Computer Controlled Machining

For this assigment, we have to:

- (DONE) Make something big (on a CNC machine).

All the files created for this assigment can be found on the link bellow:

---> DOWNLOAD FILES<---

Have you:

- Explained how you made your files for machining?

--> yes

- Shown how you made something BIG (setting up the machine, using fixings, testing joints, adjusting feeds and speeds, depth of cut etc)?

--> yes

- Described problems and how you fixed them?

--> yes

- Included your design files and ‘hero shot’ photos of final object?

--> soso

Designing the Oject

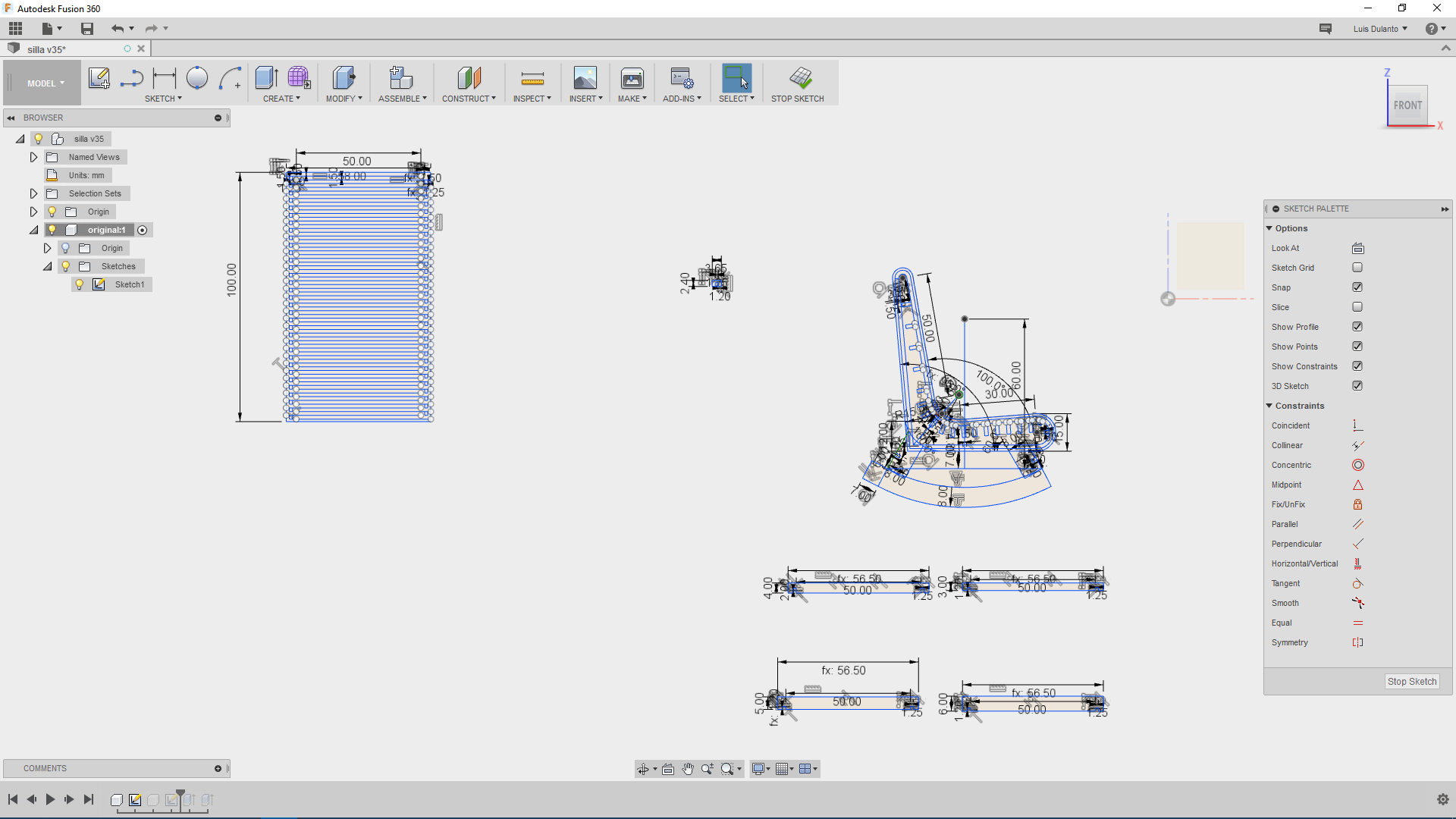

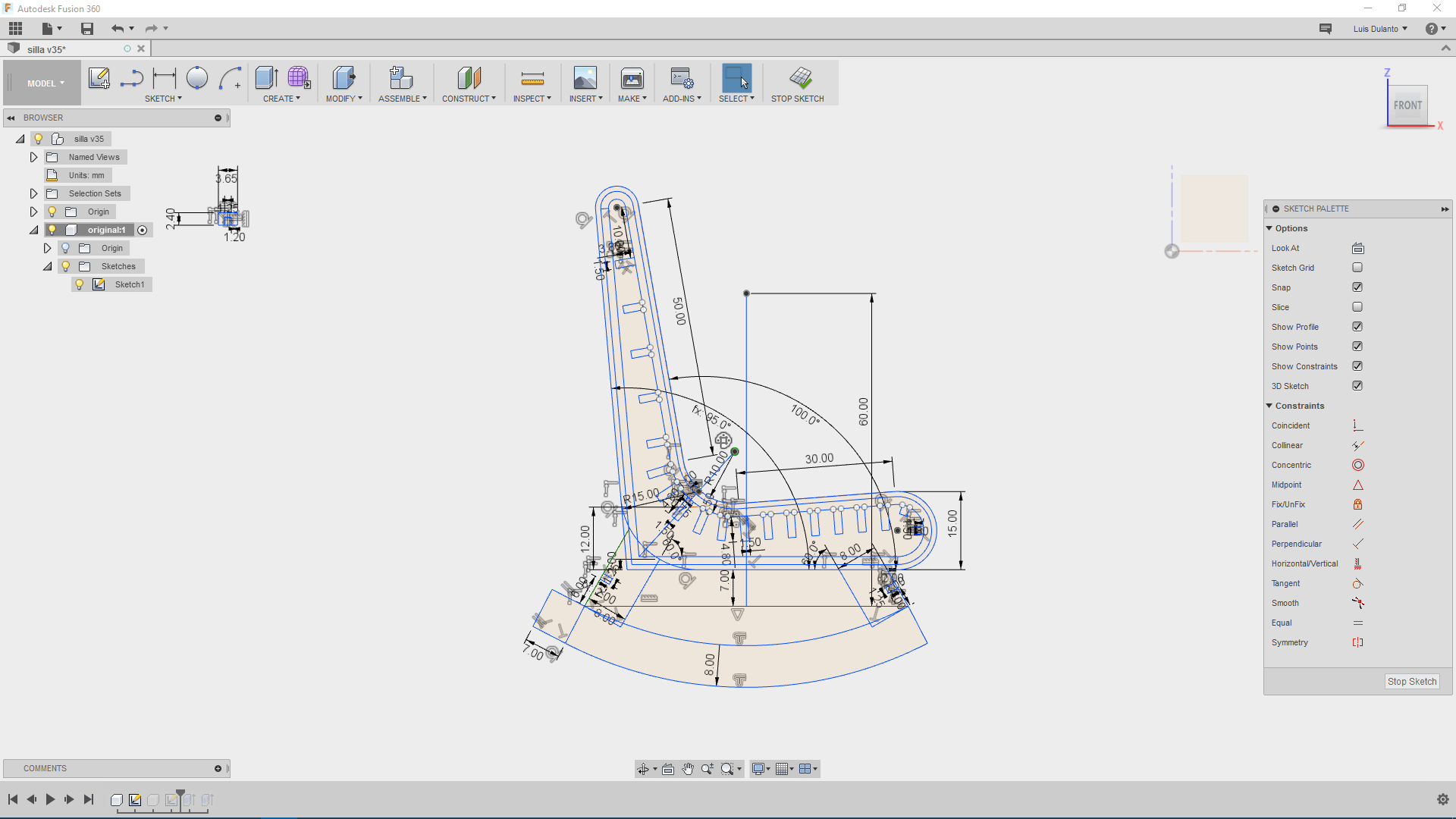

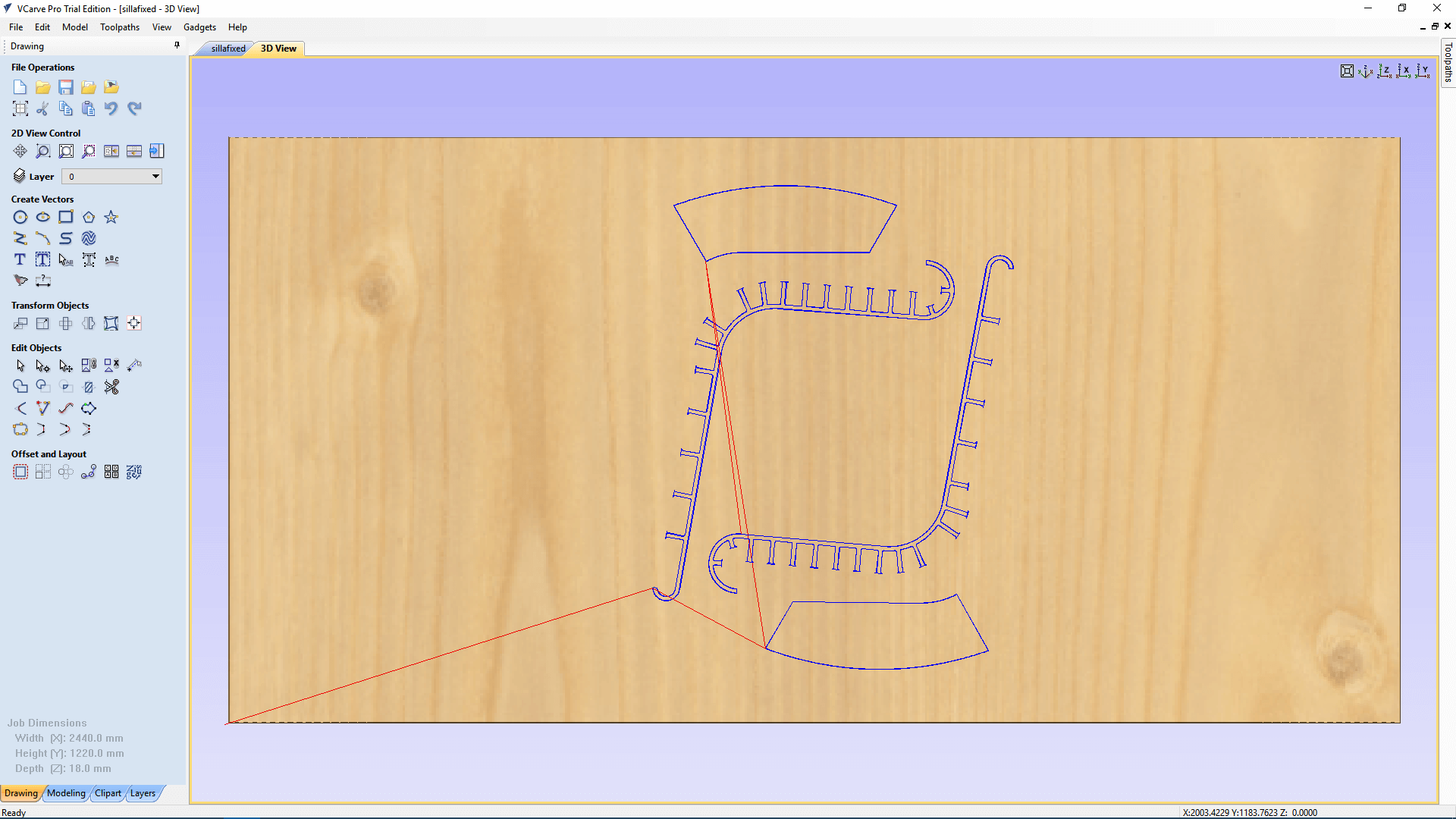

I worked with Fusion 360 for designing the object planes. The basic Idea was to design a rocking chair

This are the steps I did for this task:

1. First, I created a new component, and did a sketch of all the principal rocking chair parts in one sketch. This sketch contained a lot of construction lines which I needed to delete for milling my object.

