Week 12 : Input Devices

This week's assignment seems to be quite important for me. For my smart furniture, I need to use a sensor

to sense the person while he uses the furniture and then use this data to turn on the lights.

Assignment :

This week's assignment is to measure something: add a sensor to a microcontroller board that you have designed and read it.

Things to figure out:

- What sensor and technique to use?

- Powering the board, not from the Computer...

Niel insists on designing a new board using Attiny 45 and adding a sensors

into it. So it is also a practice in designing and fabricating a board.Attiny 45 is much smaller, cheaper 8 pin chip.

One way to get signals in is digitally within through the pin. Each pin can be connected or

disconnected to sense. Each pin can have a pull up resistor too attached to it.

So there are a lot of states just in a pin. I would like to use Attiny 44 and take out all the pins,

so that I could add more input and output devices later on.

Input Devices

My Goal is to learn and do some personal research of different input devices

and then pick on an input device for my project, mill the board with sensor traces

and program the board.

Switch

There are two switches in the inventory. Push Button

and Slide switch. Switch takes in an input as HIGH or LOW, which could be used

as imput to make any changes in output devices.

I don't need a person to mechanically switch on the light's while he is using the

furniture. So, switch is not an option for me.

Different switch types

Different switch types

Motion detection Sensor

Sensor Used: Pyroelectric Infrared PIR Motion Sensor Detector Module Hc-sr501

This detects activity. Not a proximity detector but it is activity detector.

It has several nice features including sensitivity adjustment and trigger delay.

Qualitative measurement of activity is done in this sensor. This sensor requires a 5V DC supply.

It can be used to sense the person while he moves, but sensitivity of the device can be an

issue. Franc, suggested to use this sensor for the input board for my project.

HC-sr501

HC-sr501

Distance measurement with sonar

Sensor Used: Ultrasonic Module HC-SR04 Distance Sensor

This module includes ultrasonic transmitters, receiver and control circuit.

It's 4 pinned device requies 5V DC Supply and a working current of 15mA. It has

a maximum range of 4m and minimum range of 2cm. The four pins are

- 5V Supply

- Trigger Pulse Input

- Echo Pulse Output

- 0V ground

That's what I learnt from datasheet of the sensor.

HC-SR04 Module

HC-SR04 Module

Magnetic field -

Sensor Used: IC Sensor HALL EFFECT SOT23W

This component has packages in both through hole and SMD's. These provide a

voltage output that is proportional to the applied magnetic field. This requires

a supply voltage of 5V (Min:4.5V and Max:5.5V) and supply current,

maximum of 9mA. It's a 3 pin component, with pins being:

- 1. Vcc

- 2. Vout

- 3. GND

SOT23W

SOT23W

Temperature Sensor

NTC and RTD Thermistors

So, Thermistors are temperature sensing elements, where resistance is in proportion

to small changes in temperature. This resistance can be measured by using a small and

measured direct current, or dc, passed through the thermistor in order to measure

the voltage drop produced. NTC Thermistors are negative temperature coefficient

thermistors. That is the resistance of NTC will decrease as temperature increases.

RTD Thermistors are resistive temperature detectors. Theses are positive temperature

coefficient sensors where resistance rises linearly with temperature rise.

For both SMD flat- chips are available. For those requiring a temperature measurement and varying the output

accordingly, this is a sensor to keep on track.

Light Sensing

Phototransistor

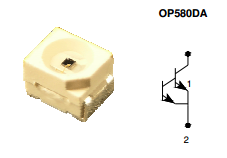

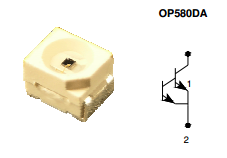

Sensor that can be used: OP580DA.

It's an NPN silicon photodarlington mounted in a minature SMD package having

application in non-contact position sensing and machine automation.

