about

one.principles and practices

two.computer-aided design

three.computer-controlled cutting

four.electronics production

five.3d scanning & printing

six.electronics design

seven.computer-controlled machining

eight.embedded programming

nine.mechanical design

ten.machine design

eleven.input devices

twelve.molding & casting

thirteen.output devices

fourteen.composites

fifteen.networking & communications

sixteen.interface & app. programming

seventeen.applications & implications

eighteen.invention, property & income

Select "mill traces (1/64)" in the dropdown menu for the aircut.

Set X,Y and Z

the offset is 1 ; depht:0

click on "make path" - click on "make .rml"

set X,Y and Z

change the offset to 4 and the depht is 0.1

click on "make path" - click on "make .rml"

When the milling is finished we will change the milling-bit for a 1/32 bit and well'll follow these steps:

load the other .png with the outlines

change the offset to 1 and depht 0,5

click on "make path"

click on "make path"

click on "make .rml"

click on "begin milling"

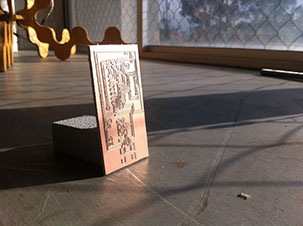

2. Cutting and milling the board.

First of all, we have to consider that our milling machine works with Linux. It was the first time that I worked with this operating system but I founded really similar to windows so I didn’t had any problem with that. Secondly, we have to know that our machine doesn’t work with a pre-installed program in our computer but it does through the internet: fablabmodules, program that allows us to handle the machine from our internet browser.

We will be milling the board using a precision desktop milling machine the Roland SRM-20.

final project

god.