Roosvelth Cántaro's Academy

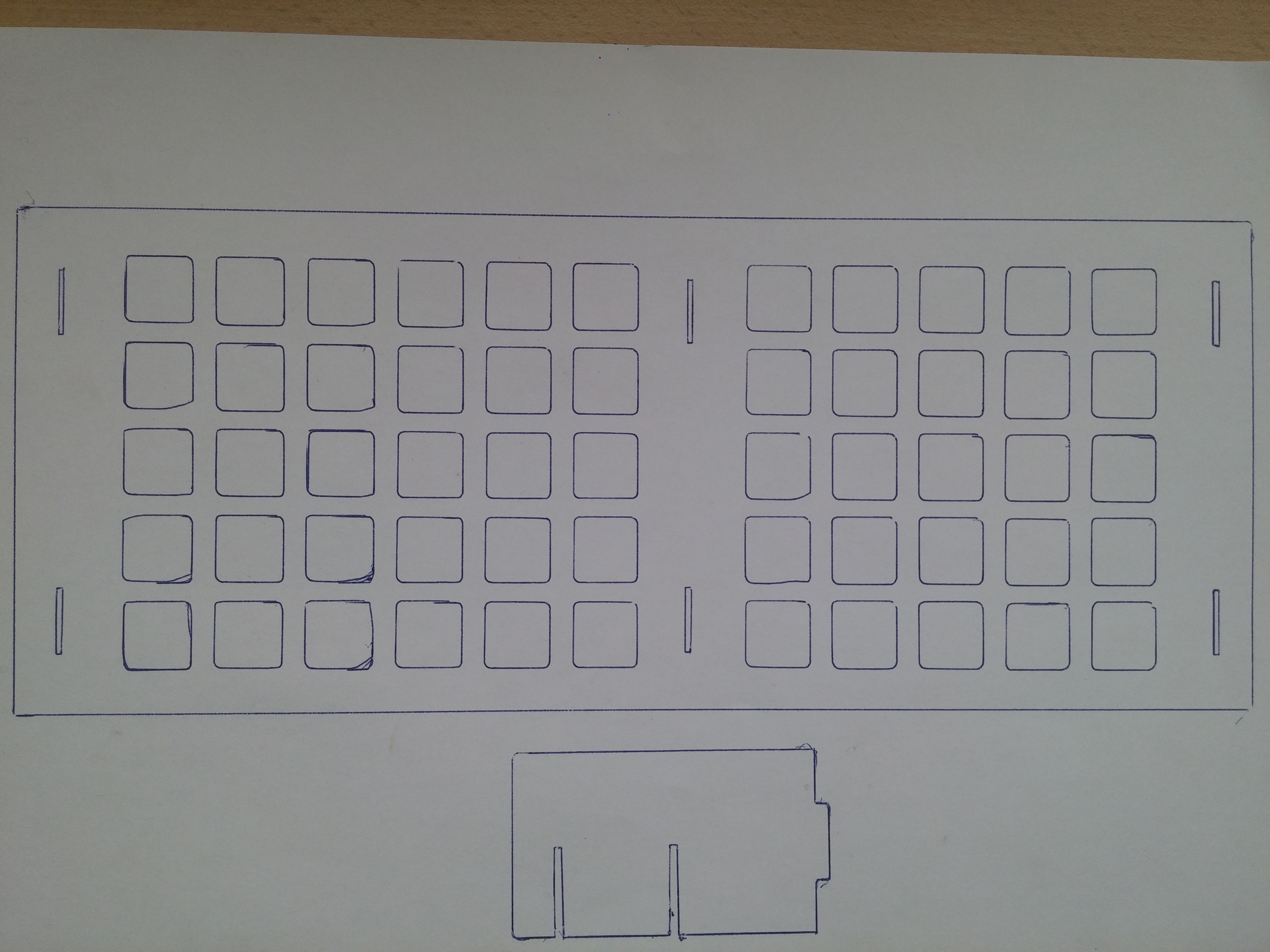

To start this week of I made some inicial simple designs to get myself in the idea of press-fit constructions. I started with the idea of making a 3D geometrical construction out of smaller 2D geometrical laser cut pieces. These are some of my inicial sketches:

