Week #8 make something big, it may sound simple but I really struggled during this assignment. The first thing was looking for an idea or something "big" to make, and I think that I took too much time thinking of something that I would like to make. The second thing was the machine it self, because the company that was supposed to deliver the machine (Shopbot) to us had some issues and they delayed the delivery.

So this week revolves around the idea of CNC or Computer Numerical Control. And in order to have a better understanding on this topic I read some of this very useful book, Make: Getting started with CNC.

A CNC is a machine whose movements are controlled by a computer through a process known as Computer Numerical Control. milling machines, 3D printers, vinyl cutters and laser cutters are all considered CNC machines.

Why computer controlled? there are many advantages to controlling a machine with a computer over manual operation: accuracy of the cuts, ability to simulate the job in software and safety.

So for this weeks assignment I decided - after long and long thinking - to make a Game Of Thrones inspired chair, I know it doesnt look anything like the real one but I saw it and loved the idea and decided to do it.

So I started designing the chair using Fusion 360 as my designing software, as I mentioned before it looks nothing like the real thing but I like it.

Then I exported the dxf file of the design, and prepared it to cut a test model using the laser cutter.

Then I used the laser cutter (Universal VLS 6.60) to cut the test model, I cutted the mdf with the default setting of the machine.

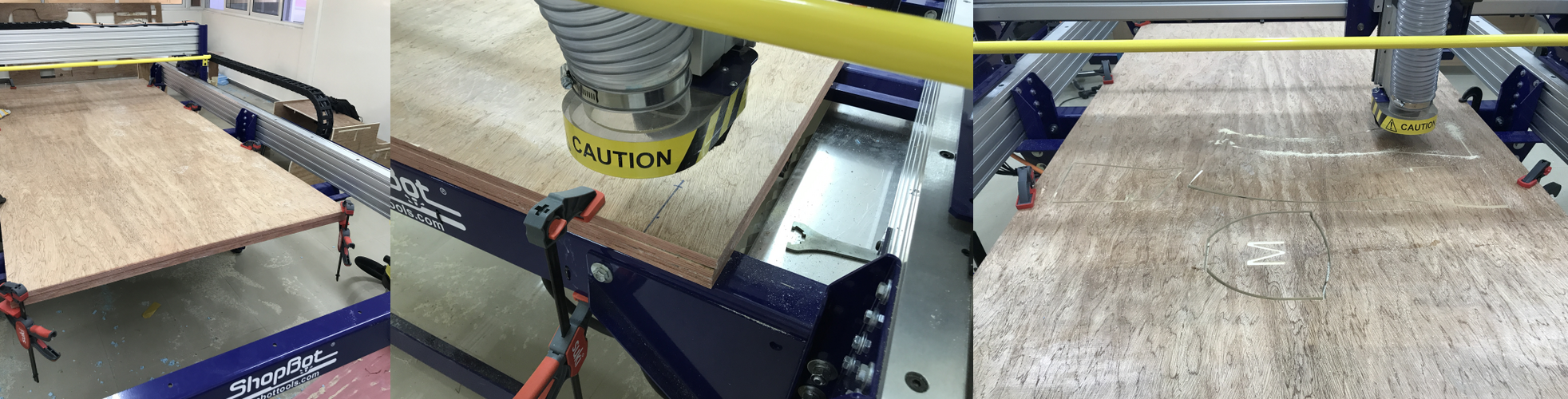

Now it's the time for the real thing, using the Shopbot to cut the real chair, so the first thing was to take the dxf file and uploading it to VCarve in order to get the profile toolpath and the pocket toolpath to start milling. I started by creating the letter M as a pocket in middle of the chair using VCarve, and then in the pocket toolpath I set the cutting depth (C) to 3mm using the 6mm down cut milling bit. For the profile toolpath I also used the 6mm downcut, the reason am using the downcut milling bit is that am going to place the plywood good surface to face upward and the downcut bit push the wood downward, so it will have a good finish. I added tabs of length 12mm and thickness of 4mm for the parts not to move while milling. Then I saved both toolpaths as one file using the shopbot to mm converter, and created the sbp file.

After getting that I was ready to mill the design. I uploaded the sbp file to the computer, prepared the shopbot for milling by clamping the plywood to make sure it doesnt move during the milling time, then I placed the milling bit in the correct position which is the (10cm,10cm)(x,y). Before starting to mill I ran the job in the air by raising the milling bit 6cm to check if everything is ok after that I started milling, and then I discovered that I have done a really stupid mistake, it was with the dog bones that I created, so I was supposed to create dog bones with the size of the milling bit which is 6mm but instead I created a 0.1 mm dog bones and of course the shopbot didnt mill them,because the milling bit was too big to do them.

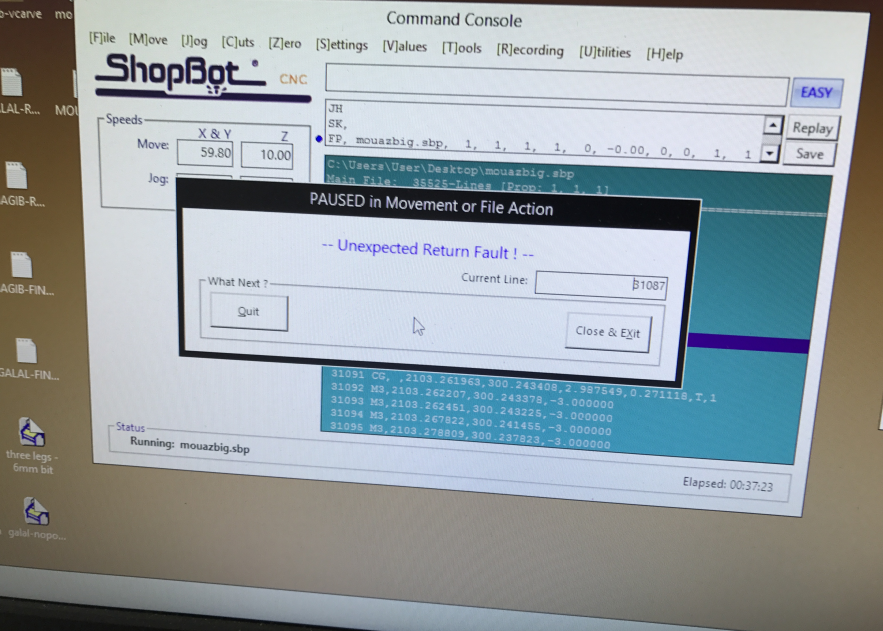

Then everything went well untill another problem happend, the shopbot suddenly stopped working for no reason at all and showed this message below.

Then to fix this problem I ran the job again but I took out the parts which had been all ready milled by the shopbot and generated a new toolpath and of course by keeping the zero x,y,z point the same, and everything went well.

After the machine finished milling I took the parts and started sanding them to get a nice finish.

And finally I assembeled everything and got this cool chair, it was a little bit loose because I think that I increased the thickness of the openings so instead of 17.41mm that I used maybe next time 17mm would be better. :)

Previous Week |-----------| Next Week