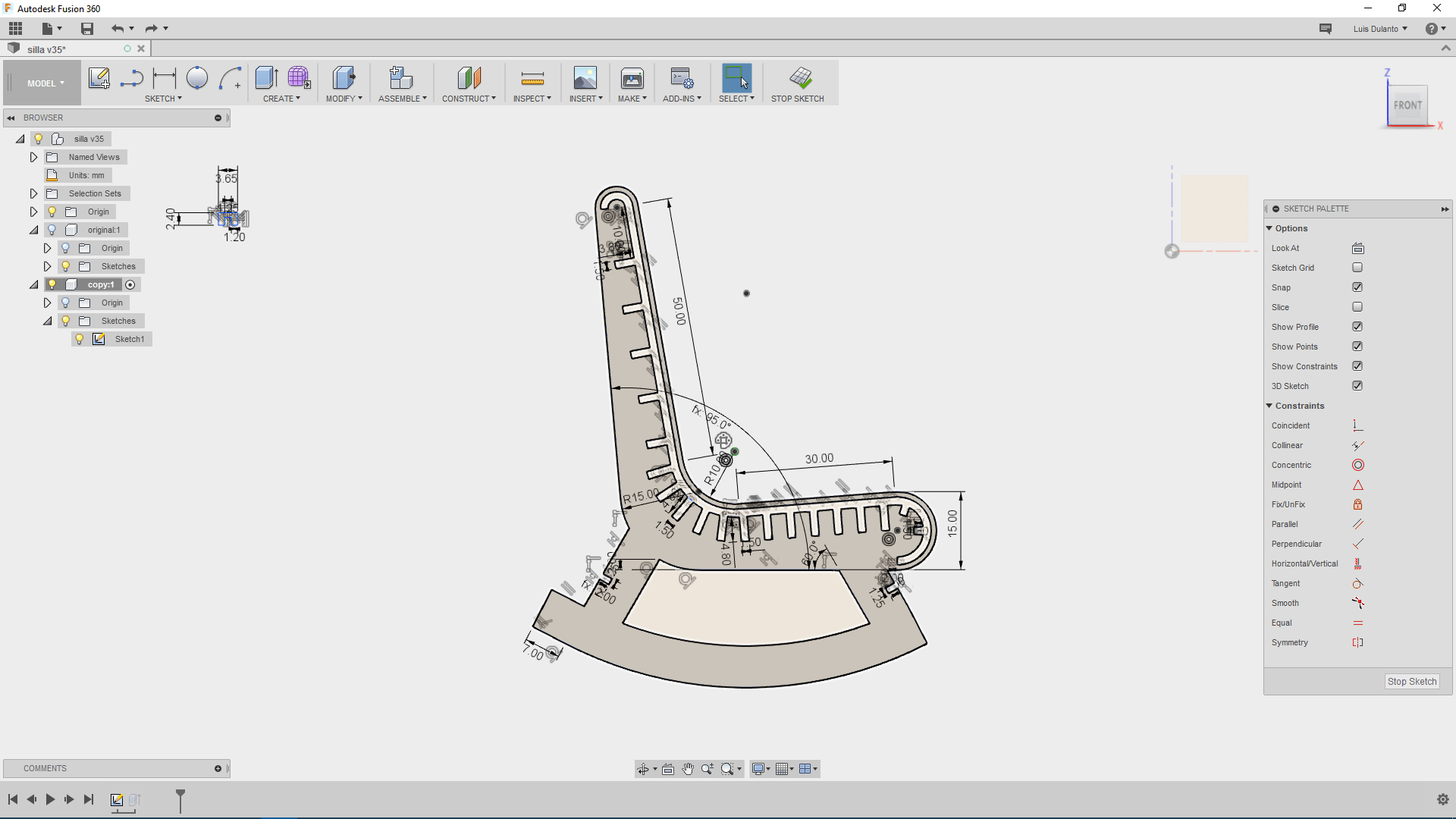

2. Then, I created a copy of the component by right clicking over the component and selecting copy and pasting it as a new component (this is done by right clicking over the principal component and selecting paste as new component).

