[WEEK17] applications and implications

What will it do?

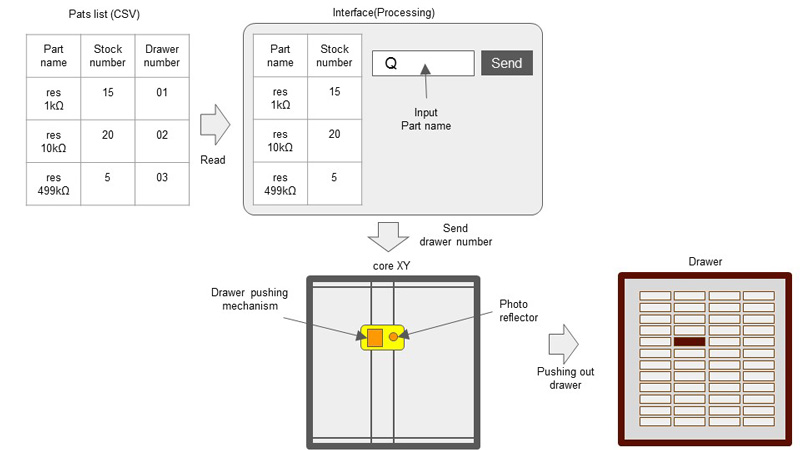

A system that can easily pick up parts and manage inventory

- When the user inputs the part name in the search box, the head of the core XY moves to the position of the corresponding drawer, and the pin attached to the head pushes out the drawer.

- When the quantities of parts become less than the specified value, the user puts black paper (signboard) on the back of the drawer. When the inventory checking operation is performed, the photo reflector mounted on the head of the core XY screen all drawers and determine the color of the back of the drawer. And then, the system notify the administrator of information on parts with low stock by e-mail.

Who's done what beforehand?

Various logistics companies developes robot that picks up some products and system that manages inventory.

For example Magazino / torucube

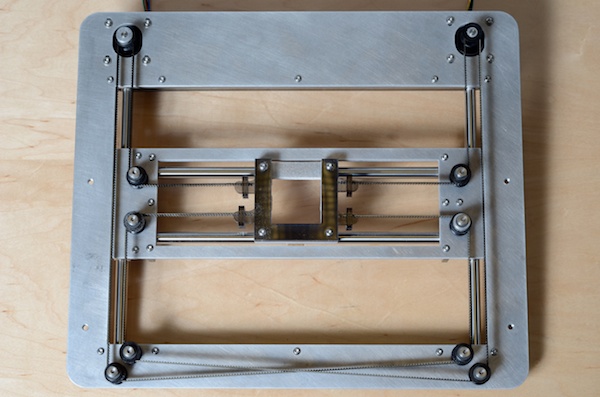

I will use core XY mechanism in this project. Many people have made various machines using this technology. For example Waterjet Aluminum Revision 1

What materials and components will be required? Where will they come from? How much will it cost?

| Part name | Quantity | Cost | Retailer |

| aluminium frame 200×200x400mm | 4 | 427 yen | MONOTARO |

| stainless shaft Ø8 | 2 | 1321 yen | MONOTARO |

| stainless rod Ø10 | 2 | 1490 yen | MONOTARO |

| linear bush Ø8 | 4 | 244 yen | MONOTARO |

| linear bush Ø10 | 4 | 251 yen | MONOTARO |

| stepper motor SM-42BYG011 | 2 | 1380 yen | |

| servo | 1 | ||

| screw Ø5 | 36 | ||

| flat nutØ5 | 36 | ||

| bolt Ø8 | 8 | ||

| nut Ø8 | 16 | ||

| oilless flange bush Ø8 | 16 | 30 yen | MONOTARO |

| timing belt W6mm | 5m | 1500 yen | AMAZON |

| GT2 pully,numer of teeth 20 | 2 | AMAZON | |

| battery | |||

| ... | |||

| ... |

| Part name | Quantity | Cost | Retailer |

| photo reflector TPR105F | 1 | 40 yen | Akizuki Denshi |

| motor driver | 2 | ||

| resistor | |||

| ... | |||

| ... |

What parts and systems will be made?

- Position control system using core xy mechanism

- Mechanism for pushing out each drawer

- System that checks whether there is any stock by checking the color of the back of each drawer

What processes will be used?

core XY

- Joint parts and other components are made with 3D printer or laser cutter.

Drawers (optional)

- Laser cutter and 3D printer

What tasks need to be completed?

CSV file

- Making CSV file that stores part name, stock quantity, drawer number.

Processing

- Read CSV file and display the stock quantity of each part on GUI.

- When you input the part name into search box, Send the corresponding drawe number to arduino.

- Receive instructions from arduino that operation is complete, reduce stock quantity in CSV file and reflect a new value on GUI.

- Send the command(number) for stock taking.

- Save the latest CSV file when shut down the processing,.

Arduino

- Receives the number sent from processing, moves to the corresponding position and extrudes the drawer.

- When a number for inventory checking is sent, the photo reflector identifies the color of the back of each drawer and returns the drawer number where stock is low.

- Send the command(number) for stock confirmation.

What questions need to be answered?

- Does it work even if core xy is installed vertically ?

- Which side of core xy is on ?

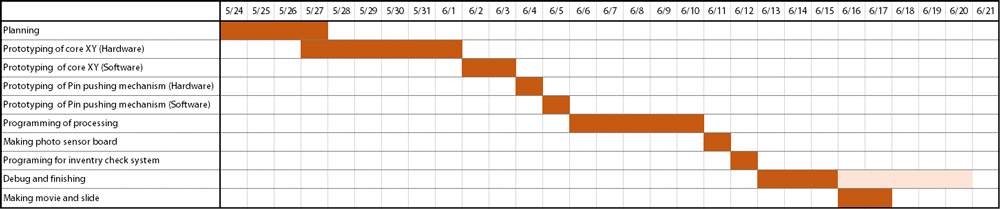

What is the schedule?

How will it be evaluated?

- I will operate for a while in my laboratory

- Ask if you have less trouble to record inventory than before

- Check if inventory quantity is correctly recorded.