Exercise 11 - Machine Design.

Requirement

- Automate your machine.

Software development for MTM

The software portion for MTM is mainly done by my other course mates. Please refer to their site for more information.

As for my contribution this week, I further modify the outer case cos I found that the previous version is not stable enough and the joint is breaking apart and will not last after the presentation.

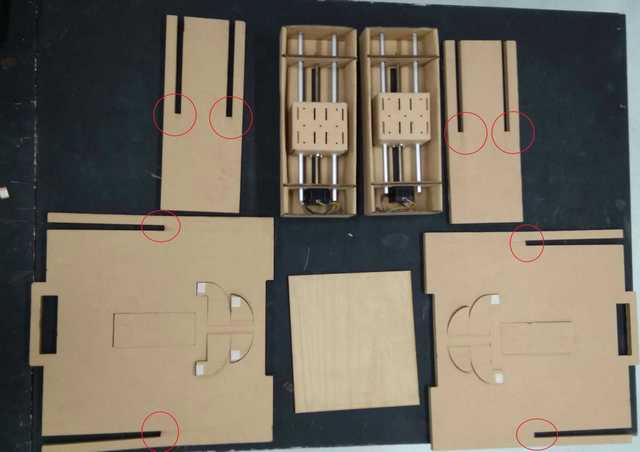

Version 1

Let take a look at the joining method used to hold the MTM and suit case : half-lap joint.

Weak points are observe during testing period and got me thinking of modifying to a stronger and better jointing method.

Crack lines and tear are appearing after numerous usage, so after some research and experimentation. I decided to change all the half-lap joint to Mortise & Tenon joint, which provided better holding and durability to the cupboard suitcase.

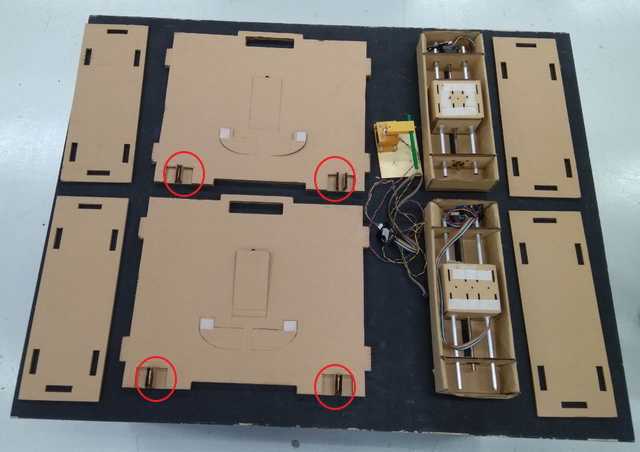

Version 2

After redesigning and laser cutting, we test out the new improved suitcase. We found that it is easier to dismantle and assemble the parts. In additional, I add extra support at the base for stability.

With the additional modification, this is end of my contrubution for this week.

My design files:

- Version 2 case

Return to top