3. I used the trim tool to delete all the construction or auxiliar lines in the sketch.

4. Then I right clicked over the new component and selected export as dxf.

Preparing Planes For Being Milled

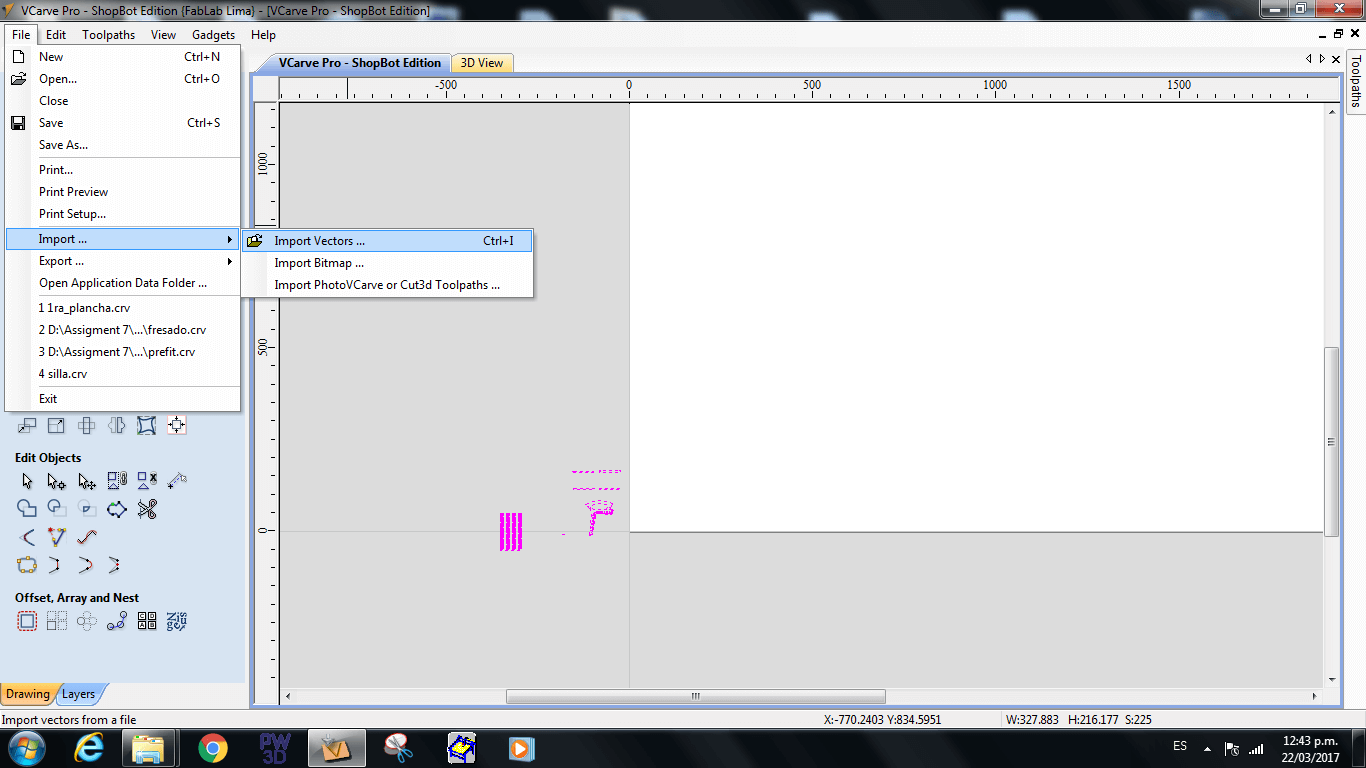

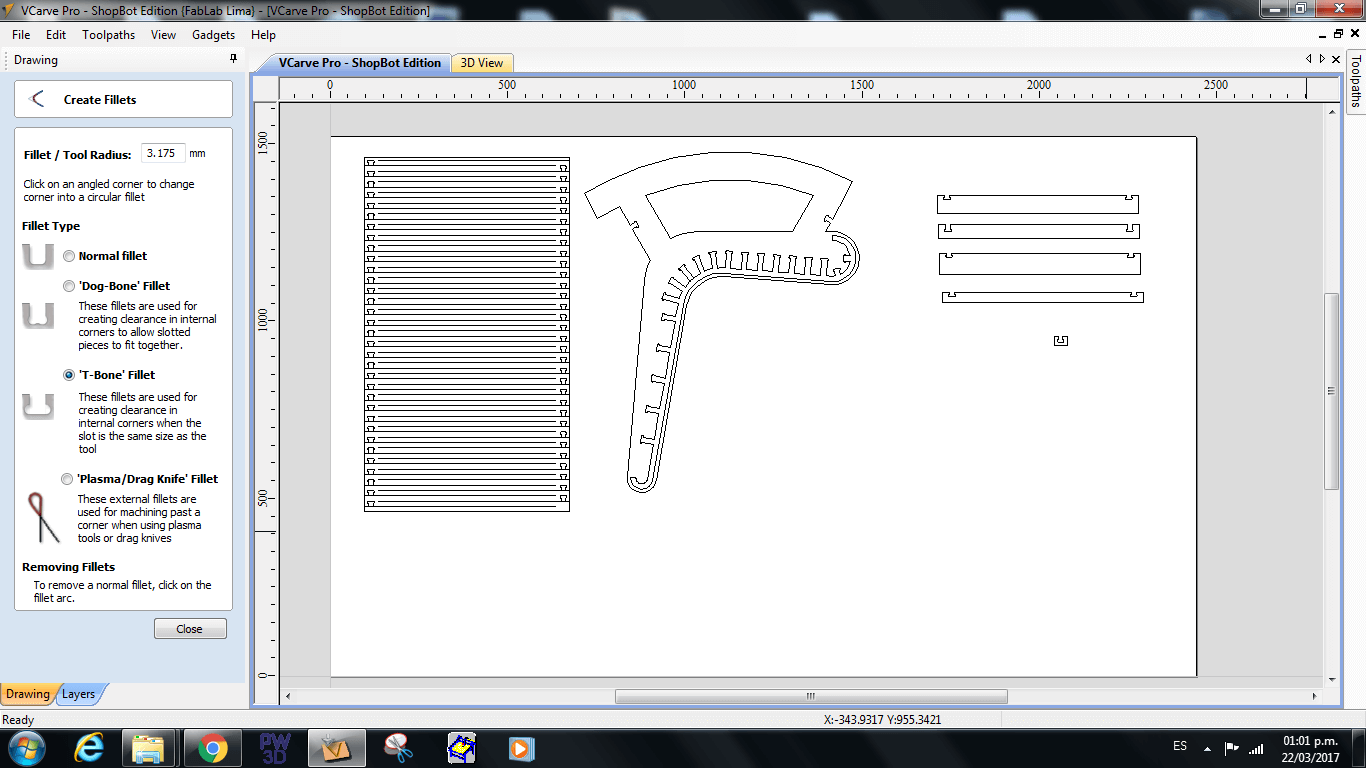

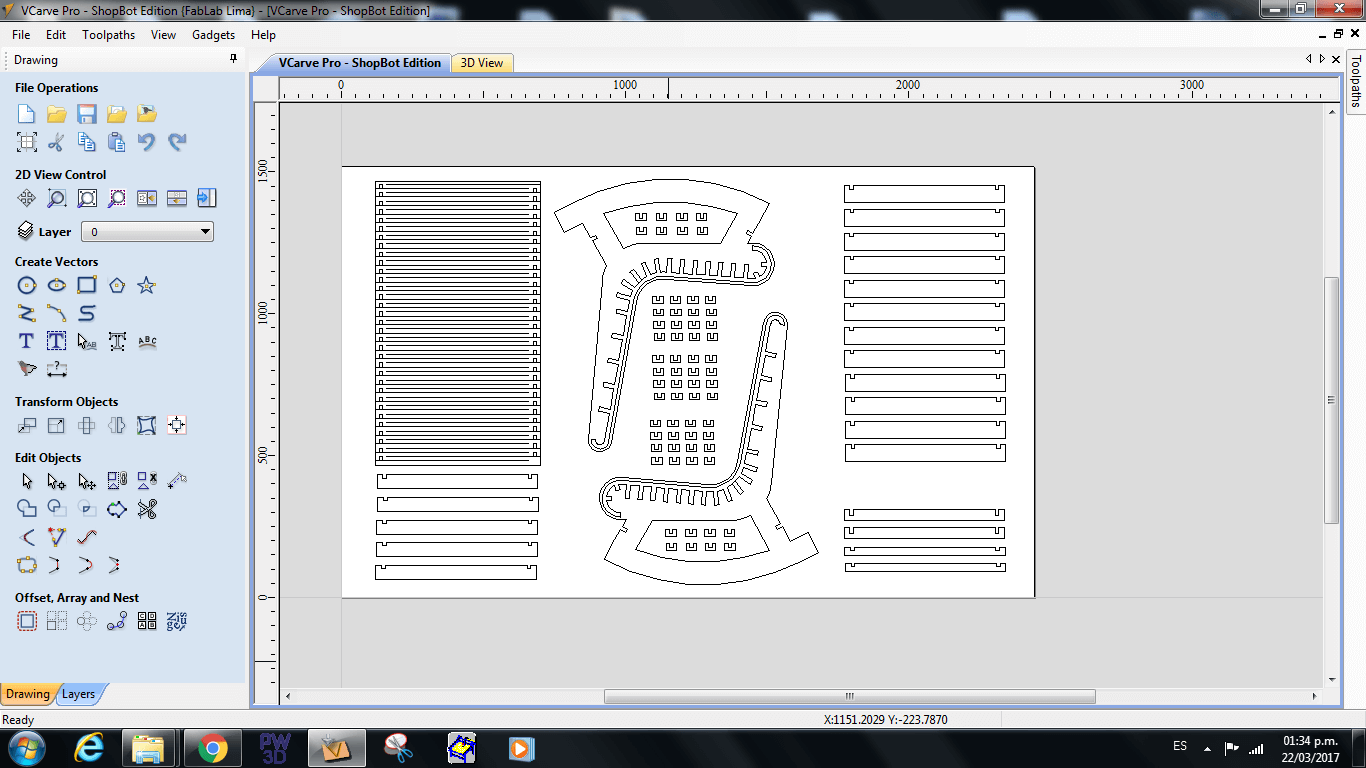

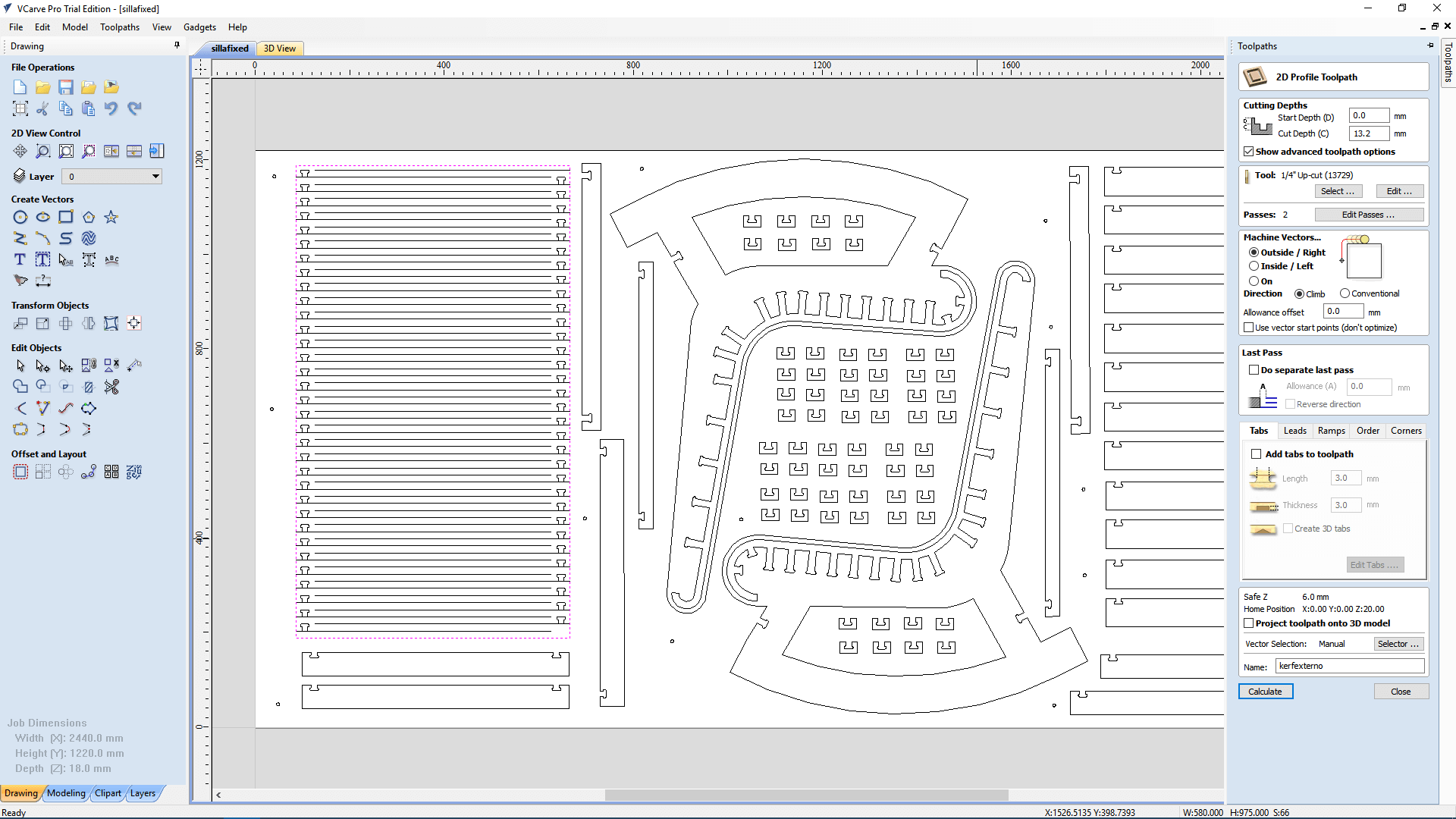

This are the steps i did for for this task:

