Download: Rhino Model Final Machine.3dm

Explained your individual contribution to this project on your own website .

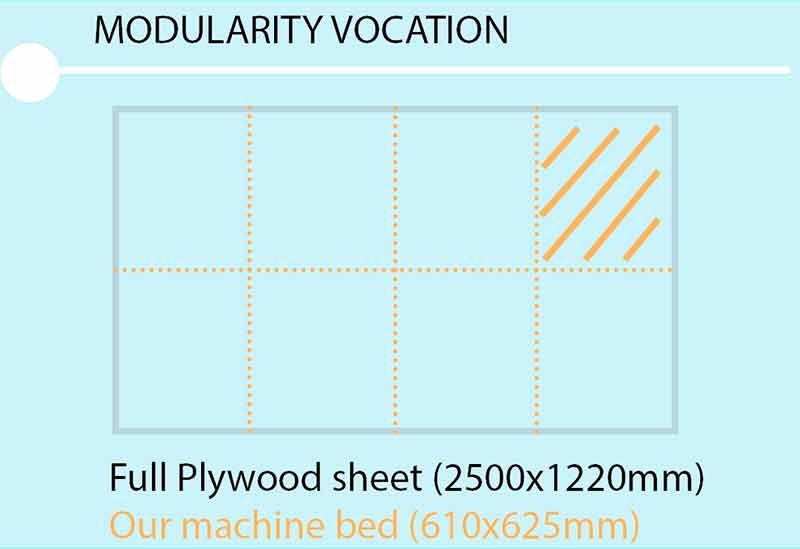

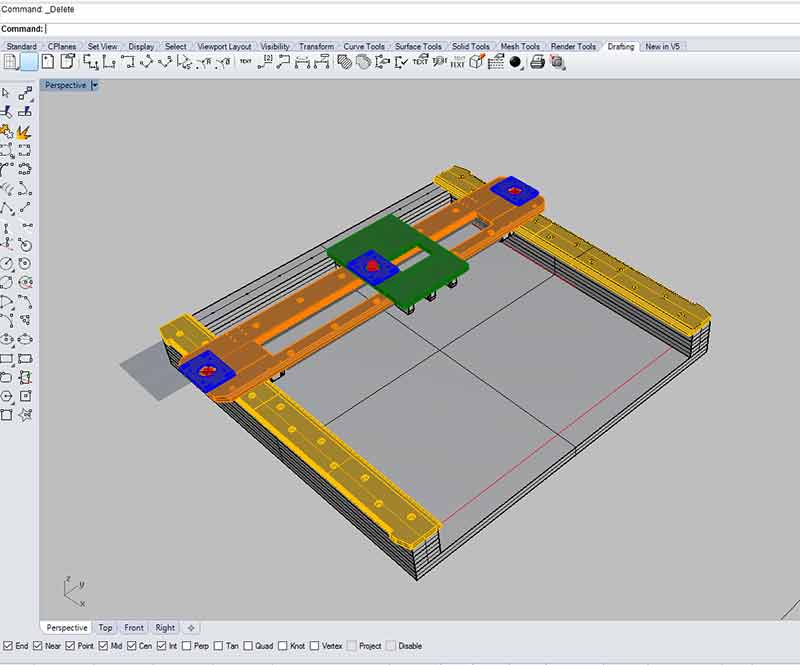

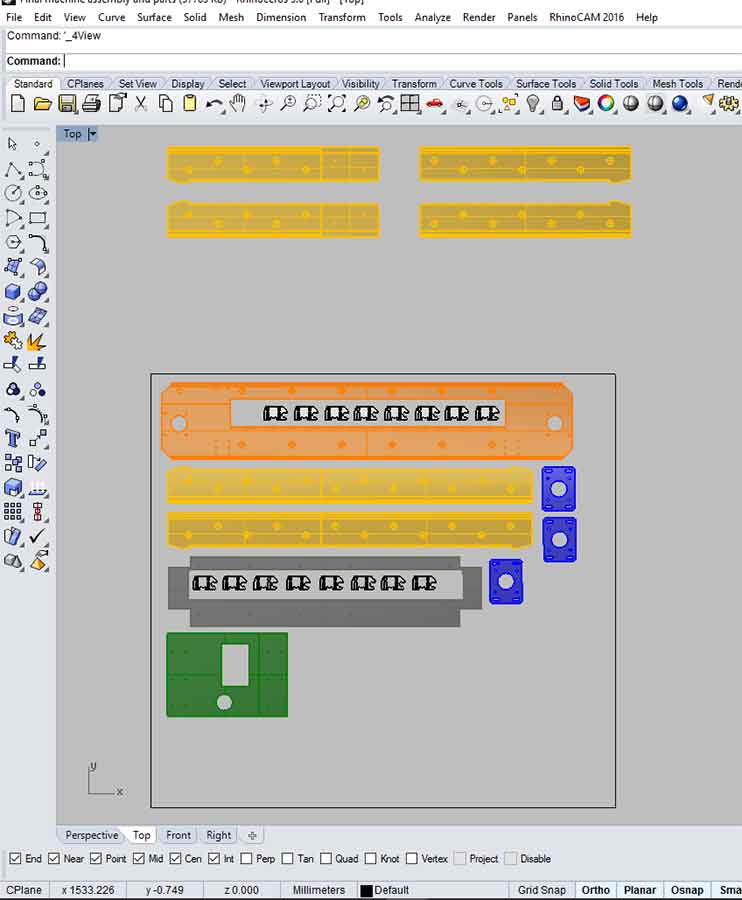

All the info about our machine and group process is on our group web page.The second week's machine was an scale up of the first one. As I was the one in charge of doing the Rhino 3d model and parts the previous week I did it again this week. For the design we had to get rid of some of our initial ideas due to the lack of time. The pressfit joins proved to be a failing point for the machine and as we didn't have time to test the material tolerances to make it work we ended up getting rid of it. We stayed with the fabable materials investigation and used HDPE. As we used brand new materials we could set its size to our taste. We decided to make it 610x625mm. These measures came from the modulation of a 2500x1220 plywood sheet, which is very standard measure here. The idea is that once the machine is fully functional it can grow itself to a full sheet of plywood size. We found there was a piece of HDPE big enough to fit our design. I was very excited to use this material as it is low friction and seemed perfect for the rails. As the machine scaled up, I had to searched for a way to have a squared railing and support. The support was designed to be built out of 3 layers of 30 mm MDF. They were modeled to have a series of machined holes that would square them with screws (or so I thought). This was the same tactic used for the HDPE rails and MDF base, machine the same hole pattern as in the support trusting that the squares will maintain them align. We mixed last week’s machine design with the Jen’s Hank Machine. This changed was mainly on the gliders as we decided to mill them instead of 3d printing them. One of the things we gave up on during this

-Rails: Milled 12 mm HDPE

-Frame: Milled 30mm MDF

-Slide blocks/tighteners: Milled 12 mm HDPE

-Gears: 3D printed

-Motors: Nema 17

-Electronics: Arduino, CNC shield and polulus steper controllers

I also did the RhinoCam. I had to talk a little bit with one of our fabmanagers as HPDE is a material not used a lot. Also it is an expensive enough material to try not to mess it up by doing a crappy cam. This are the values we used and the result was very good. I think we should have gone a little deeper with the V-Shape tool, but the overall milling was great. It is an awesome material to work with.

HOME