Ruby Sun

Fab academy 2017

Week 14: Composites

A. Using Rhino for design

B. Using Roland Modela Player 4

C. The Milling process

D. Making the composites

A. Using Rhino for design

The concept for the composite is to make a hand which is in the action of holding somthing in the palm and the inspiration is from the picture from below.

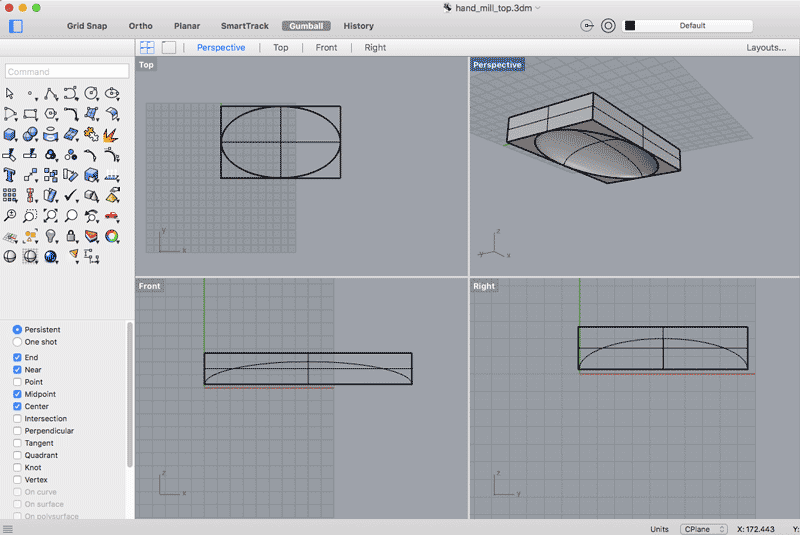

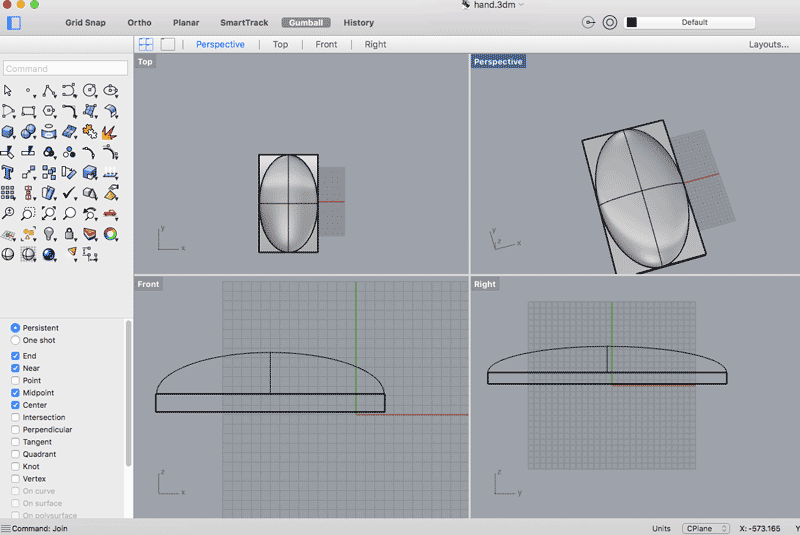

After knowing what i want to make, i used Rhino for drawing the mold, which contains two parts, the top and the base. The piece of cloth which is hand-shaped, will be put in between the mold to make the curve shape.