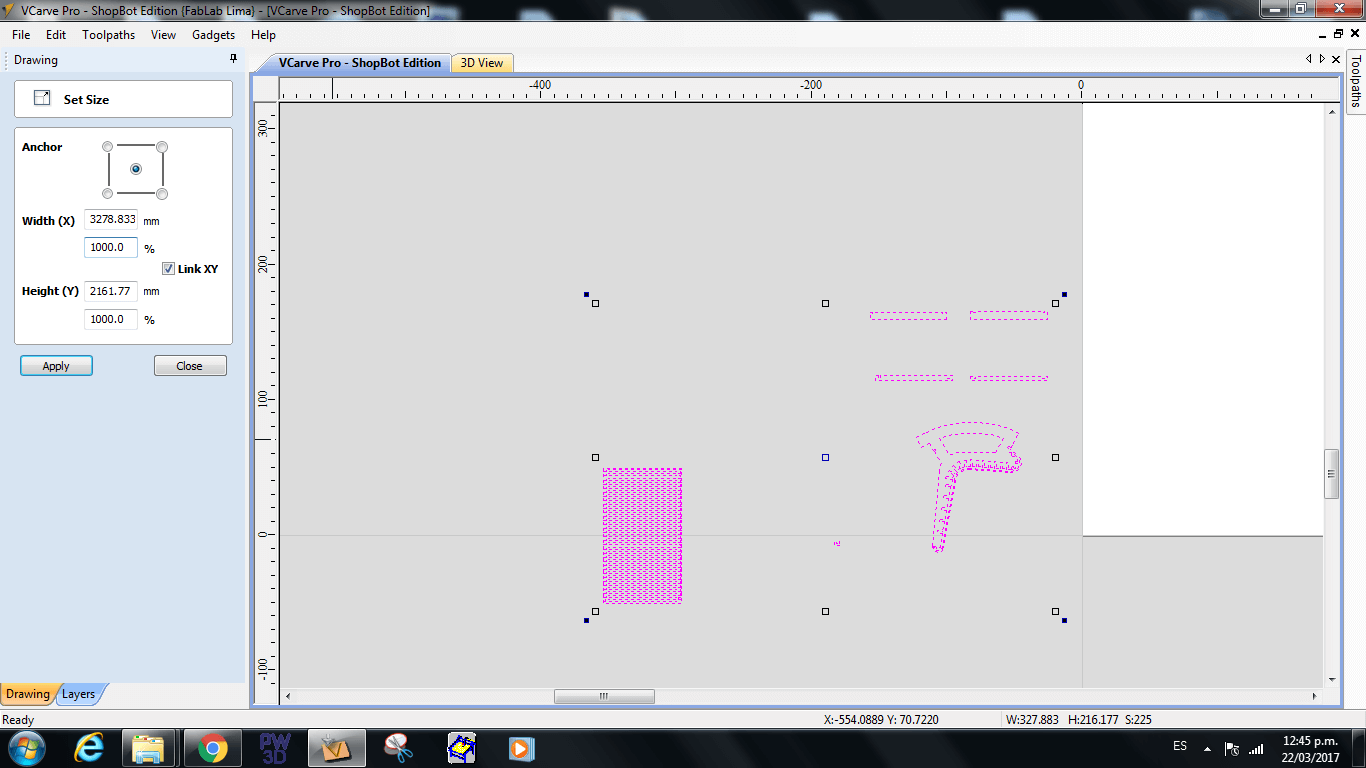

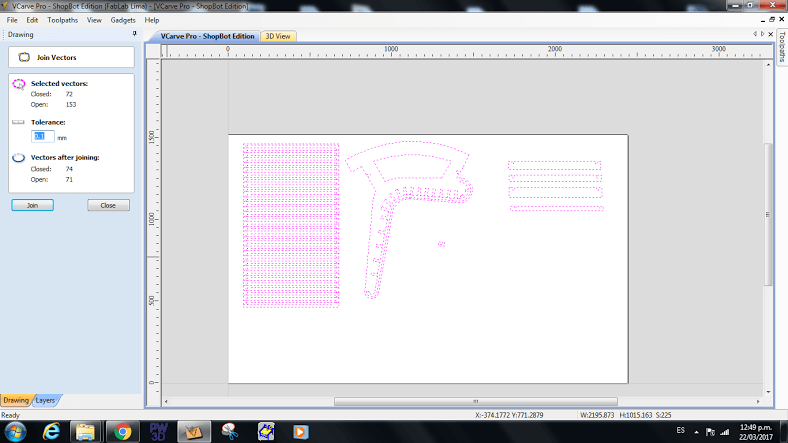

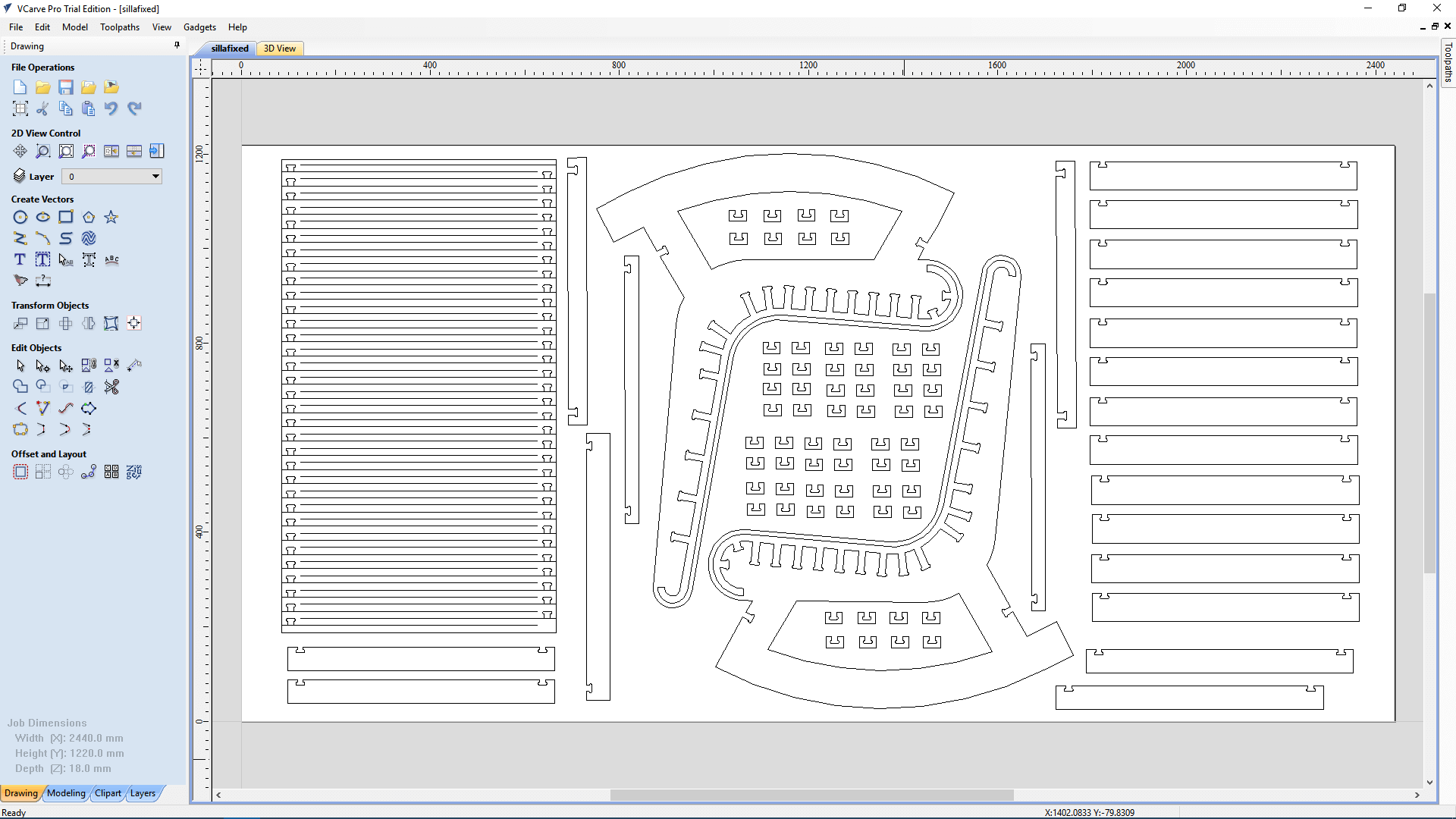

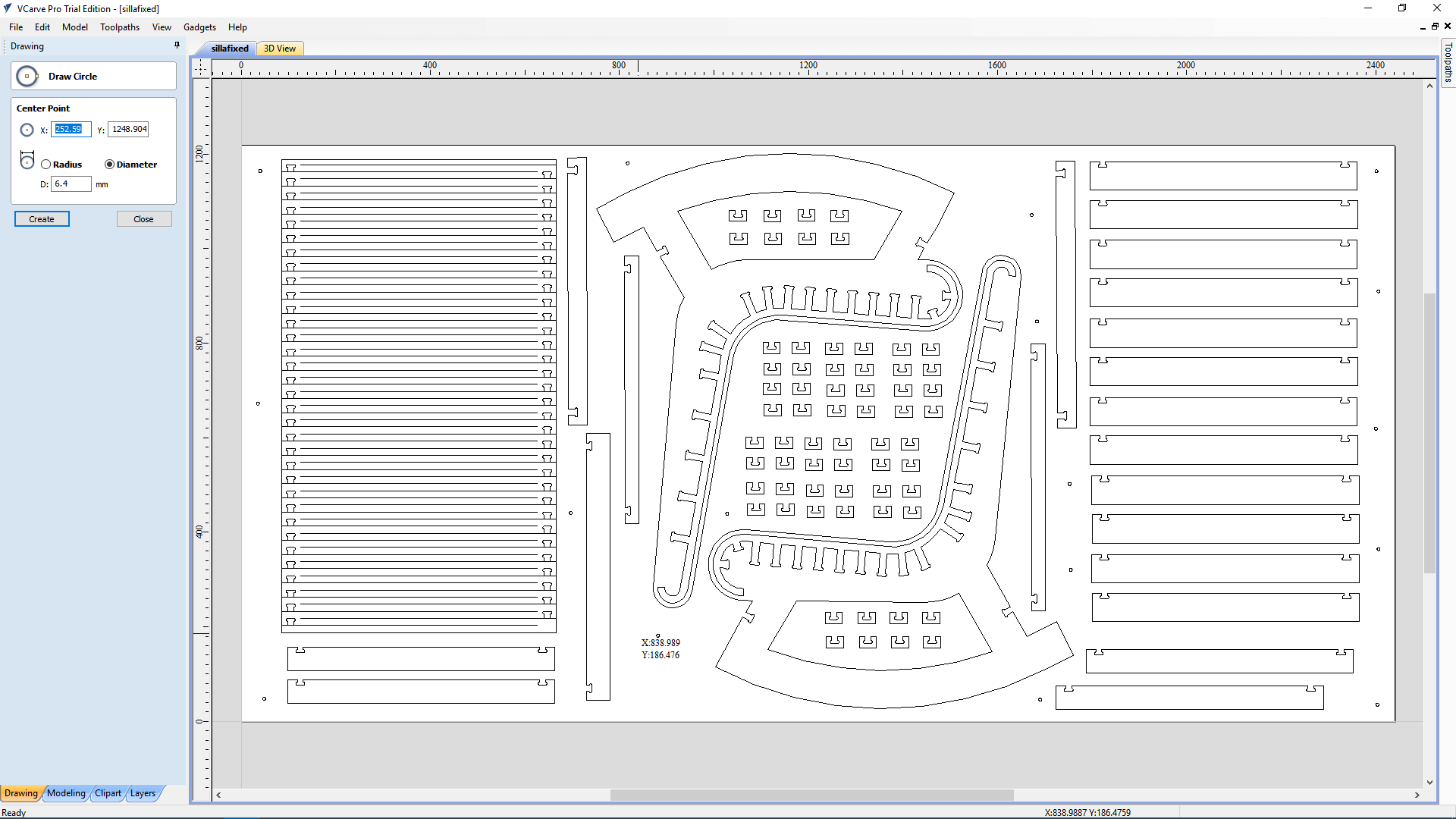

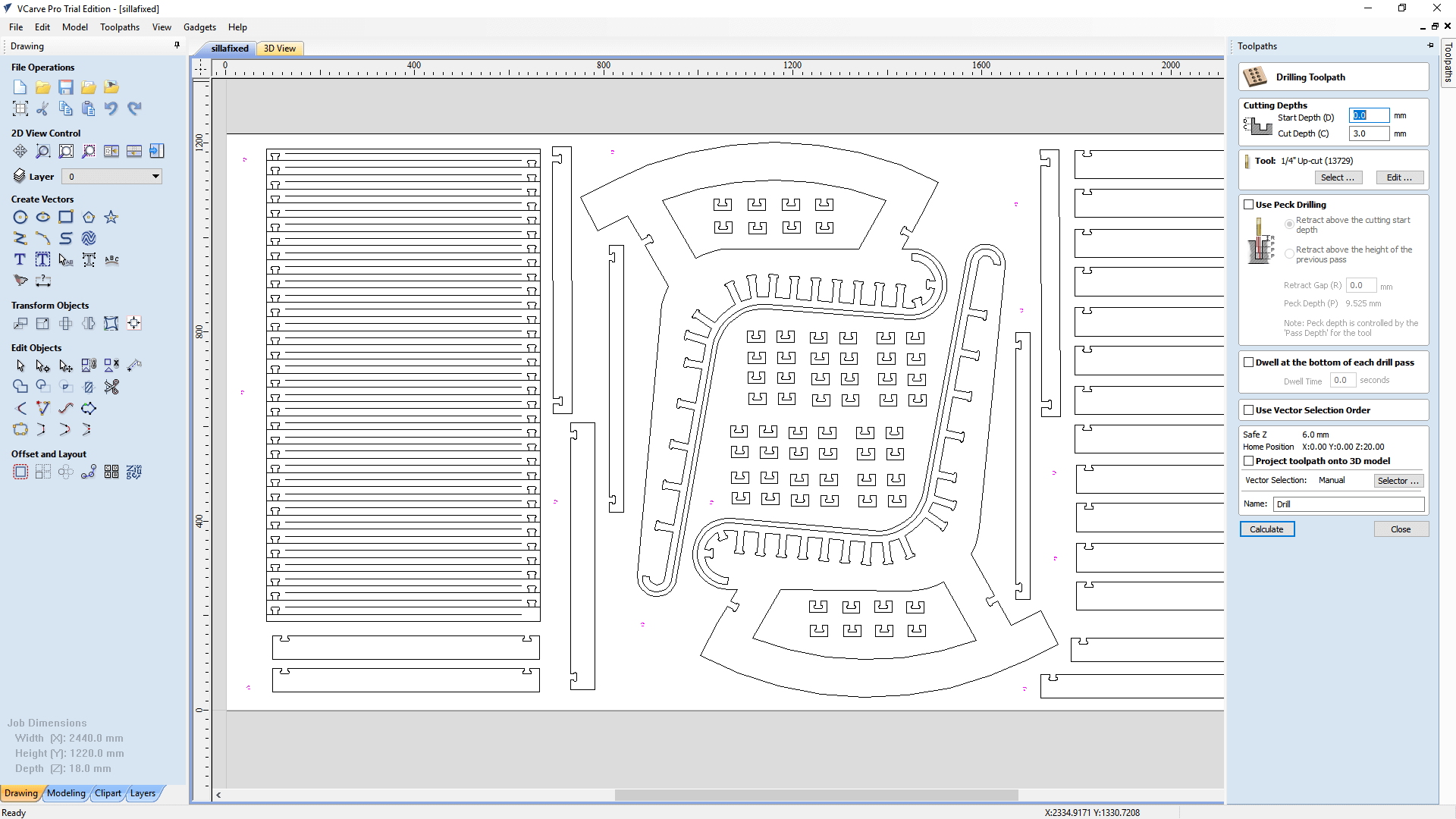

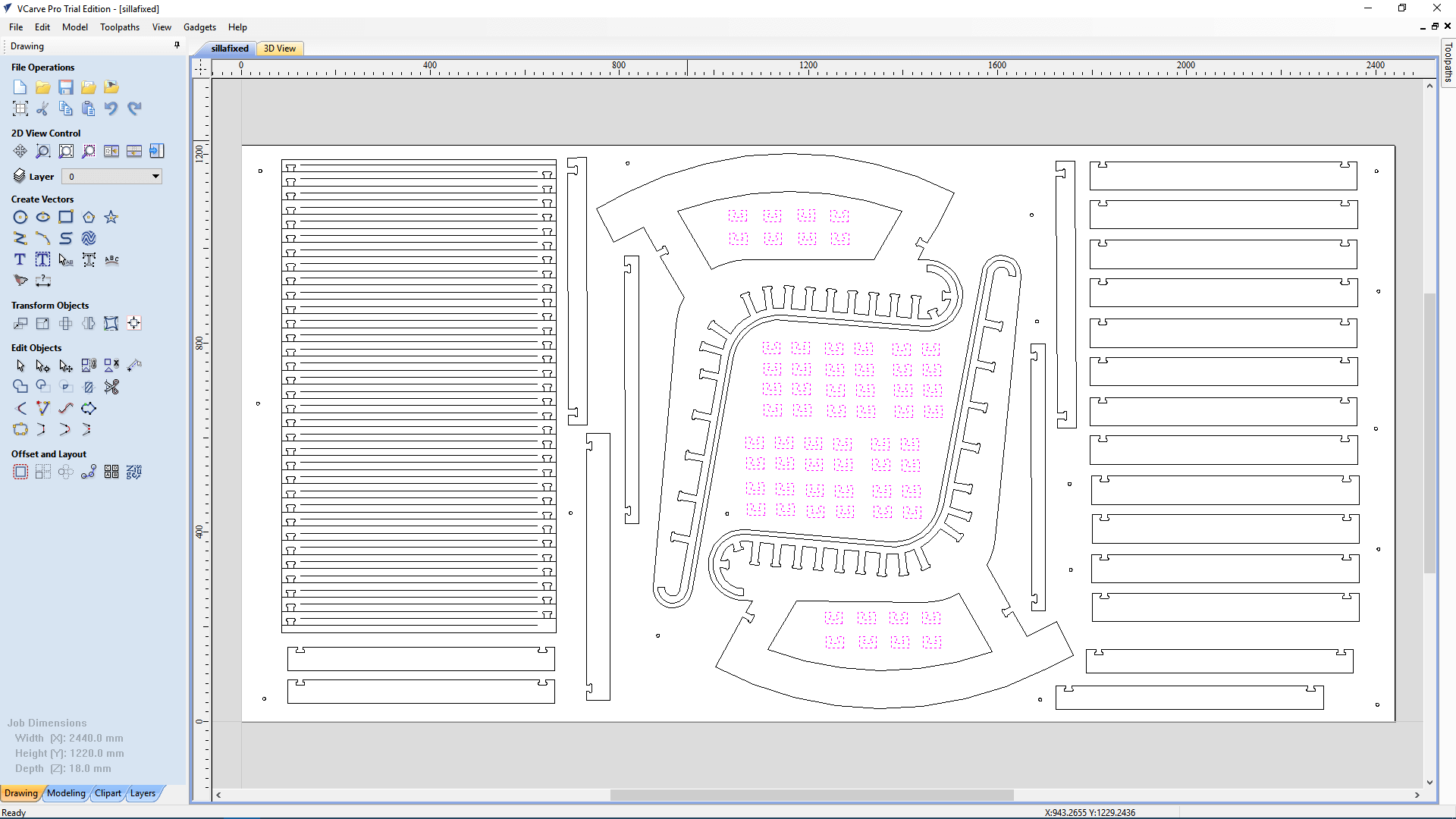

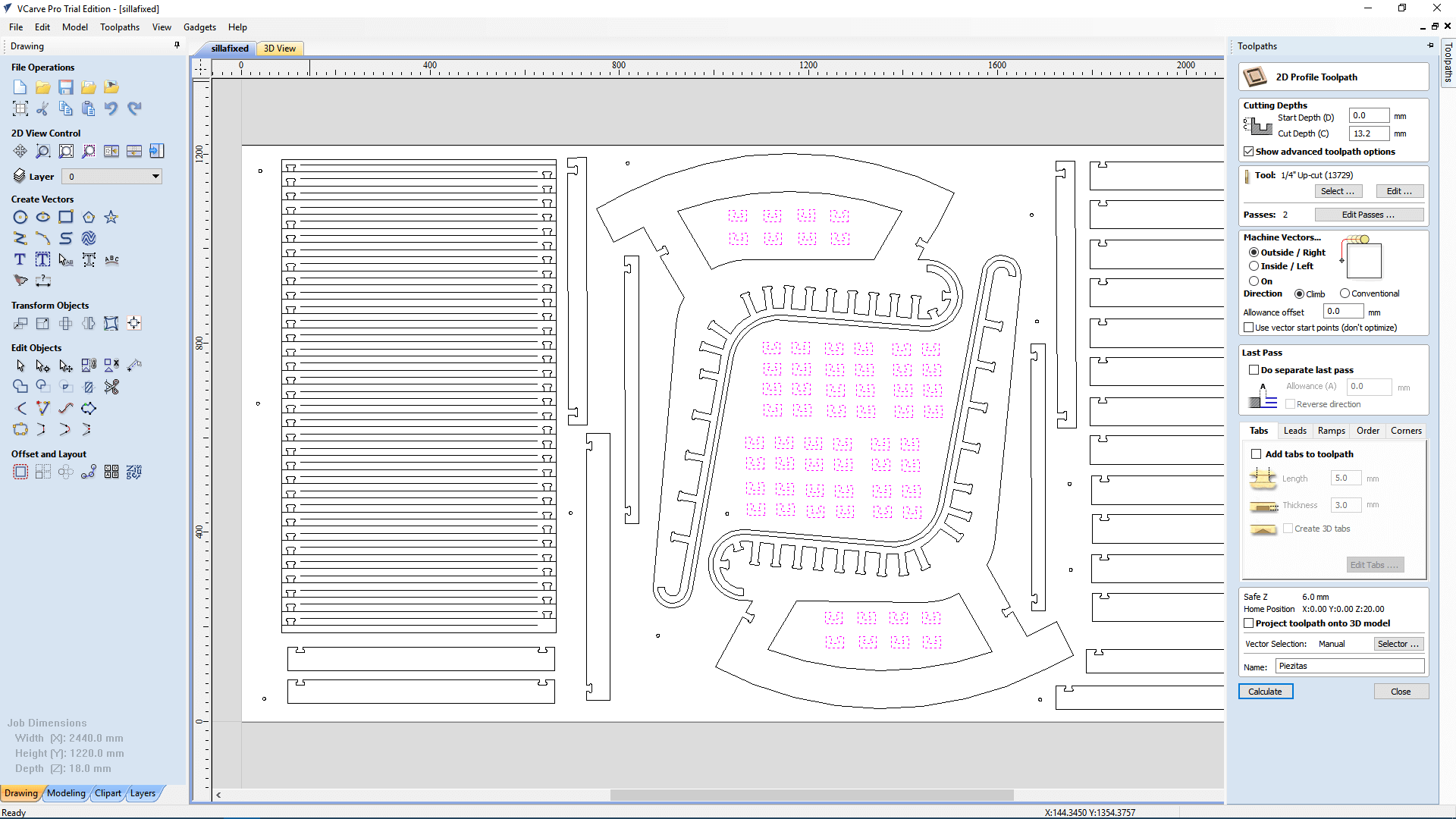

