- Design appropriate objects within the limitations of 3 axis machining

- Demonstrate workflows used in mould design, construction and casting.

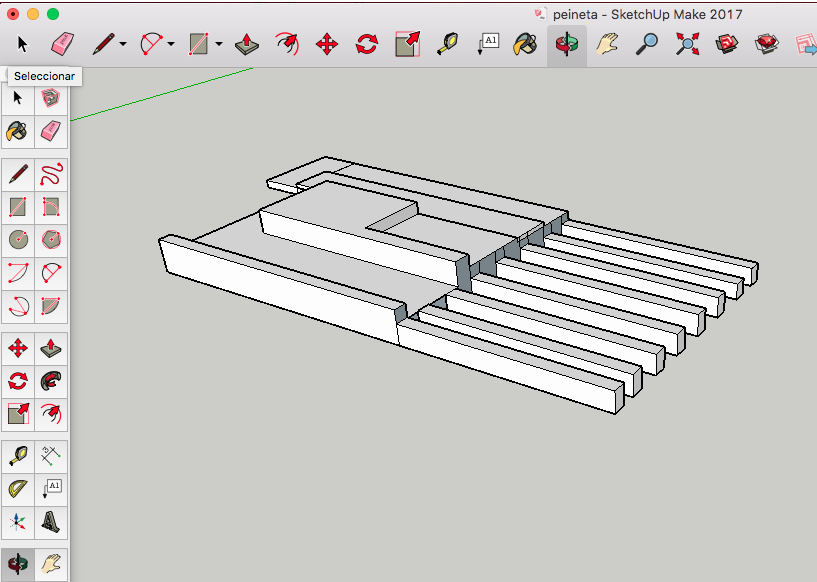

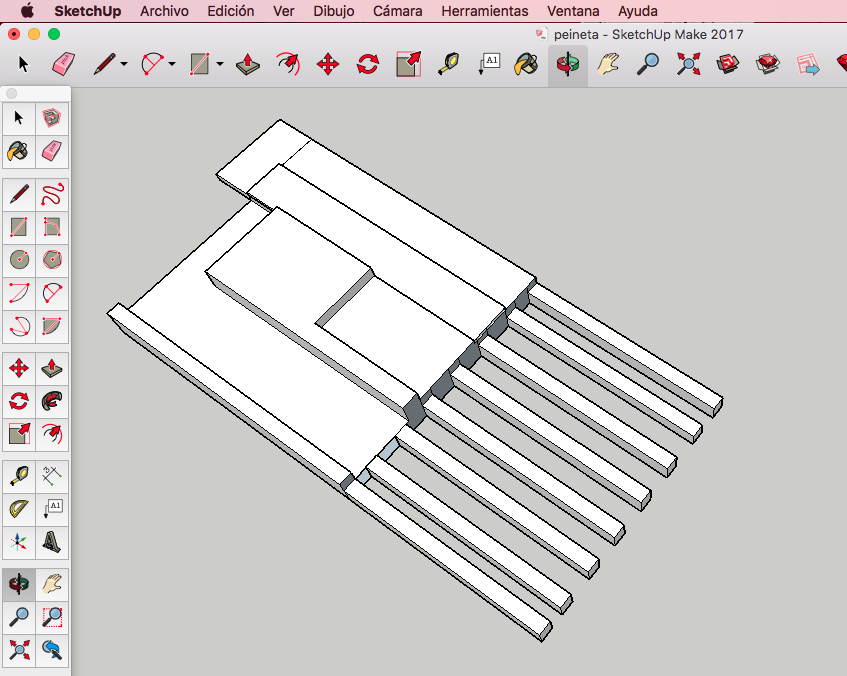

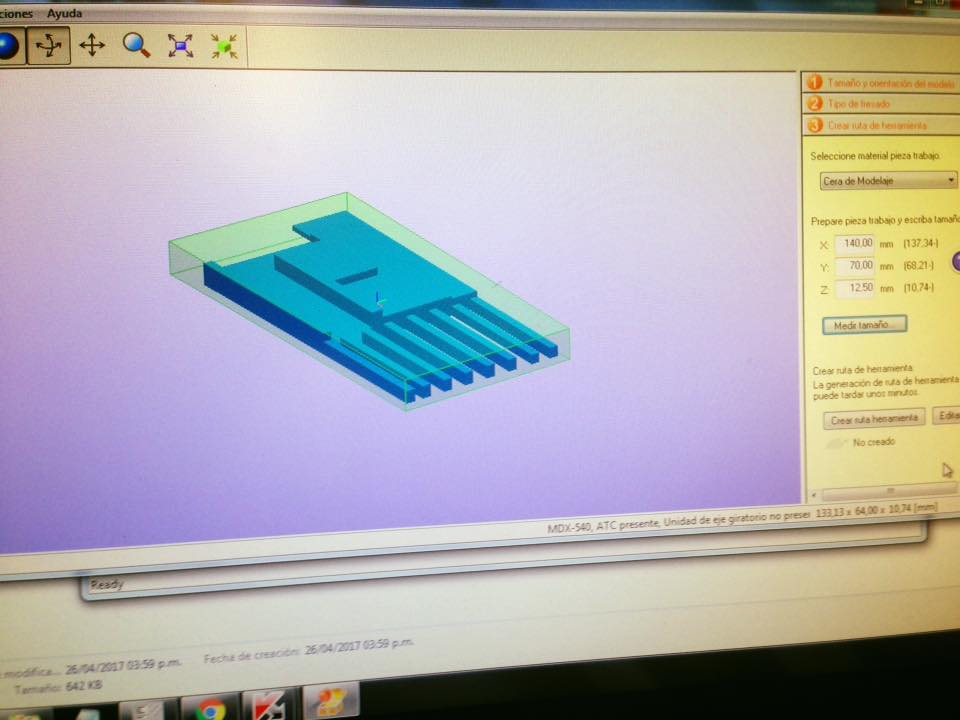

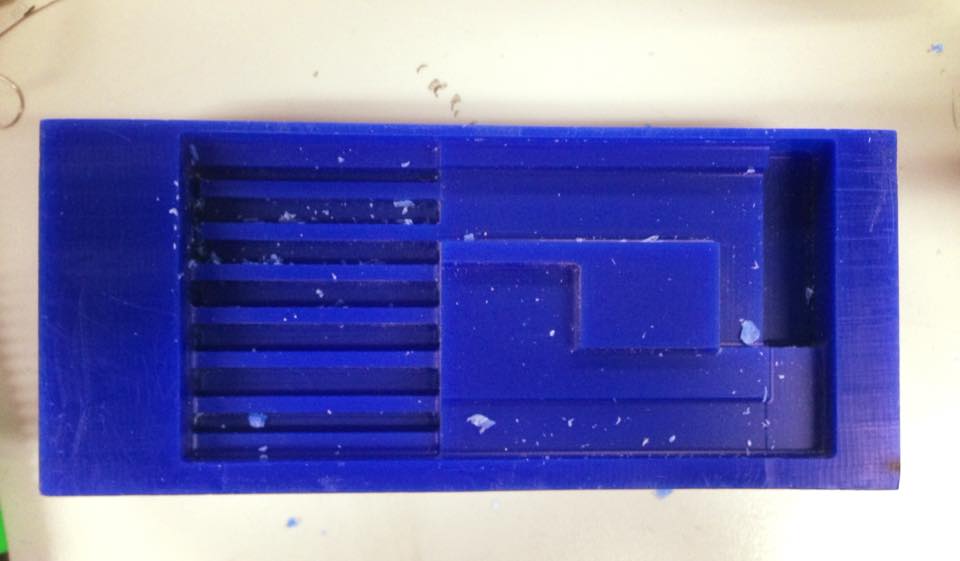

I used Sketch Up to model a hair comb in 3d and export it in .stl

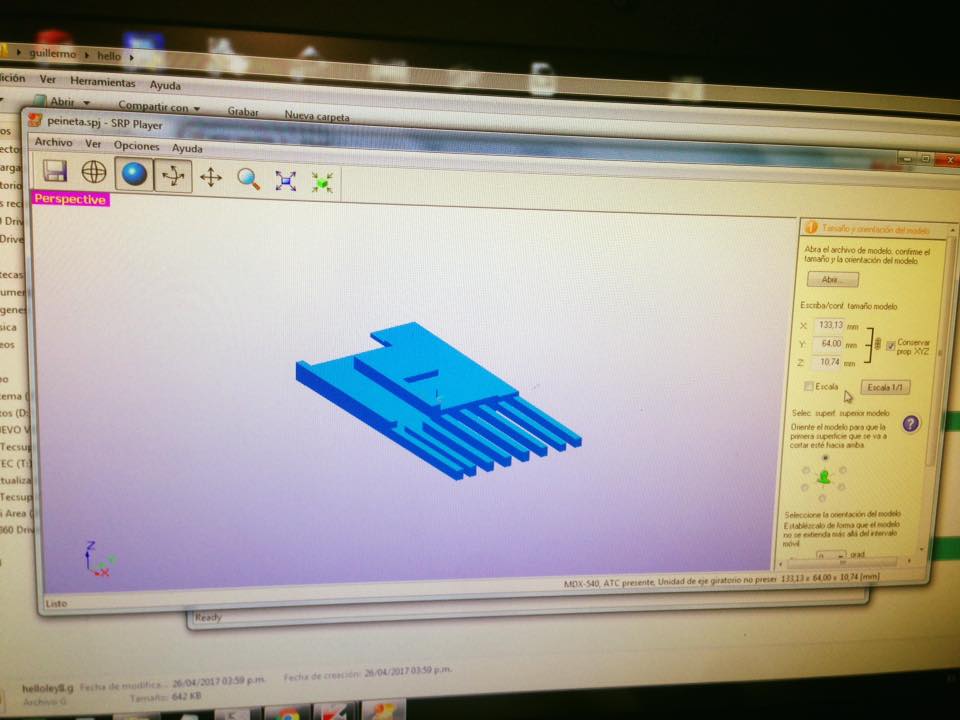

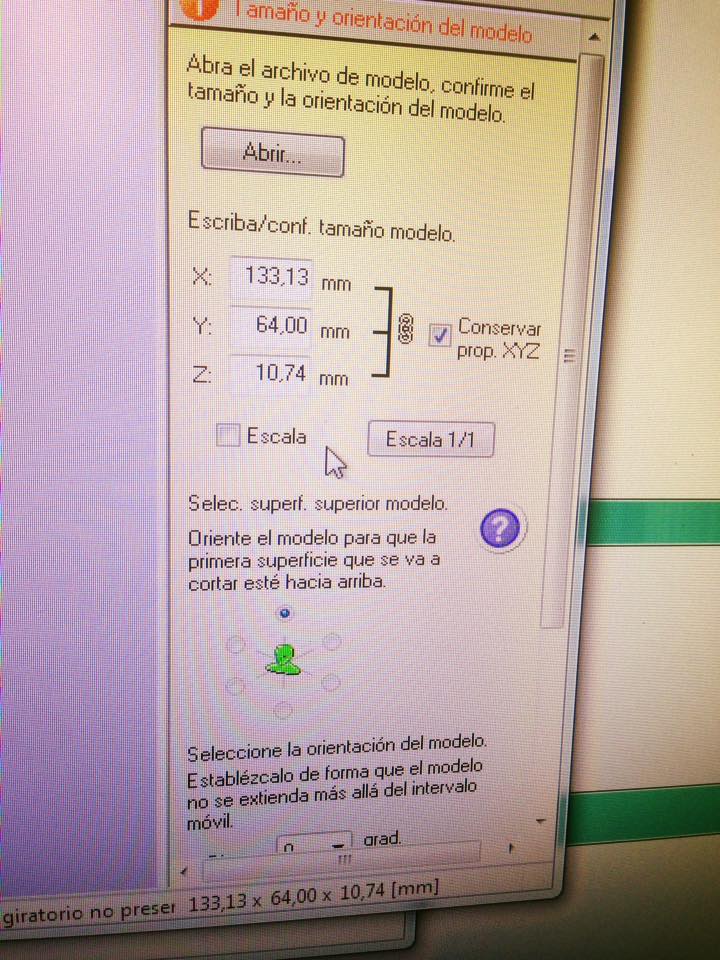

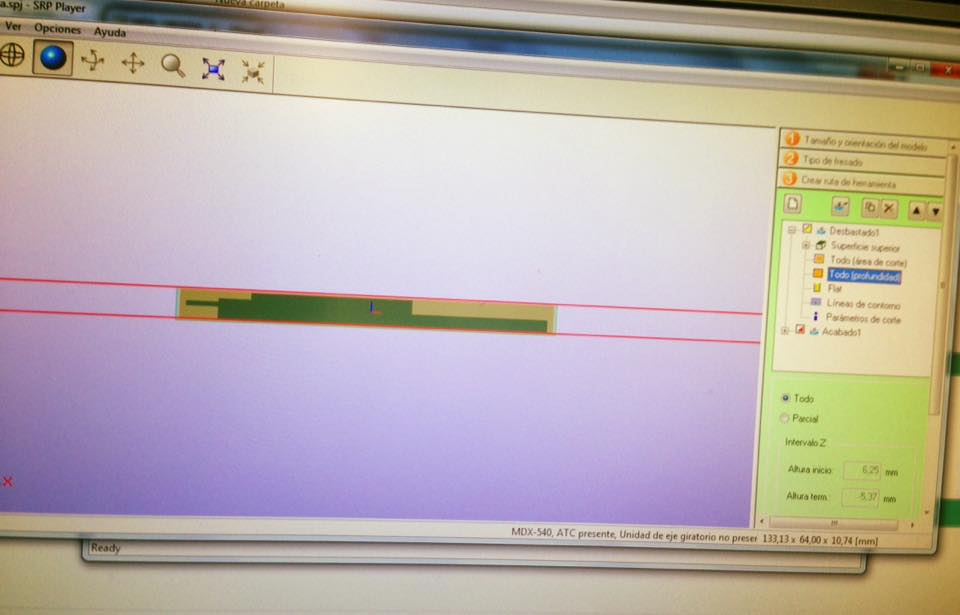

Then I used the SRP PLAYER wich is the default Modella MDX-540 software.

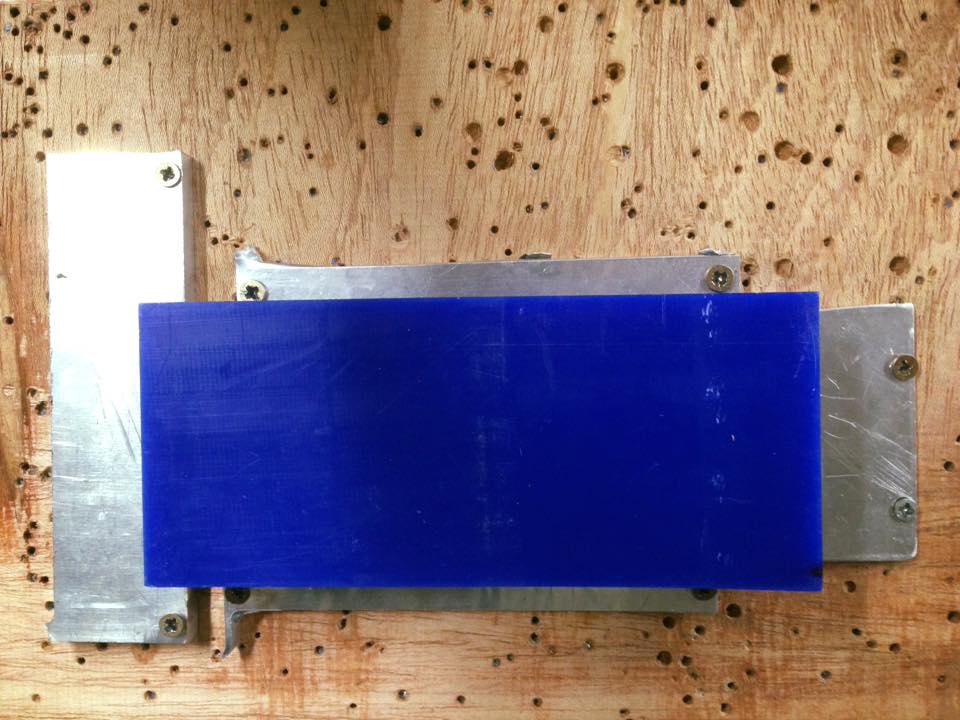

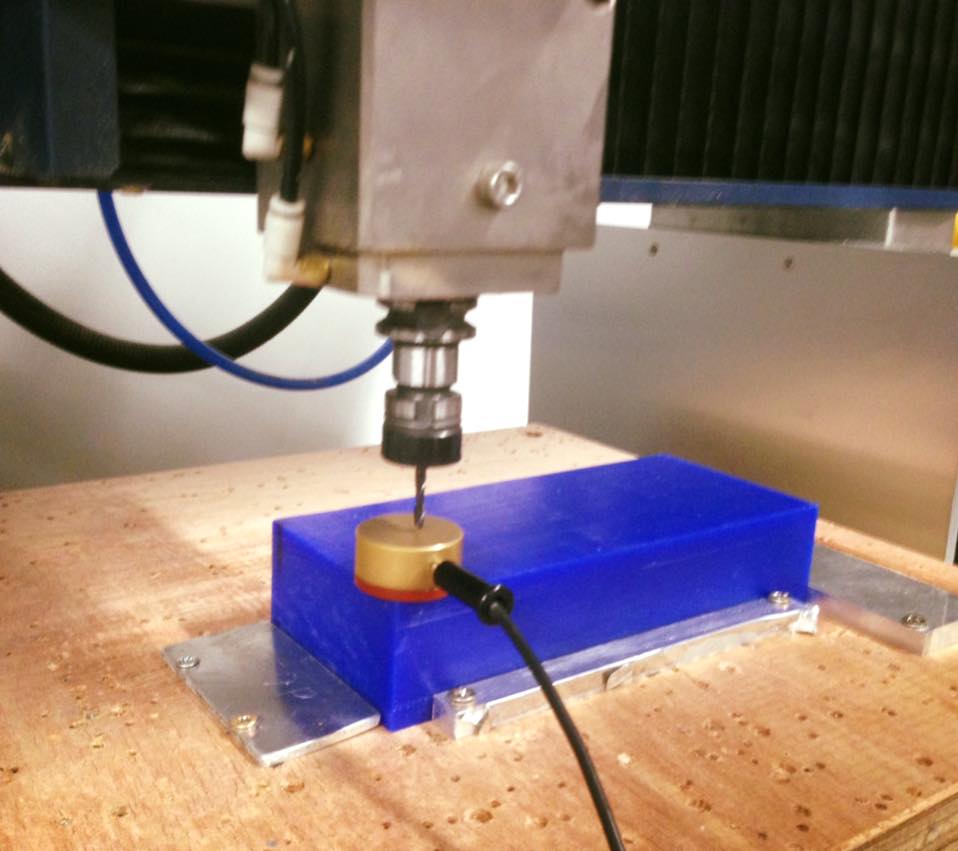

Before setting the parameters, the block of wax where the mold its going to be milled needs to be set on the Modella. We used metal barriers fixed with screws to stop the wax block from moving.

With that in place, the parameters can be set (x, y , z)

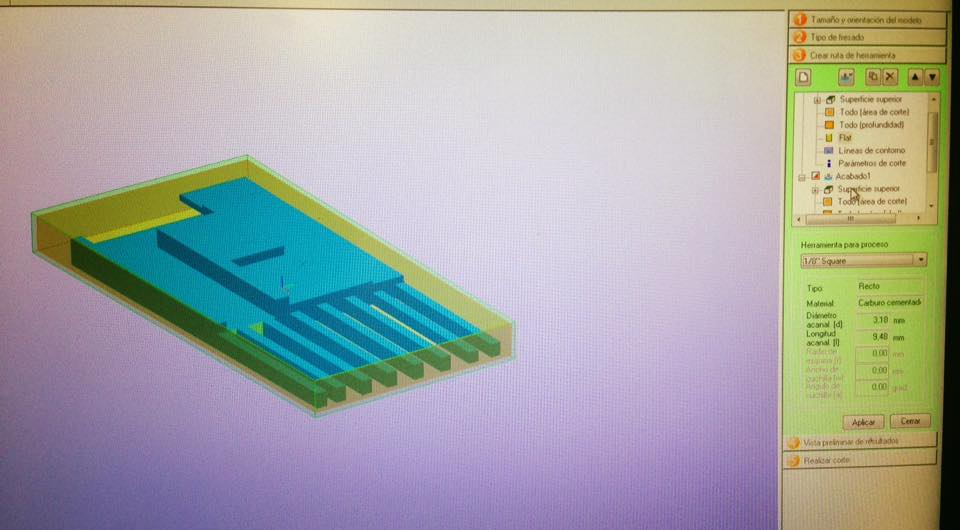

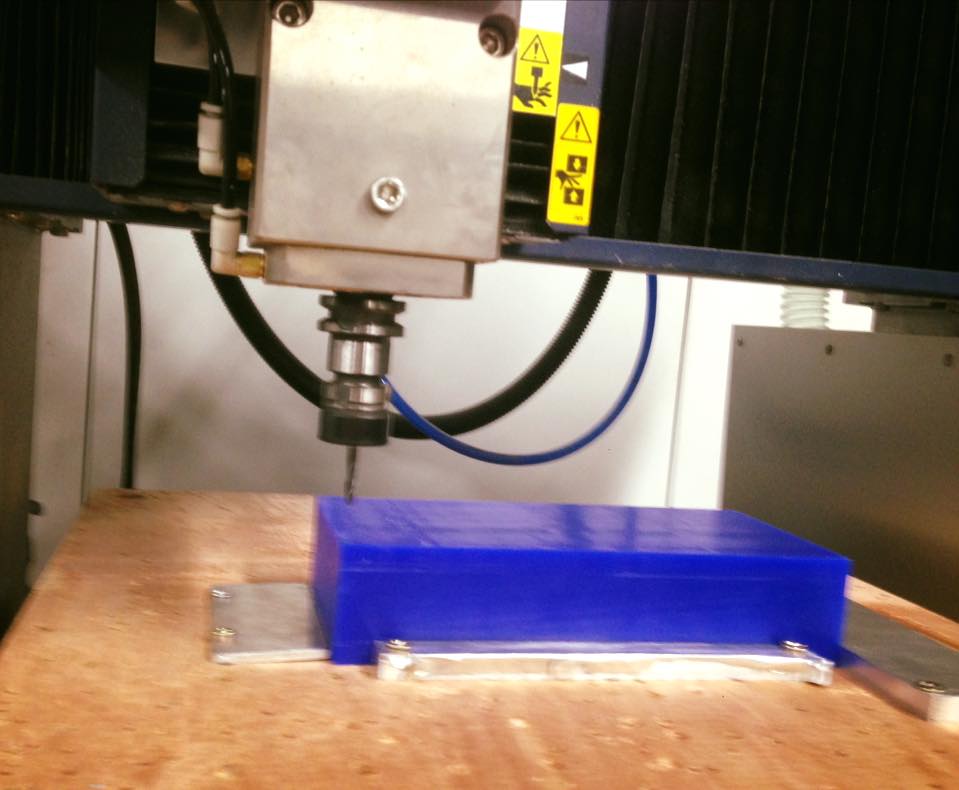

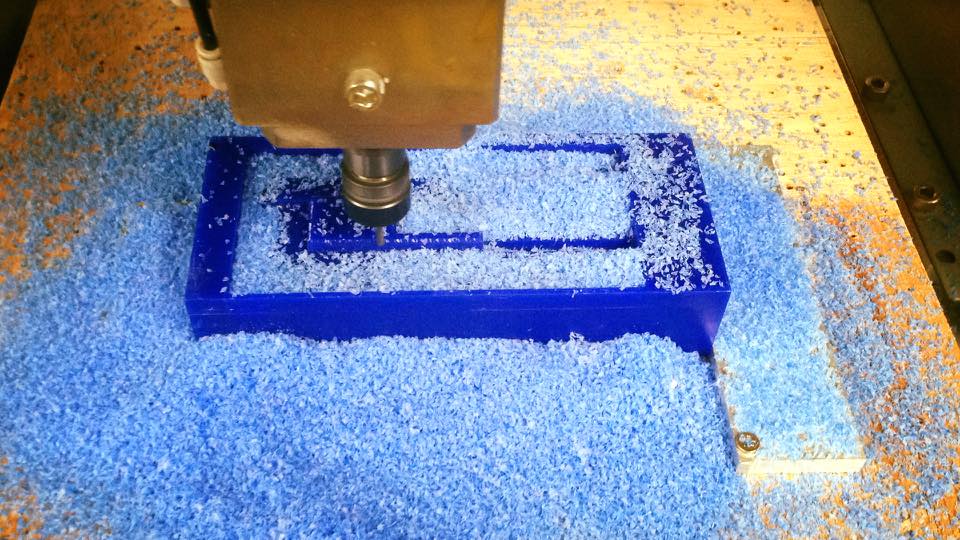

The Modella needs to do two Jobs here, first the milling with the 1/8¨ flat endmill.

Then, it must do the finishing 1/8¨ ball endmill.

The endmills must be measuared before setting “Z” on the middle of the design.

Work in progress:

The result:

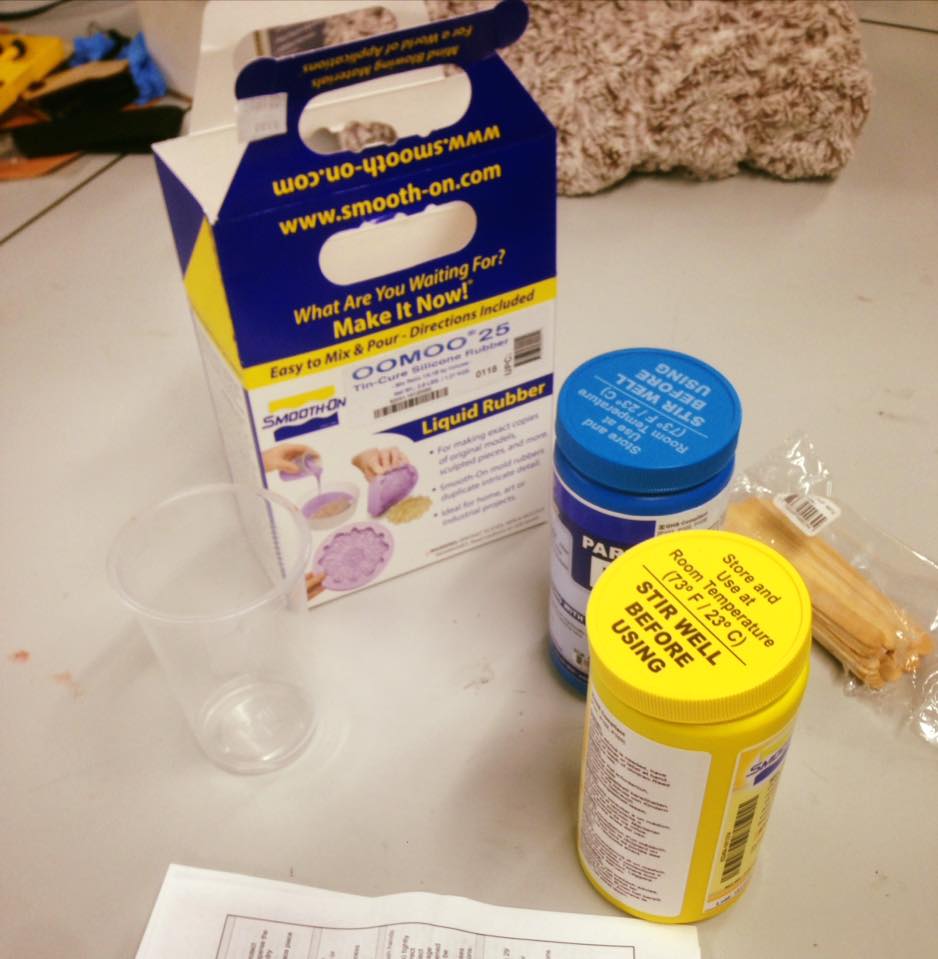

With the wax piece milled, the next step is to take a sillicone mould. For that I used the OOMOO 25, which is a liquid rubber of two components A and B, both need to be mixed with the same quantity.

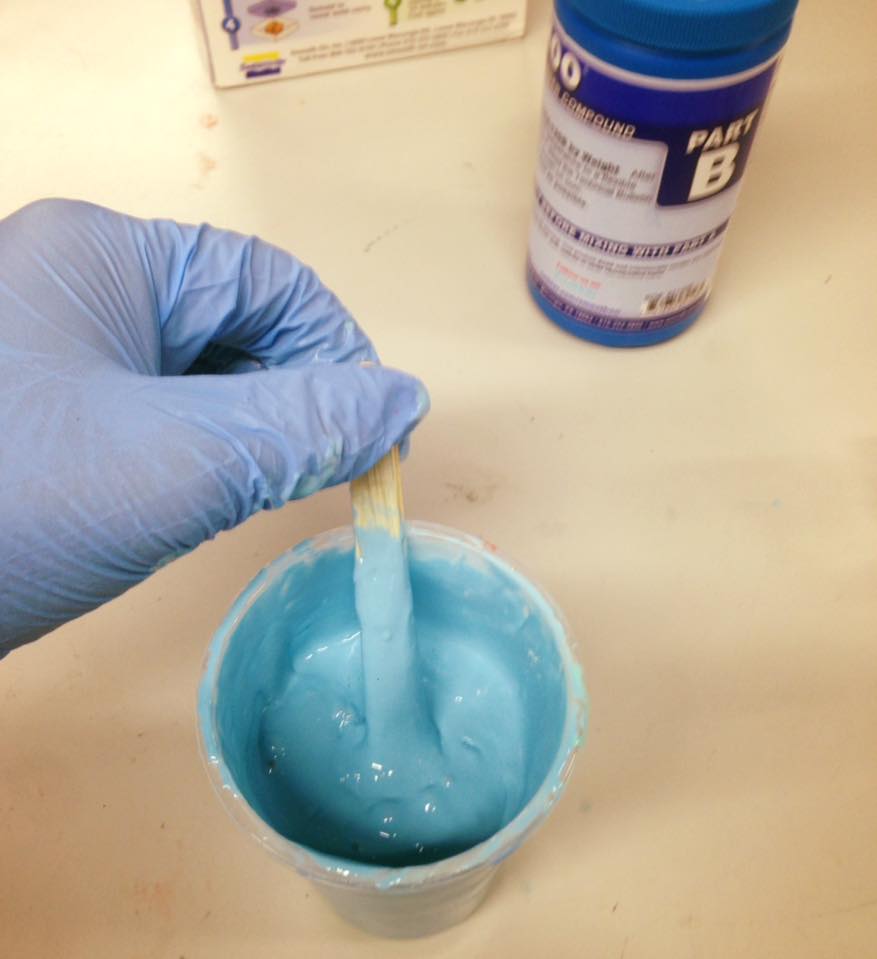

The components must be mixed for 3 to 4 minutes to get a Homogeneous mix.

I needed a structure to put a round the wax so the sillicone won´t spill. I discovered some plastic kind of lego forms in a container in the lab. It worked pretty well.

The result:

At the end I did two moulds while waiting for the first casting to be done, so I could do more pieces faster.

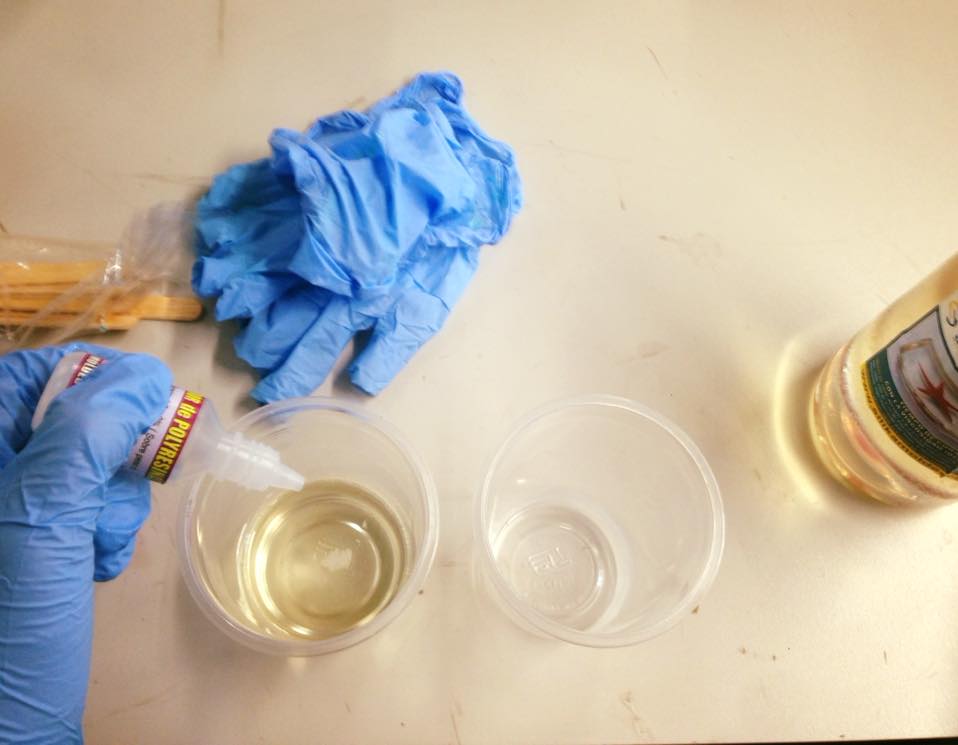

For the casting part of the assignment, I used epoxy resin from a local Brand and its catalyst. One part catalyst for five parts of resin.

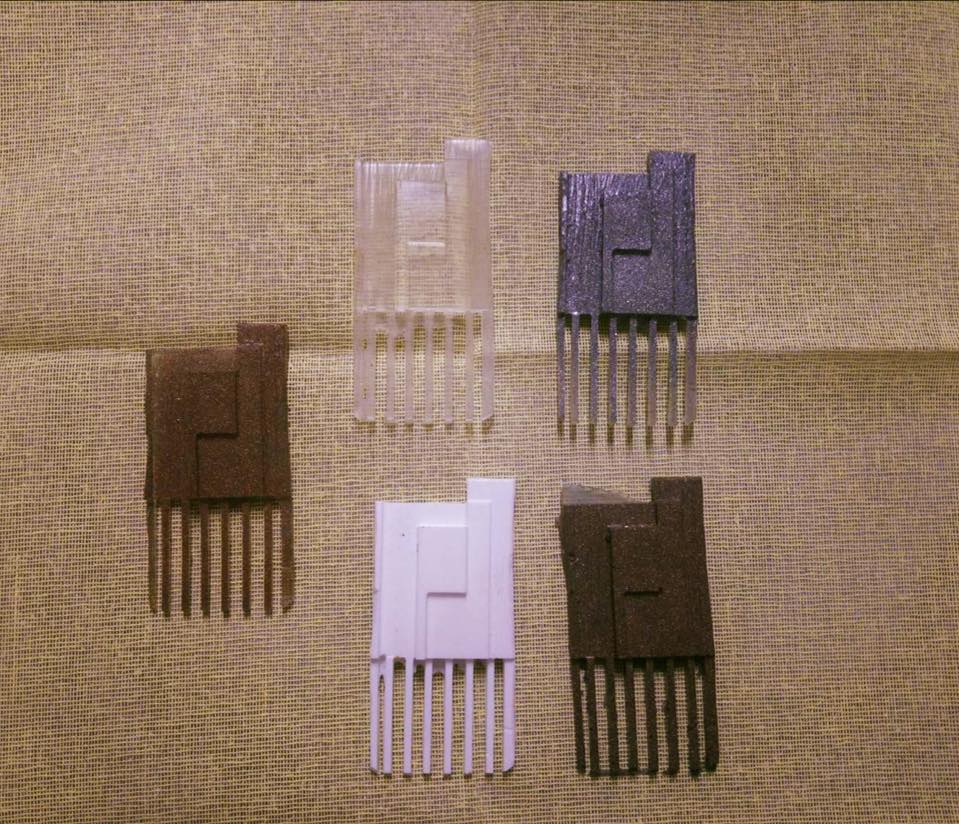

I made several tries, for the one I used just the resin, then I mixed it with the dust left on the modela from aluminum and bronze. Finally I tryed one with the Smooth- Cast 305.

The final product: