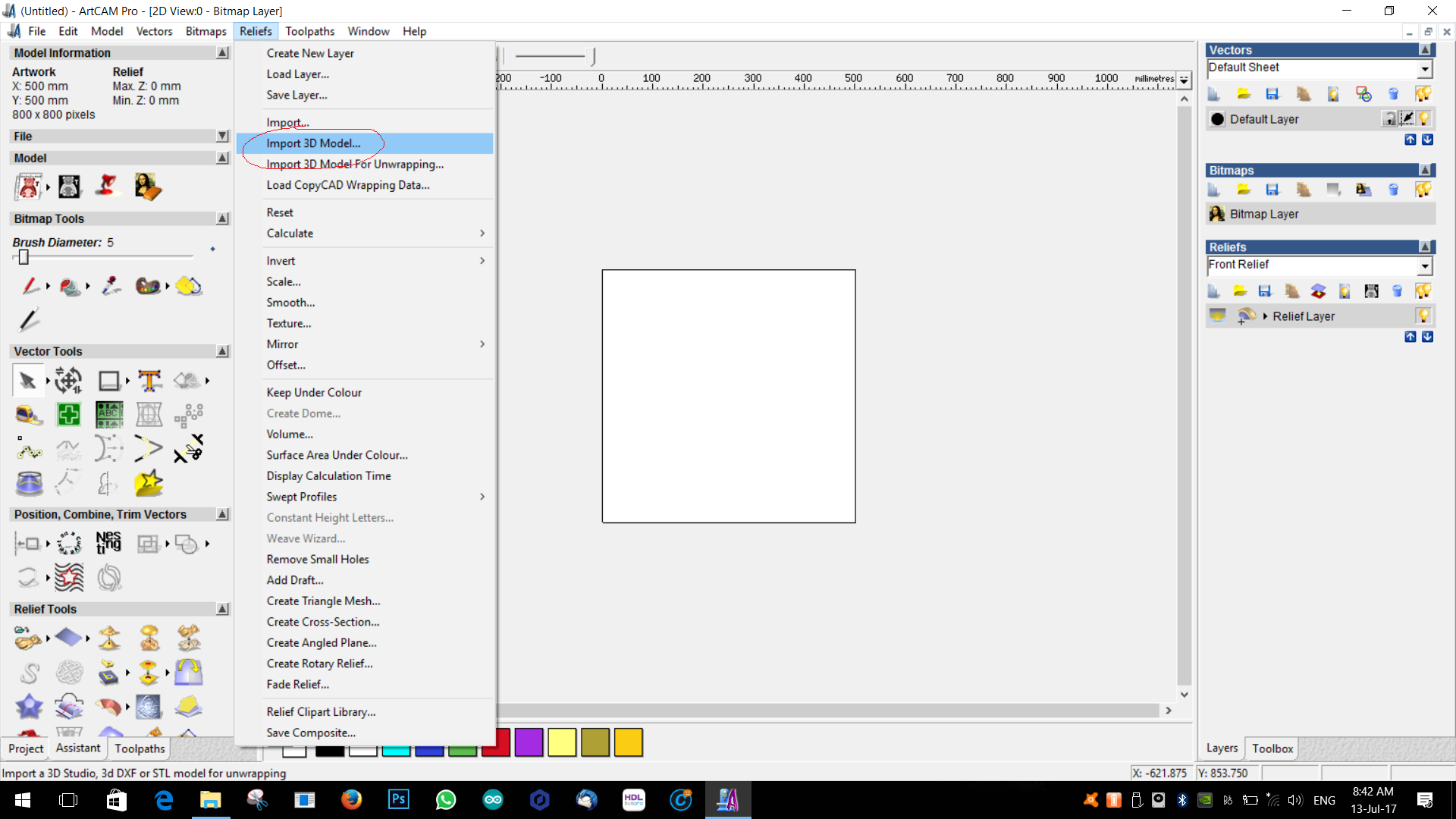

Preparing the file for CNC

I downloaded the .STL file from Onshape -> open the file in ArtCaM -> Open 3D model -> Choose File -> Choose Dimension -> Arrange to center and scale dimension -> 2D view -> Macke rectangle -> Double click -> set the depth. Below are images.

Cutting with CNC

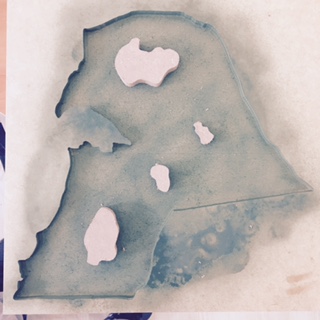

I uploaded my design on the CNC and cut my design on two stages. on the first stage i cut the shape of my map. then i thoght i should add another layer so i designed the oil resuirvors cut them and fixed them on the map and i sprayed them with black color.

Making the Composites

In order to make the required output. i went on the following steps:

1) I covered the whole surface of the map with plastic.

2) I mixed the mentioned earlier resin in a ratio of 2:1.

3) Used the cutton sheet as my first layer and distributed the resin evenly on the cutton sheet.

4) Used the rice bag as second layer and distributed the resin evenly.

5) Used the cutton sheet again as my third layer and distributed the resin evenly.

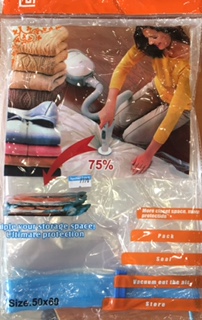

6) I placed the full object in the Air Vacum map and removed the air out of the bag.

7) Leave it for 24 hours to dry out.

Precautions:

1) Avoid Contact with skinand eyes, wear gloves.

2) Do not mix the components of the crystal resin with the comp

onents of the glazing resin.

3) resins are not approved for food contact.

4) Do not ecxeed 150ml of crystal resin preparation per mix.

Output

The result compsite was not as it was predicted. the resin used for the composite did not hold very well. therefore, the lab provided new resin and constructing the new composite went again.

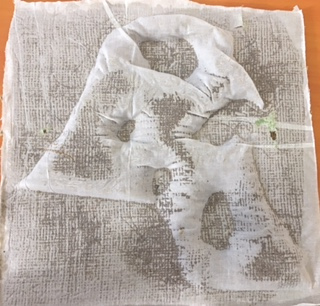

Re-Doing The Composite

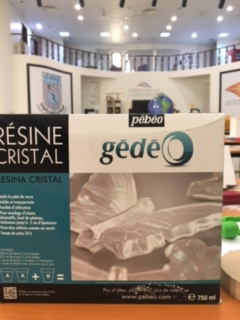

The same process of doing the composite mentioned earlier have been done again with the following resin:

Output

Downloaded files

Oil resuirvors

Board File

Kuwait Map