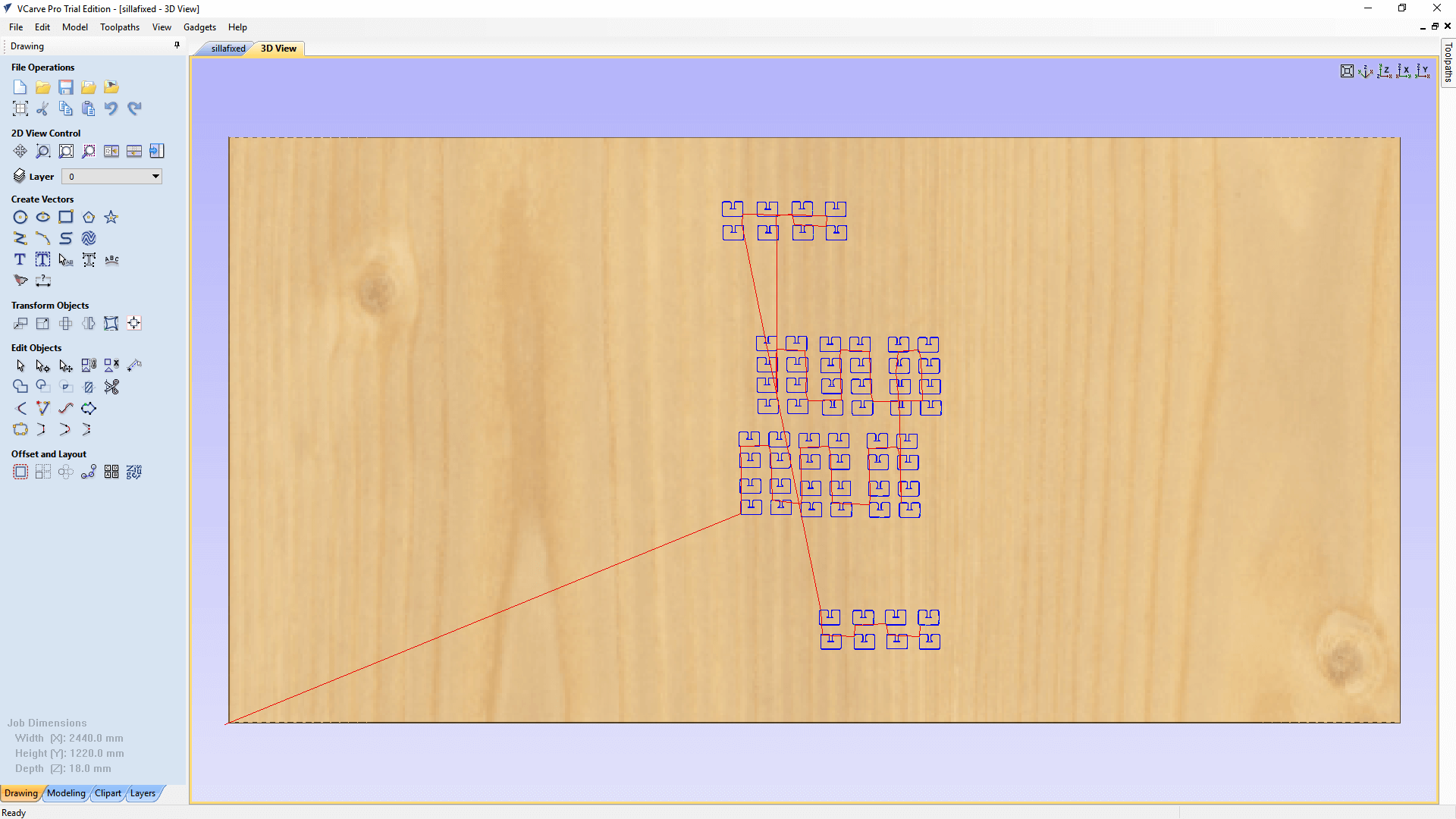

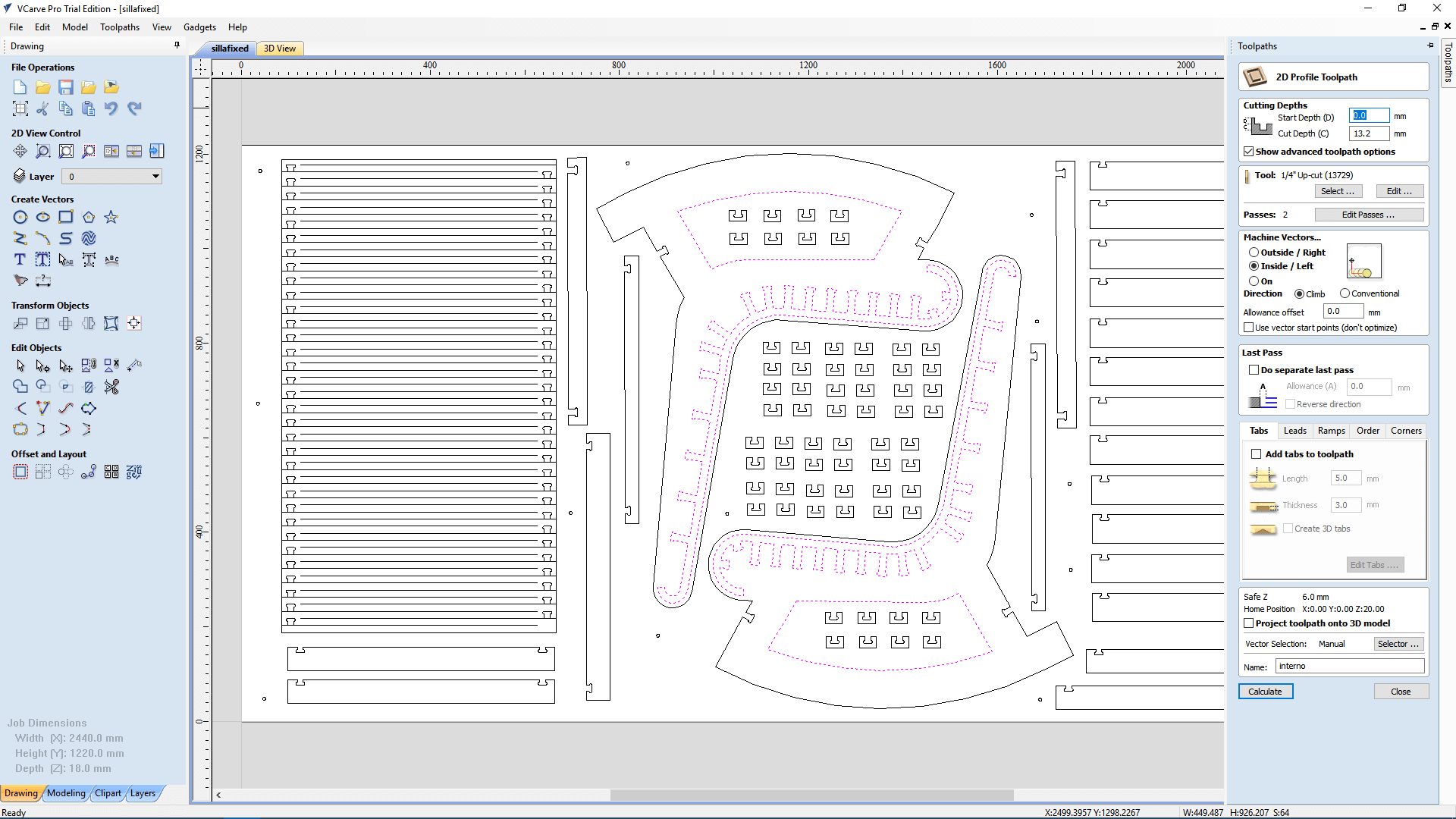

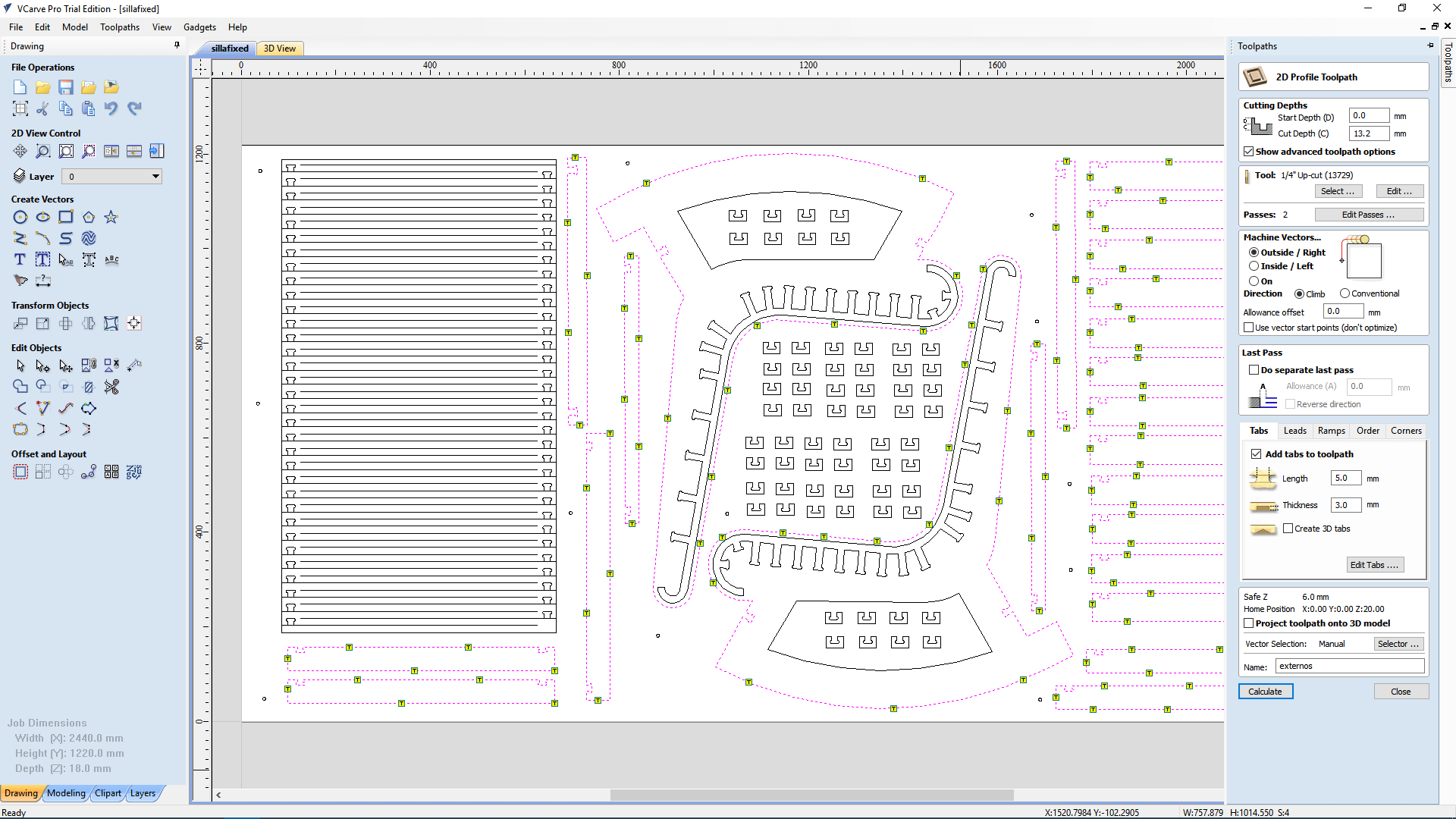

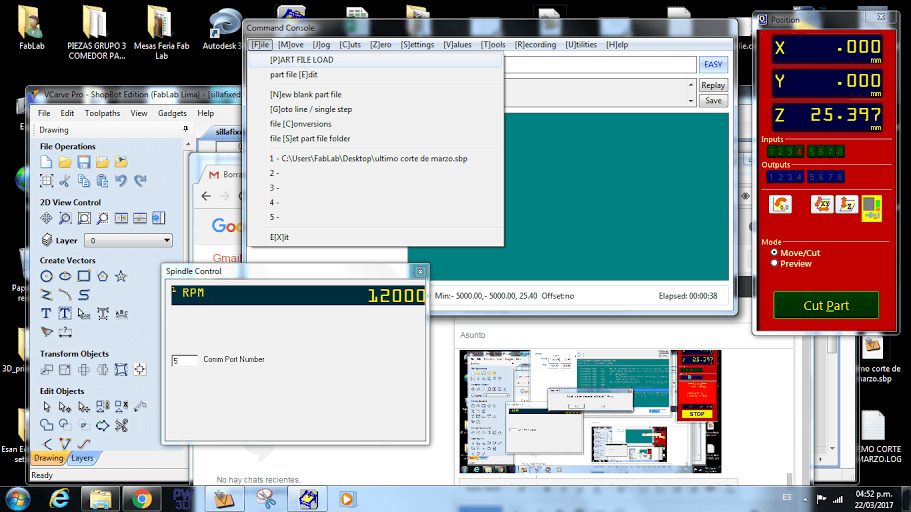

1. First I oppened the Vcarve software created a new document and imported my design by clicking on file import-> import vector.