OP580DA

OP580DA

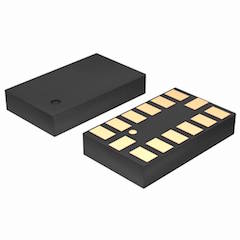

Accelerometer

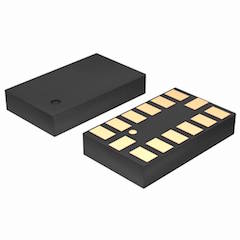

For measuring the acceleration of a moving or vibrating body. There is Dual axis

accelerometer (MXD6235M) and also three axis accelerometer (ADXL343).

three axis accelerometer-ADXL343

three axis accelerometer-ADXL343

For this week's assignment, I at first choose to build the transmit-receive version of

the step response circuit. Variations of this circuit can be used to measure resistance,

capacitance, inductance, position, pressure, proximity, tilt, acceleration,

humidity, touchpad, multitouch, etc. Using this I thought to control the relay driver. But,

later I choose PIR sensor to be used for my input board. If I get enough time, I'll come back and

explore on the step response circuit.

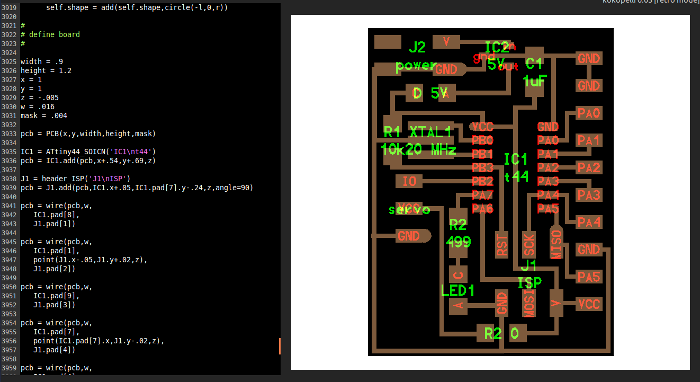

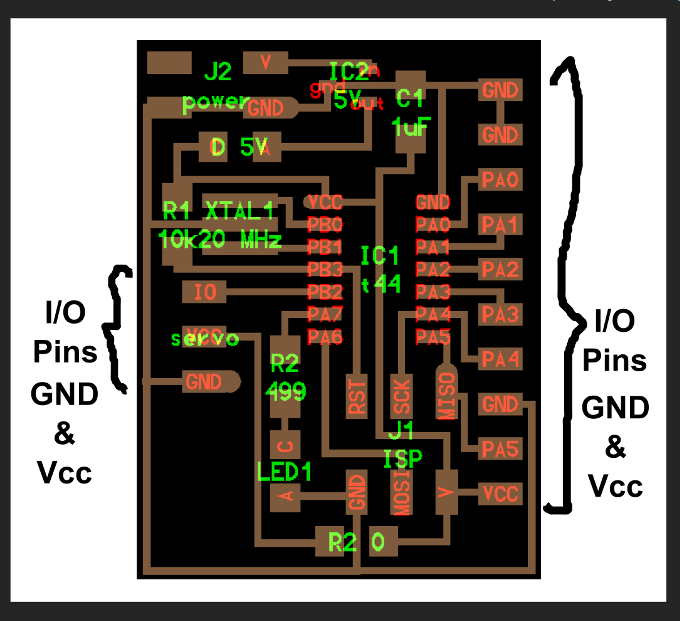

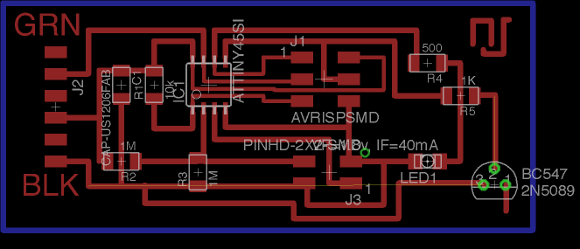

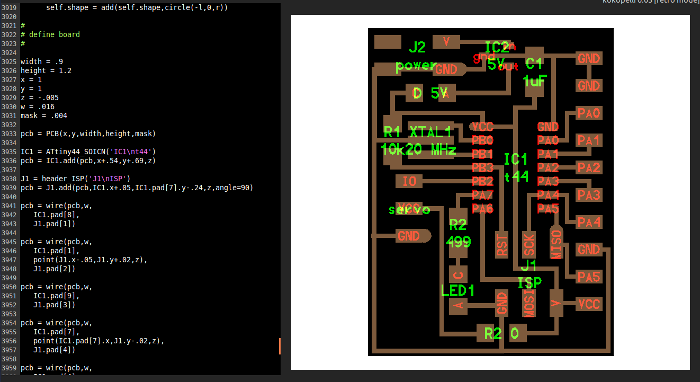

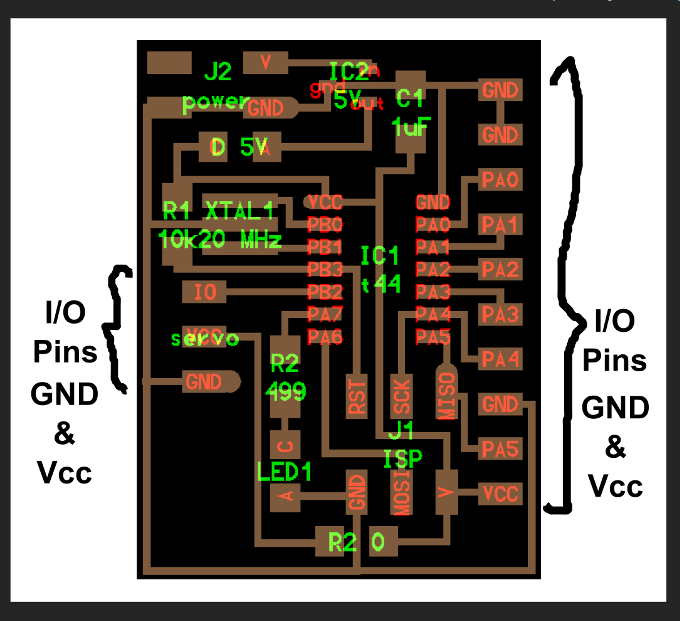

