Week 3

Computer-Controlled Cutting.

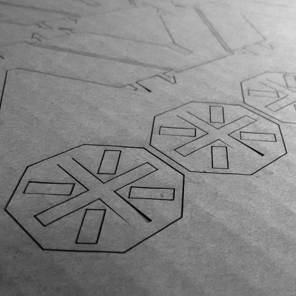

ASSIGNMENT: design, make, and document a parametric press-fit construction kit.

ASSIGNMENT: design, make, and document a parametric press-fit construction kit.

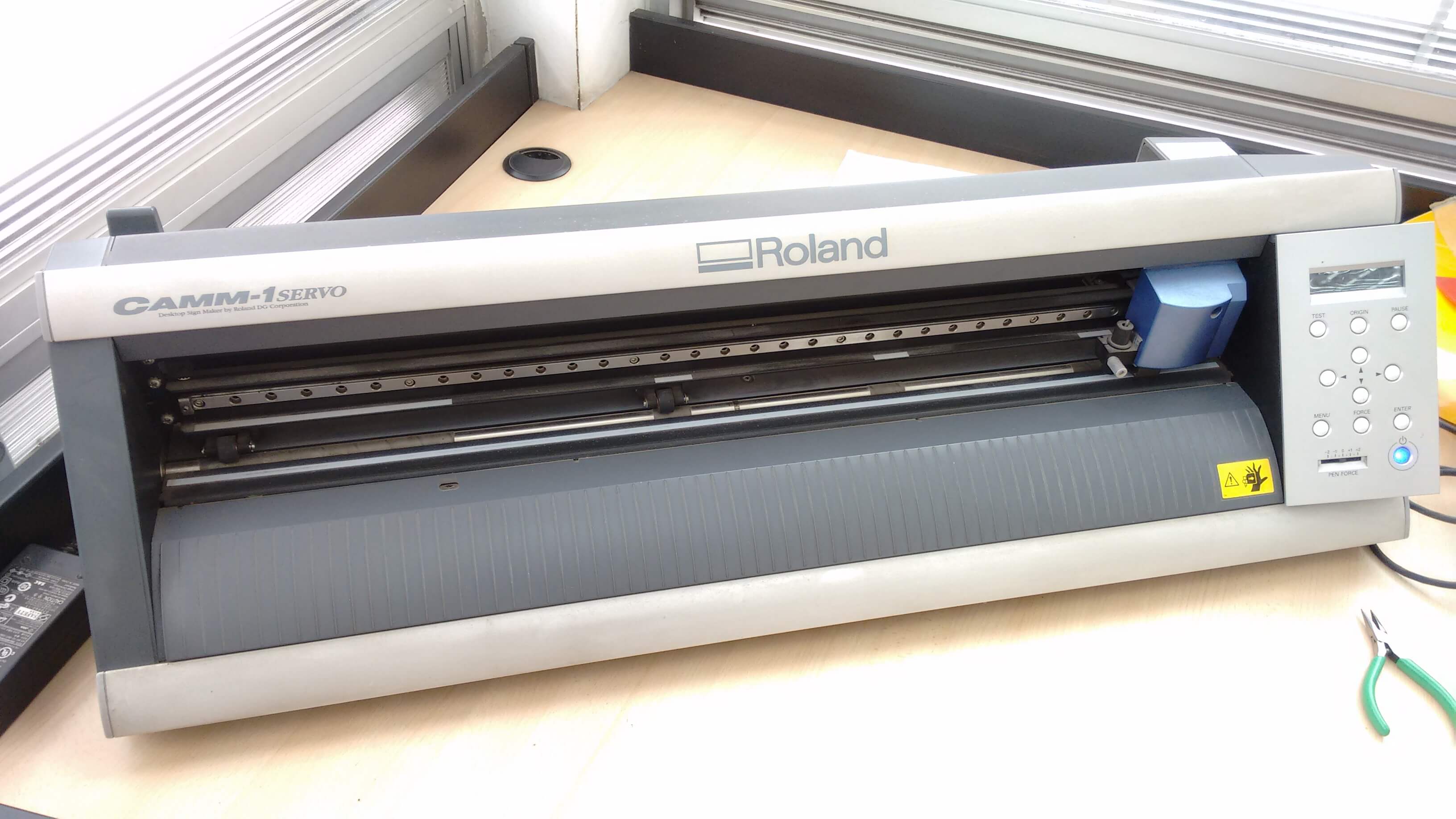

This week the assignment is basically experiment with digital cutting tools. Here in the Fab Lab TECSUP, I have experienced with two cutting tools, EPILOG LEGEND ROLAND 36EXT and CAM-1 SERVO.