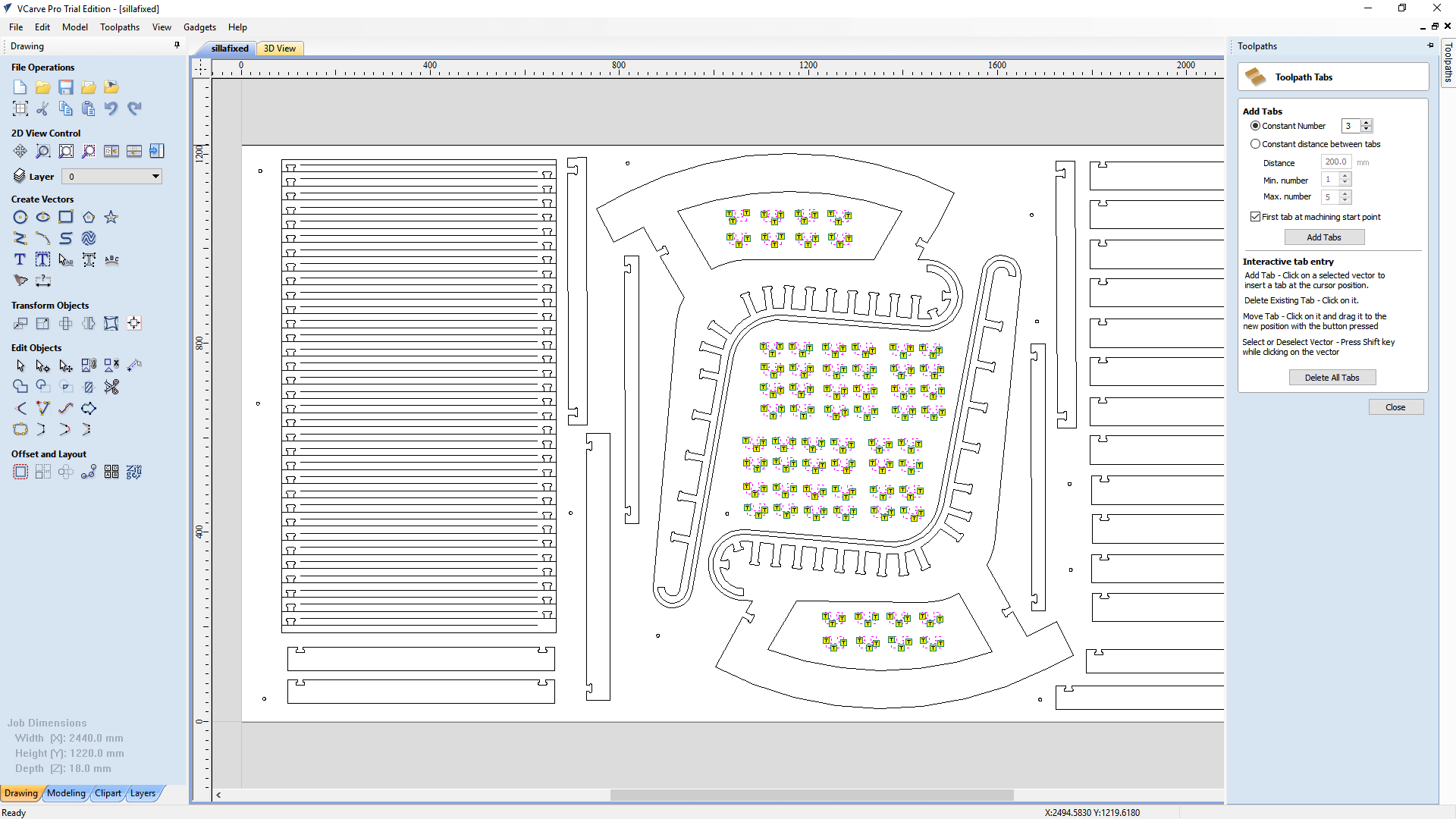

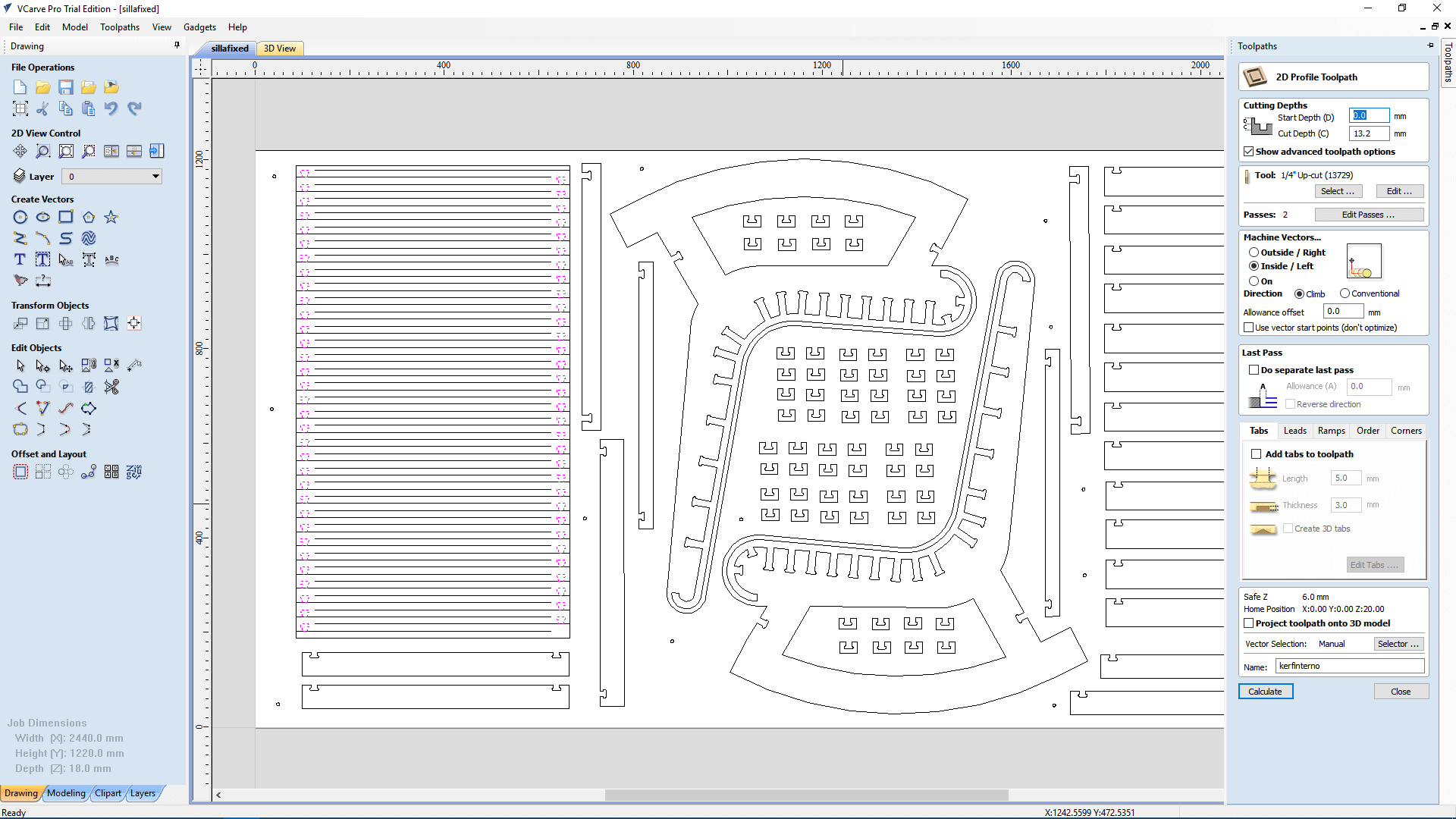

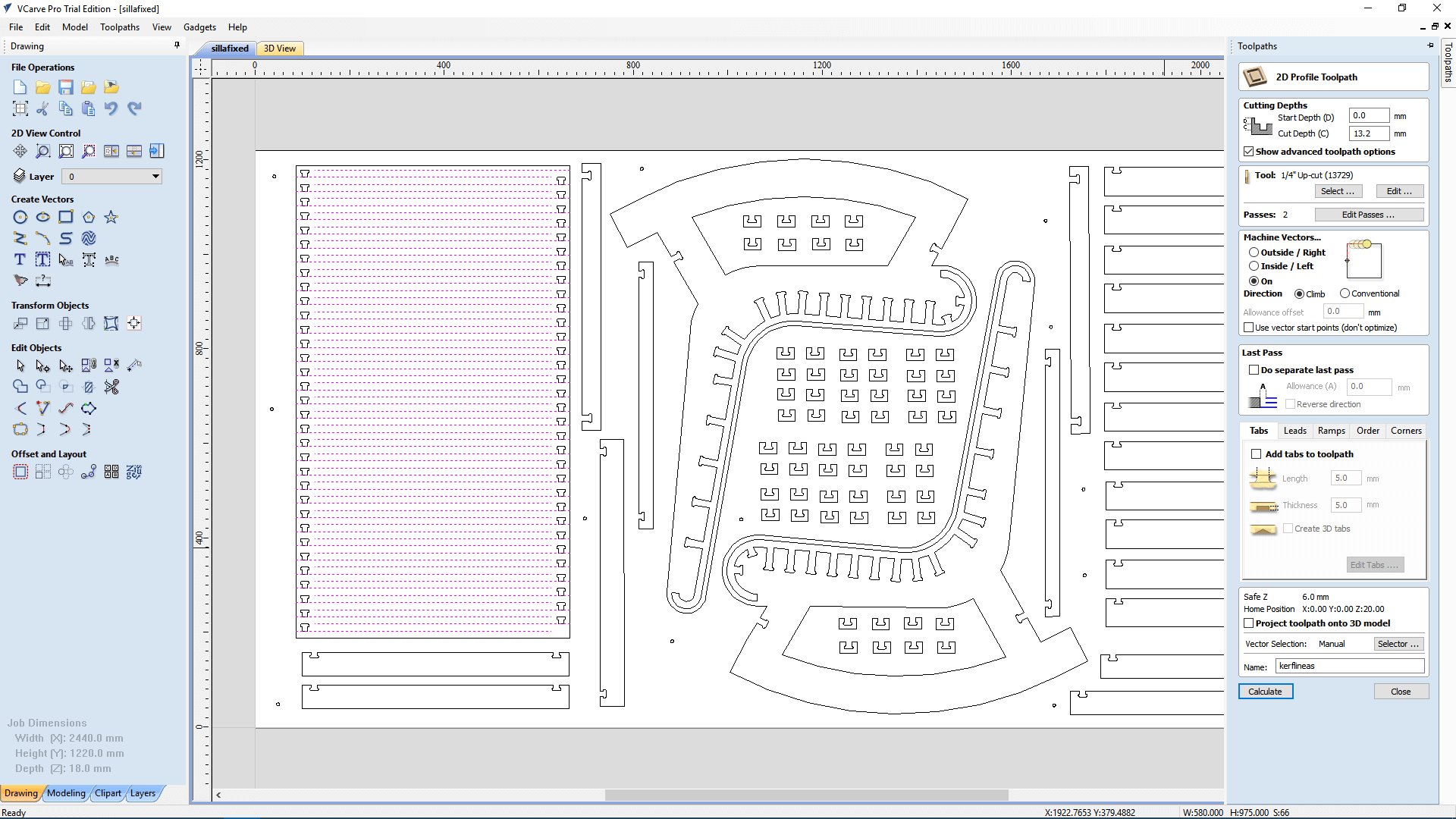

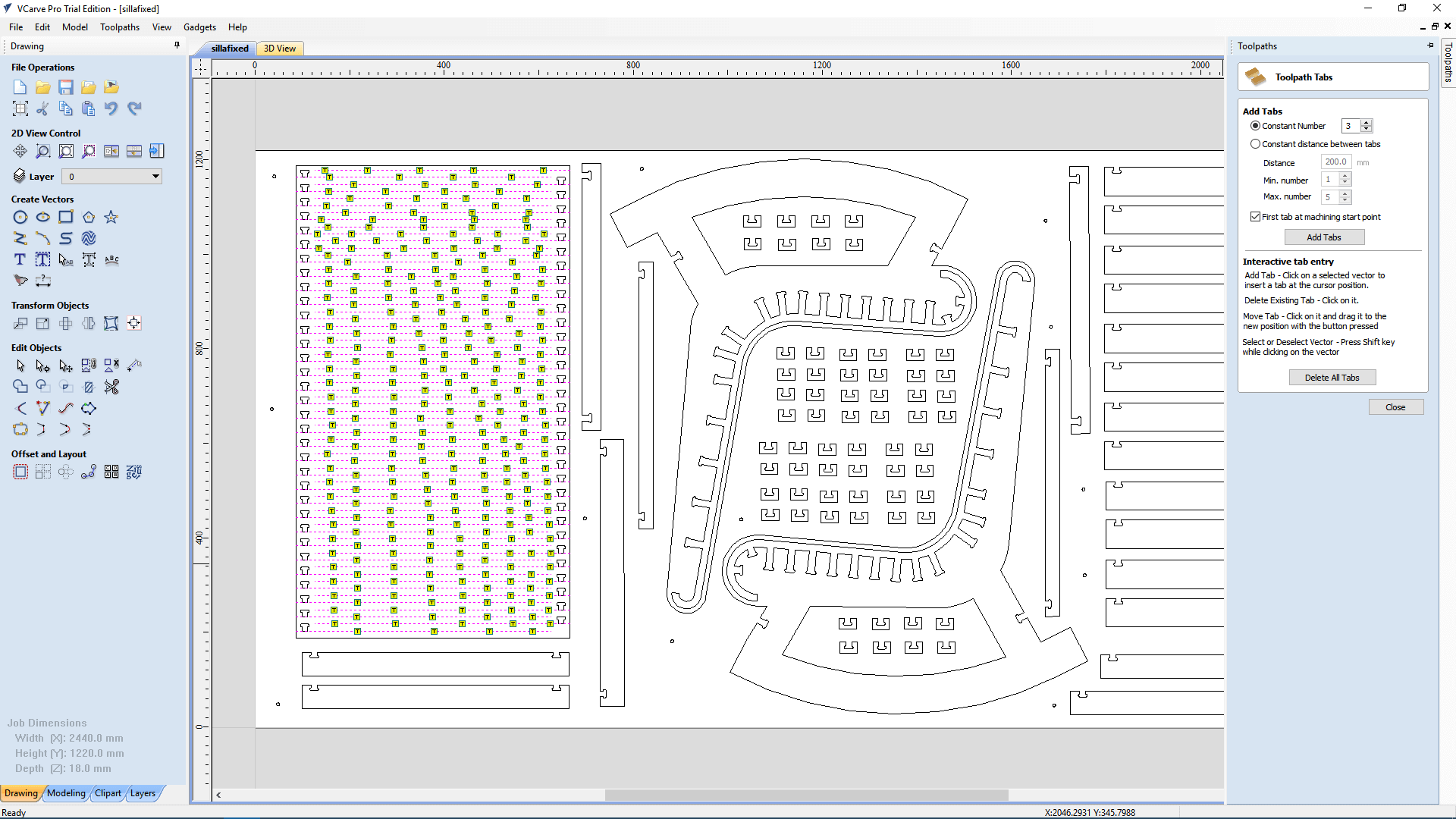

21. I selected the external cut of the kerf and added tabs to every sub.piece of the kerf.

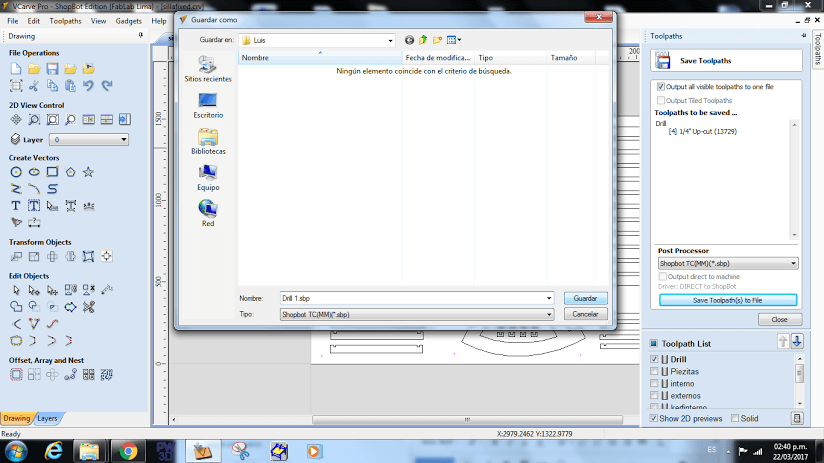

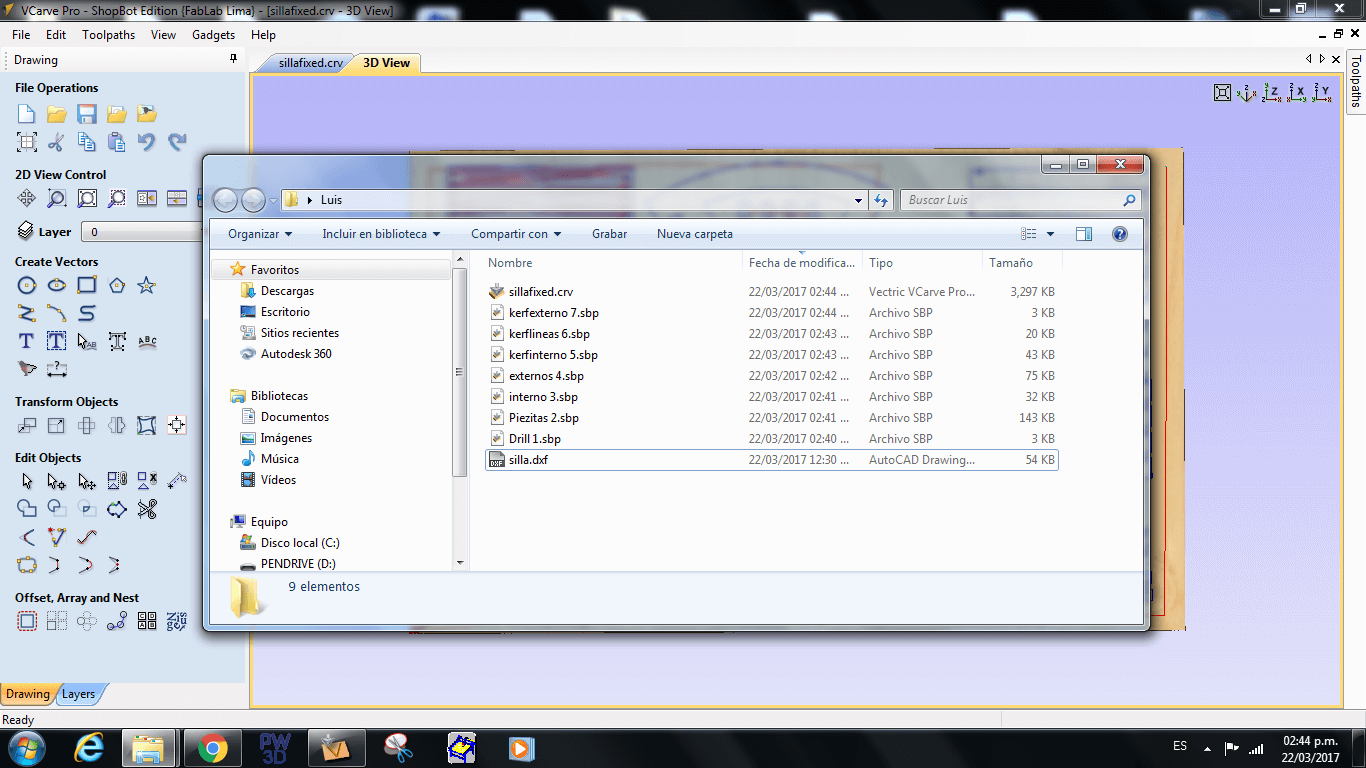

23. Finally, I clicked on save and named the milling path with a number which represents the order of milling.

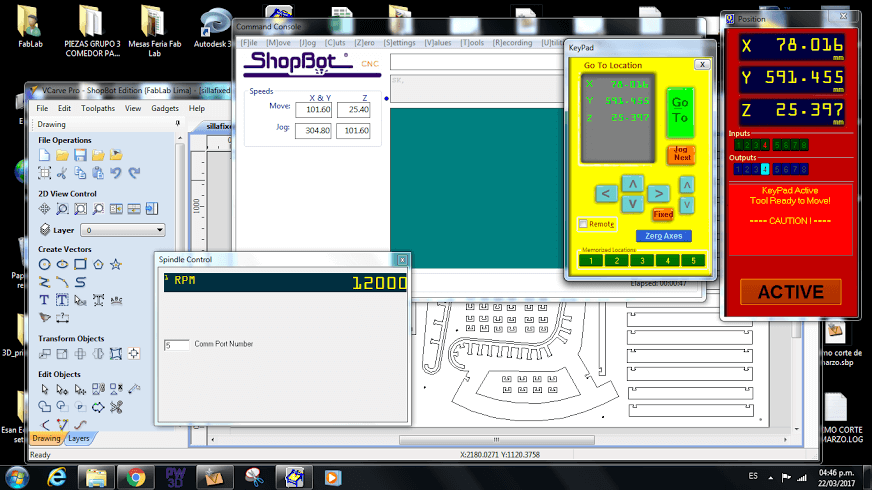

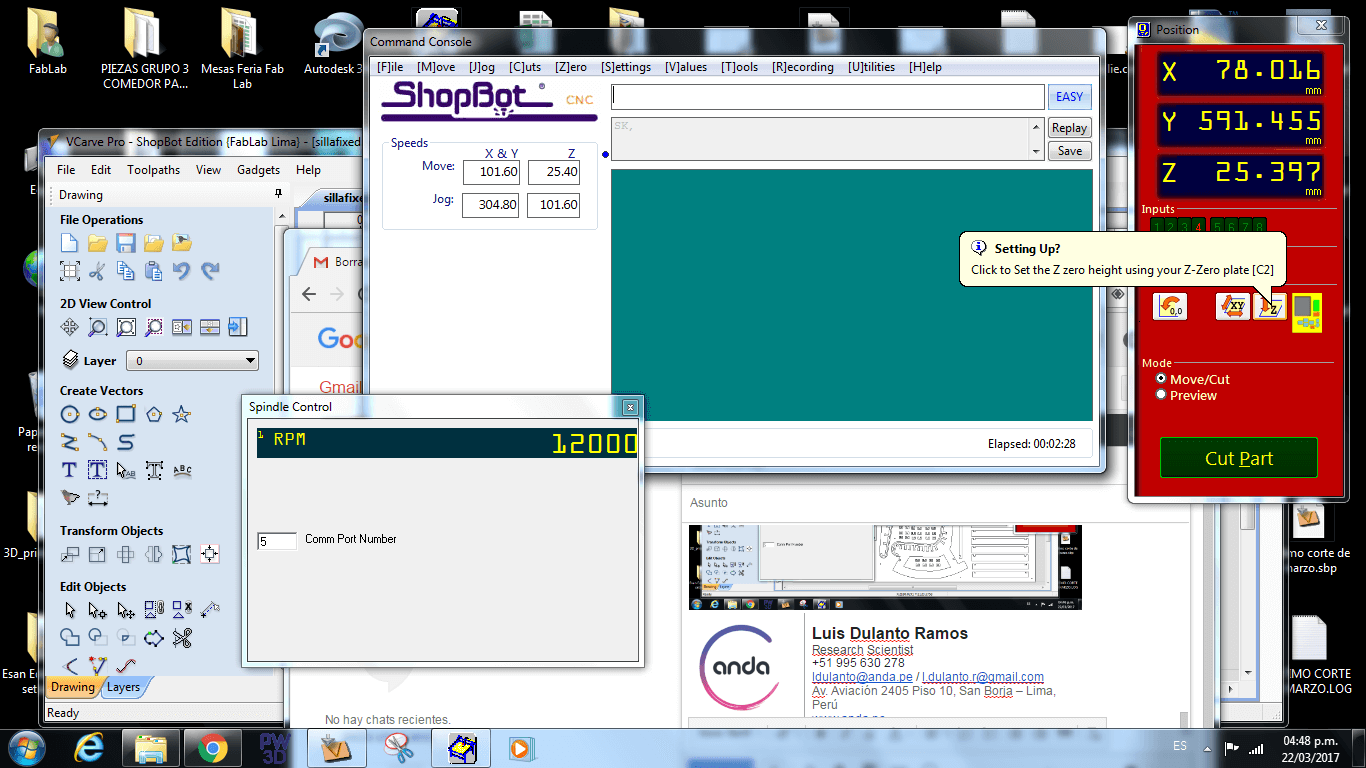

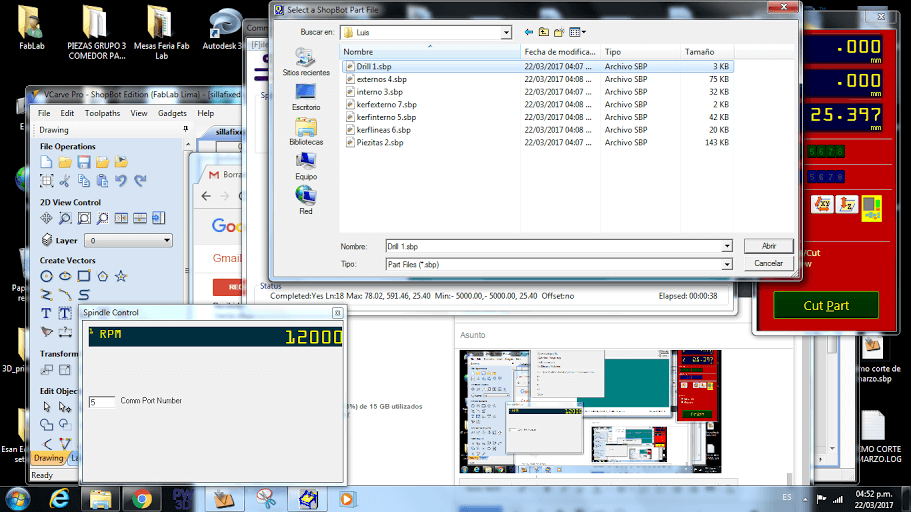

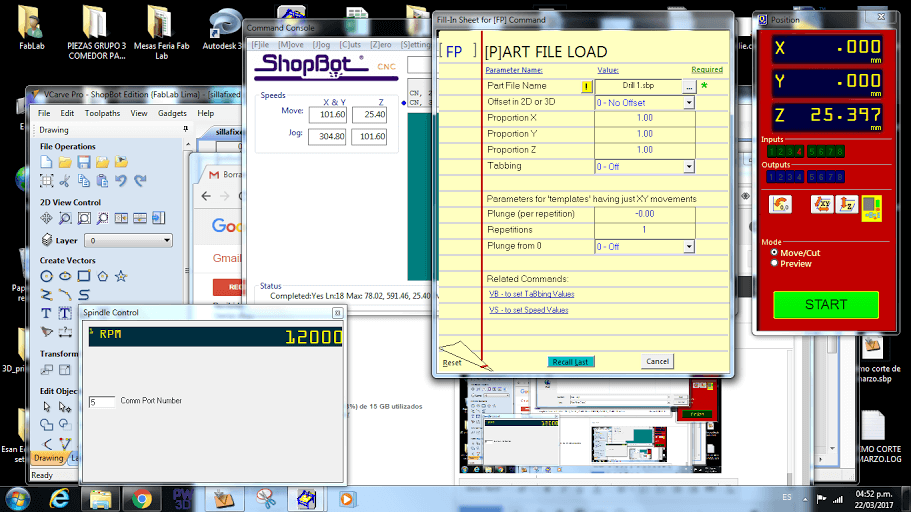

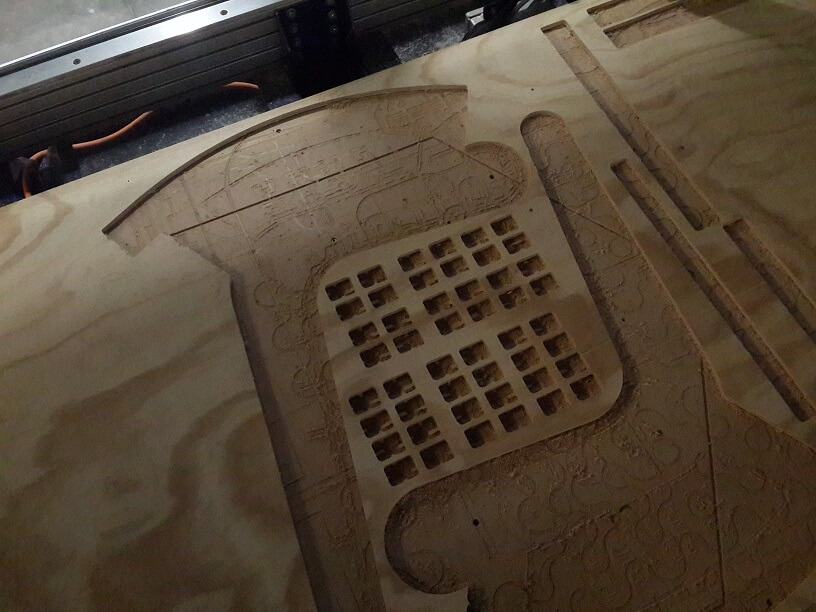

Working with the Shopbot milling machine

