Week 14

Composites

The fourteenth lecture on Wednesday May the 3rd was about Composites: materials, design, processes, mold, safety. Assignment given by Neil for this fourteenth week was:

- Read material safety data sheets (MSDS) and technical data sheets (TDS) for the resins;

- Design and fabricate a 3D mold (~ft2) and produce a fiber composite part in it

Designing and fabricating a 3D mold, and producing a fiber composite part in it

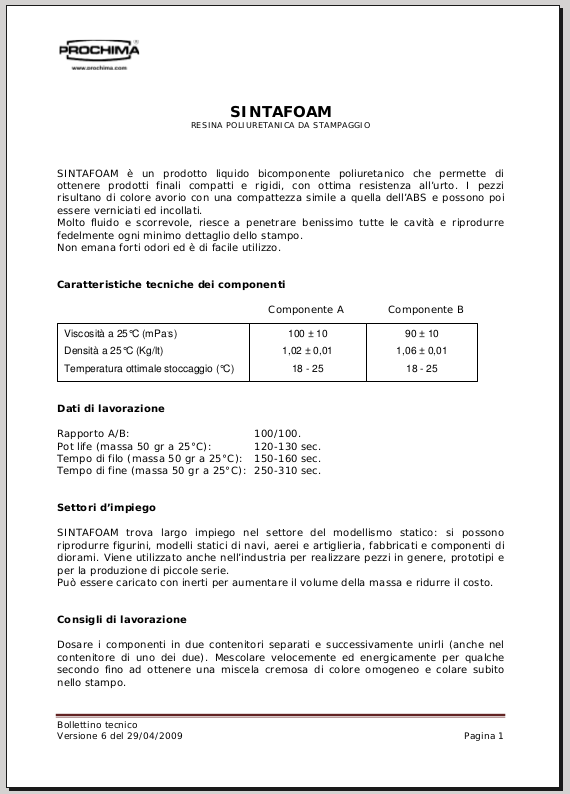

For this week assignment I used a resin from Prochima, one of main resin manufacturers in Italy for rapid prototyping: I decided to use Sintafoam 1.1 resin, a bicomponent resin based on Polyurethane. From the technical data sheet it's possibile to understand that components have to be mixed in a 100:100 proportion, that storage temperature has to be from 18°C to 25°C and that "pot life" is quite short (120-130 seconds).

