07. Computer-controlled Machining

use fusion360 to design the module that will be used in CNC milling

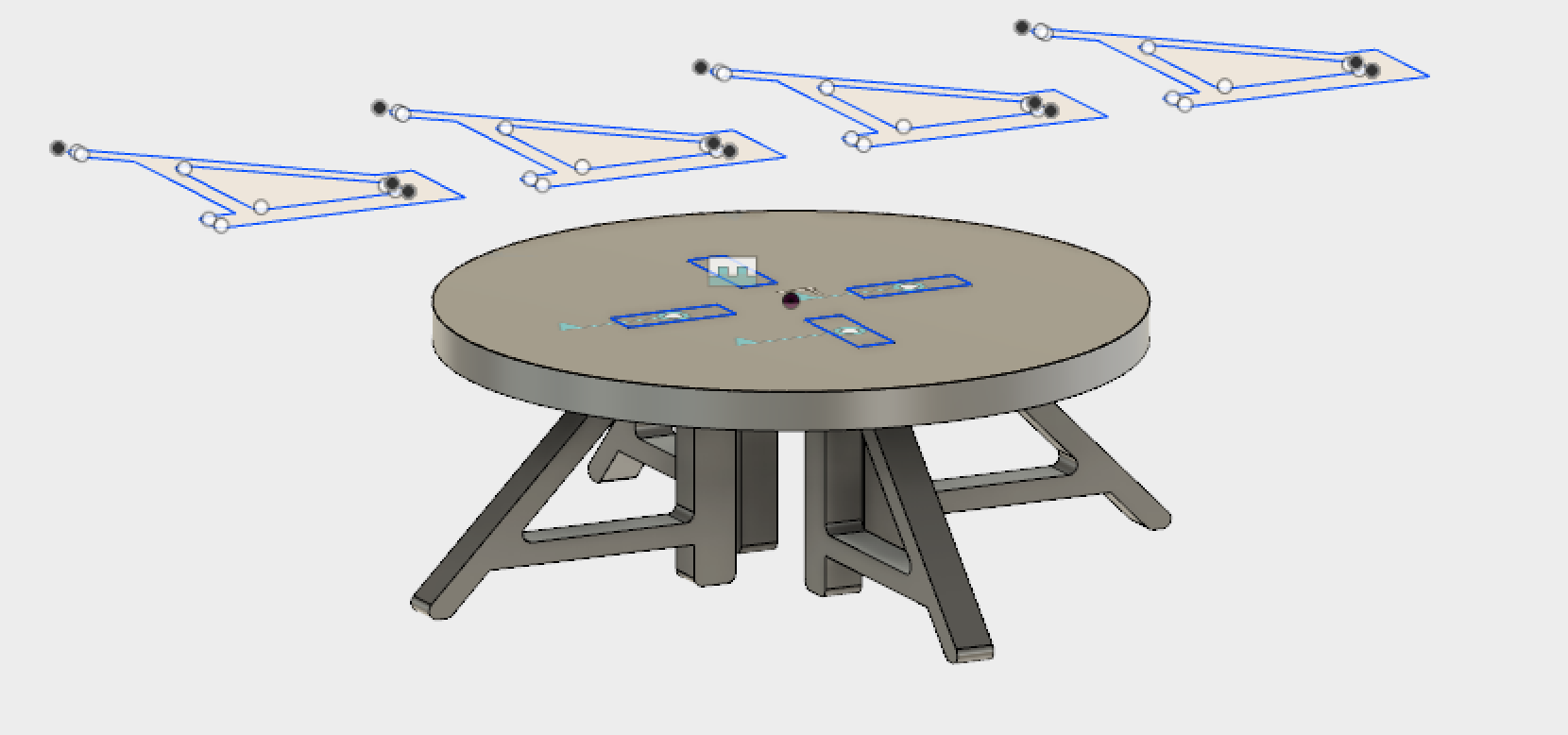

I had an idea to design a sofa so I used the Fusion360 to design it

I spent 4 hours to design one and modified the original one, but I then found there are some mistake on the basic of the design so the whole design need to be changed, so I redesigned one

