WEEK-19: Project Development

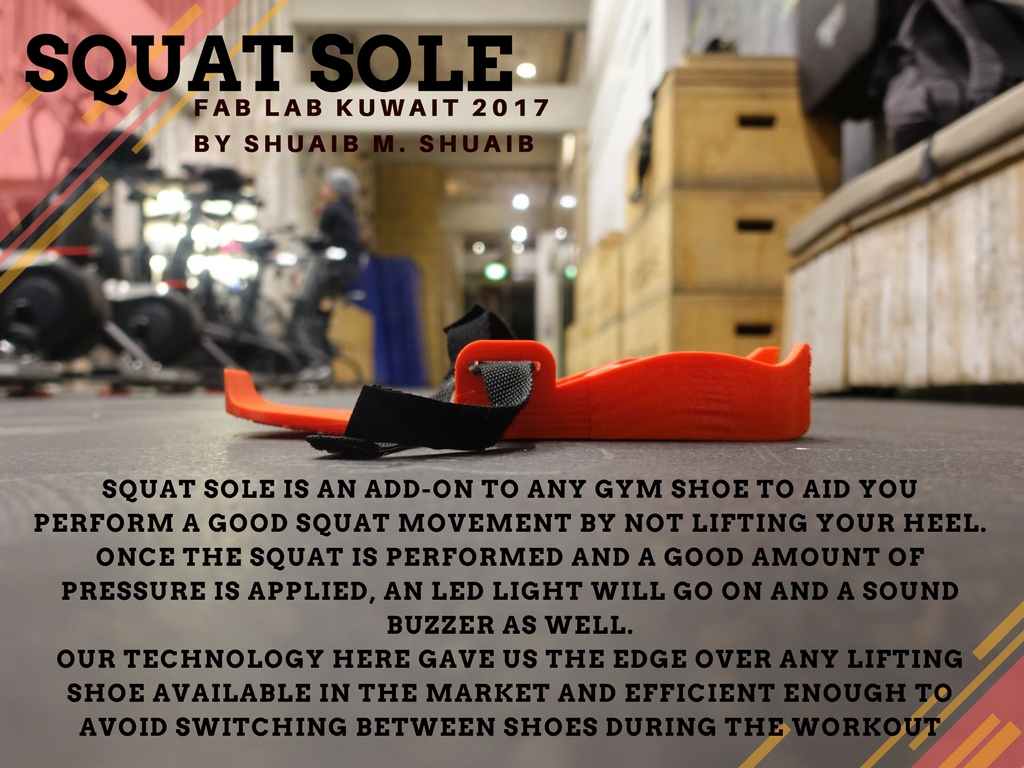

About SQUAT SOLE

Squat Sole is a state-of-the-art training kit for those who seek injury free work out. as we all know, the foundation of the body is the foot, with every step we take whether in a work out or day to day activities, the correct motion of the human body begins with the how you step on the foot.

I believe such knowledge will require a huge campaign to create awareness of where or how you should step while working out but with the help of the technology these days, we can tackle this issue and solve it easily with the Squat Sole.

In Squat Sole, we are creating an external shoe sole that you can attach under any gym sneaker and senses where exactly you are stepping on your foot. The concept is very simple and straight forward, and it could be further developed by connecting the sole through an application that shows the progress of your squat step whether in the middle of the foot , on the toe or at the heal which is the recommended location.

Here is the link to my final project page. you can also find it in the top header as well.CLICK HERE.

Answer The Following Questions:

what is the deadline? How much time do I have left?

I have created a timeline for myself as i am trying to start few days earlier to catch up with time and have a time coushin for any back up plans. The time plan as mentioned in the previous weeks is as follow:

1) Planning Stage: May 28th to Jun 1st 2017 . Completed

2) Design Stage: June 4th to June 8th 2017 . Completed

3) Execution Stage: June 11th to Jun 15th 2017. On Going

4) Testing Stage: June 18th to Jun 21st 2017 . Pending

what tasks have been completed, and what tasks remain?

Completed Tasks:

1) Design Stage

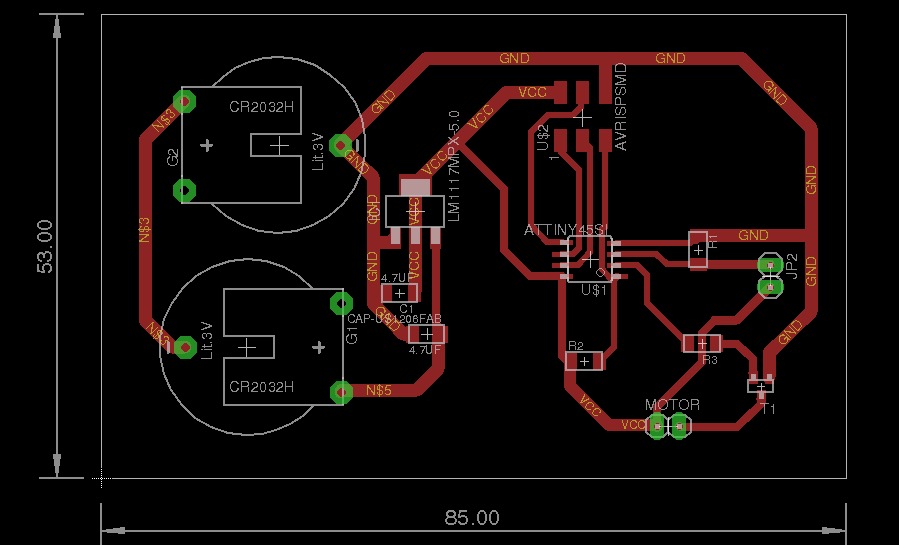

2) PCB Design

3) PCB Milling

4) PCB Soldering including the pressure sensor

5) PCB Coding

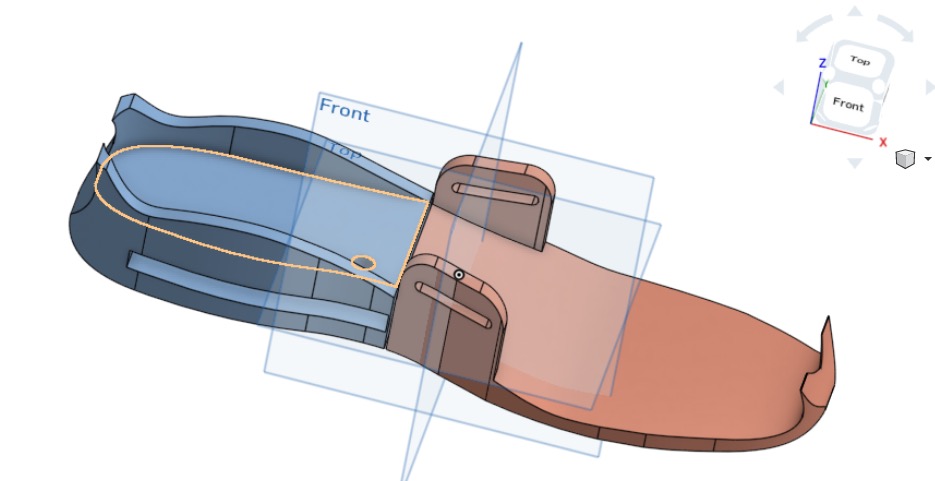

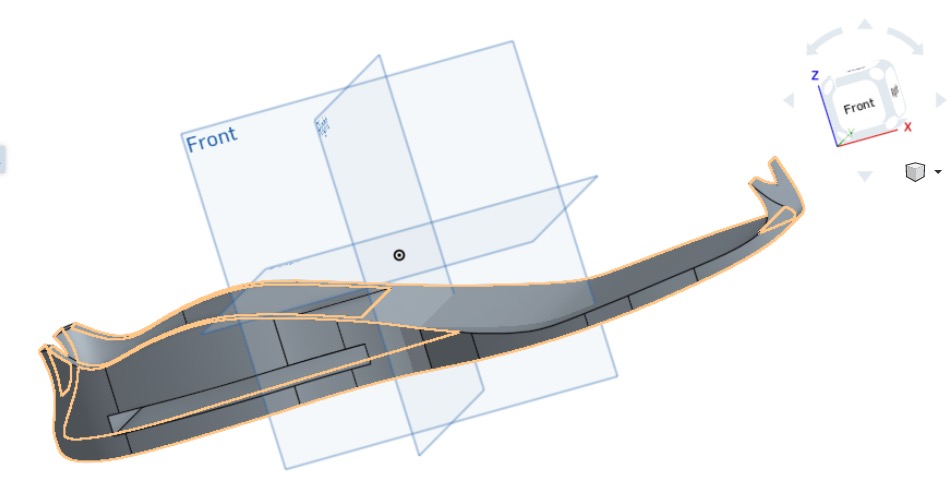

6) On-Shape Design

Design Completion to Date

to date, I have completed the design stage including the 3D design the PCB Board design for the vibrator motor concept ONLY. I will give it a shot. In case the vibrator motor doesn't work effectively, i will be adding an LED and a buzzer in the PCB design and remove the Vibrator Motor. below are the completed designs so far

Below is the PCB Design of a Vibrator motor in the first Trial:

Incomplete Tasks:

2) inject the PCB board into the sole

3) inject the vibrating sensor as well into the sole

4) testing and commissioning including the vibrator motor

5) IF NEEDED, redesign and re-produce the 2nd trial of the LED light and the Buzzer

how will I complete the remaining tasks in time?

I will try my best to get the design stage over with and complete the execution phase on time because I feel that a lot of testing time will be required to find the most comfortable squatting position to work with.

what has worked?

Found the proper code to apply on the PCB after the milling and soldering process is completed.

what hasn't?

Complete the 3D Printing the shoe sole as fast as possible since the 3D printer is not of a good quality

Inject the PCB board into the sole

Find a comfortable squatting position

test the sole at a professional level in a close by gym, get a feedback and modify

what questions still need to be resolved?

1) find a good position of the vibrating sensor

2) size of the PCB board is very challenging having a low quality milling machine.

3) printing a plastic edges for the board to avoid the sharp edges

what have you learned?

Time is the number-1 priority in this project

the process between the design and execution MUST have a cycle of testing and commissioning looped into your process. such project will require to test and reproduce again if any step did not go as planned. So I should have always allowed a sufficient time for the testing cycle.