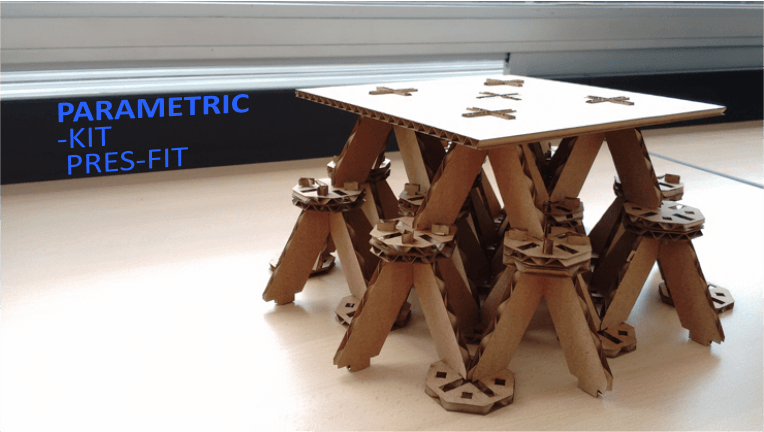

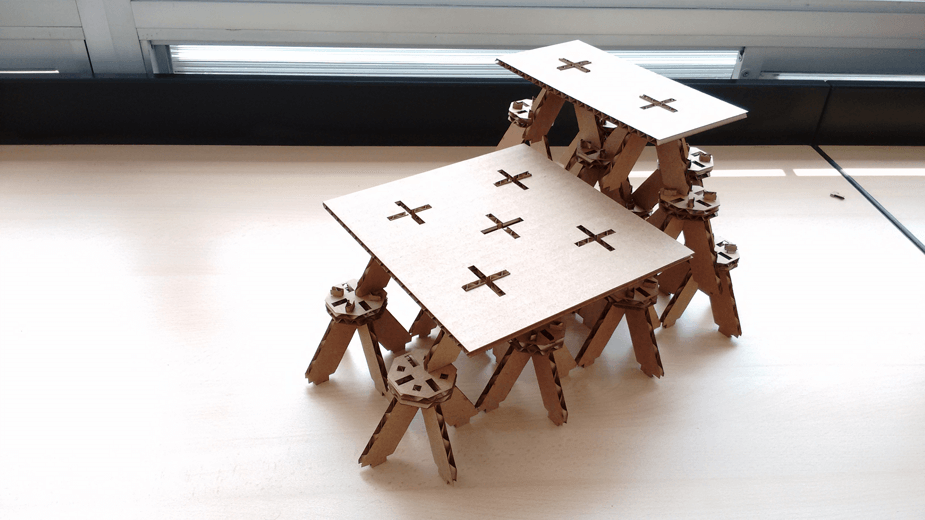

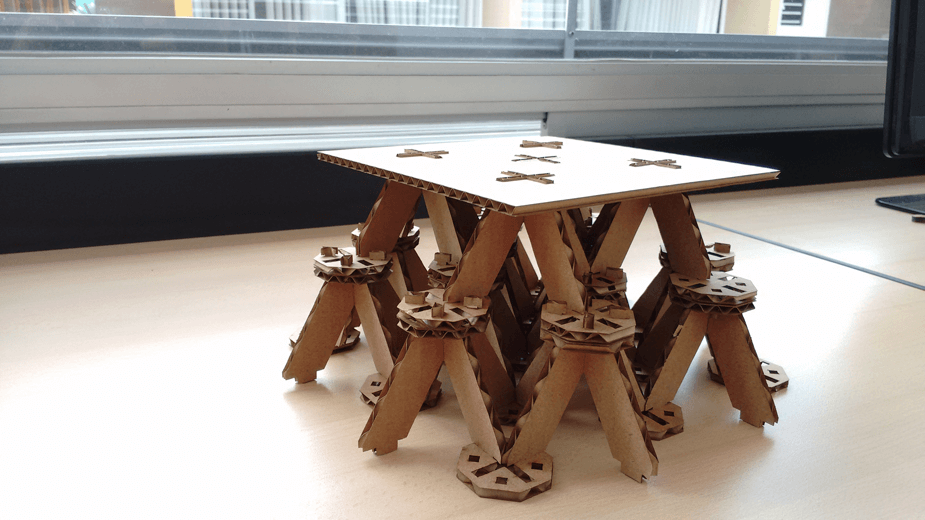

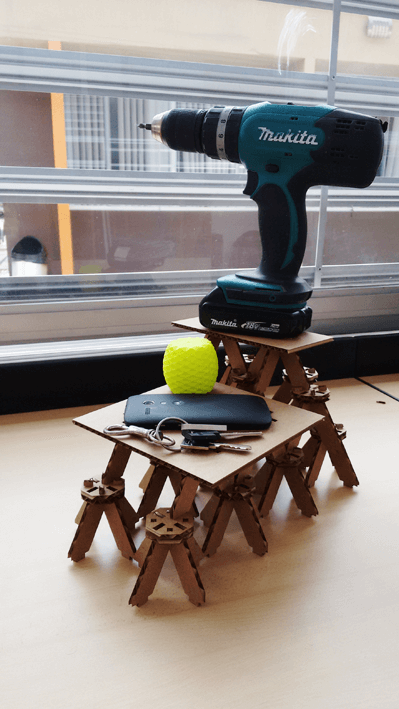

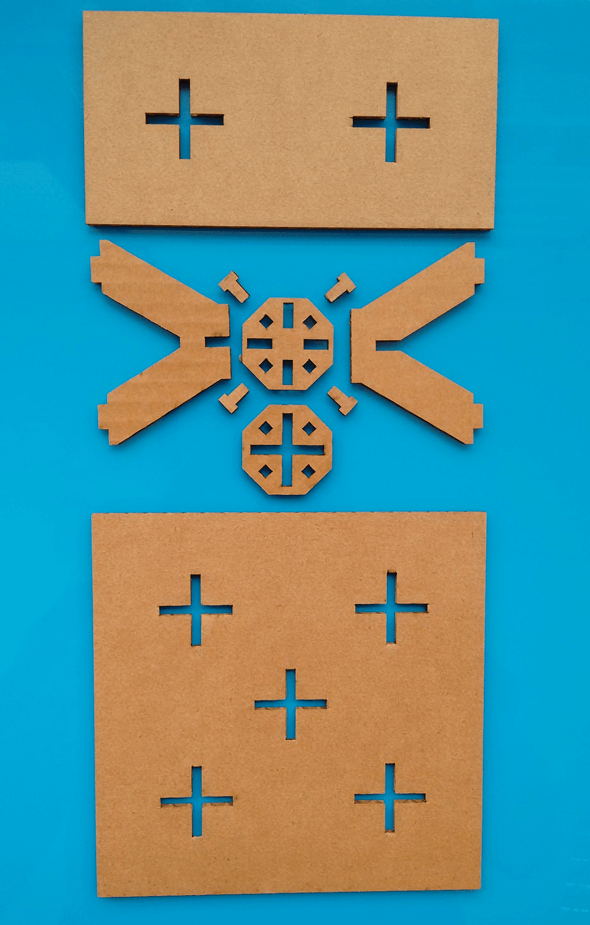

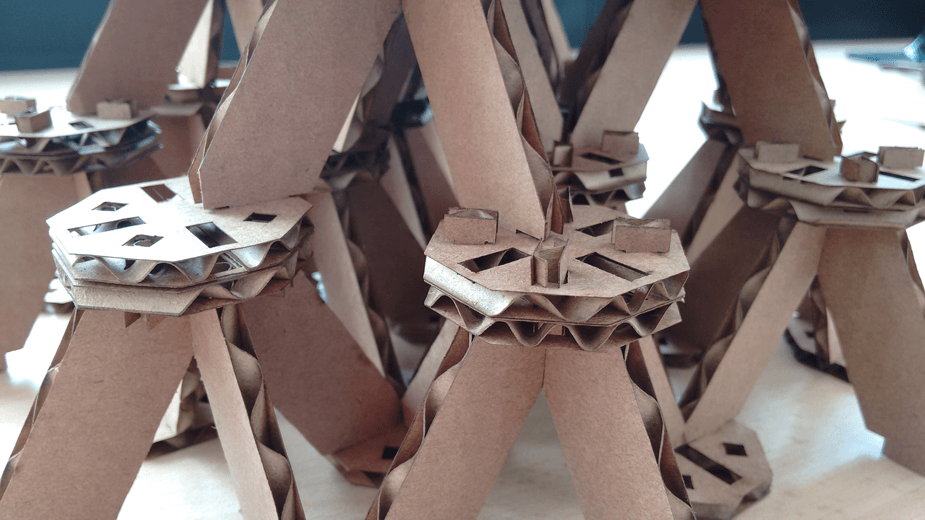

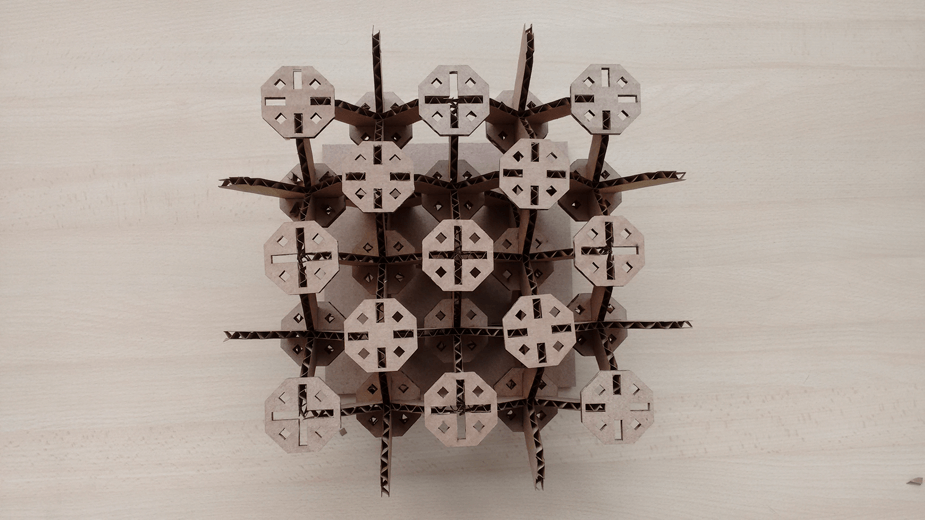