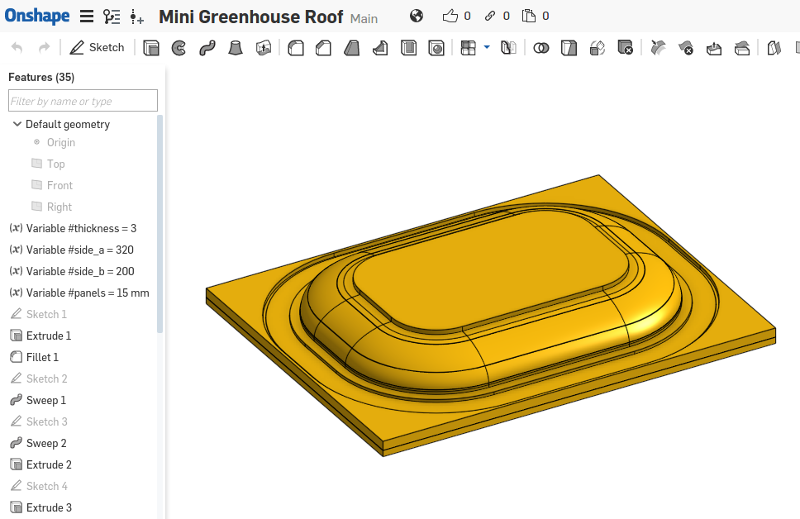

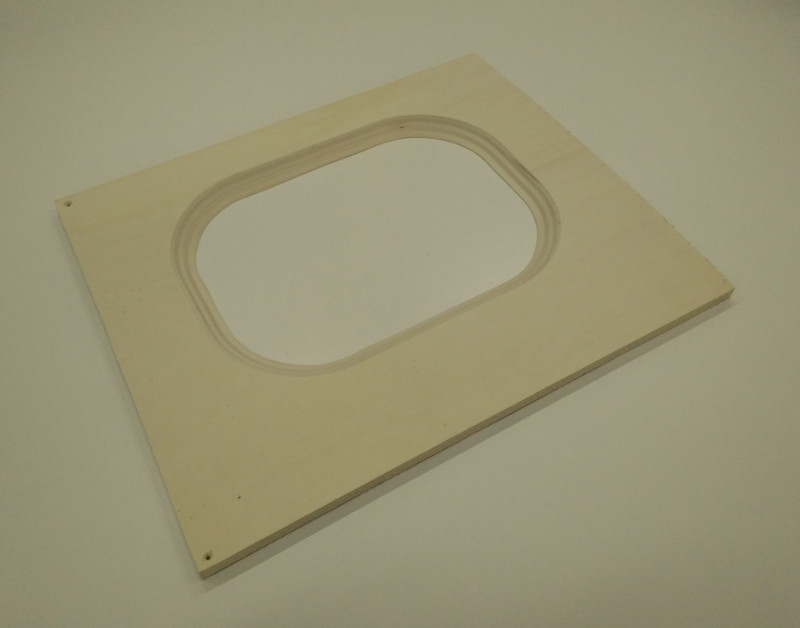

For this week's assignements I decided to produce a Mini Greenhouse Roof, believing composite could be a good component for the scope: very resistant to water, rain, hailstorm and also good to protect plants from sun. I used once again Onshape cloud 3D design software; this is the first part of the mold:

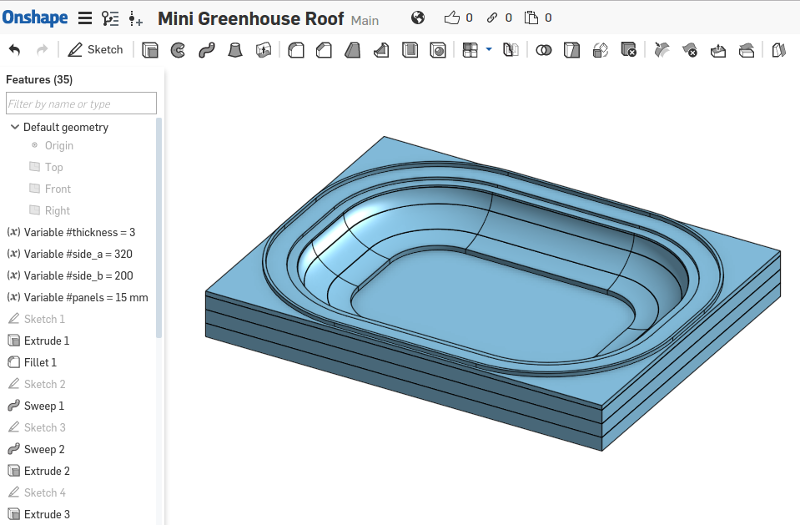

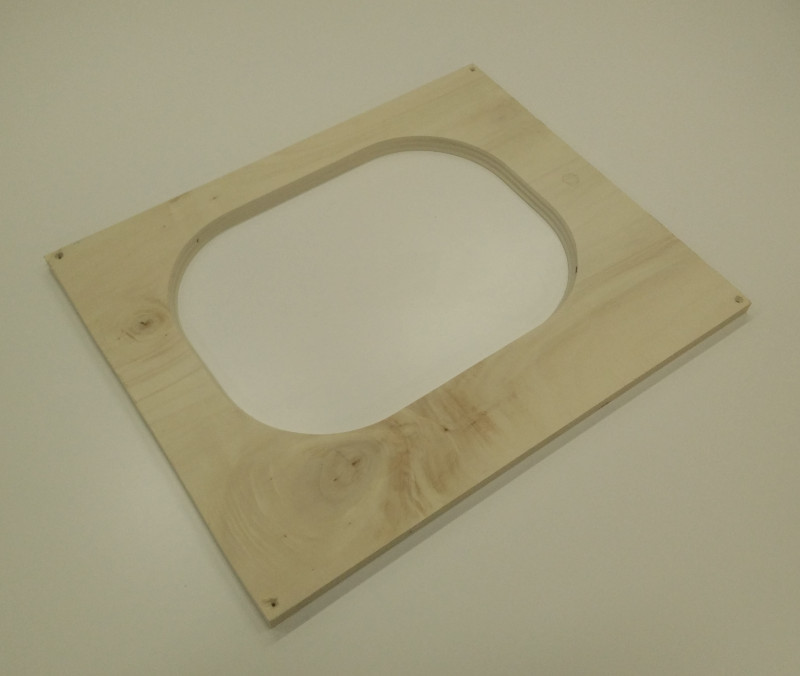

and this the second

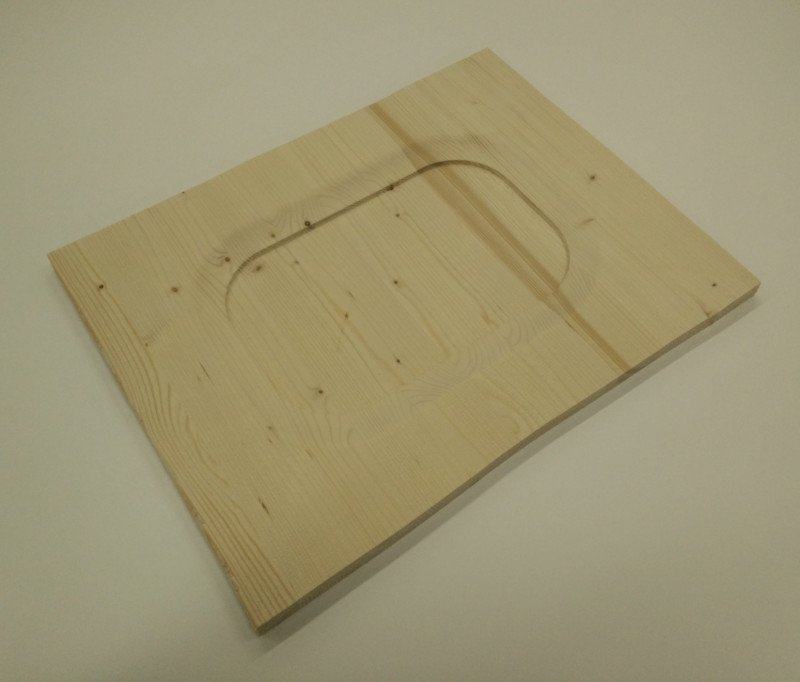

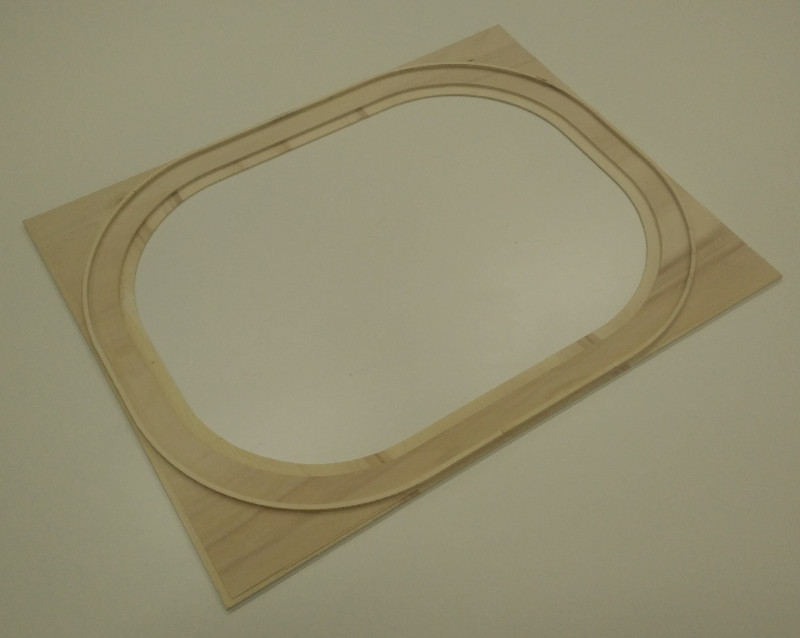

then I milled different parts

(...CNC-Milling...) / 1 -Part A-1

(...CNC-Milling...) / 2 -Part A-2

(...CNC-Milling...) / 3 -Part A-3

(...CNC-Milling...) / 4 -Part A-4

(...CNC-Milling...) / 5 -Part A-5

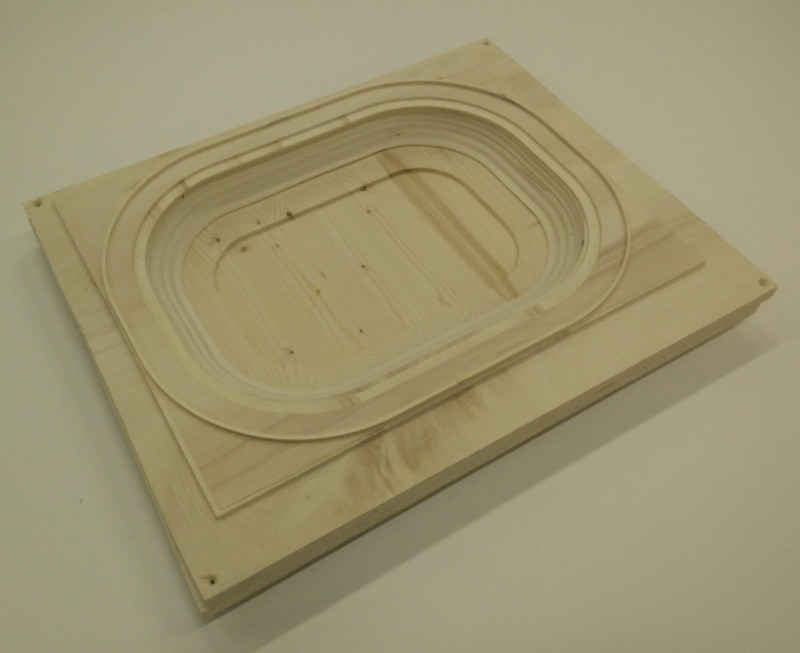

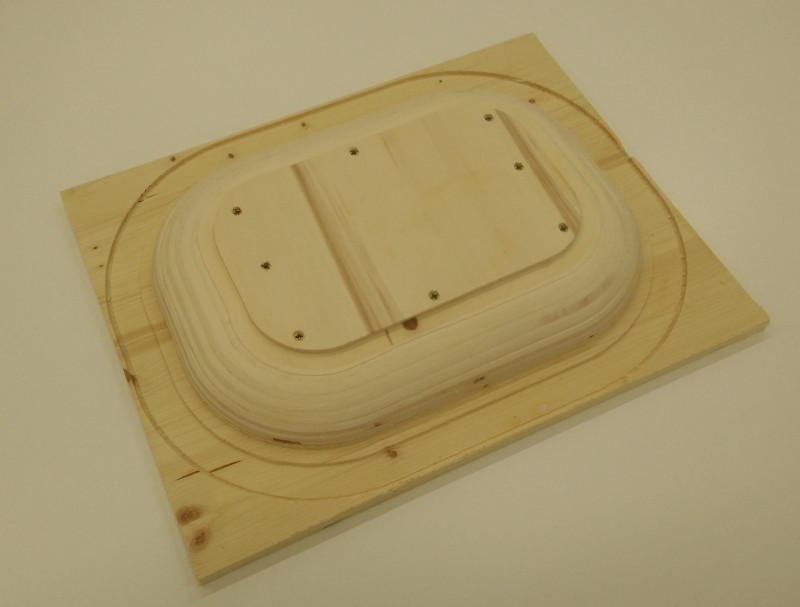