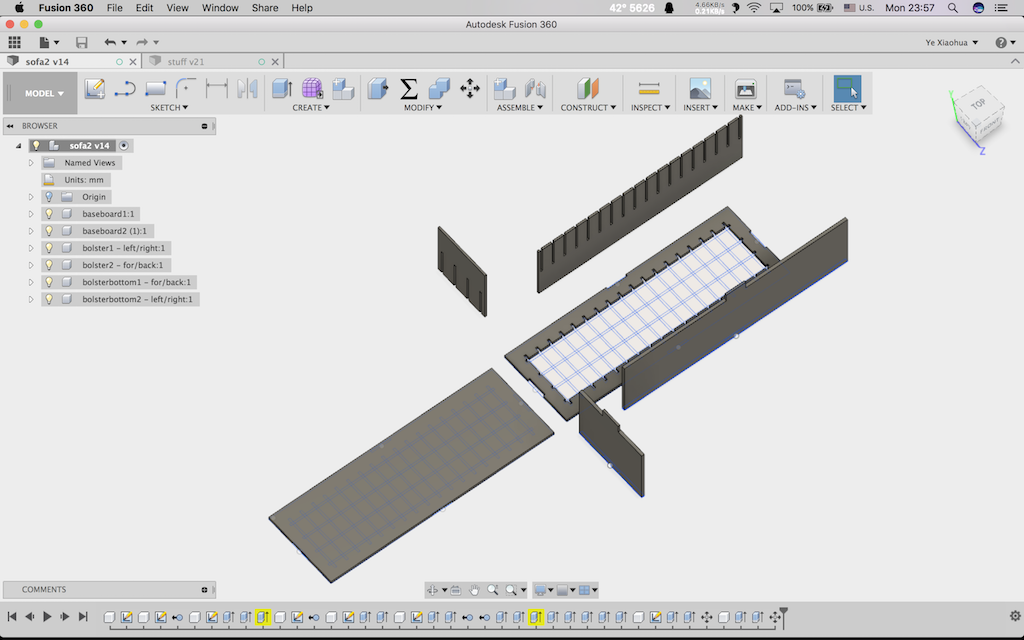

Here is my first design, and the mistakes are in the baseboard and the bolster's press-fit holes.

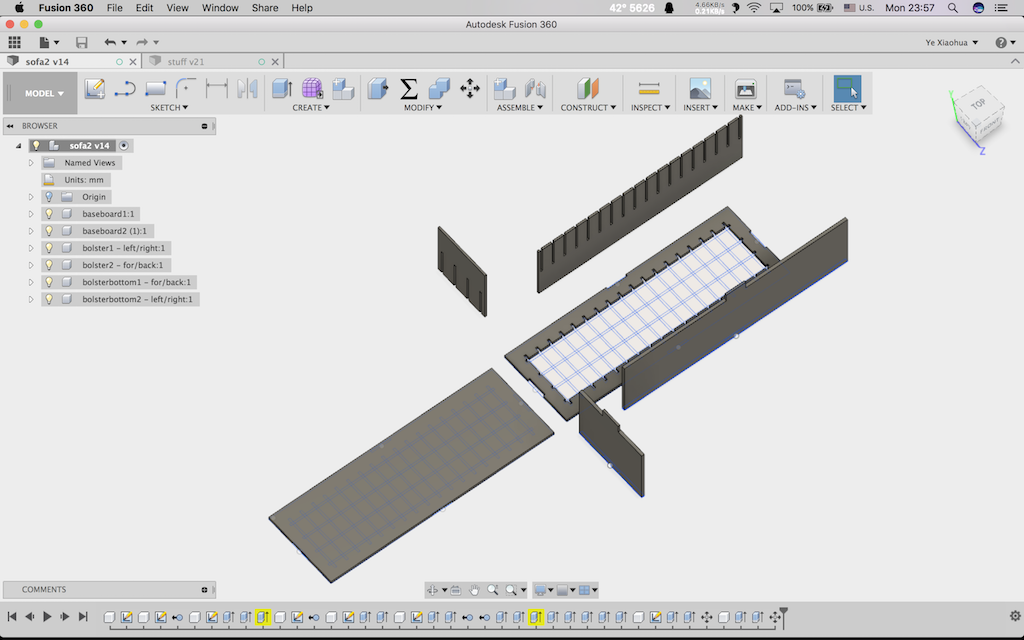

Then here is my redesign:

Actually, it is a long sit rather than a sofa since there isn't any back bolster behind