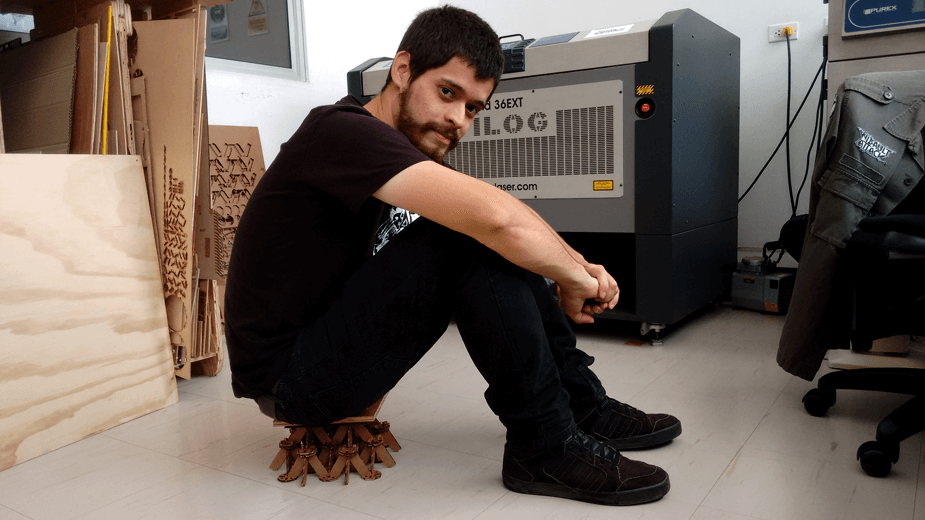

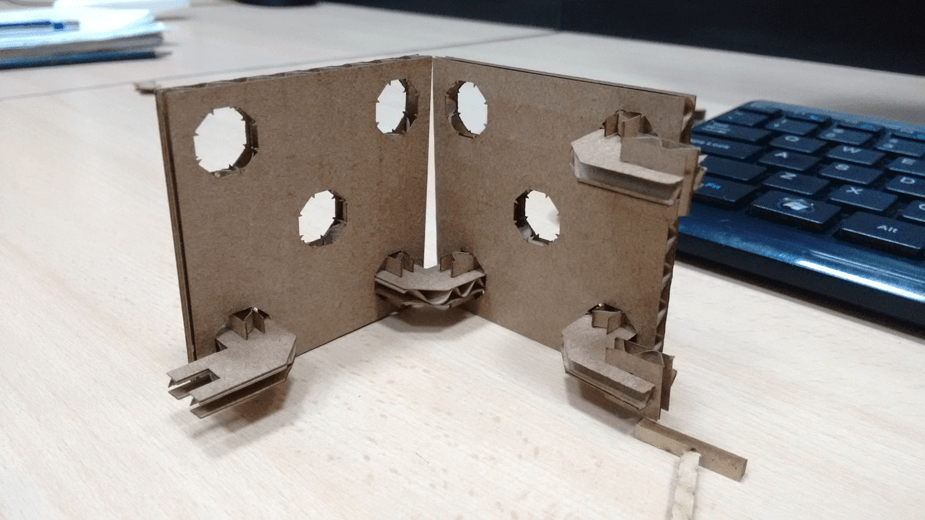

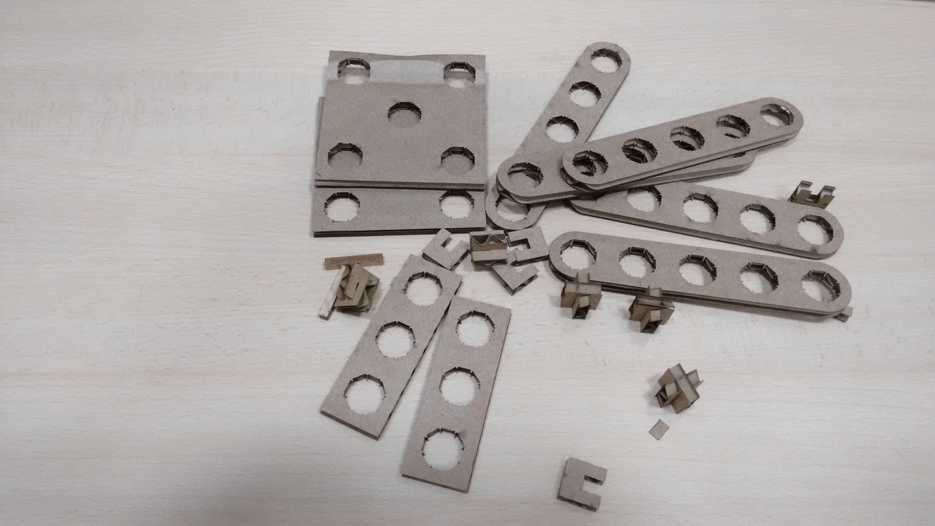

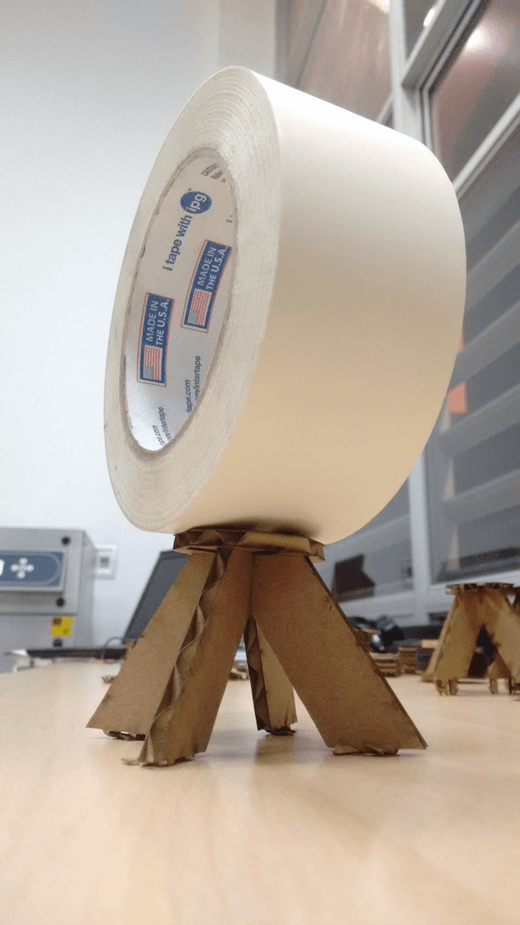

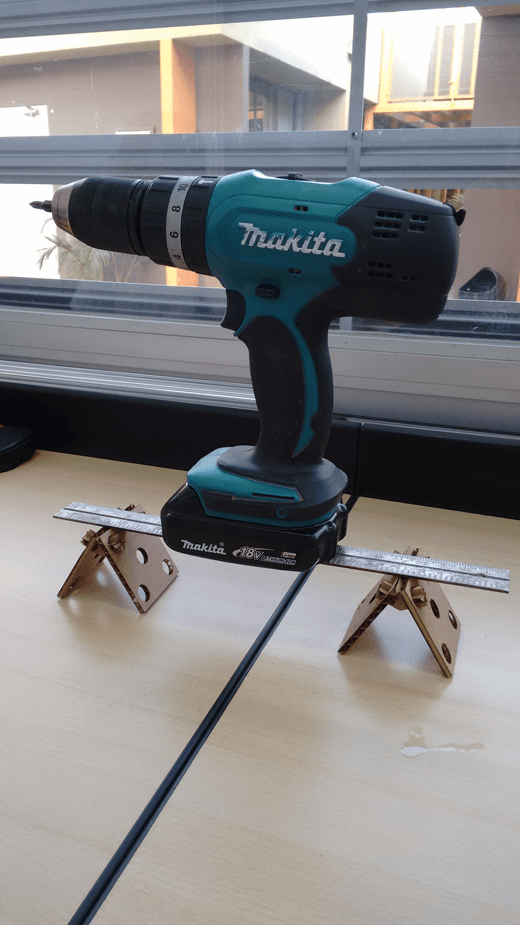

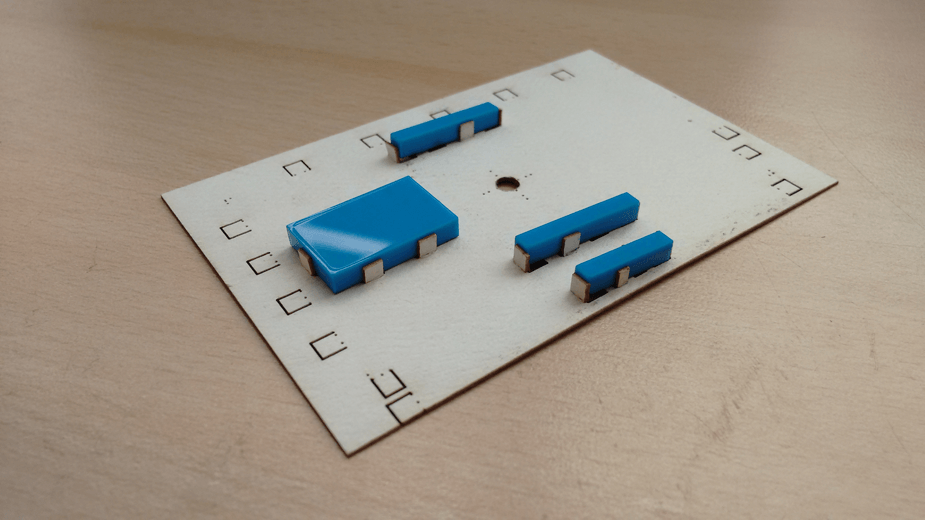

To my construction kit, I designed modules that allow me to organize objects on a desk at different heights and surfaces.

With the versatility and flexibility of my construction kit, I have the possibility to go playing with the organization of small spaces in work surfaces, and the best, it is resisting heavy objects.

