Exercise 3 - Computer-controlled Cutting

Vinyl Cutter

In my Fab Lab in library, we have vinyl cutters, we have one that I often used is Silhouette Cameo.

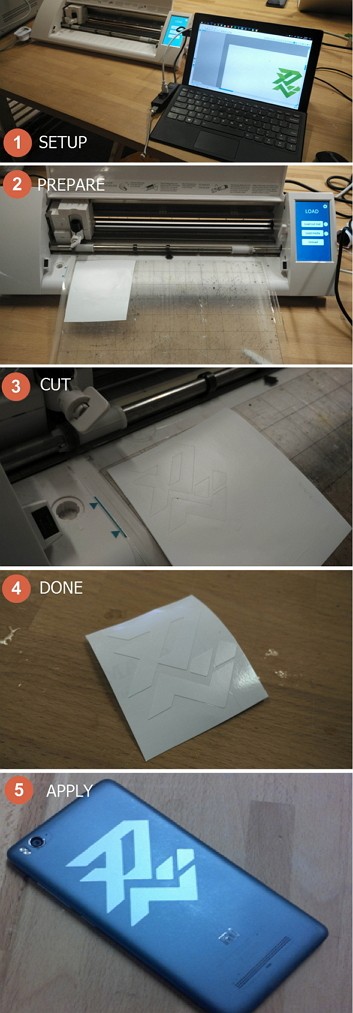

As an avid gamer, I've decided to choose a spray found in "Overwatch".

Endure and Persevere

This spray pronounced as "nin" in Japanese & "ren" in Chinese, it means 'Endure' or 'Persevere'. Which also translates to what I am doing now in Fab Academy, to endure and persevere through! I plan to paste it on my Mobile phone as a backing decal.

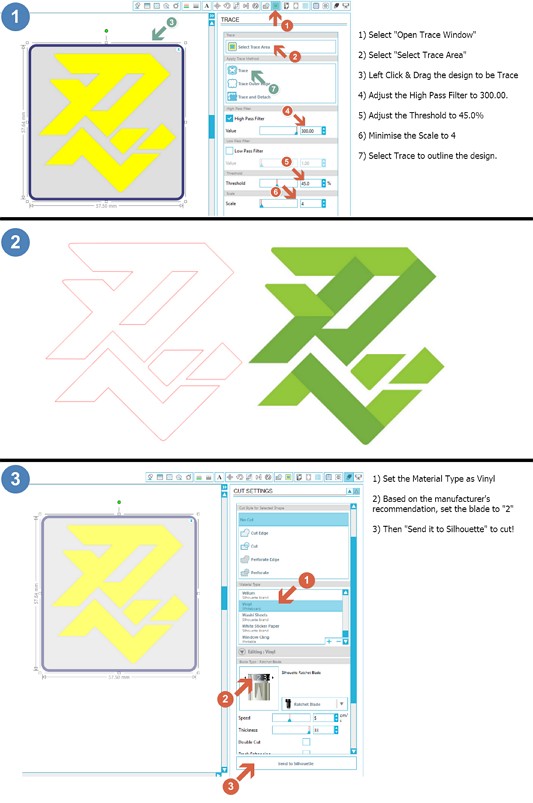

1) First, I will import the image into the Silhouette Cameo.

2) From here, I will have 2 options:

- Manually draw the character

- Using the trace function to trace the outline of the character.

3) Before I start either of the options, I need to measure the size of my mobile phone and decide the size I want to cut.

it measures to about 650mm, that is my limit

4) As for Manual , I need to be very precise on the drawing for the edge. Therefore I have decided to use the "Trace" feature for the design.

Preparation

5) I will be using some vinyl scraps I salvaged from fail prints. The following picture, I will show the process of the design being cut out.

Group work on exploring Kerf

Kerf is something new to me especially on Laser cutters. There are many methods to finding Kerf.

I will list down some methods here.

So what is Kerf? Group Work

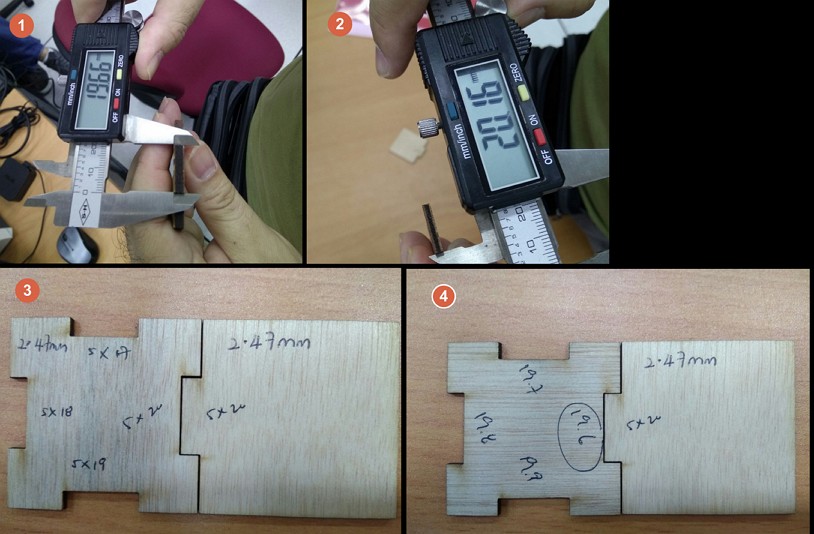

We tried on plywood and made 4 sided female connectors of each 0.1mm difference to see which size fits the best.

We started with 20mm and slowly work it's way down to 19.6mm

After cutting we realised that 20mm female is too big and it fits loosely. That is mainly caused by the laser cut which burns through the wood, eating up the material, aka Kerf.

We measured the male and female of both joints and the measurements are stated below.

Personal experimentation & Parametric Joint Design

My Colleague Mark explained to me and showed me that this website, Ponoko has a good explaination on this.

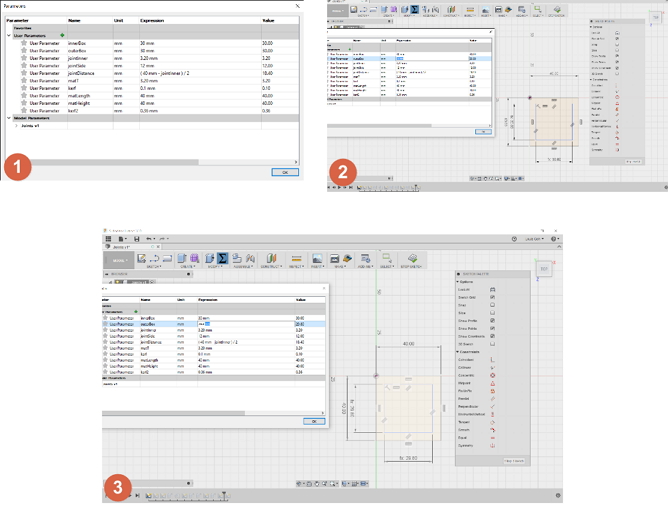

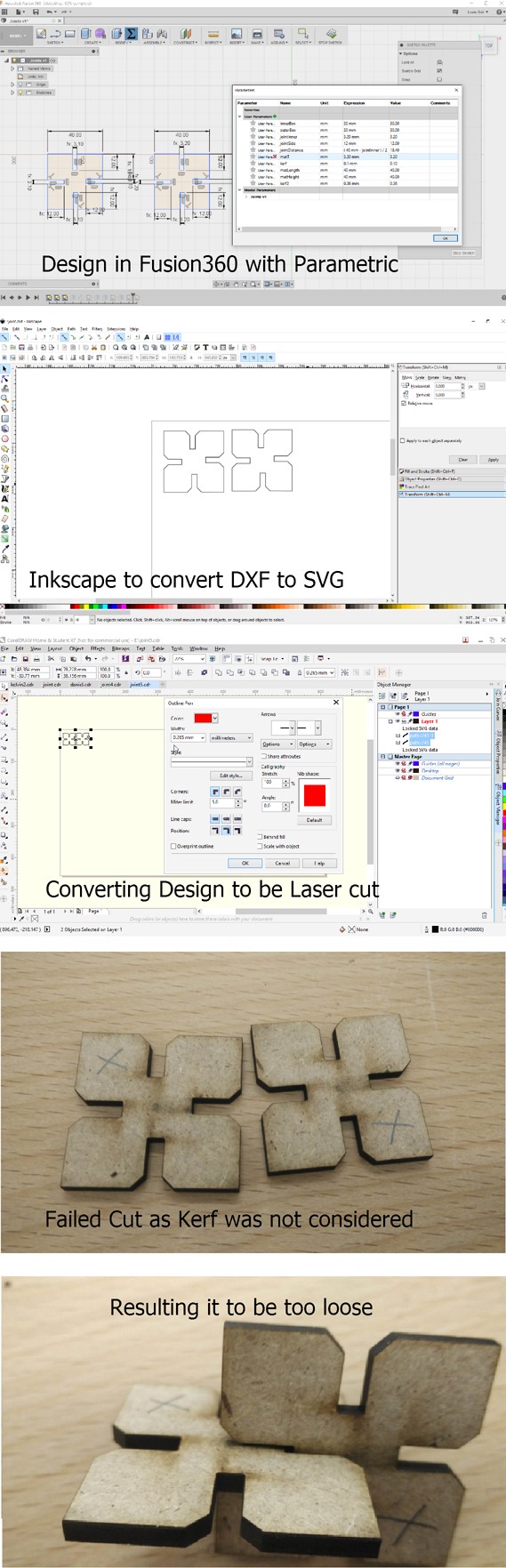

I designed my testers & joints in Fusion360 by use the Parametric feature, I find it a really awesome feature which I have never tried before!

Refer to write-up in Wk 2 - CAD for how to use Fusion 360 here

Here is how Parametric function being used

To make a Parametric design, one way is to write down the Parametic values using the Σ symbol found in the Modify dropdown. As shown in image 1. You can give a name to the side, for my example, I am using "outerbox" on 2 sides of the square (box).

Next, draw a box and select one of the sides and modify the side's length and name it "outerbox". What it does is it will get the value of the "variable" and apply it on the box length.

So, what makes parametric awesome? Here is the benefit of it, at any time you want to make changes to the box, I can click on the Σ symbol and give outerbox another value, it will then apply to all sides of the sketch that is named under "outerbox".

I followed the ponoko's tutorial and realised our laser cutter's kerf for MDF is approximately 0.36mm.

How do I get the value?

I measure the original value of the width of the inner box and the width of the 2nd box.Therefore, inner value - outer value = Kerf.

I cut 3 samples to fit into the square frame, each of 0.01mm differences.

On my Laser cutter, settings I had to experiment with the values and I decided to follow my Guru's advice, to cut go through 2 pass instead of cutting it 1 time.

I am suprised after cutting the 3 different values, the 30.37mm had a looser fit than 30.35mm!

But I decided to go ahead with 0.36mm kerf value just to be safe.

So now, on my Fusion 360, I adjust the value for my design for the joints.

After designing, I export the sketch to DXF format and open in Inkscape to convert it to SVG.

Once done, I use Corel Draw to convert the outlines to be RED in colour and Black lines to Engrave.

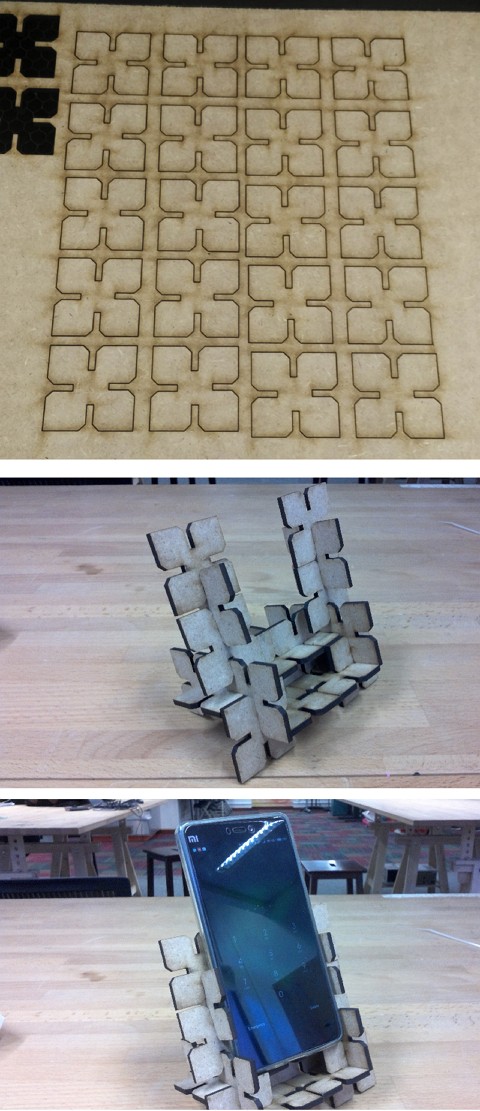

I was shocked that the values didnt work! I was wondering what went wrong!

After much research and finding, I realised that to do a press fit, I tried to do an additional step to find out the value!

(Inner width - Outer width) / 2 = Kerf for press fit

I measured the Inner Width & the Outer Width of the press fit. Find out the difference

3.60mm - 3.20mm = 0.30mm (kerf)

with that, value, I divided by 2 and get 0.15mm. That value I will adjust in my Fusion 360 for the Kerf value differences.

I played around with the values from 0.1 to 0.15 and came into a conclusion that 0.1 gives a better fit.

I've decided to make a Mobile Phone Cradle using my Press Fit Construction kit

References

Ponoko Blog on Kerf

Download the Spray here

Download the testers here

Download the press-fit joint here