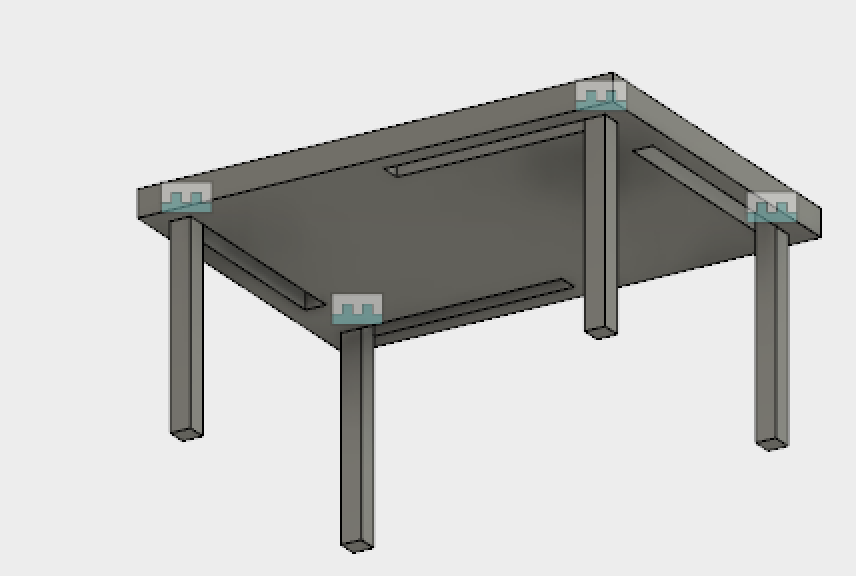

Something wrong again with this sofa's design, at last I change the idea and make a desk for me when using computer in my bed.

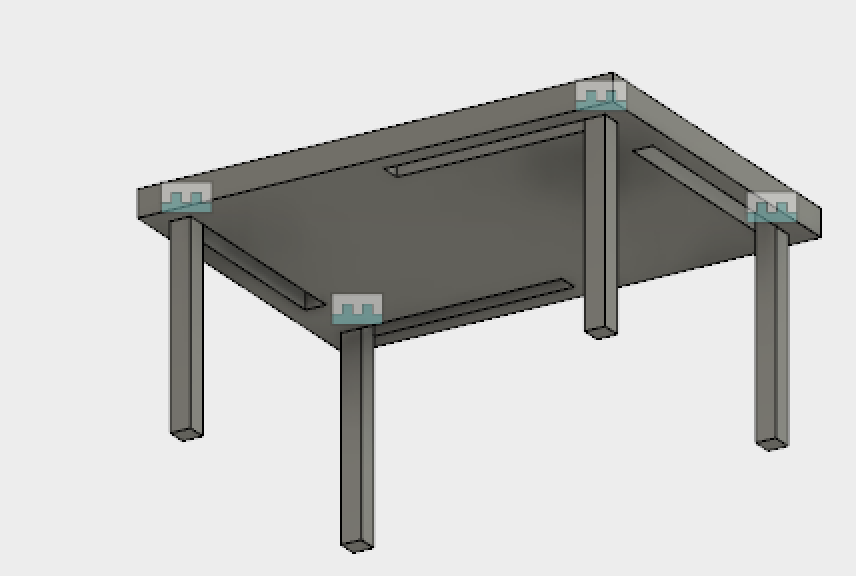

Here is my design:

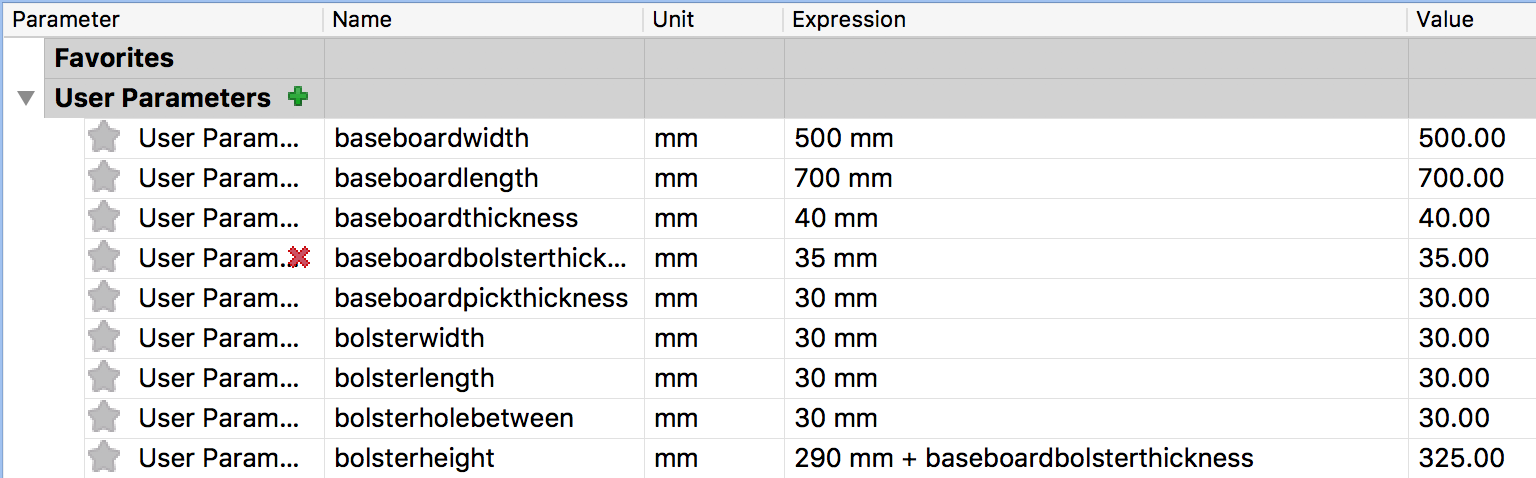

I set the parameters when designing the desk so that I can change the parameters when the thickness of the boards are different.

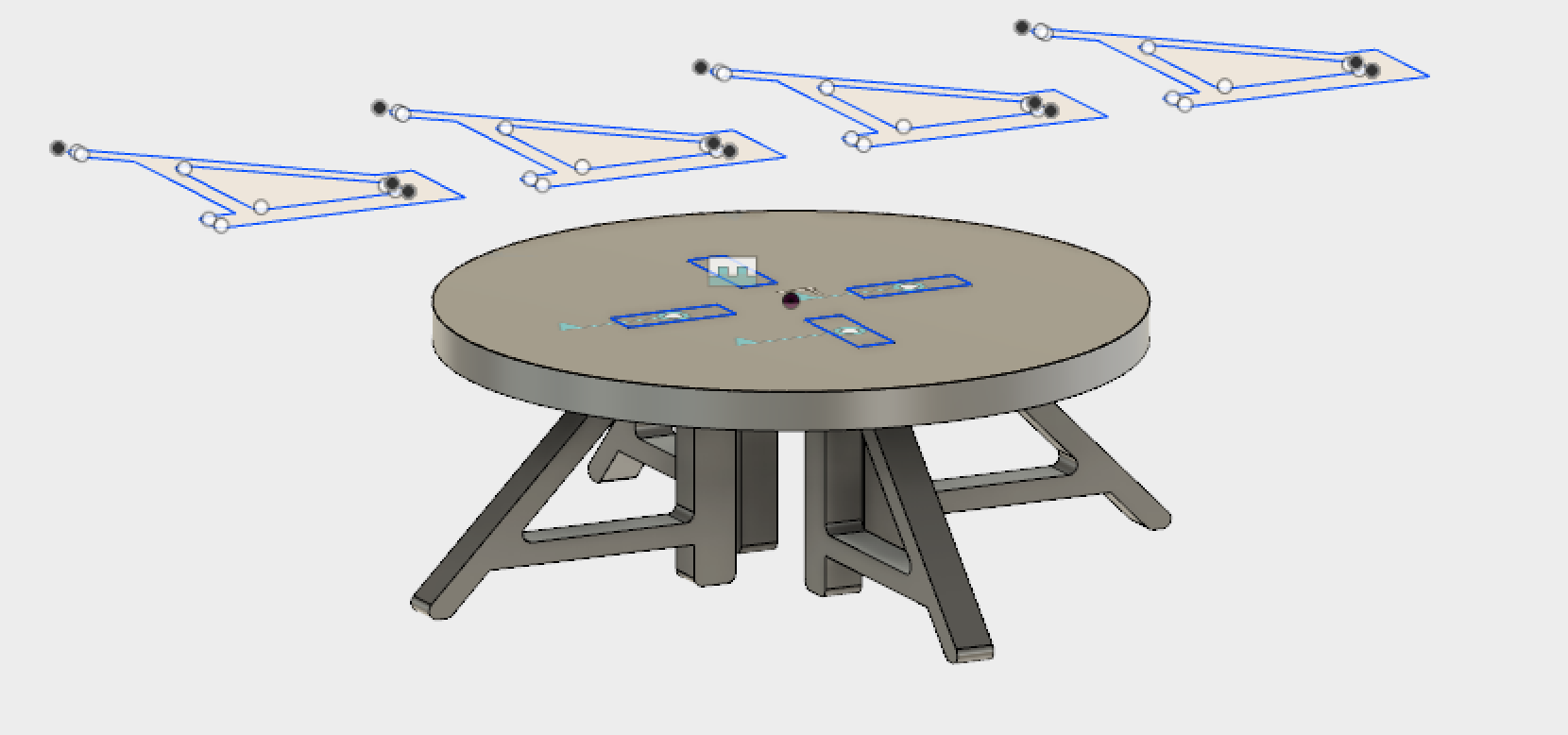

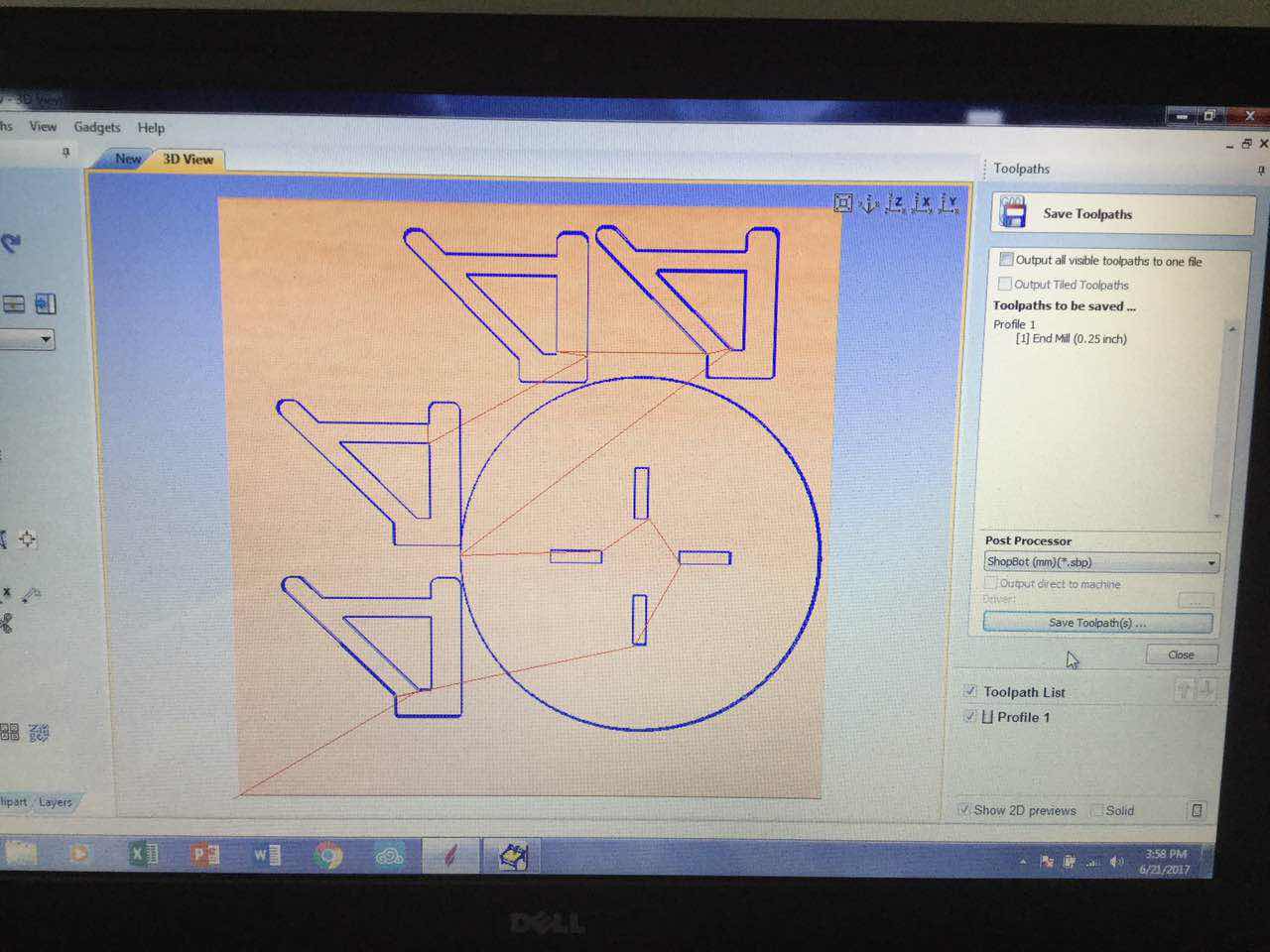

(June 21) I redesigned another files for the cnc week since I found that my original design is not a vector design.