B. Using Roland Modela Player 4

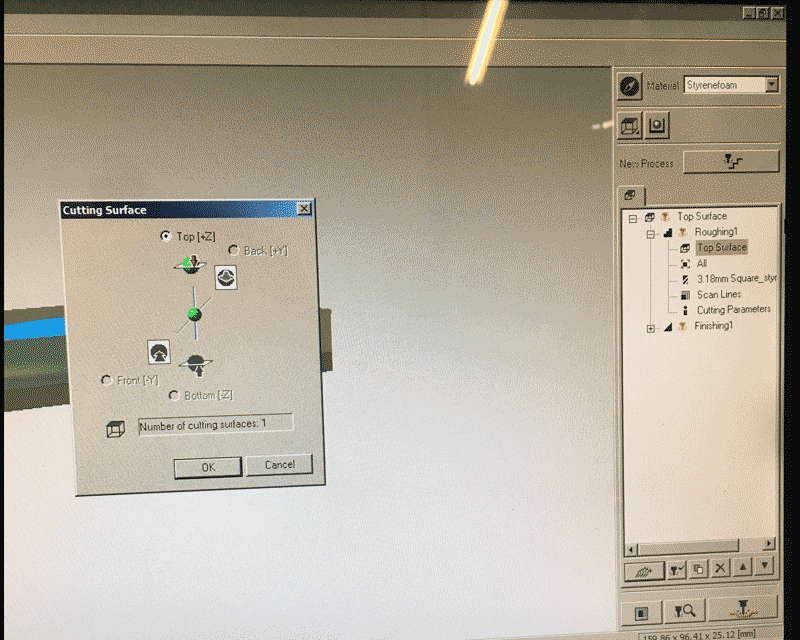

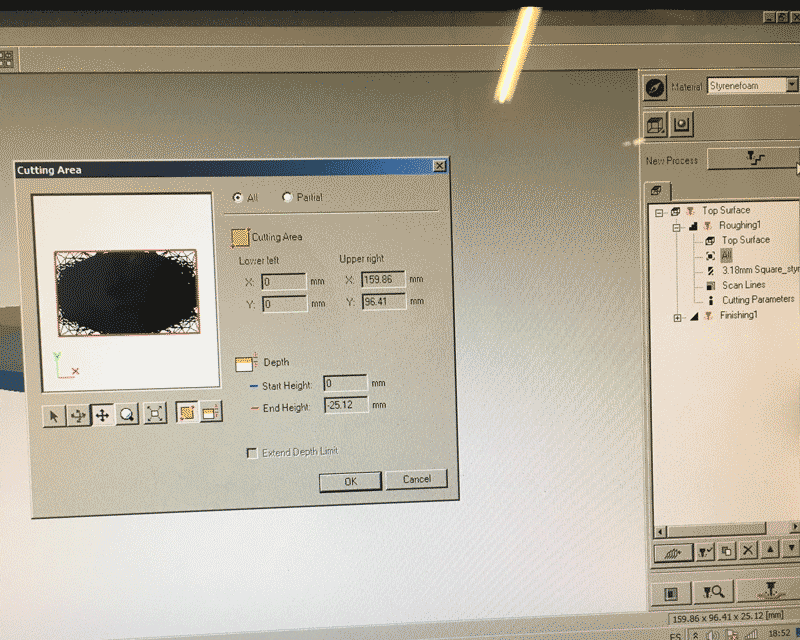

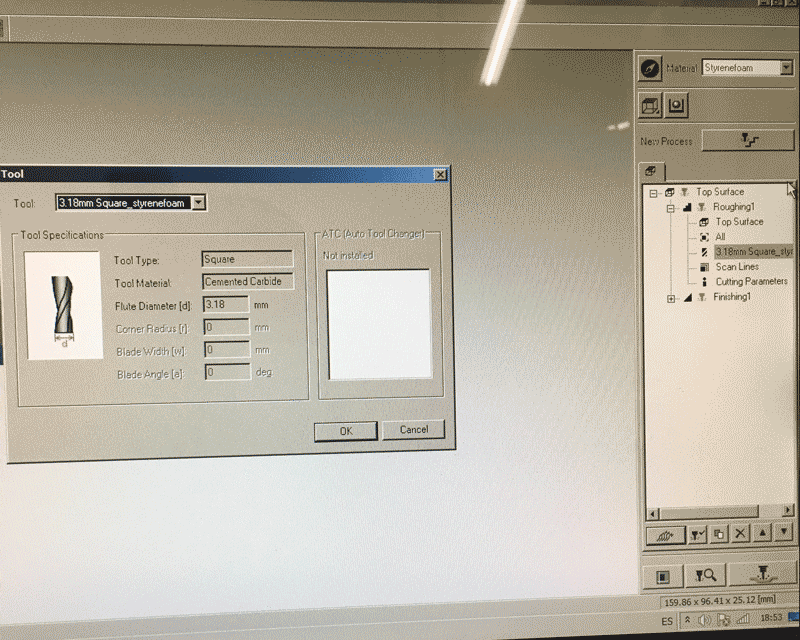

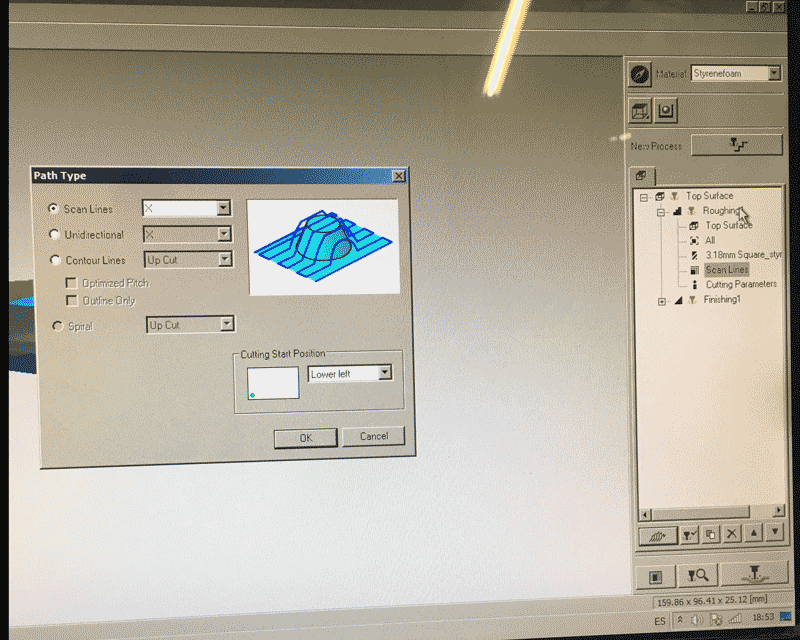

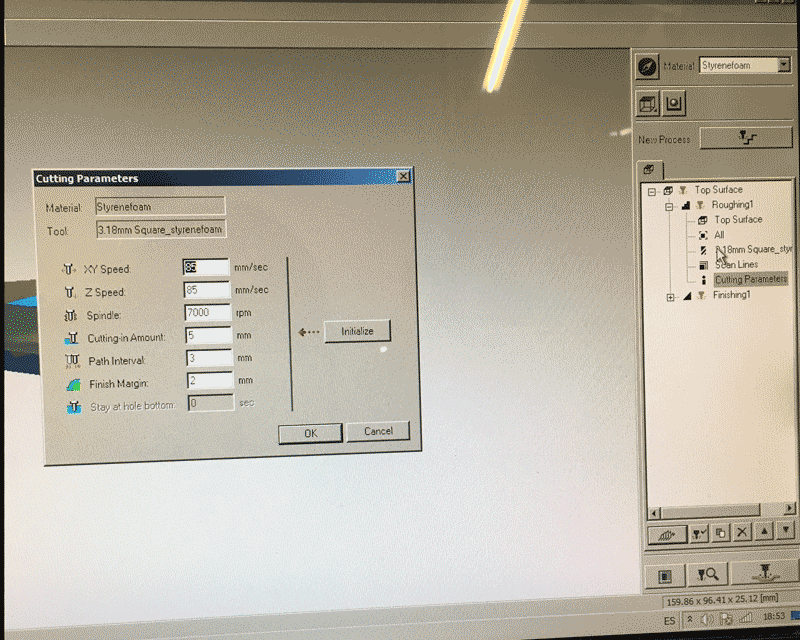

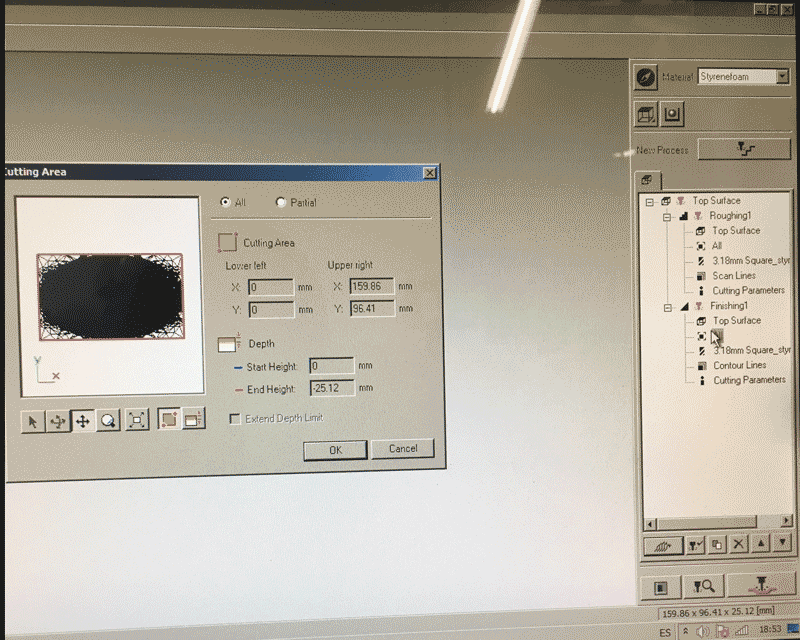

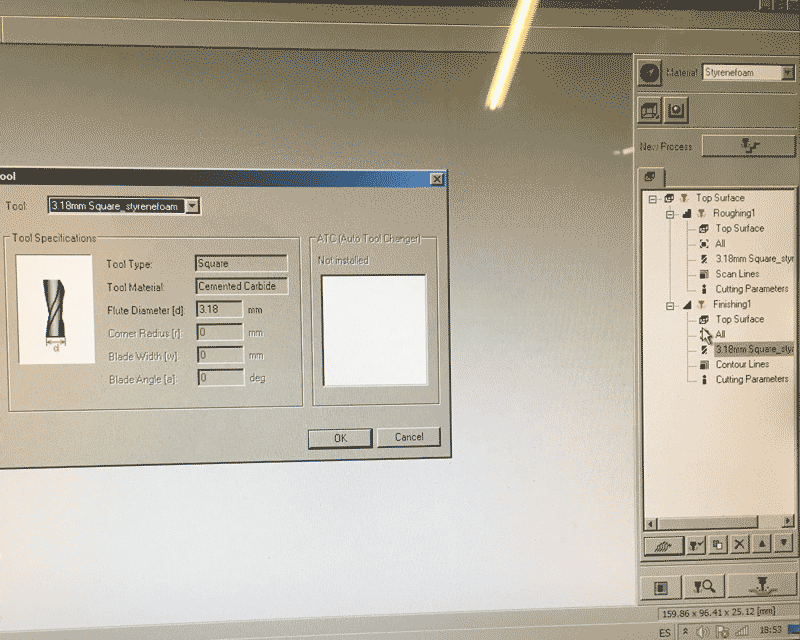

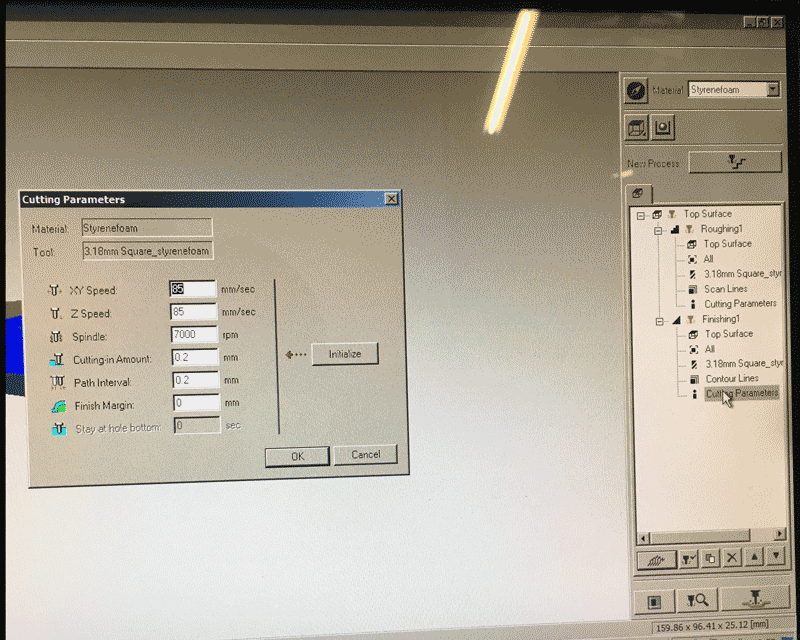

After designing the mold, then the design is being put into the Roland Modela Player 4 for creating the .rml file for milling. Here are the steps.

Before pressing the button next to the 'New process' for creating two milling process, I have to choose the material first and this time I used 'Styrenefoam'. The first one is roughing and the second one is finishing.