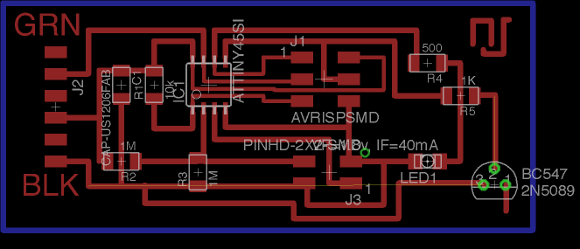

Making the circuit board

Making of the circuit board came out after doing many changes. Initially, I thought of using

an ATtiny 45 as the microcontroller. I needed only very few I/O pins which needs to be connected to

PIR, relay driver, and indicator LED. But, later on franc suggested to use a micro controller

with more pins, so that you can use it to extend the project later on. I've used ATtiny44 as

the microcontroller. In order to provide external supply of 5V I've

added voltage regulator LM7805. I also added a LED to indicate the status of whether PIR Detects motion or

not. The PIR sensor HC-SR 501 has three pins, 5V, GND and Output pin. I'm connecting the output pin to the pin

5 of the microcontroller. I'm connecting LED over pin 7 through a 499 ohm resistor. I used kokopelli for designing the

circuit.

Kokopelli being used to define board

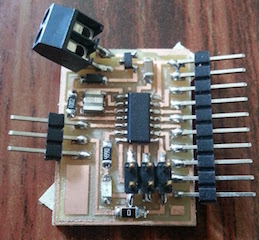

The I/O pins taken out from the board using jumpers.