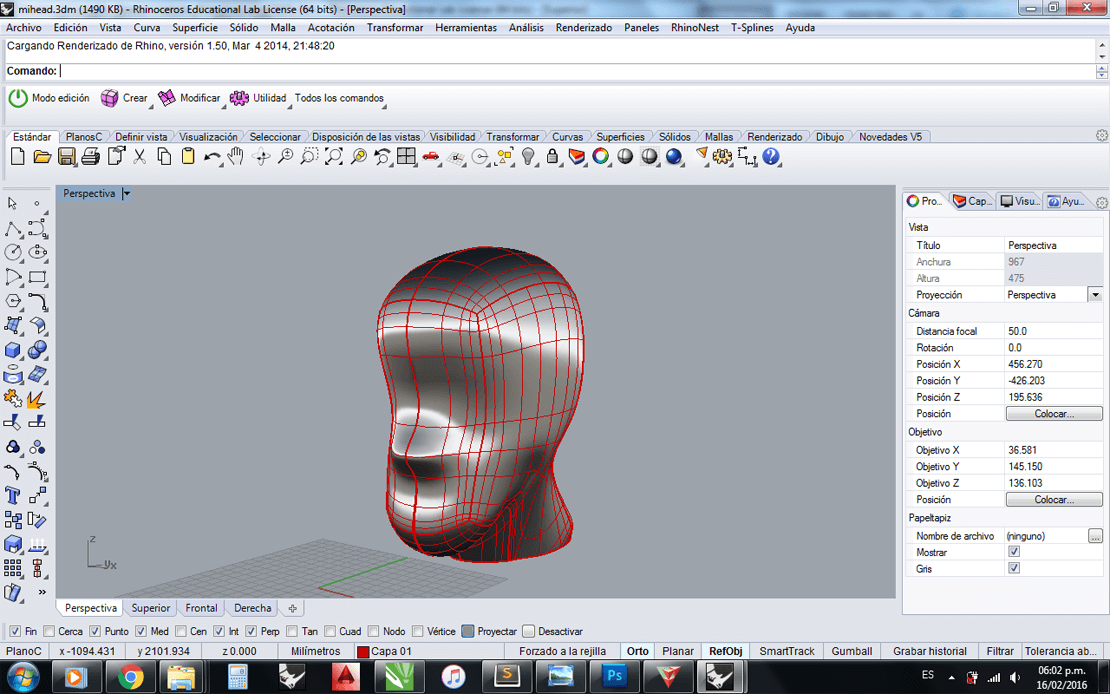

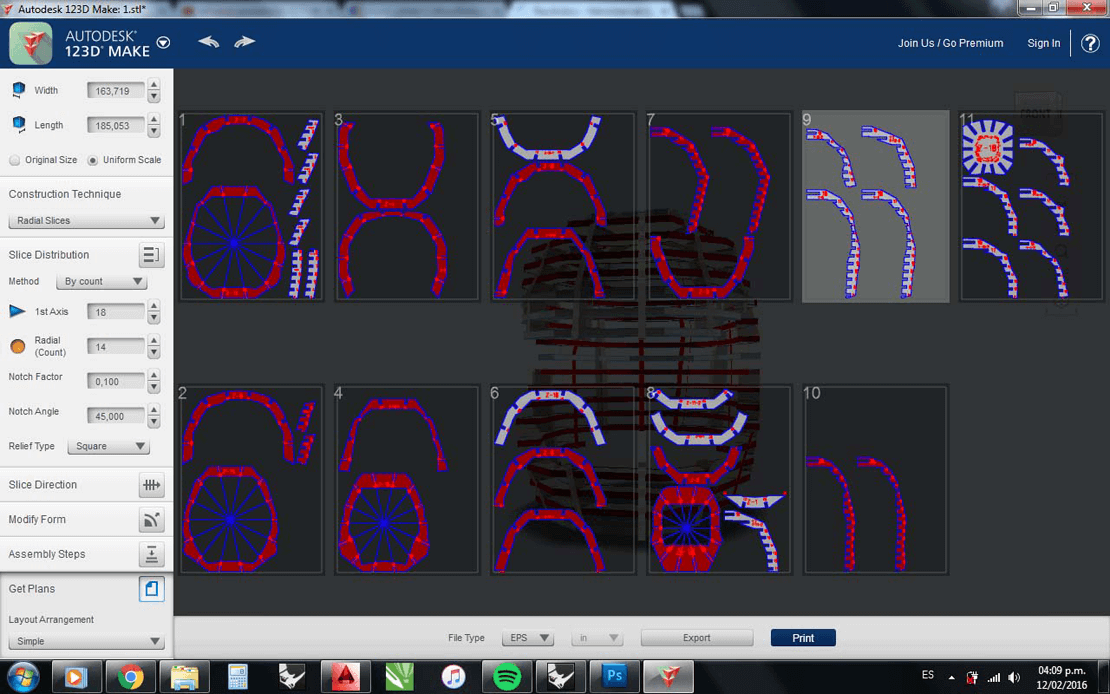

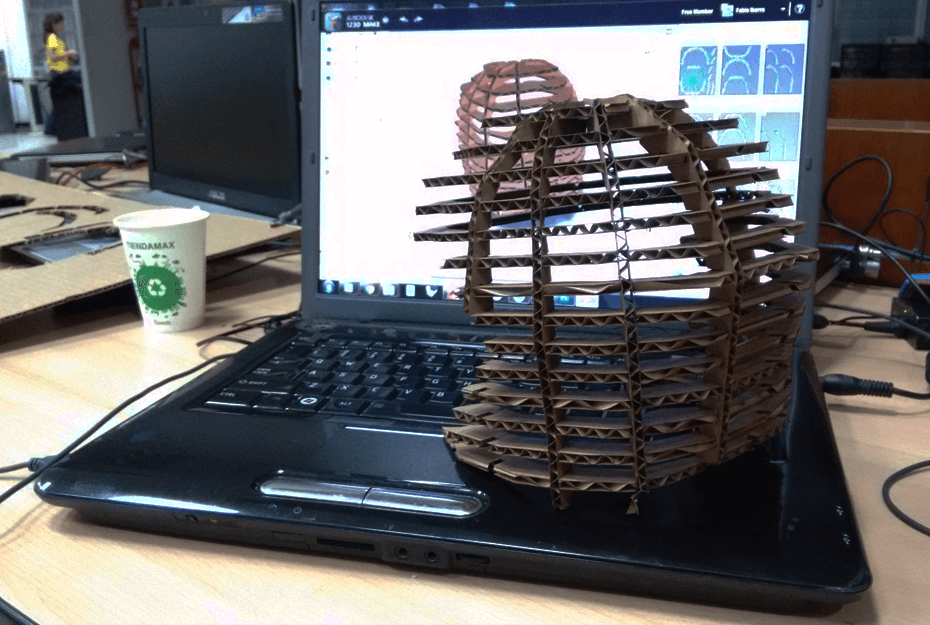

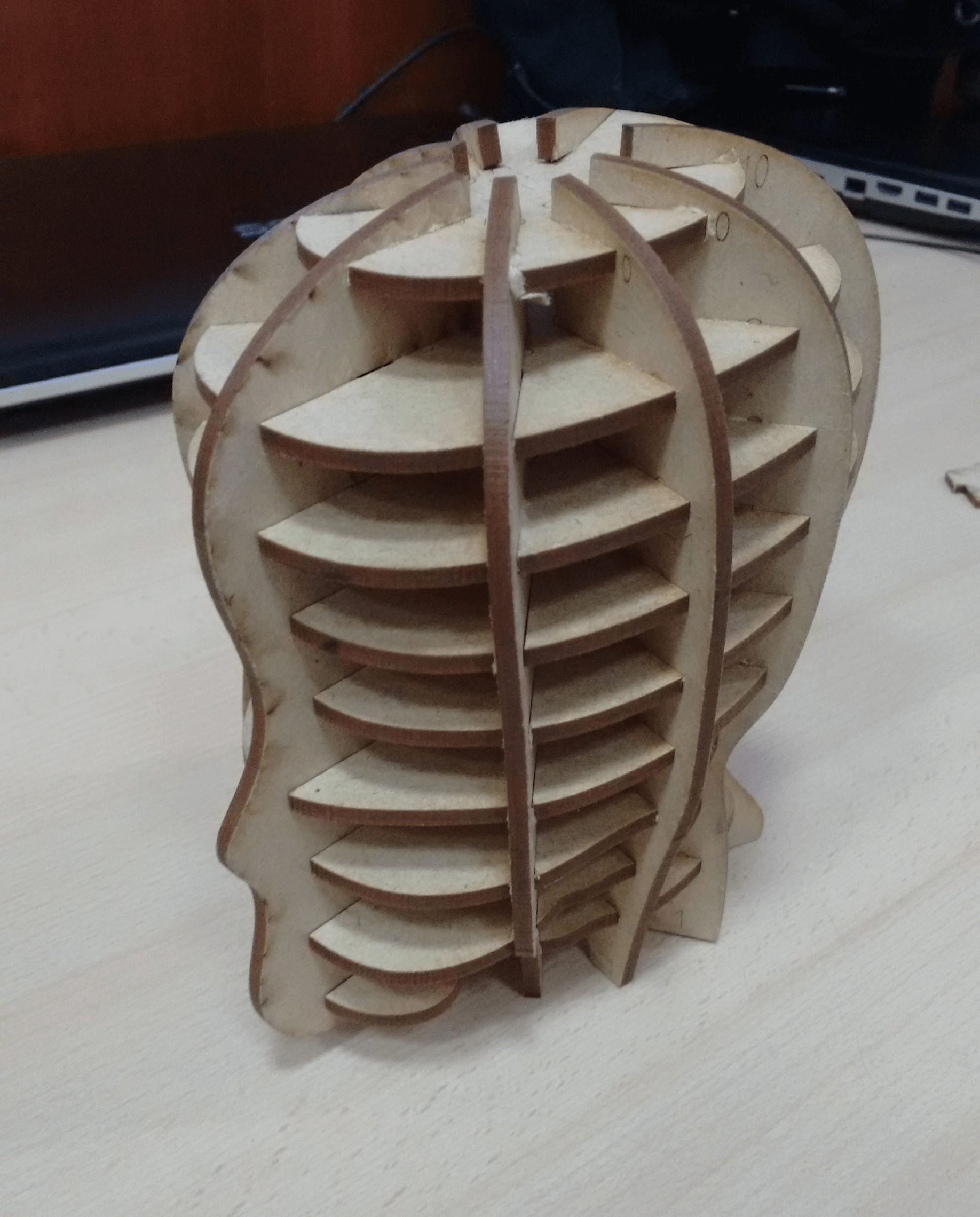

Since I'm a beginner in using these digital cutting tools, first I tested with "123d MAKE" Autodesk software, this software allowed me to understand the basic principles and factors to consider when moving from one 3D software to a three-dimensional physical objects.

The exercise I did was exporting an object made in rhinoceros to 123D MAKE.

As conclusion concerning "123D MAKE" I could say it's a good tool to get started in digital cutting tools, has a very interactive, intuitive and friendly interface. The downside of this software, I think it is limited and does not allow me to have total control over the unions that I need for my final project.