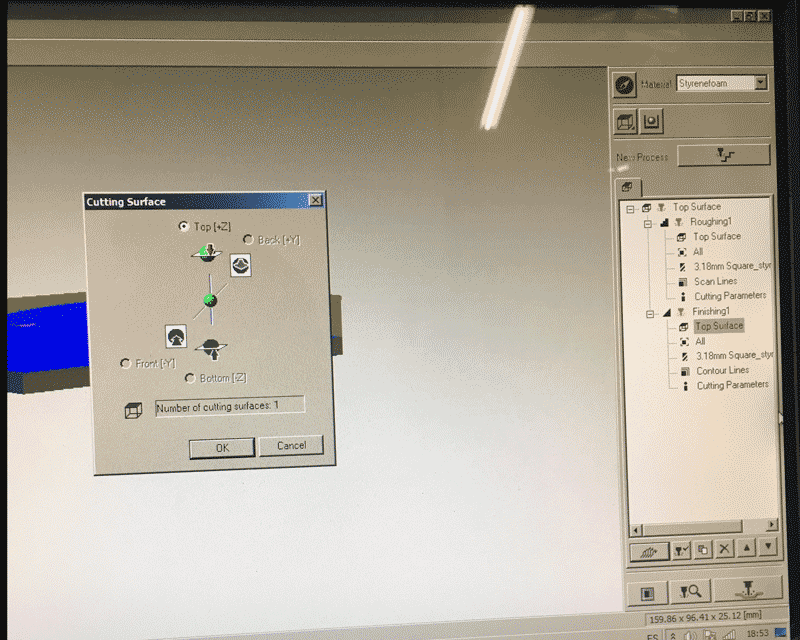

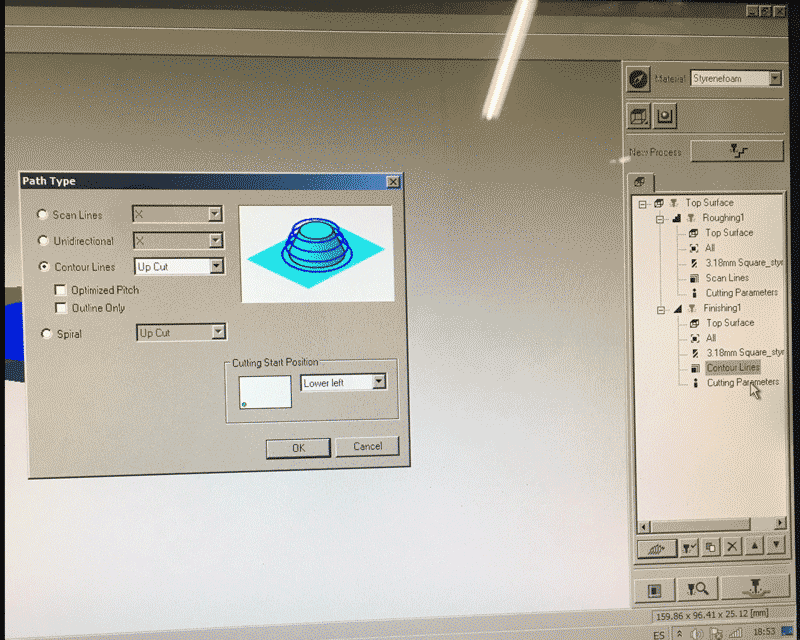

This is the second process, which is the finishing.

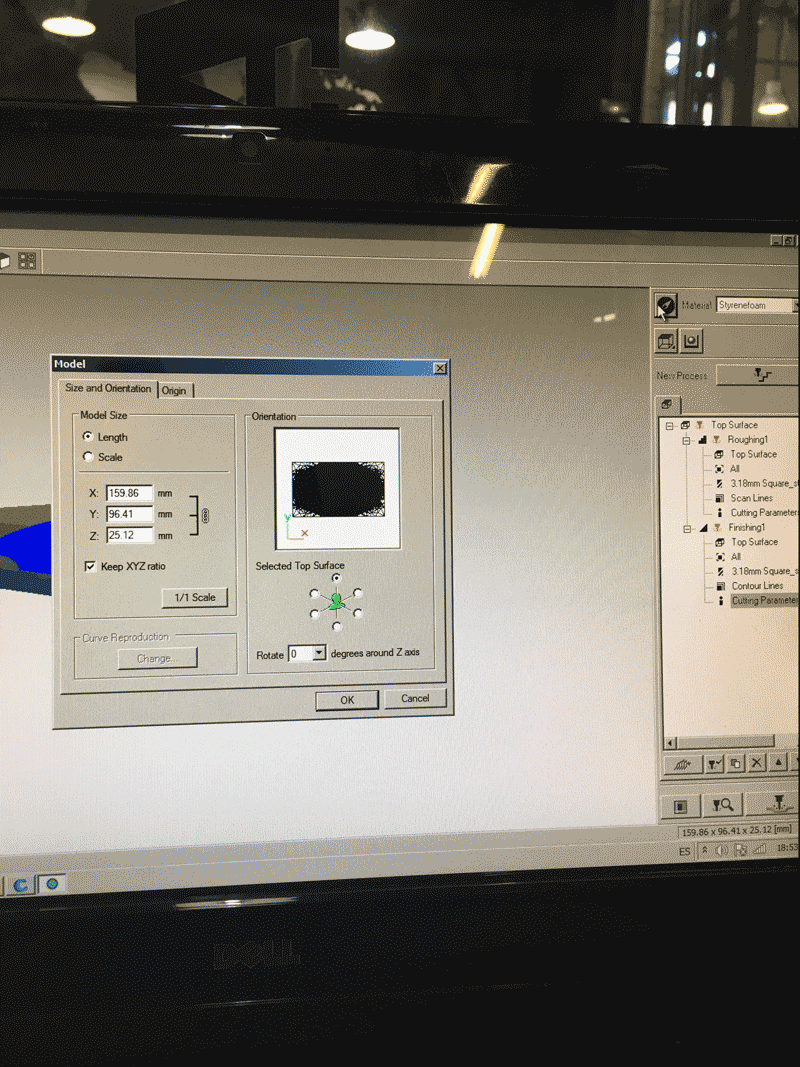

Below is the setting for the model part, which is the button next to the material 'Styrenefoam'.

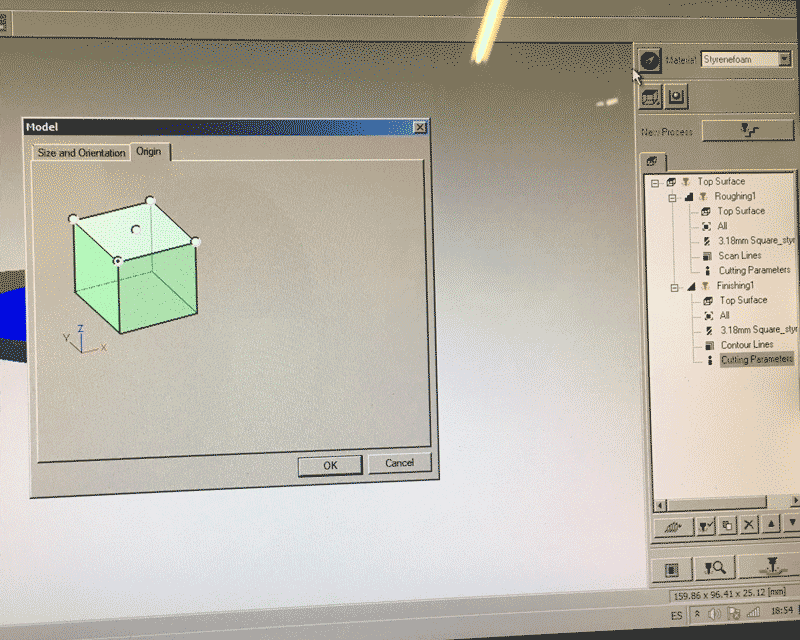

For the model, the origin is set to the corner as illustrated in the diagram.

C. The Milling process

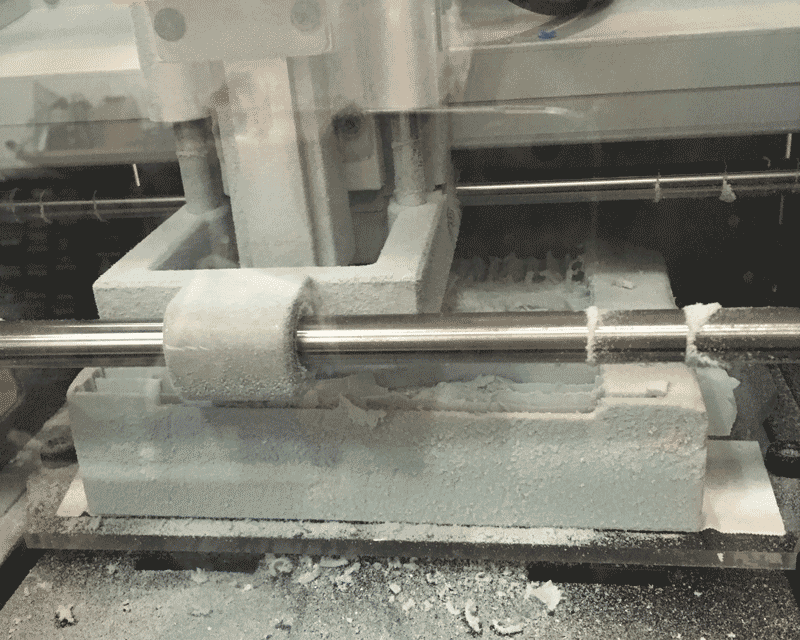

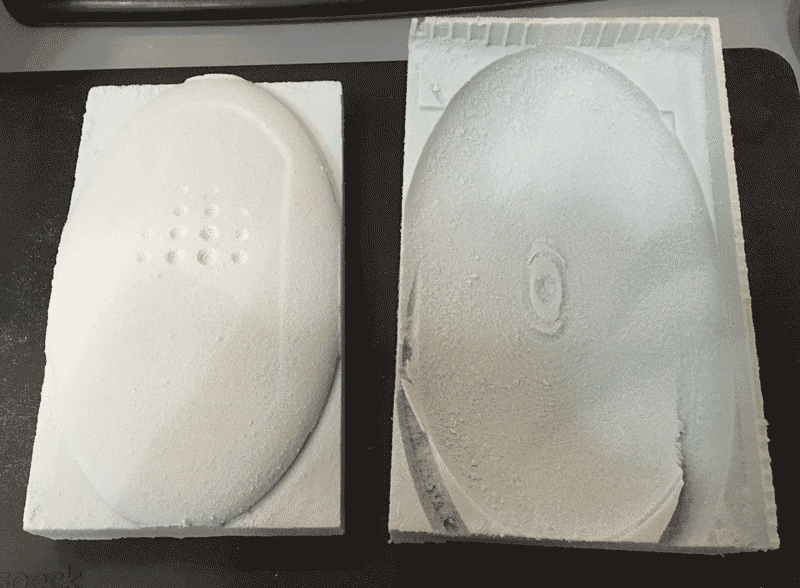

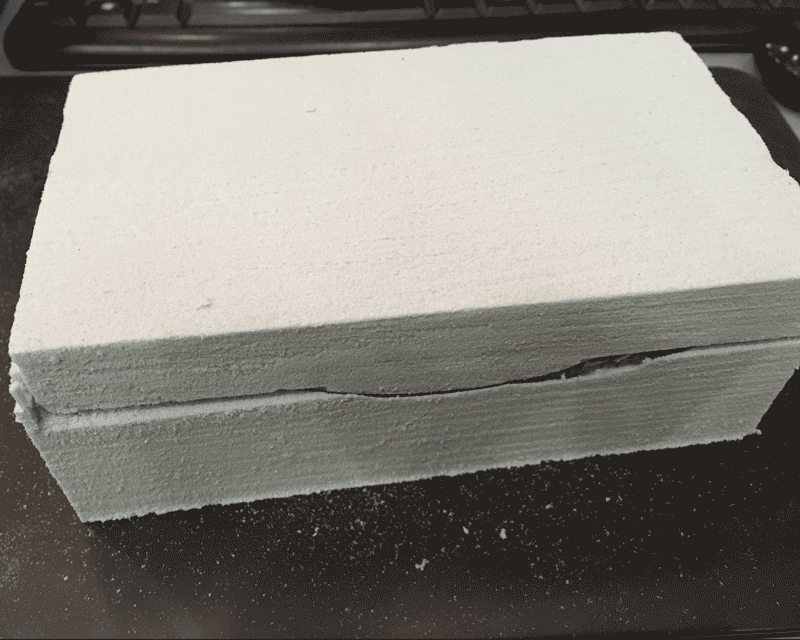

Since i used an old foam, which have some pattern already, therefore after the milling, there are some circle marks left. For the improvement, i should make the drill a bit deeper to cut underneath the original marks. Below is the result after the cutting.

D. Making the composites

Firstly, put the transparent plastics on top of the mold.

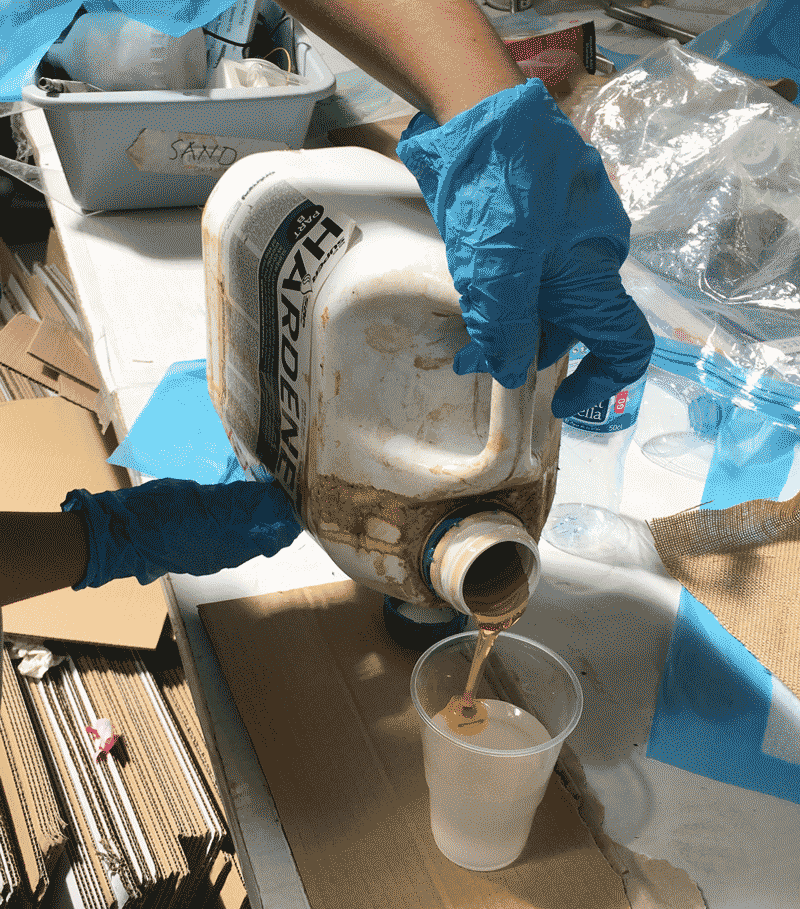

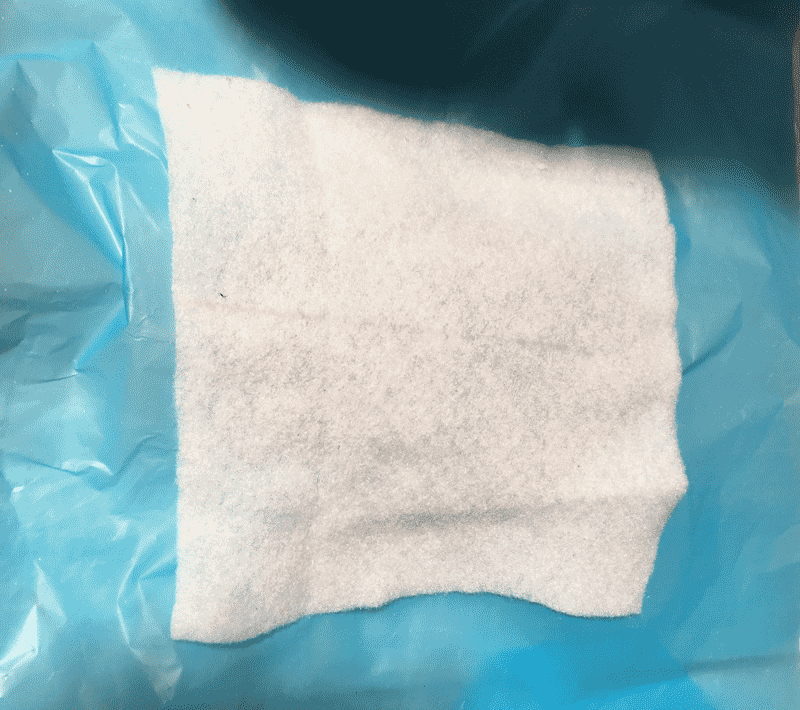

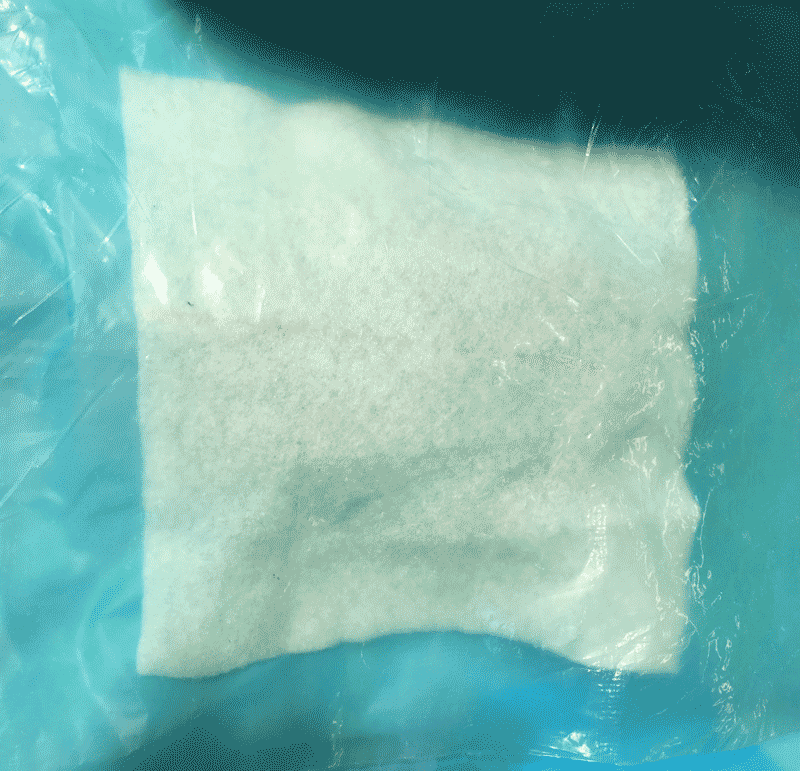

Then, put the hand-shaped cloth.

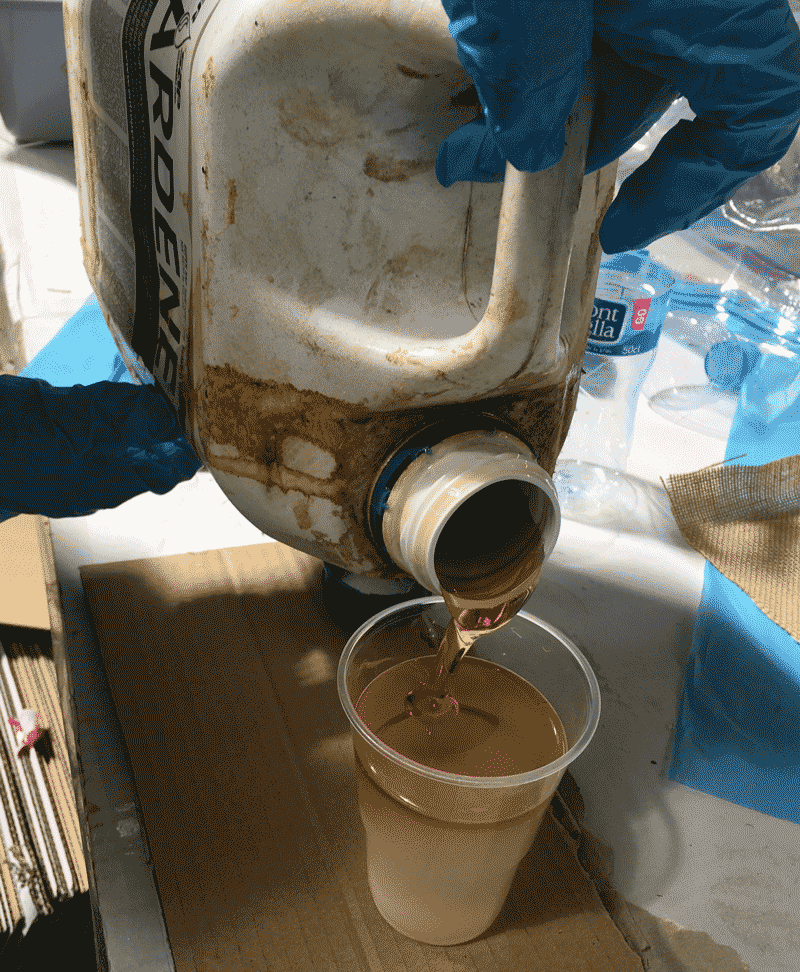

Prepare the entropy resins, which replaces petro-checmicals with renewable, biobased materials. Before using the chemical, it is important to read the material safety data sheet (MSDS) and Technical Data sheet (TDS). After reading the instructions, I know that I will have to mix the chemical as fast as I can before they have reaction to become hot. Pour the Epoxy part A into a cup first, then pour the Hardener afterwards. The ratio is 2 portion of part A for 1 portion of part B.

Furthermore, Mix them well.

Spread the solution on the cloth. Since there are three layers of the cloth, spread each layer evenly.

Then, put the blue plastics, followed by the white layer. Finally, put the green plastics.

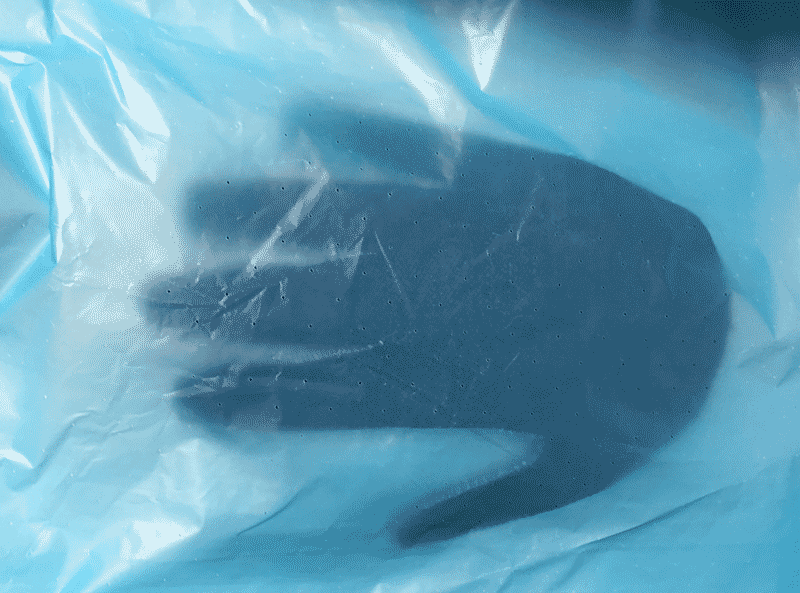

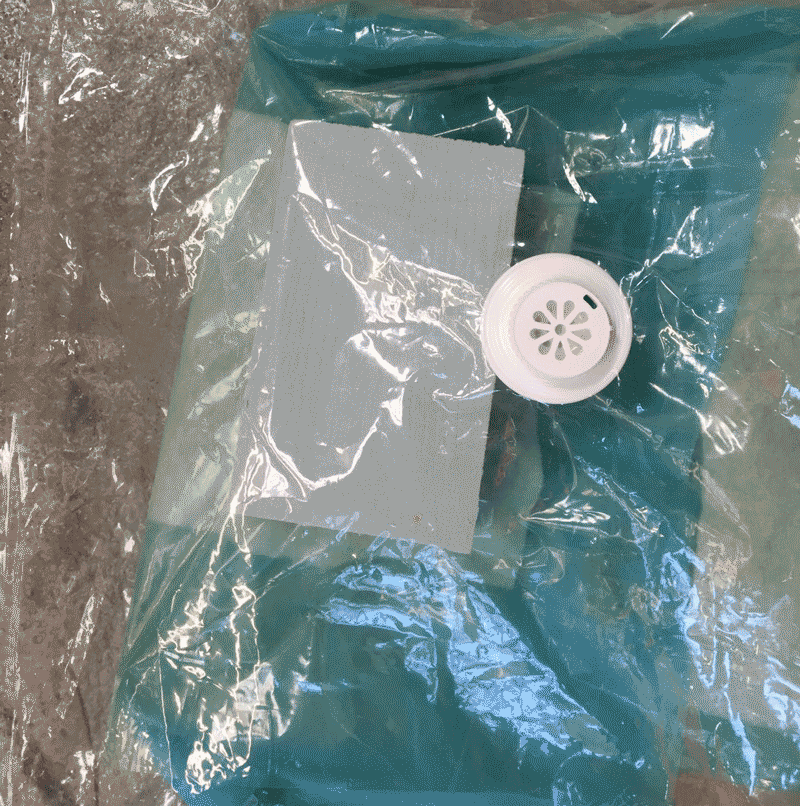

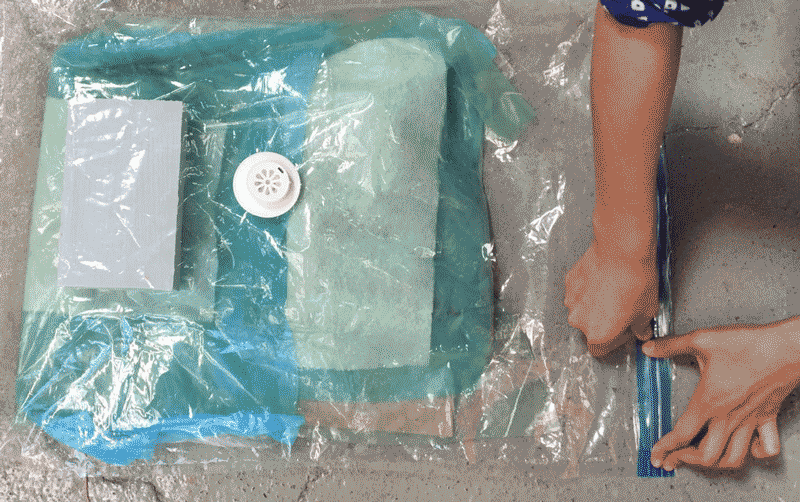

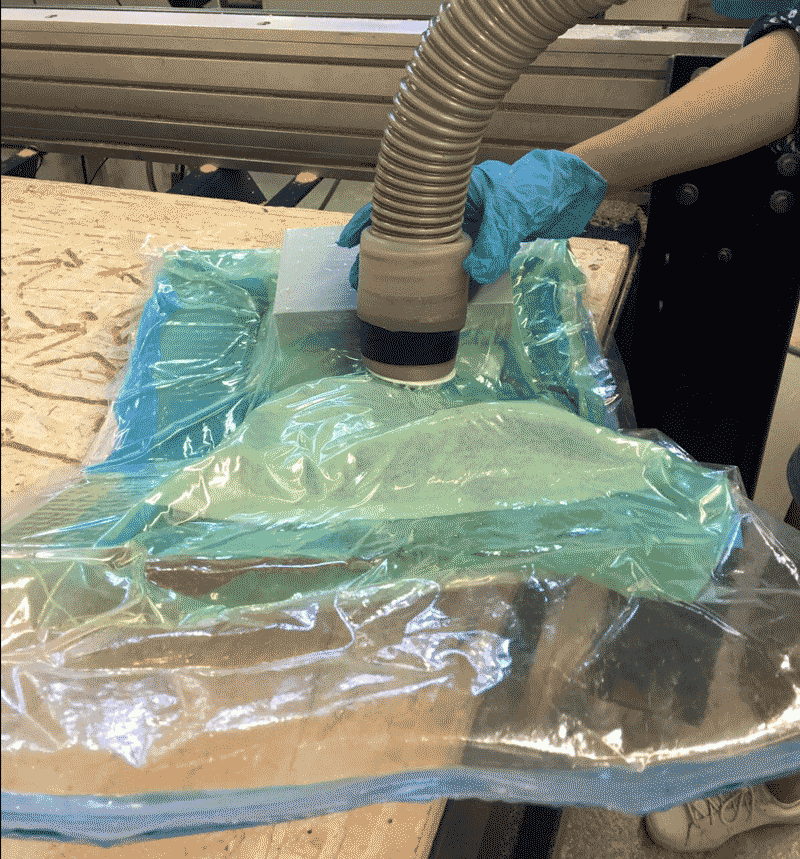

Finally, put the 'top' mold on top of all the layers and put everything inside the vaccum bag to lock it up.

Afterwards, Use the vacuum cleaner to suck out all the air inside the bag.

Below is the final outcome of the composite. However, there is a big difference between what I expected and what is the outcome. I think for the improvement, less solution should be used, since i can see the excessive amount of yellow solid surrounding the cloth. Also, for the improvement of the mold, I should mill it deeper or use a new block for foam before milling to have a smooth surface.

Please press the link for downloading.