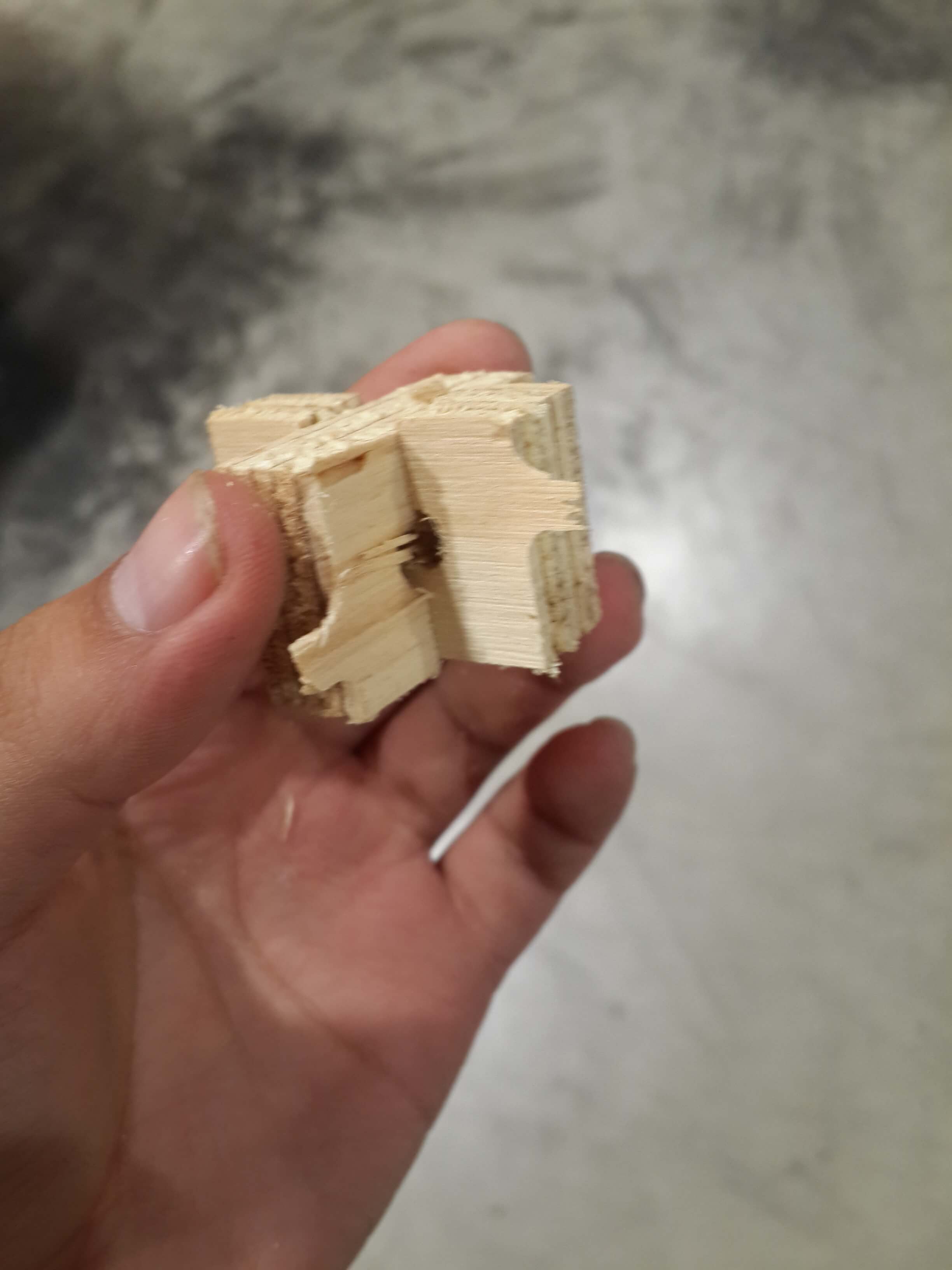

Just to mention, I had many problems when trying to mill the piece designed for kerf bending. At a begining I put only 3 tabs to each line of the design of this piece with a width and height of 5mm x 3mm, however this was not enought. Since when I tried two mill only three consecutive lines of the design, the tabs broke and the wood started to vibrate forcing me to stop the machine. So I fixed this by adding two to three more tabs to each line (having 5 or 6 tabs per line) and giving it a 5mm of height to all of this tabs instead of 3 mm.

Also, when I tried to mill, the machine stopped suddenly like three times and I got a message on the pc saying that it was disconnected. I am not really sure about this, but it seems that the auditory protectors that were on the shopbot were hitting a cable connected to the miller, so I retired and the machine never stopped again. When this issues happened I just recalibrated the machine and resent to mill the pieces that were incomplete because of this sudden stops.

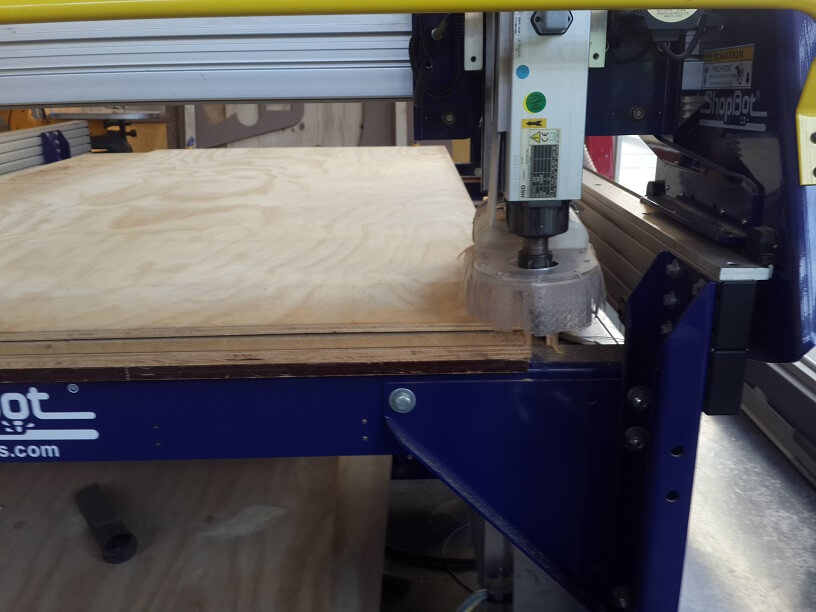

In general, this were the steps I did for milling all the pieces:

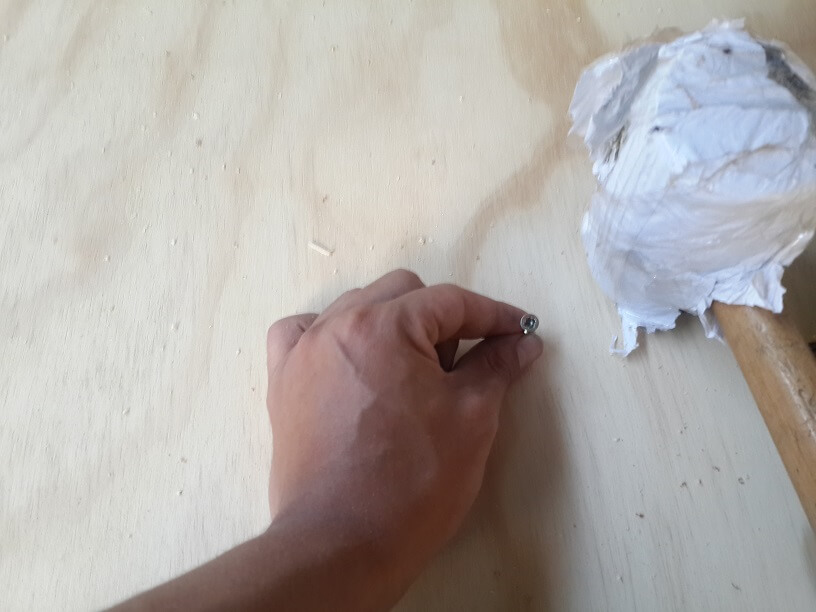

1. I putted the board over the shopbot and fxed it with some presses.

11. After that, I fixed the triplay board to the shopbot by using some screws and a driller.

Final Result

Finally I a assembled all the pieces

And tested the rocking chair with myself.