Roosvelth Cántaro's Academy

• Automate your machine.

• Document the group project and your individual contribution.

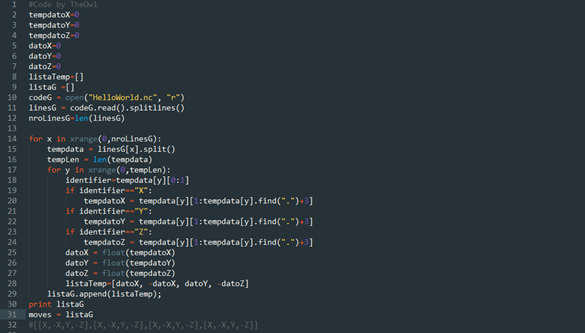

This programming of the machine CNC milling machine of pipe, it allows me to enter the coordinates in which we want to move the tip of the drill and so carry out engraving on PVC tubes.

The Programming begins putting all the coordinates to the point [0,0,0], which means that the axis "X", "Y" and "Z" are zero.

Then go to the part where the program interacts with the user and ask some coordinates. It first that me goes request is that you enter the coordinate that with regard to the axis "X" after us requests that the income it coordinate for axis "and" and finally us will ask enter the coordinate for the axis "Z". All this will be stored in the array "ListaTemp" and send them to the machine to make it work.

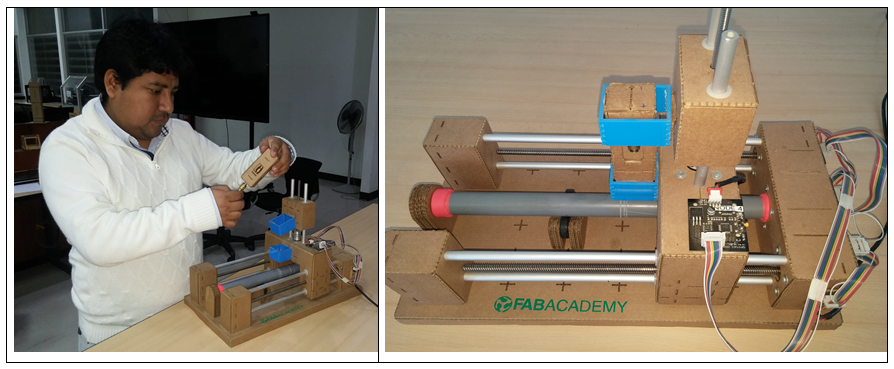

- X and Y: these two axes perform one movement as a whole.

- Y: in this axis obtained rotational movement clockwise and counterclockwise.

- Z: In this axis, the spindle moves to cut the PVC pipe.

This part of the assignment to work with my colleagues Fabio Ibarra and Eduardo Yallico.

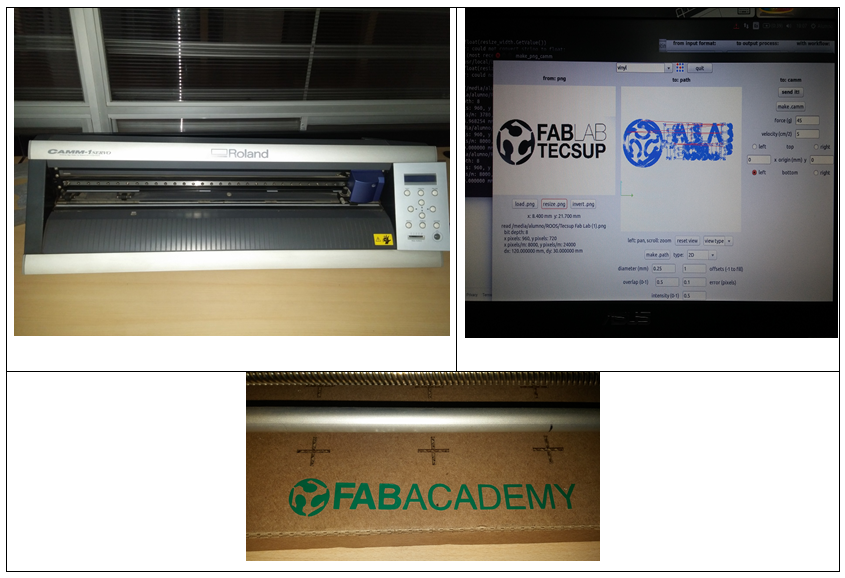

Also perform cutting of vinyl material with Roland machine to have a better presentation of the CNC machine.

Recognise opportunities for improvements in the design

To improve on the design, it would be trying to use other more consistent material, so this way you can work more forcefully and not only use carton for the design of the machine because it can present efforts during operation and work support.

The problem was to convert the format of "G" code to the coordinates system that uses the machine to move. The machine uses a coordinates system to move. The "G" code does not use arrays, but yes coordinates.