My contribution during this week, which is the group assignment was in making the mechanical parts of three axises of our 3D nutella printer with the help of my colleague Ahmed Abobaker. The first thing I did was to look online for some inspirations, like if others have done something similar, and I already had some experience as I participated in the making of a three axis milling machine before, then I came across Nadya Peek, Machine That Make: Stages and then my colleague told me about this really cool project called McNulty Machine.

I started first by making a box using makercase.

Then after that I modified it using CorelDraw, so that it can fit to the stages.

These stages have two parts. The body which is the place where you fix the stepper motor and the other part that moves along the axis when the stepper motor rotates.

In order to make these stages we needed: - RB Stepper Motor 17HD + thread (x4) - 3 mm Acrylic - 10 mm steel rods - 10 mm linear bearings

X axis.

Y axis.

Z axis.

Base.

And here we are testing one of the axis.

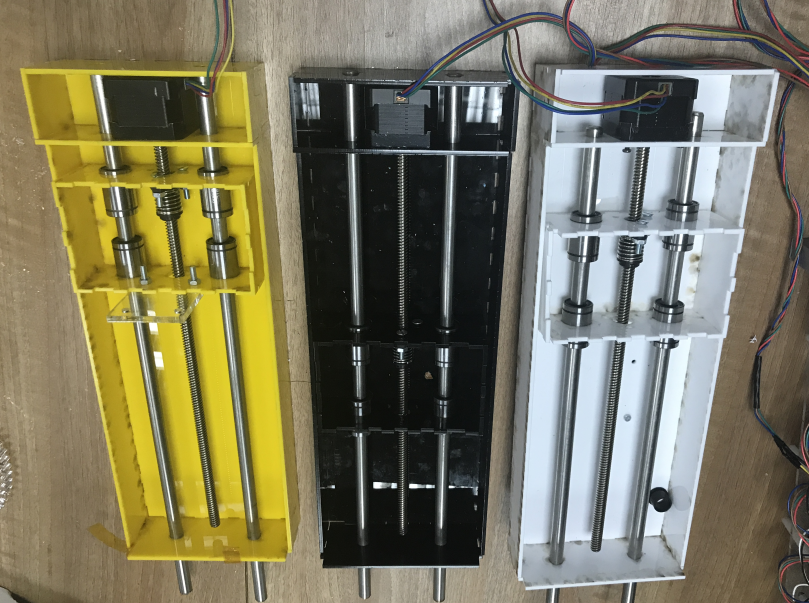

The three finished axis.

And finally the Food In Layers Machine.

Regarding my contribution in this group assignment, it was really nice to work with my colleagues during this assignment, I mean we had been doing individual assignments until now, so it was really nice to do something as a group. regarding the machine it was really nice to make this kind of machines that can be assembeled for different kind of jobs.

You can visit the machine page to see the machine in action.

Previous Week |-----------| Next Week