[WEEK03] Computer-controlled Cutting

1. Group assignment

1.1 Change settings

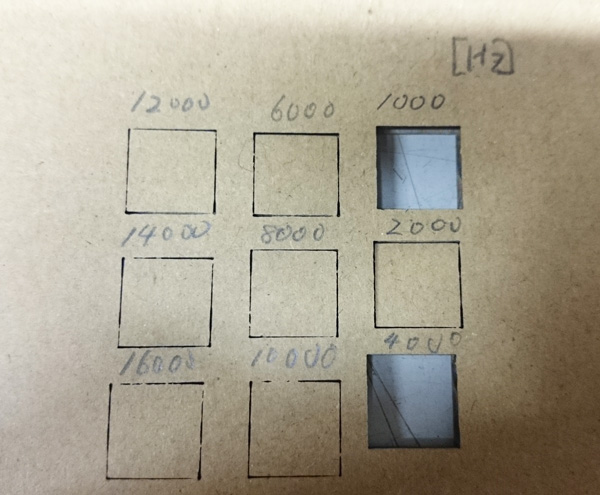

We tried to use lazercutter with various settings. I took charge of a frequency test. So I cut the simple model, changing a frequency from 1000 to 16000.

| Material | Cardboard |

| Thickness | 3mm |

| Lazercutter | trotec speedy 100 40W |

| Power | 80 |

| Speed | 10 |

| Pass | 4 times | Frequency | 1000-16000Hz |

It seemed that the lower frequency was prefered. I did not expect this.

1.2 Make dimension slot

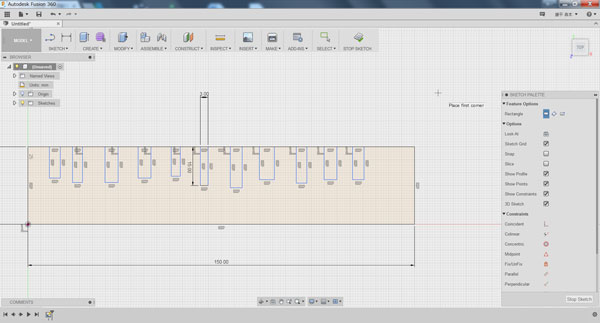

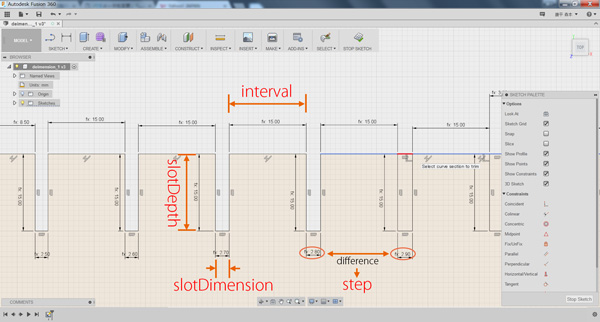

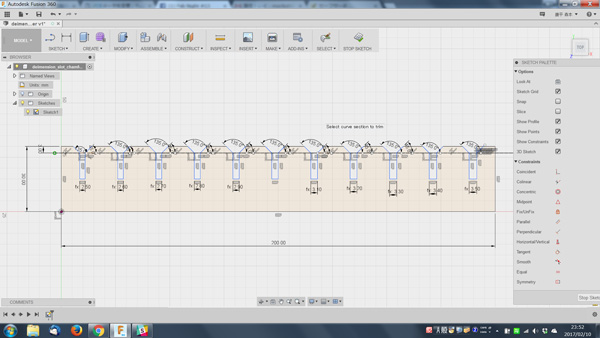

The cardboads we had were 3mm thick. So I set it as the reference size,and modelled the sketch that the slot dimension was parametrically variable by 0.1mm with Fusion 360.

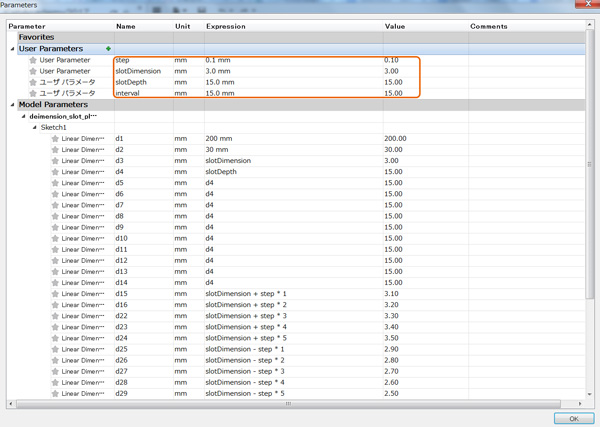

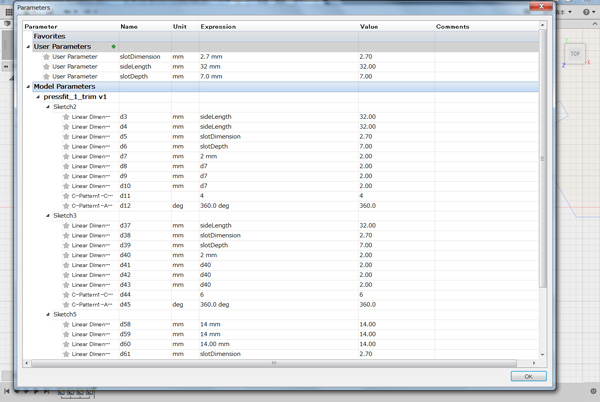

I set the variables as following pictures to change the size of slot.

I mede chamfered each corner.

I saved it as dxf file and imported to the illustrator to cut with the lazercuter.

I set the parameters as follow.

| Power | 80 |

| Speed | 10 |

| Pass | 4 times |

| Frequency | 1000Hz |

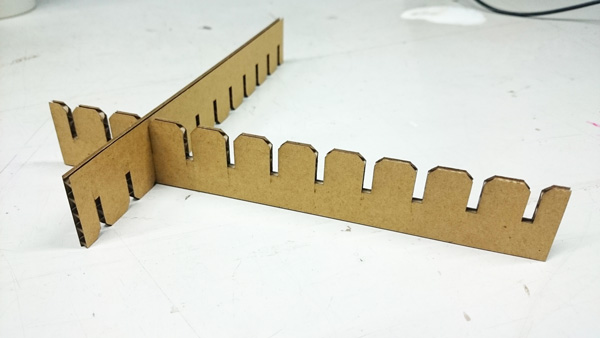

I tried to fit each slots and confirmed that the optimum value of slot dimension was 2.7mm.