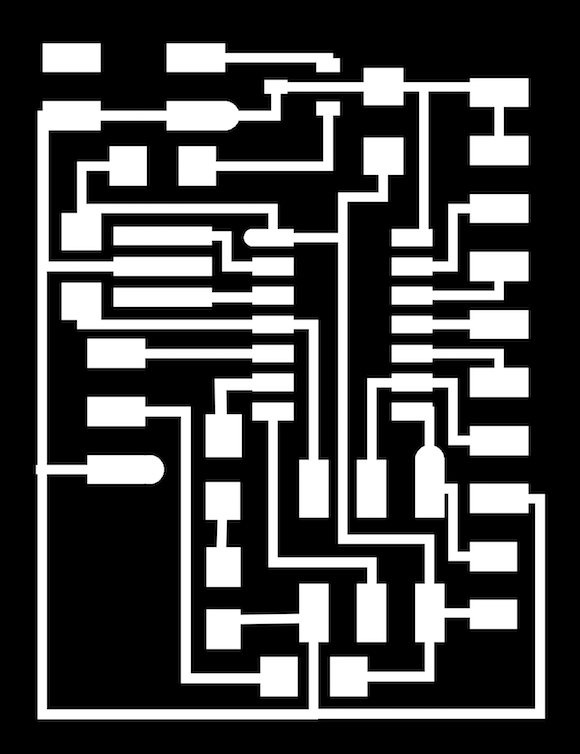

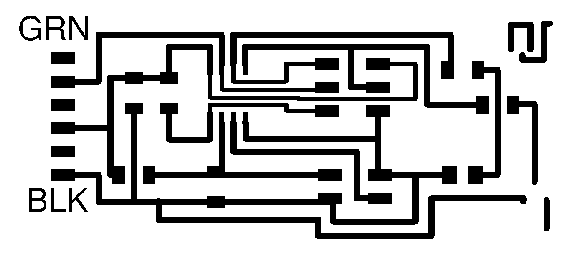

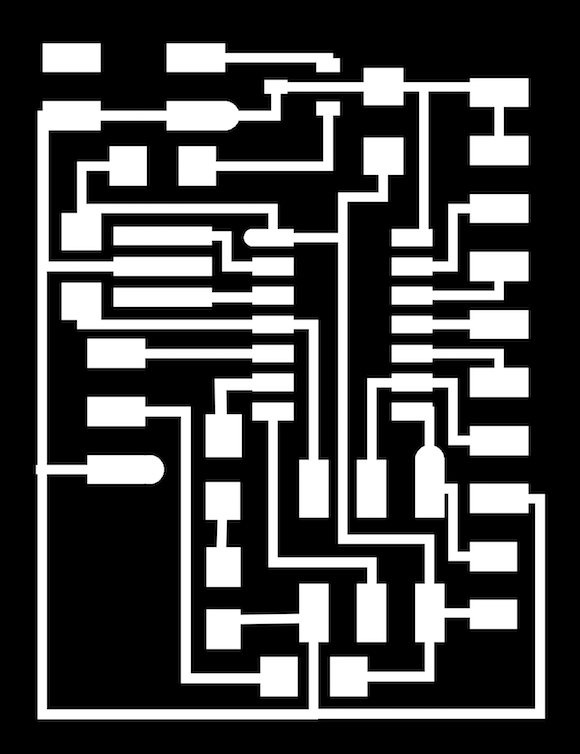

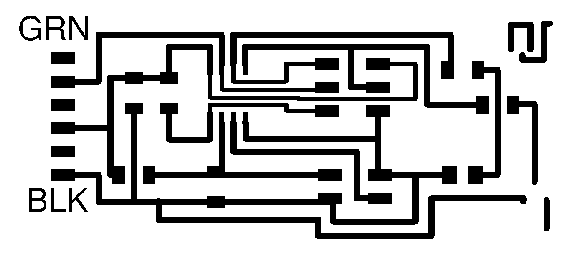

Board Trace

Board Cut out

Design File of the input board in kokopelli

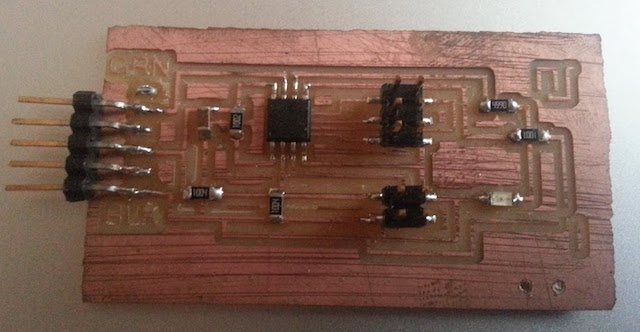

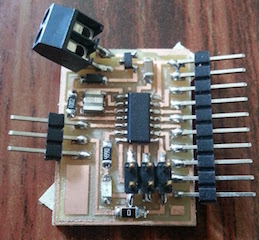

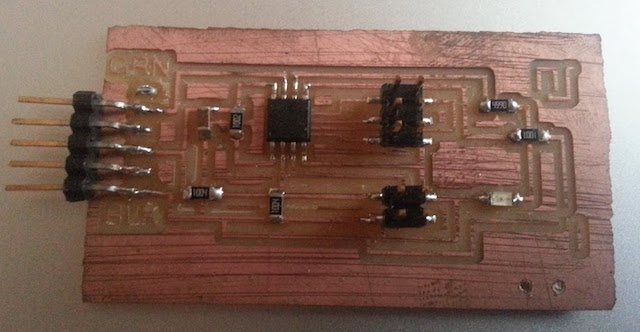

Stuffed Board

Programming the board

I used Arduino IDE to program the board.

int pirPin = 5; //the digital pin connected to the PIR sensor's output A2

int ledPin =7;

//SETUP

void setup()

{

pinMode(pirPin, INPUT);

pinMode(ledPin, OUTPUT);

digitalWrite(pirPin, LOW);

}

}

//LOOP

void loop(){

if(digitalRead(pirPin) == HIGH)

{

digitalWrite(ledPin,HIGH);

delay(100);

digitalWrite(ledPin,LOW);

delay(100);

}

if(digitalRead(pirPin) == LOW)

{

digitalWrite(ledPin,HIGH);

delay(500);

digitalWrite(ledPin, LOW); //the led visualizes the sensors output pin state

delay(500);

}

}

Download File

Arduino program for PIR sensor

Step Response board

The ATtiny 45 microcontroller has only 8 pins, so it has limited number of I/O pins and

all are used except for the pins used for ISP. It is possible to use the pins used for

In-System Programmer(ISP) as I/O pins when ISP is not connected. I've noticed that the MISO

and MOSI connections of the ISP is connected to the PB0 and PB1 pins and these could be

used as an output for relay and a status indicator LED.

The idea is to place the foil papers with a sandwiched thick form. When one of the

foil [TX] is pressed to the RX foil there will be an increases readout value proportionally to

the force applied. Take a threshold value of this value above which the relay [output device] is

given signal. So when Relay is given HIGH signal, this turns on the LED strips inturn.

Board design

I did the board design in Eagle. In eagle, once the components are dragged in from the library, we can

use auto routing feature to connect between the components while board designing. But sometimes the auto

routing will not give you all the wire connections. So, its better to manually connect the components, which

is a day task indeed. I have added indicator LED and Transister BC 547, these are the changes I made to the niel's

board.

Board png images...

Whole Circuit

Whole Circuit

traces

traces

Outline and drill hole

Outline and drill hole

The relay needs to be connected to the microcontroller through a transister. The transister is used

to control the relay. The transistor is driven into saturation (turned ON) when a LOGIC 1 is written

on the PORT PIN thus turning ON the relay. The relay is turned OFF by writing LOGIC 0 on the port pin.

Both relay and the indicator LED are my output devices.

I will describe my circuit for relay and power supply unit in the output device assignment page. I milled the

traces in the copper clad using modella and 1/64 inch bit. I couldn't cut the outline, since the inventory went

short of 1/32 inch bits. I thought to use the chain saw to cut the board out and later only realised that the

holes needs to be drilled for the transister I have used, which is a through hole component. Later I tried to

drill holes manually, but then the smallest of the drill bit available was still drilling a big hole. I'm trying to

find a solution for this so that I can drill hole and complete stuffing the board soon and start programming the board.

Design Files of stepresponse board

.sch file, .brd file

Stuffed Board

Programming the board

I tried to program the board. At first tried to check whether the LED was working perfectly so as to show the

output on the board. But then, as I plugged in the board through FabISP, the LED turns on.

I checked for short connections, found one removed it. Further checked, still the LED remains on.

Later on, checked for if the resistor is of right value, it too is. I'm trying to debug the board.

What I learnt from this week's schedule...

Learnt about different input boards

Found out which input board is apt for my project

Tried a hand on step response board...it still needs more exploration.