So here we are at one of the weeks that I think we will have fun while doing the assignment, its molding and Casting week, and for this weeks assignment we were assigned to design a 3D mold, machine it, and use it to cast parts.

For this week, so as a fan of batman I chose to create the batman logo as my mold in order to cast later something useful with it, so the first thing was to download this Batman sign picture:

Then I started by drawing the logo using the sketch tool on Fusion360 :

Then I mirrored it and extruded it :

M Then subtracted it the first time :

And again to get the tooling design:

Then I exported my STL file to prepare my design for milling using fabmodules :

When it was time to move to the milling part we faced a problem because I glued the wax to the plate that was set before for milling the PCB and I could not getting it in because it was too high.

So, I had to design a new plate so that we dont remove the other one because we will use it later for milling some PCBs, so I designed one for the Roland SRM-20 :

And cutted it using the lasercutter (Universal VLS 6.60) and the material was acrylic with athickness of 4mm and the pwer and speed were the default in the machine for cutting 4mm acrylic to:

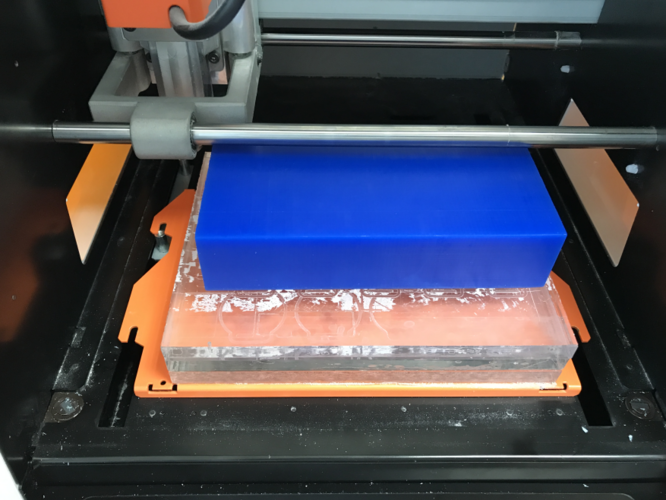

And then placed the wax on it to start milling :

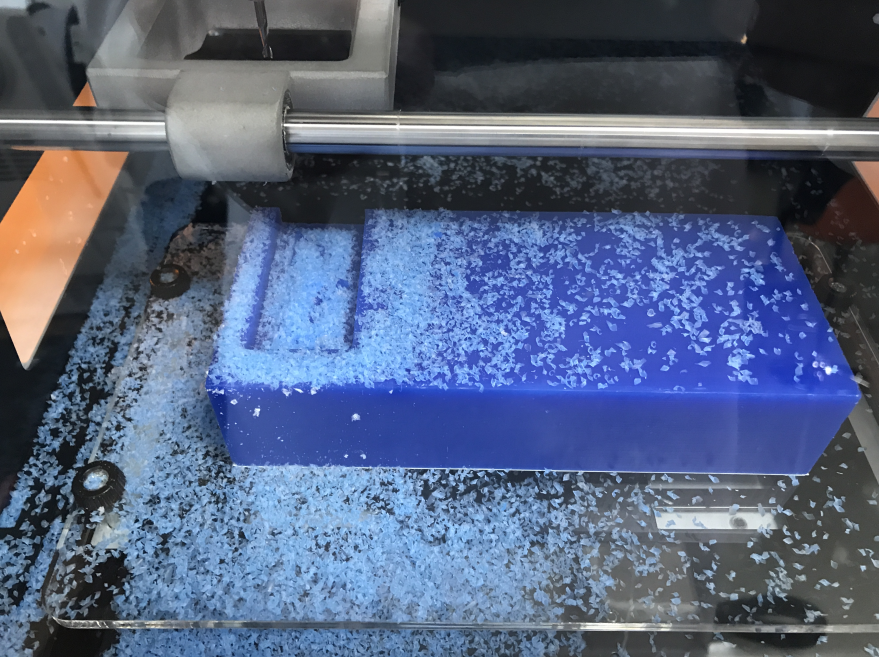

Then started milling using a 1/8 inch drill bit for the wax rough cut and 1/8 inch drill bit for the wax finish cut and got the toolpath for both:

And faced another problem, the design shifted a little bit to the right, but its fine I will fix it later :

For making the mold I used this silicon, Mold Max 30. It says in the product sheet that we should dispense the required amounts of parts A and B into a mixing container and mix for 3 minutes and after pouring the mix the curing time is at least 16 hours at room temprature 23C:

By the way I fixed the problem of the shift in the wax by sticking a plastic card to the side.

Then I placed the mold in a vaccum bag to suck all the air bubbles out, and placed it to cure for at least 16 hours as the product sheet says.

Then after 18 hours I took the mold out, and it was very good.

And now its time for the final part which is casting something into the mold. So I decided to create a bat candle and for that I went and bought a few candles from the supermarket and melted them and then casted the melted candles into my mold.

And finally I got my candle for some romantic bat time.

Previous Week |-----------| Next Week