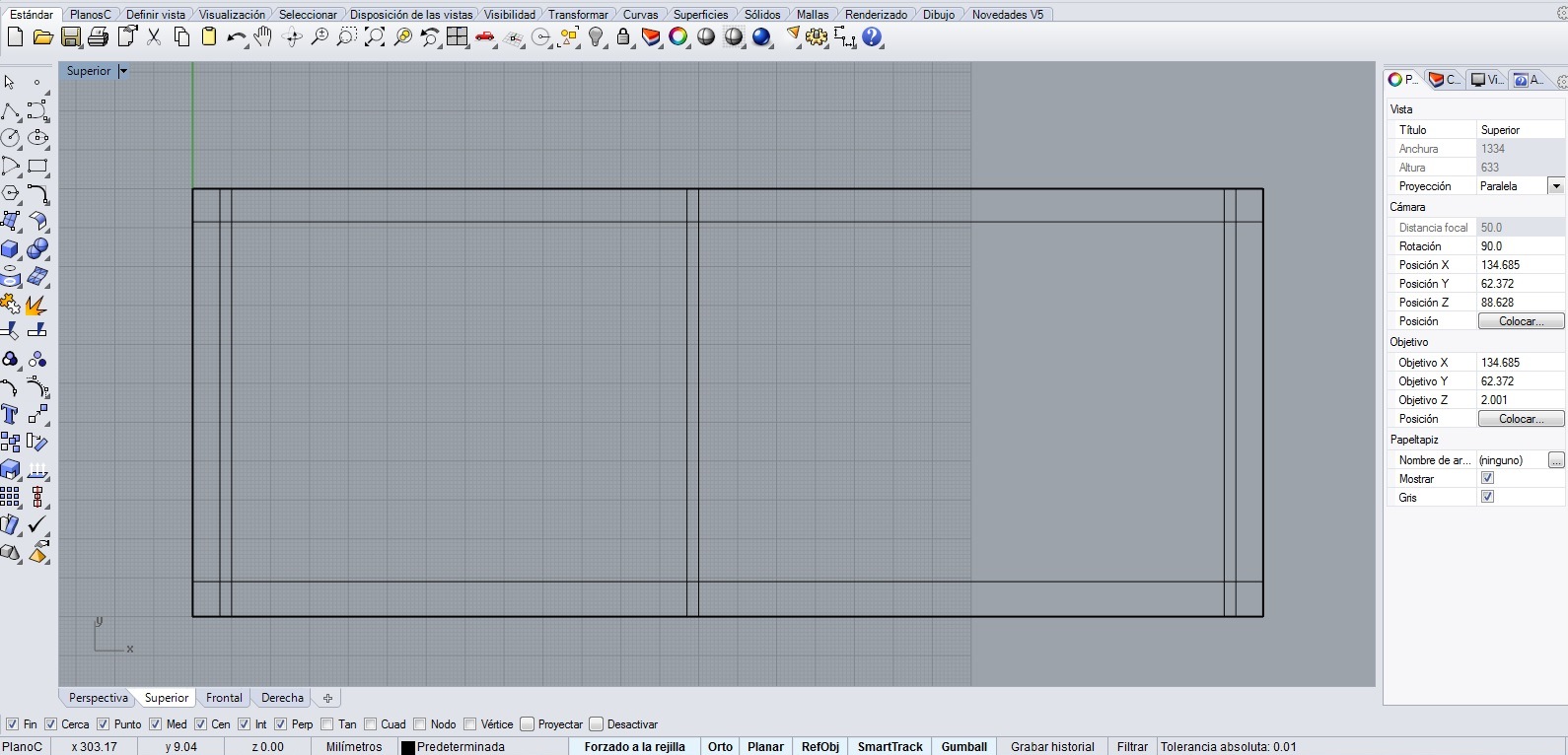

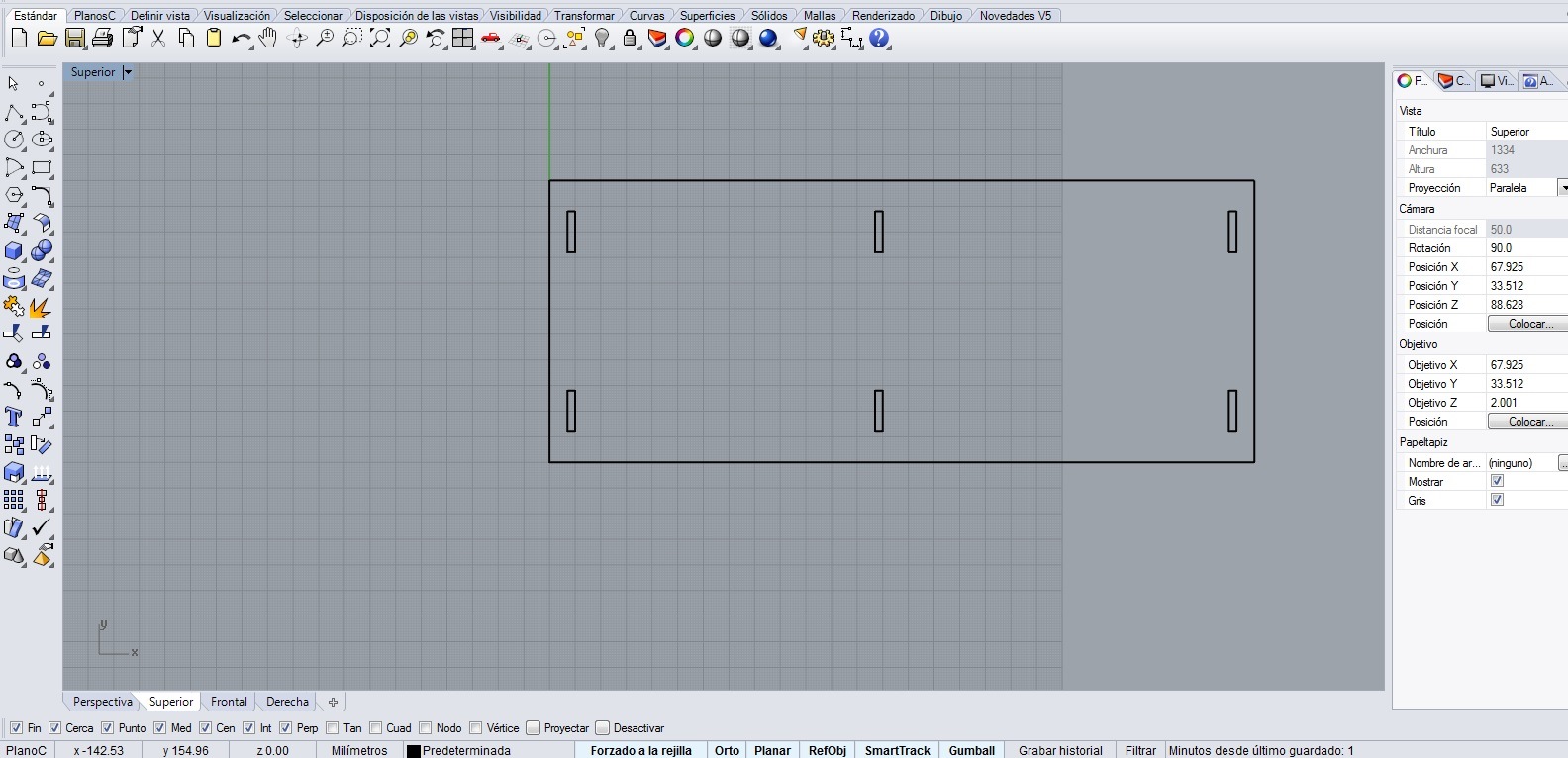

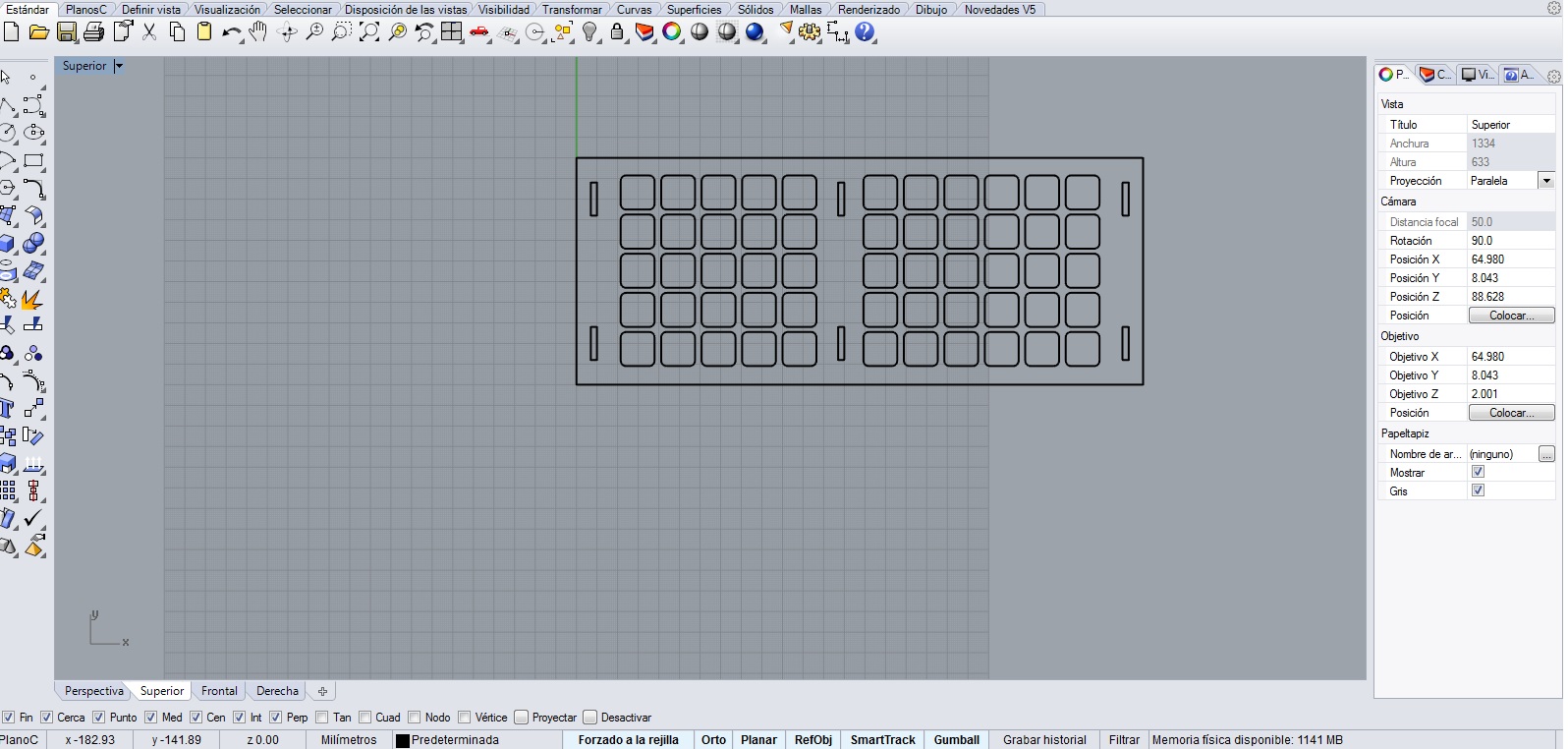

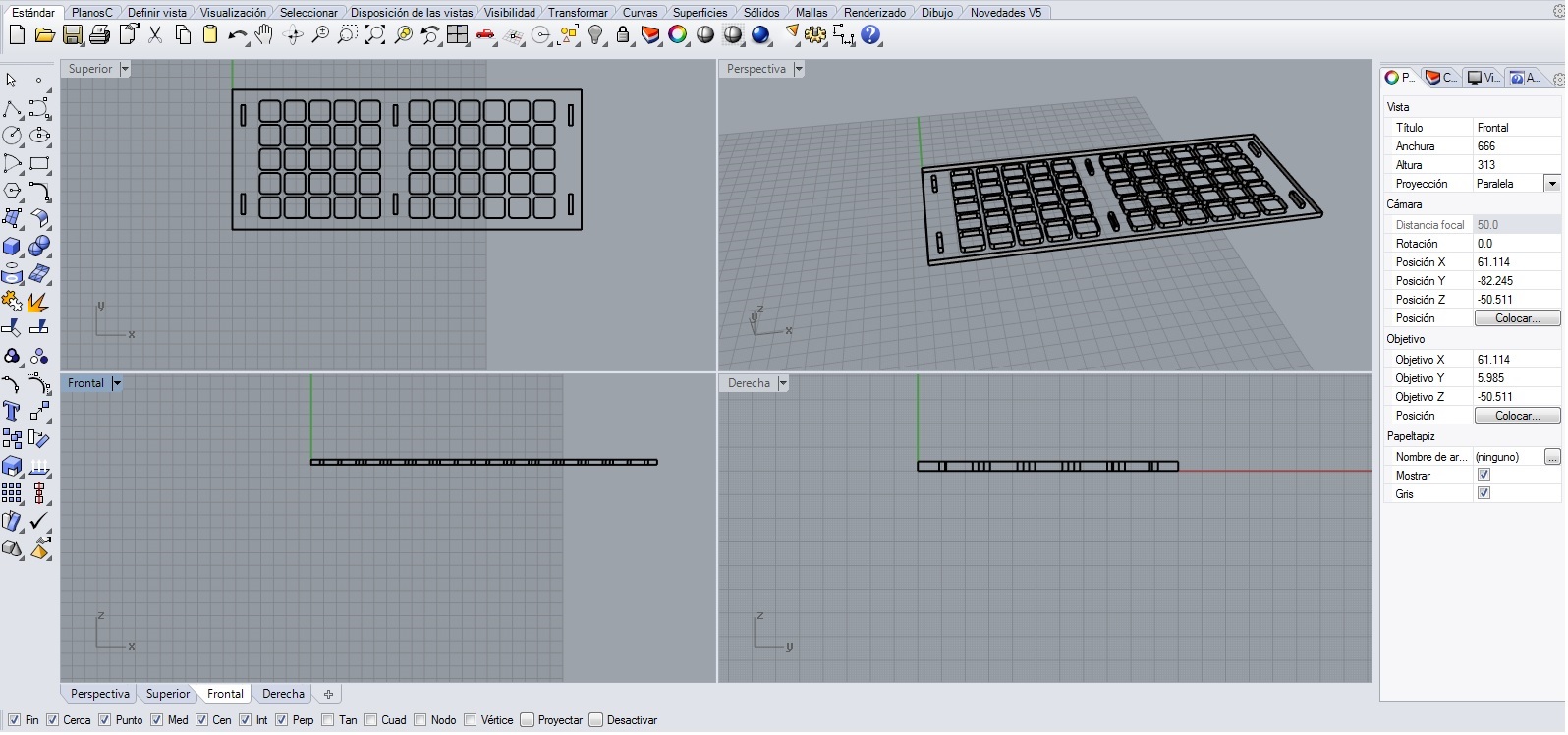

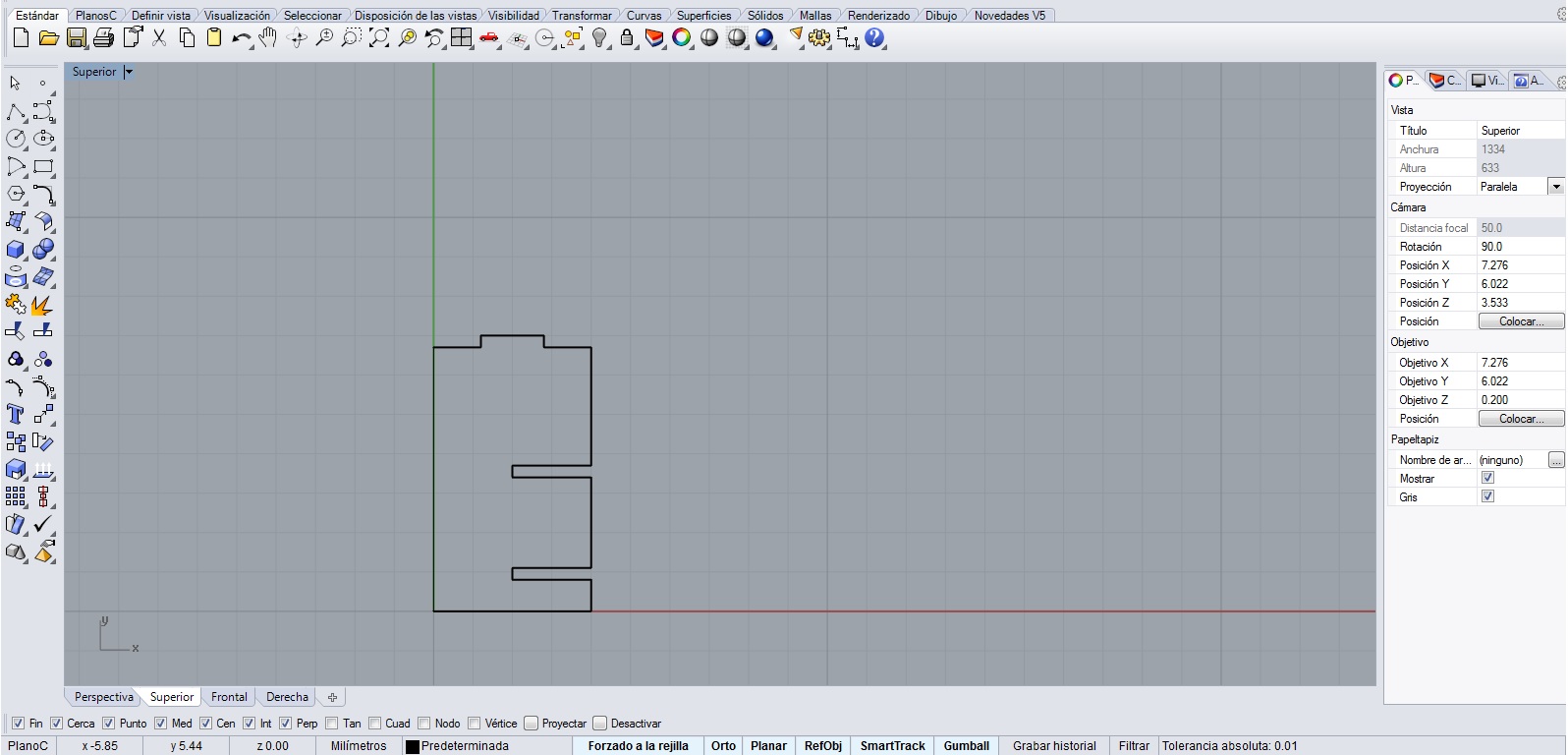