Putting together Part A

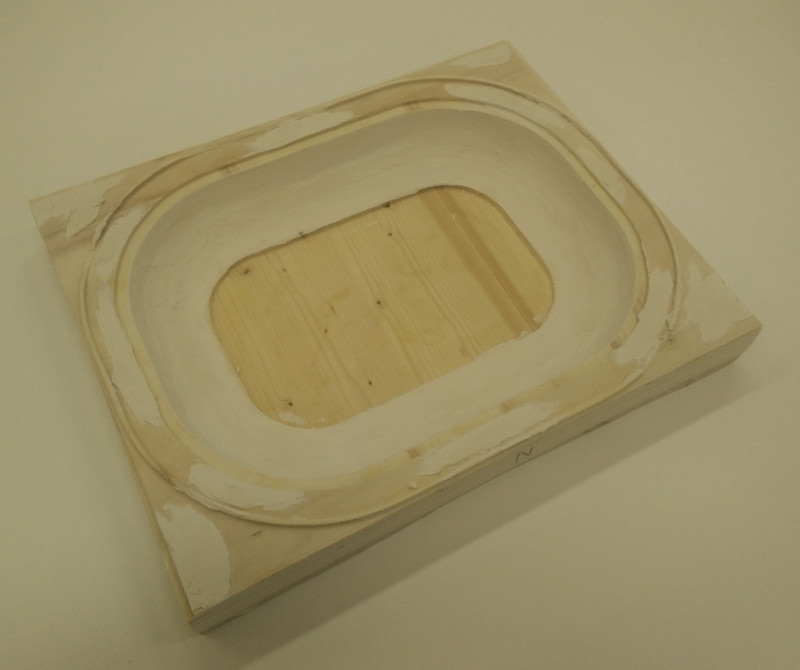

Putting together Part B

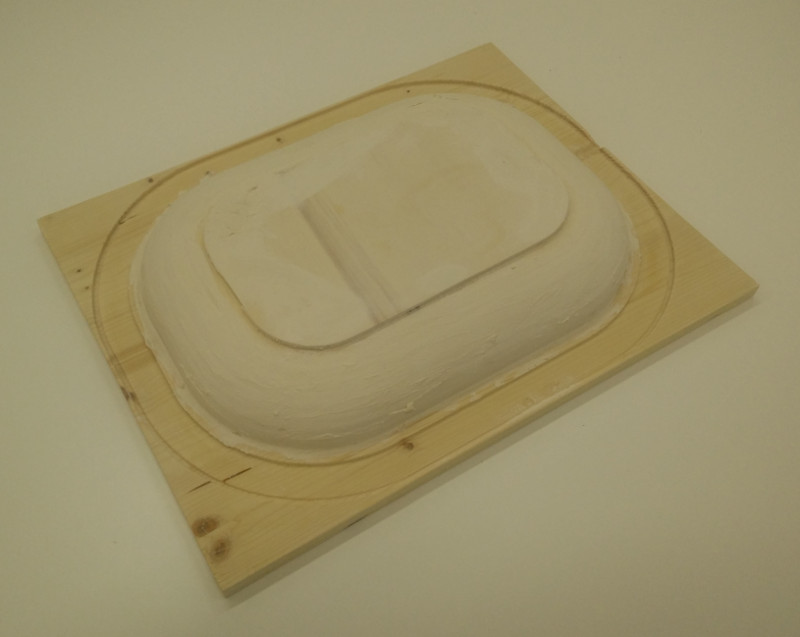

Plastering Part A

Plastering Part B

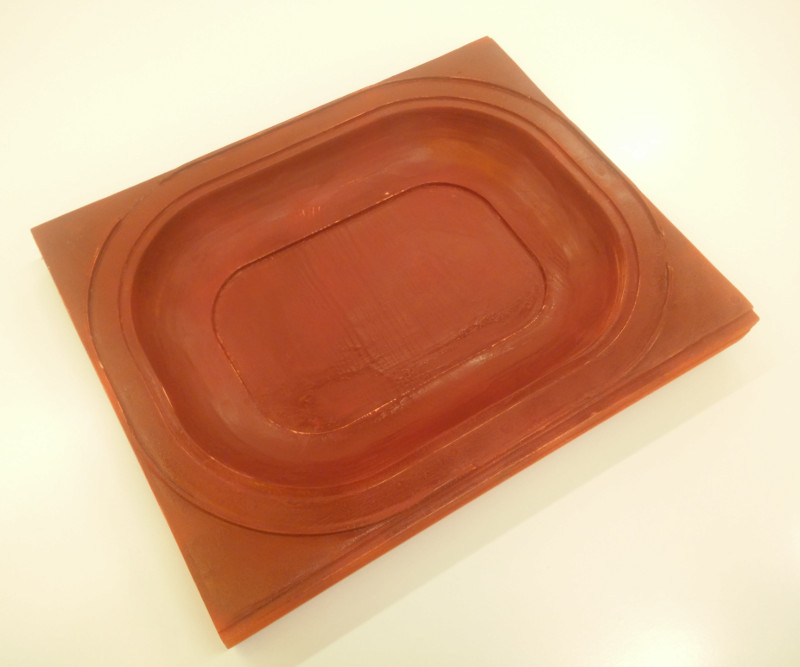

Painting Part A

Painting Part B

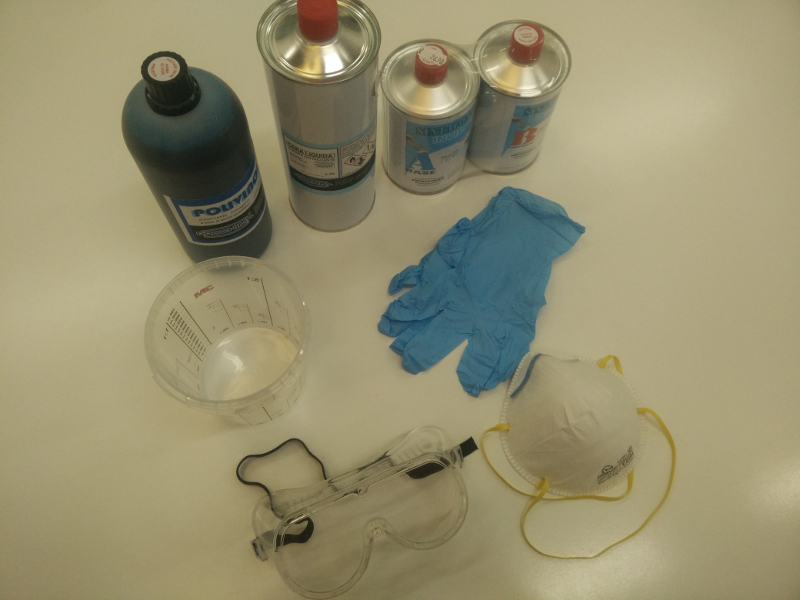

Time to make the composite resin! A small safety note here it's necessary: since resins and fibers can be very dangerous, it's important to make composites with high caution and protection: gloves, dust mask, eye protection.

As said before, resin components (A+B) have to be mixed in a 100:100 proportion; since pot life is very short (120-130 secs), I had to be quite fast

I used cotton and jute natural fibers, crossing layers and adding mixed resin components

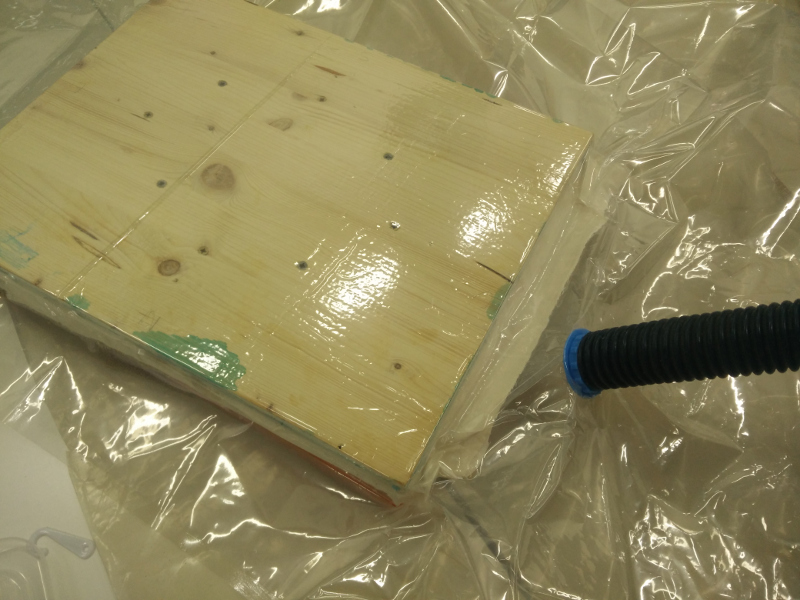

To create compression I used a vacuum bag (small note-to-self: as pointed out by guru instructor Bas Withagen during global review process, this step is not necessary when already having a two-parts mold ready for mechanical compression; furthermore, pulling out air does not really influences -in positive or negative- resin behaviour)

...and two 30 liters tanks full of water!

After 24 hours, I extracted the Mini Greenhouse Roof. Here's the final result: not perfect, but maybe fine for an absolute-beginner level, and good to be used.

Source files

- roof.sldprt -Onshape output SLDPRT File