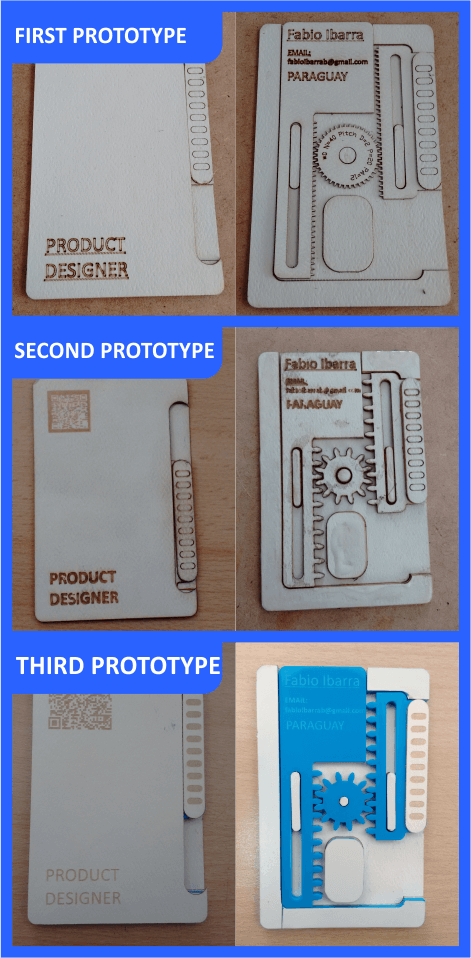

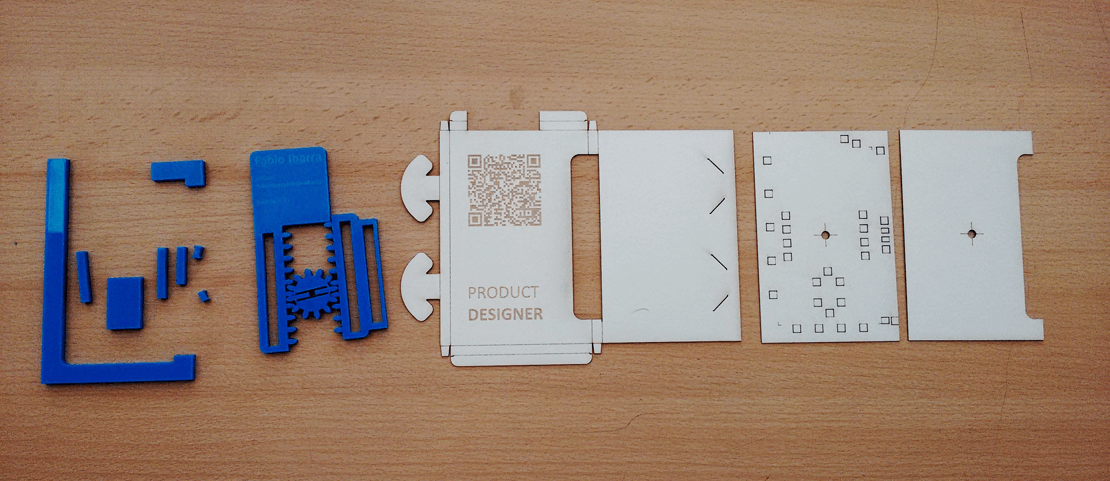

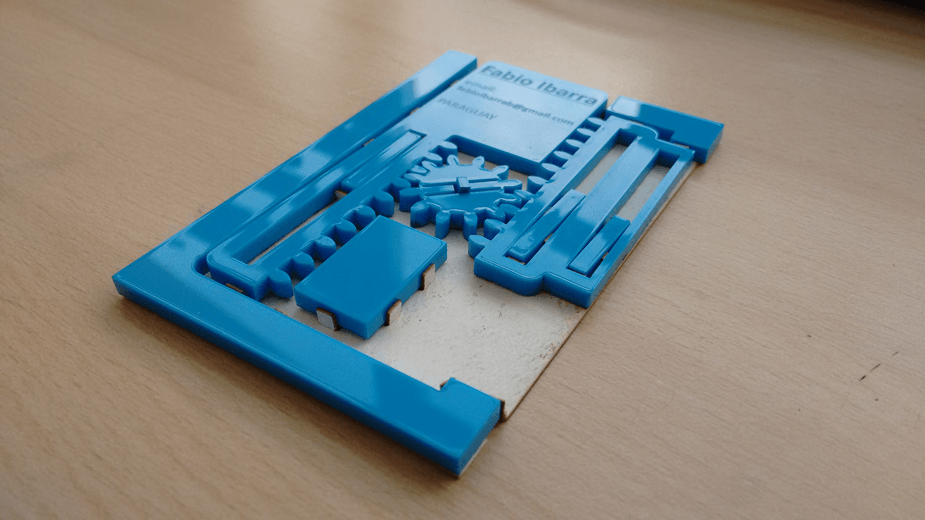

I took a little time to design and build a personal card. I want my card pretty special, so I decided to include in it the possibility that the user interacts with it.

I made 4 prototypes become fully functional only one of them. Using only laser as a cutting tool, this exercise could experience cutting and raster paper and acrylic.

One day we had a video conference with Latin American Fab Labs and showed it to Beno Juarez, who had made me a very particular question:

With the question in mind, I began to re-design my card trying to avoid glue on it. I did not have good results, but served enough to explore the possibilities and facilities that can give us a laser cutter for the development of any project.

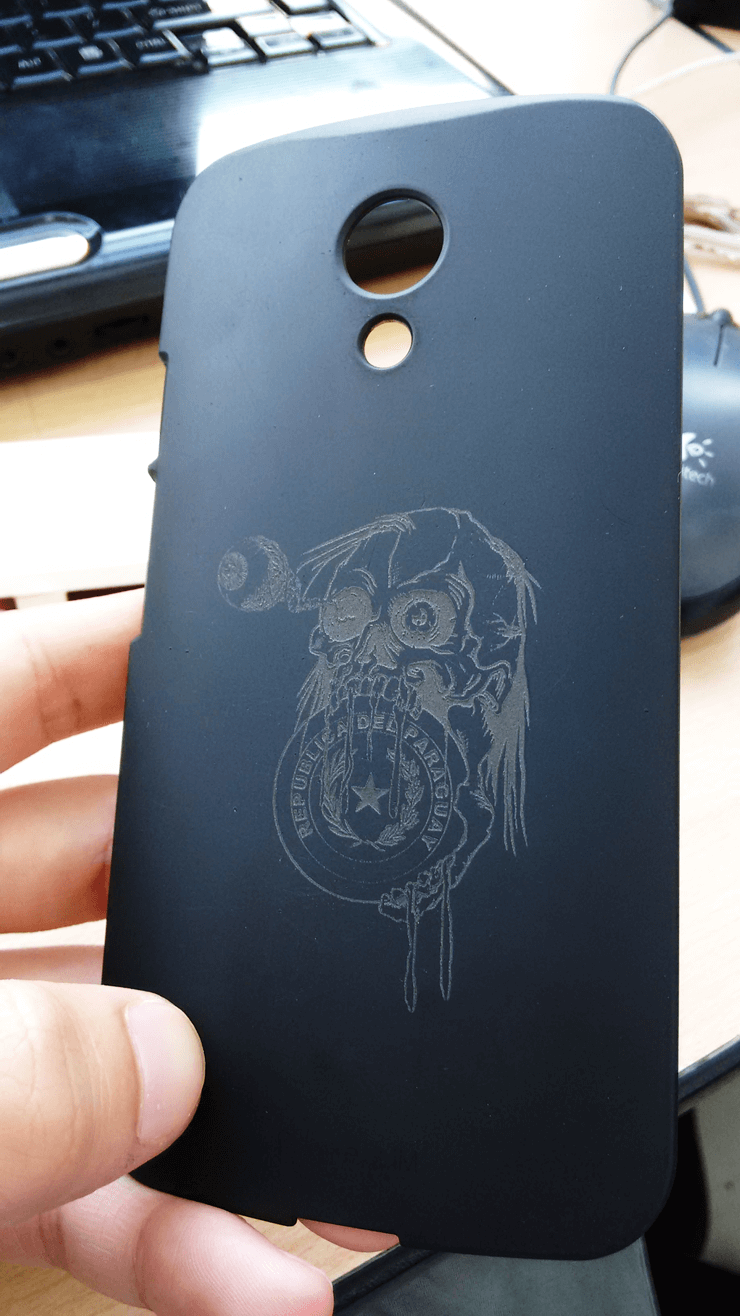

At some point I had some time to personalize the cover of my phone, that I experienced with "Raster" laser tool.

To cut vinyl in the Fab Lab we used the ROLAND CAMM-1 SERVO. The software used is MODULES FAB with Ubuntu.

Corel file: headcut.cdr

Corel File: helmetcut.cdr

Corel File: joinprueba.cdr

Corel File: Kitmodules.cdr

Rhinoceros File: Kitparametrico.3dm

Rhinoceros File: Spacialmodules.3dm

You can download the heavy files (more than 1MB) here from DROPBOX.

- The kit meets the requirements of assignment.

- Great experimentation with laser cutter.

- I had problems with the parametric tools.

- Explore more options parametric tools.

I'm currently taking this course in FAB LAB TECSUP, in Lima-Perú, through CIDI FADA UNA with the support of CONACYT and PARQUE TECNOLOGICO ITAIPU FOUNDATION

©DESIGNED AND BUILD BY FABIO IBARRA - FAB ACADEMY 2016

EMAIL: fabioibarrab@gmail.com