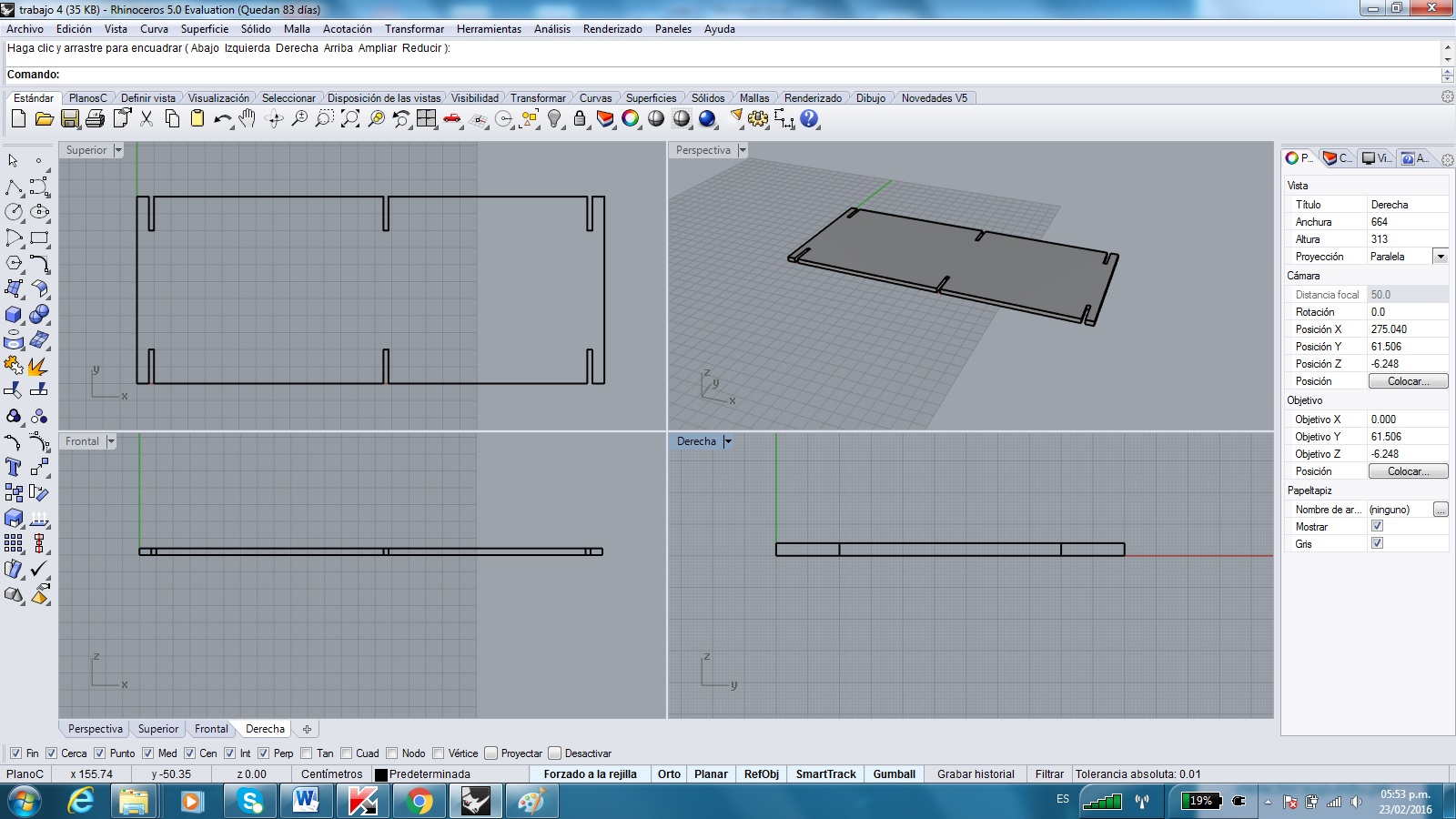

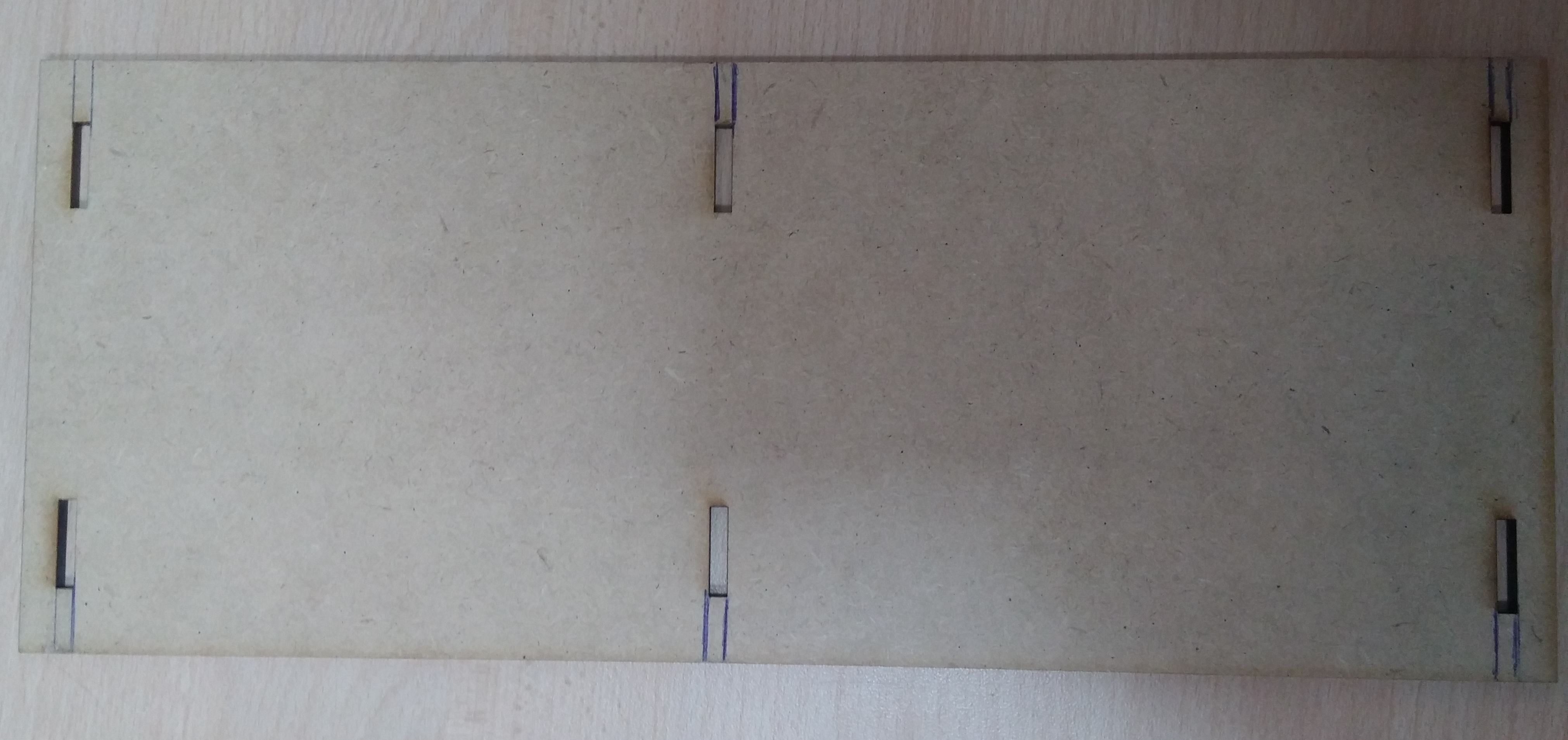

I have decided to model tub rack (because there is a great need in my work) to use the software RHINOCEROS 5 as a way to become proficient in the program. As it´s shown in the pictures, I have drawn each needed piece in order to transfer them to the cutter. The measurements are in millimeters.

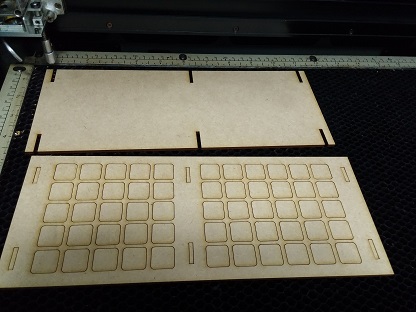

Send the designs onto the lasercutter. I went with a simple first design with very basic interlocking since I was looking for something aesthetically pleasing. Then it was time to play with them and see where that would lead me.

After the first mockup of pieces I realized that my design would work better if the holes would be on the edge of the plate. So it took me two design attempts to place them where they would work best.

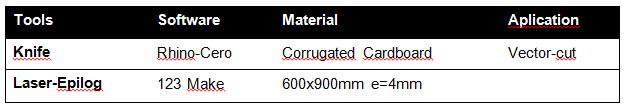

For the design of the kit pressure will do the following:

-Design program Rhinoceros.

-Pass the design of the program to the STL extension

-Send to the laser cutter.

-Implement the cut design.

Configuration: Speed: 50 % Power:40 % Freq:500 Hz

PROBLEM AND SOLUTION:

. The problem I found is the lack of information in the part of design with Rhinoceros program, for this consult with teachers and students who have knowledge of design and also through tutorials and so this way I could perform the task of three week.

. The design of support of test tubes for the part of my Department was useful because it has greater stability with test tubes as opposed to what was in Chemistry Laboratories.

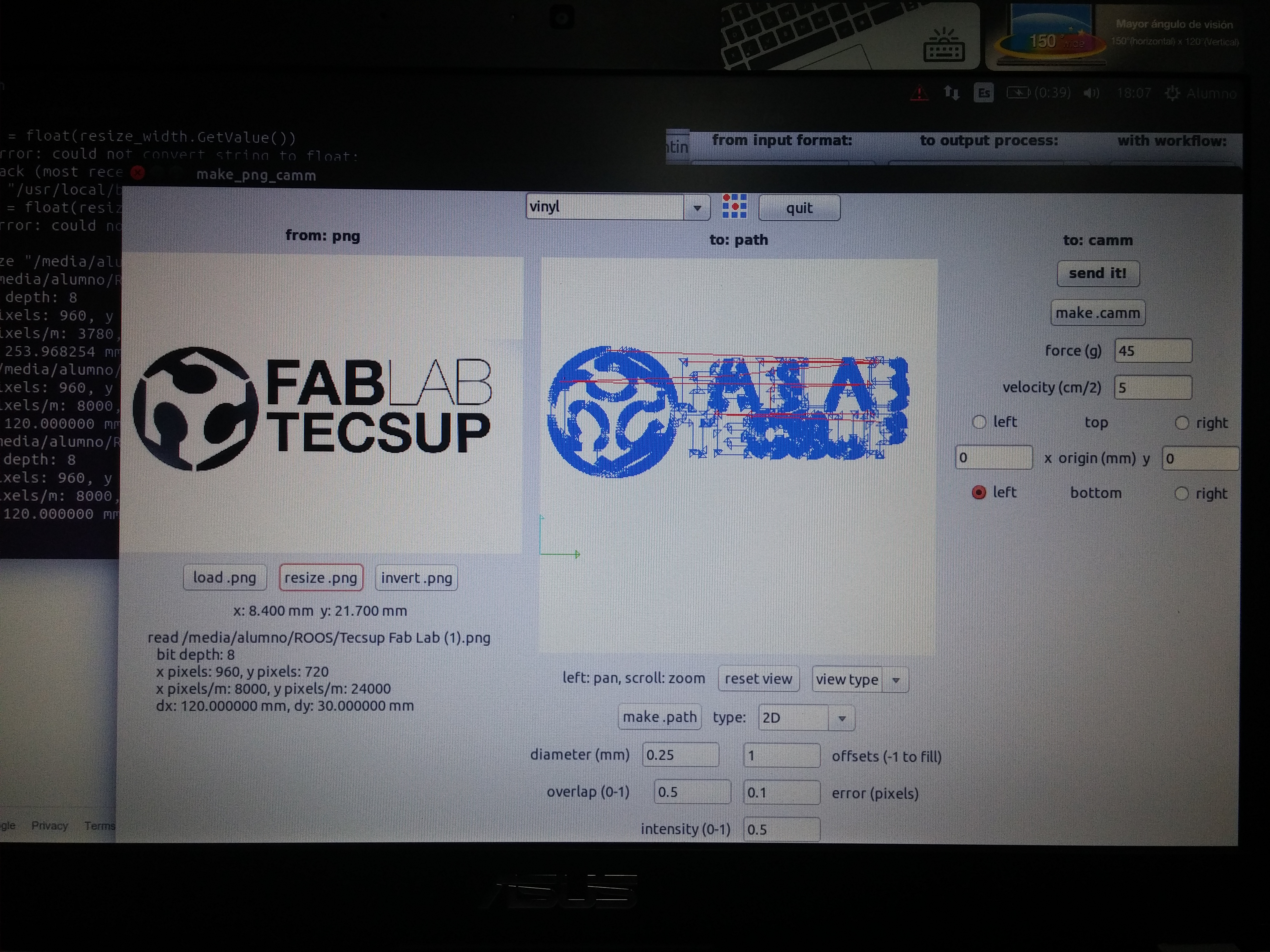

About vinyl cutting, you can see my work HERE

Here you can see the parameters I used

Here you can see the process of vinyl cutting: