Week 14

Mold Making

The assignment this week was to machine a 3D mold and make a fiber composite part in it.

My final project is a relatively large vacuum chamber for degassing molds and dehydrating green wood. I need a lid for my chamber and decided the strength of composites would make a great way application for this week.

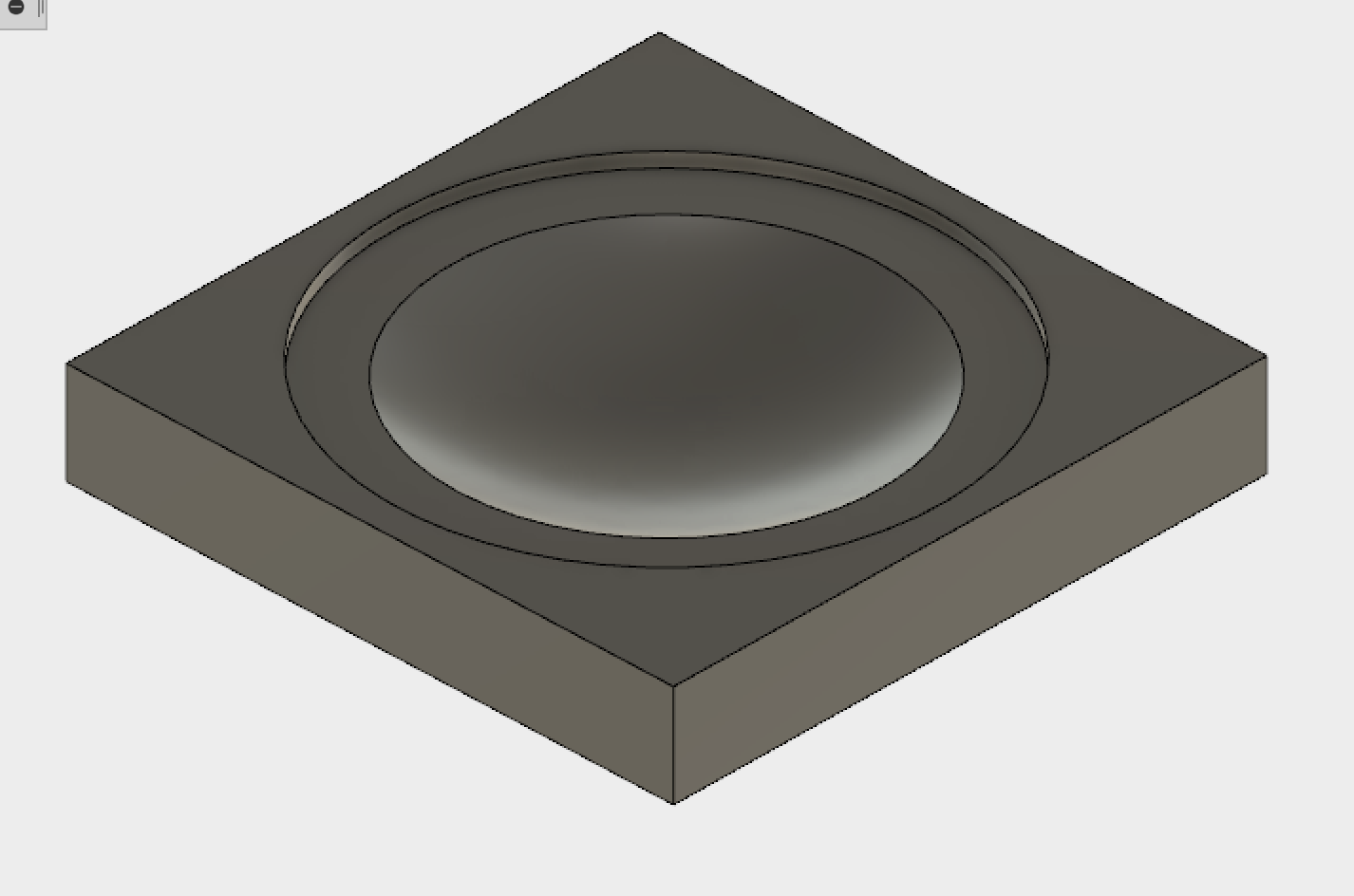

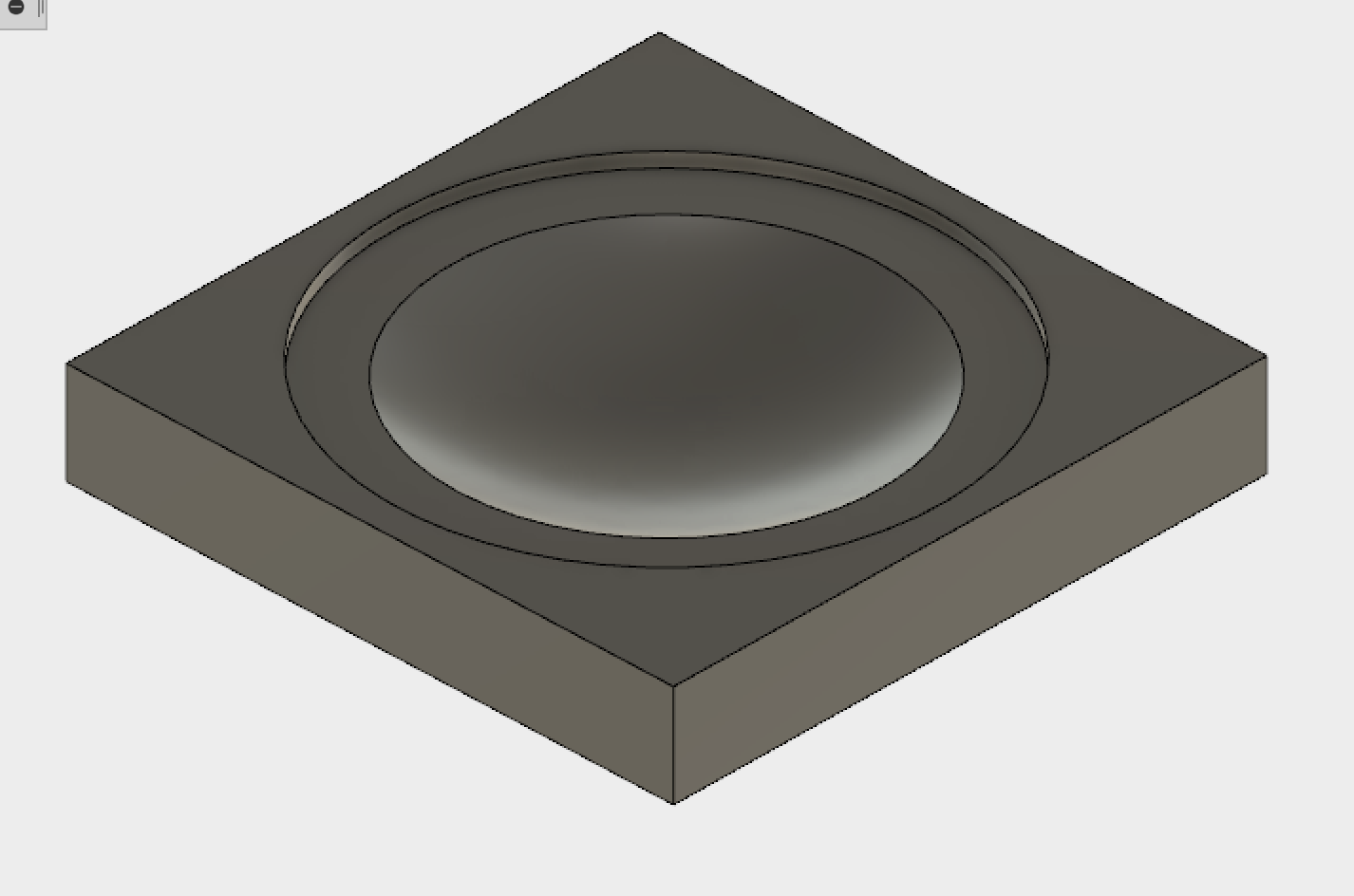

The first task was to draw the actual lid, which I did in Fusion 360.

I then converted the lid drawing into positive and negative molds for a simple clamshell design.

You can download the mold file here.

I initially milled the mold out of hard foam on our ShopBot, but unfortunately had a significant mechanical problem in the middle of milling.

Our dust boot got jammed on the foam and broke both the mold and itself when I was ~75% finished.

Amazingly, I actually got this moment on footage as I was filming for documentation at the exact time it happened.

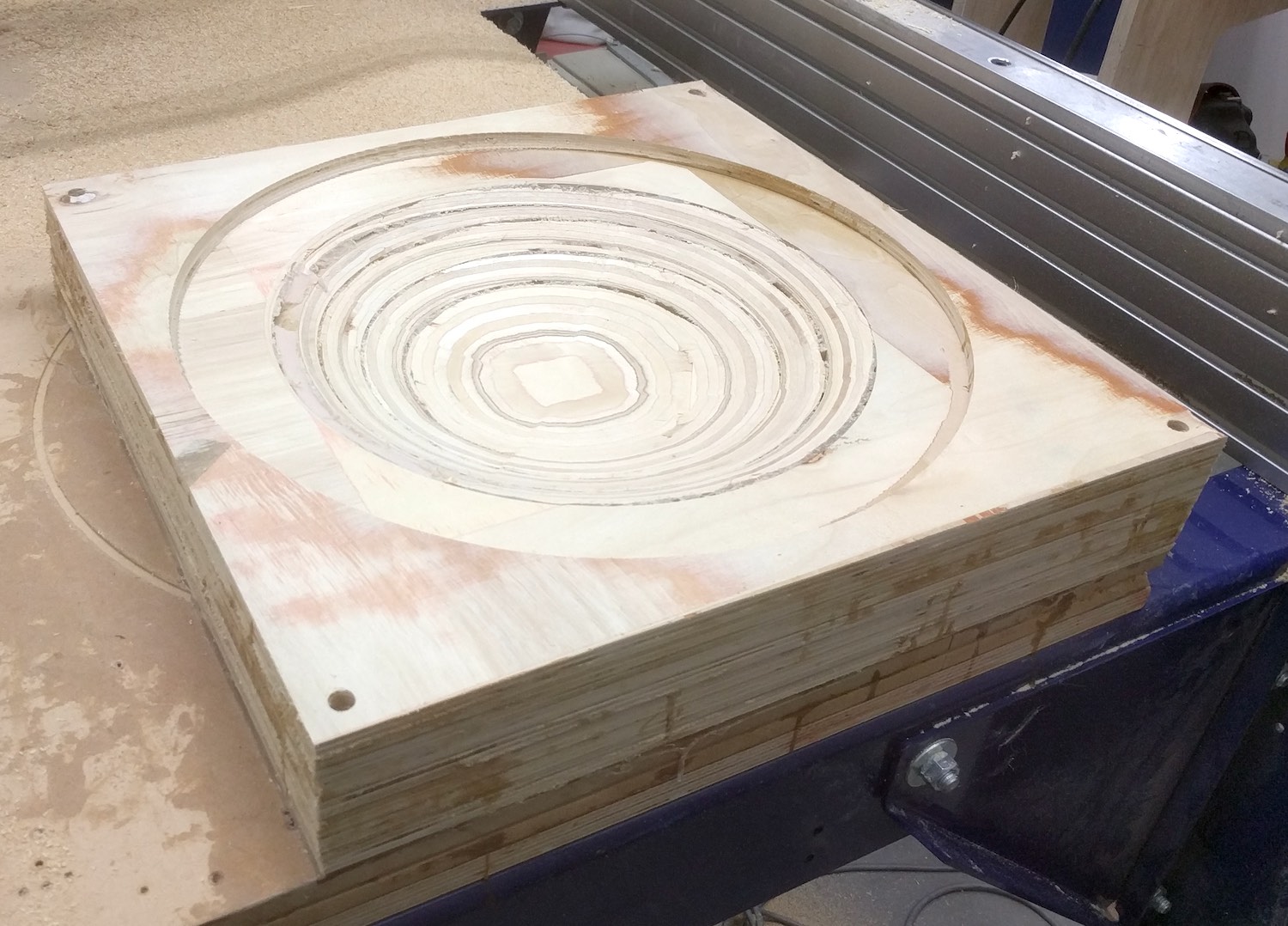

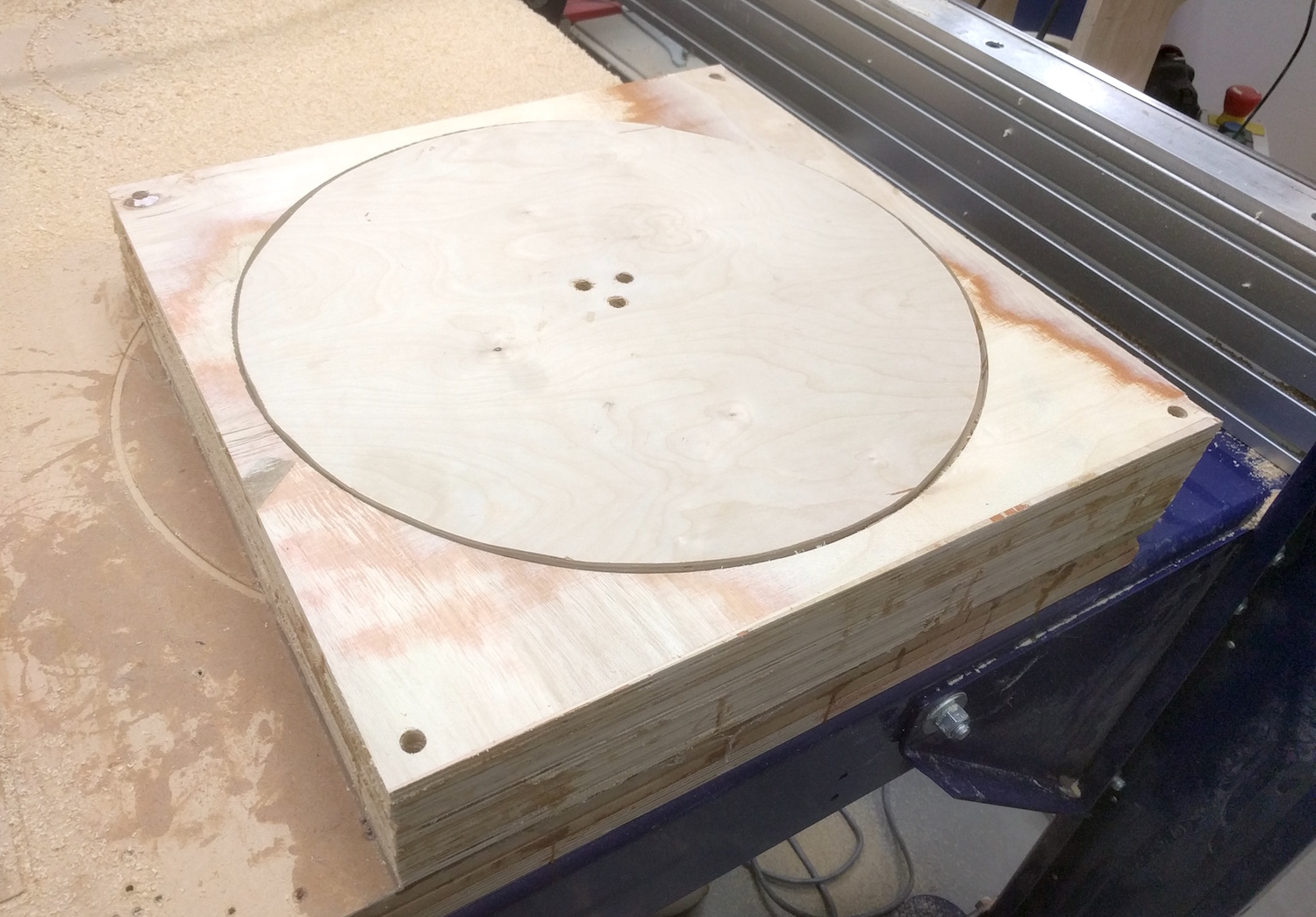

We didn't have any extra foam available, so I had to think quickly and ended up making my positive and negative molds from stacks of plywood.

In order to conserve material, I actually rough milled the sheets before stacking and gluing them, creating rough steps approximating the shapes for my mold.

I milled out the top and the bottom of my mold separately, performing both rough cuts and a fine cut with a stepover of ~0.05"

The top of the wood mold getting finished

The bottom of the wood mold finished

They fit together!

This piece will be under considerable stress when a vacuum is pulled in the chamber (~14.5kN) so it needs to be extremely strong. As a result, I decided to use 10 layers of burlap. This resulted in a very thick piece for composites (0.75cm thick!)

Hopefully it's strong enough!

The raw piece that came out had rough edges and a poor surface finish.

The raw lid out of the mold

So I first trimmed the edges on the ShopBot, giving me a perfect circle.

Trimmed to a circle

Then I sanded the surface and sealed it with a light coating of epoxy. I am certainly glad to be working with a natural material, otherwise this finishing process would be incredibly difficult.

Finished lid

Overall I'm very happy with the piece and can't wait to see the whole project come together!