Download

Dimension slot (.f3d): Download the file

Dimension slot (.ai): Download the file

2. Indivisual assignment

2.1 Press-fit construction kit

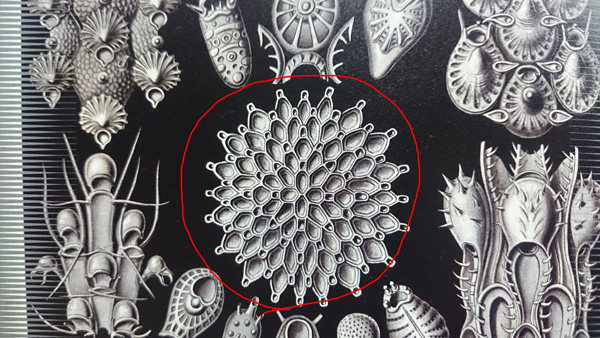

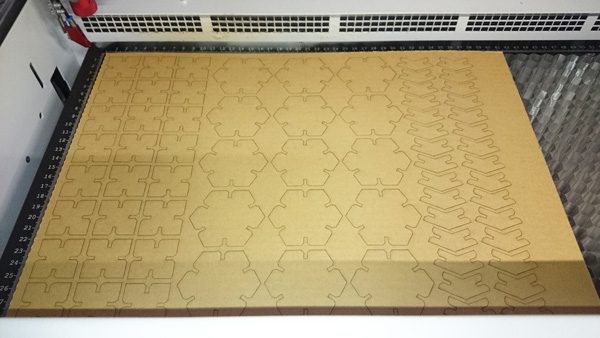

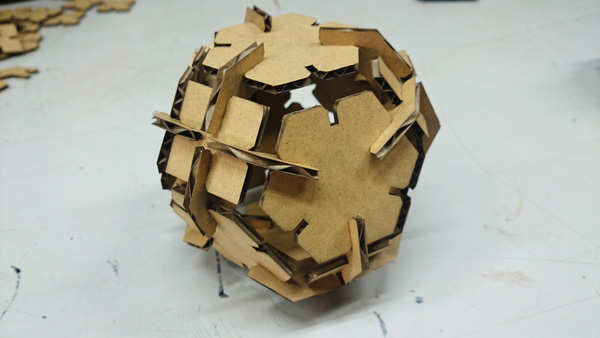

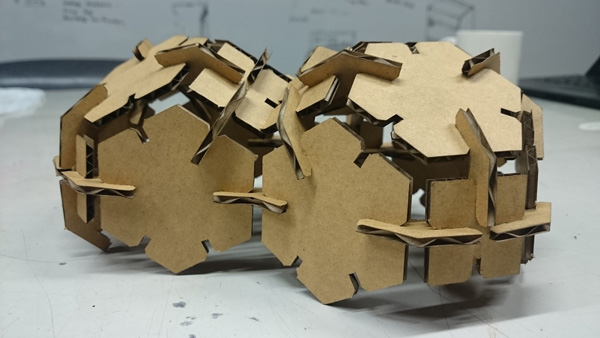

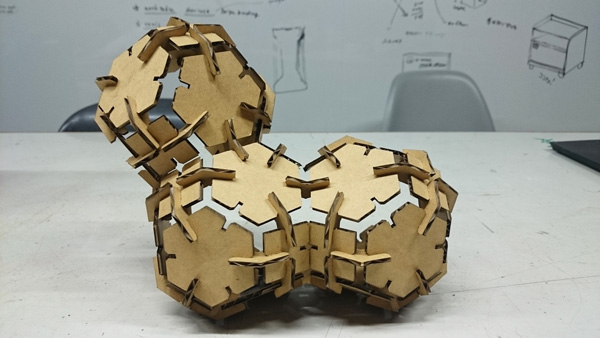

I tried to make object with square and hexagon referring to the space packing model in the nature. The images source was the following picture.This is a drawing of bryozoa(Ernst Haeckel"Kunstformen der Natur"1904)

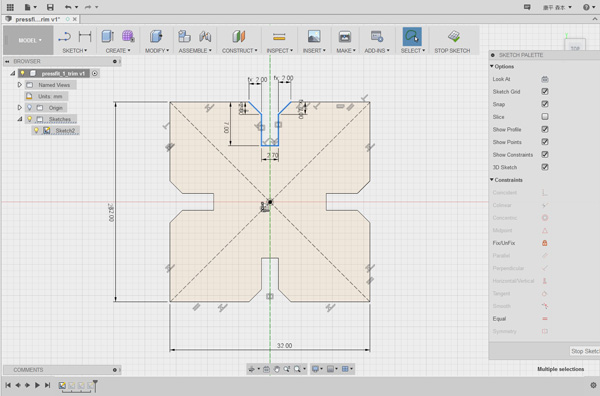

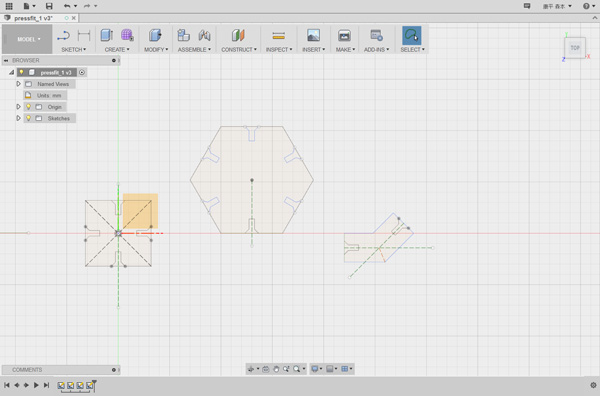

I modelled three sketches,square,hexagon,and joint parts.

The slot dimension and the side length of each figure change parametrically.

I can make the objects in multiple ways.

Download

Press-fit construction kit (.f3d): Download the file

Press-fit construction kit (.ai): Download the file

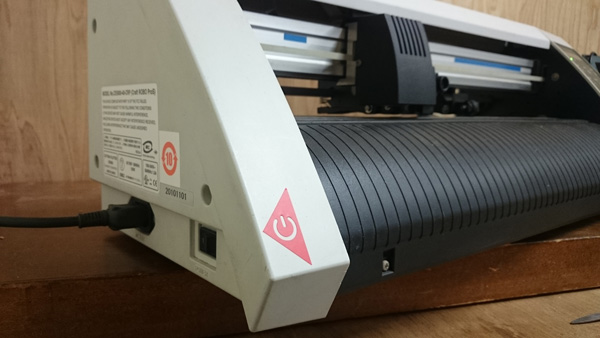

2.2 Make a sign on the vinylcutter

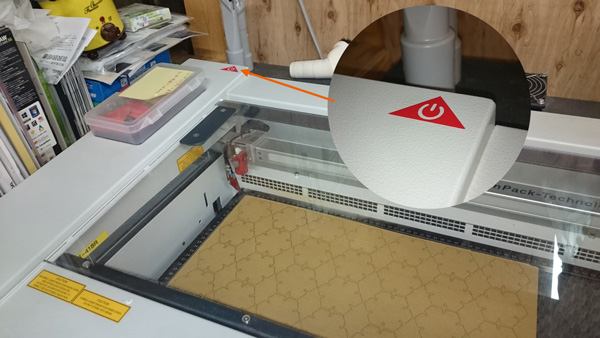

Power supply switches of some machines are attatched to the back or side. It is hard to find them. So I made a sign for these hidden switch. This model was made by illustrator.

For vinylcutter:CE5000-40-CRP

For 3D printer:Makerbot Replicator 2X

For lazercutter:trotec speedy 100