mill it out by using shop-bot

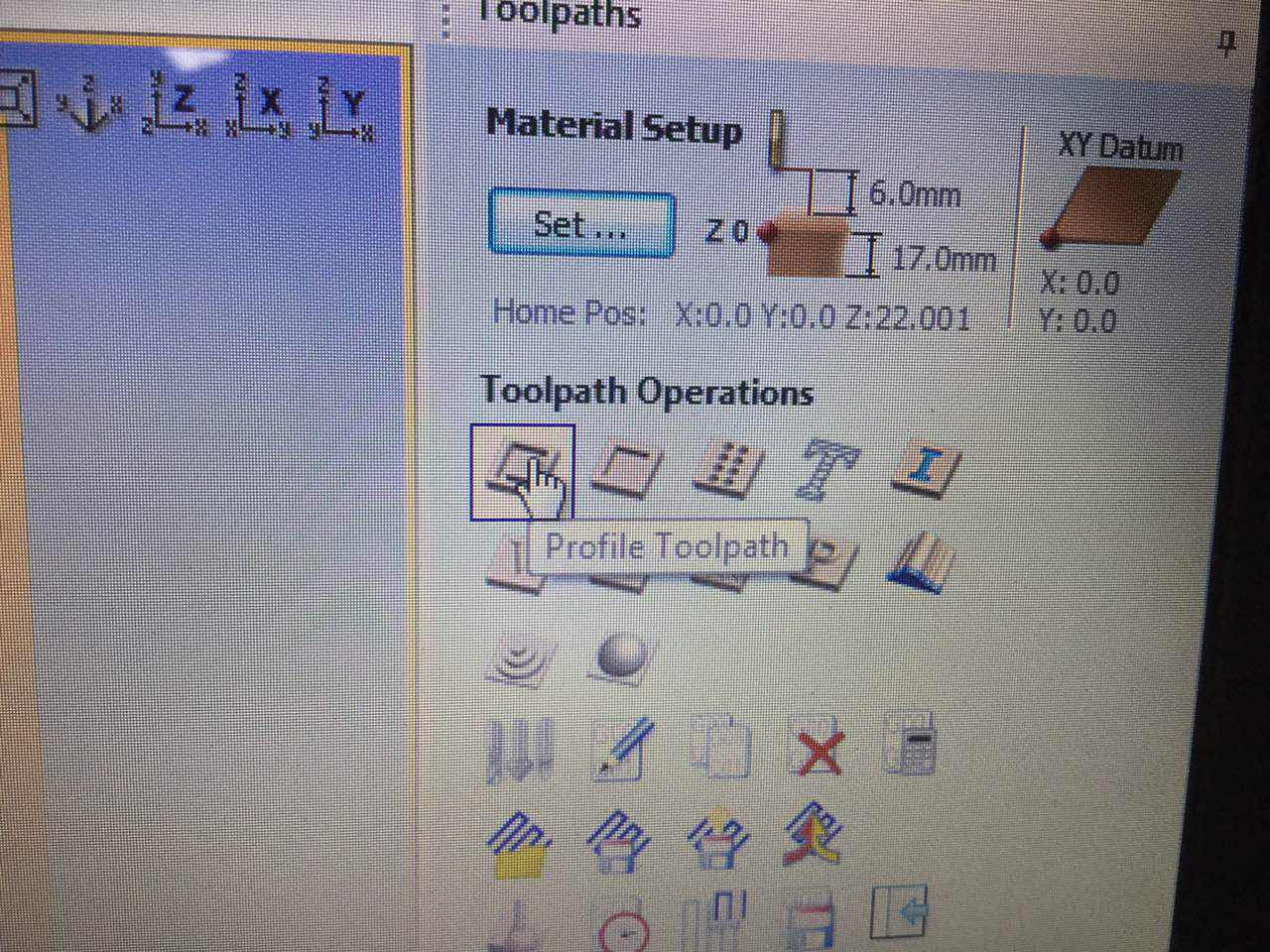

1. Design the toolpath using the Asipre:

First, export the DXF files through the Fusion360 and import it.

Then select Profile ToolPath

Select the whole vectors and calculate it:

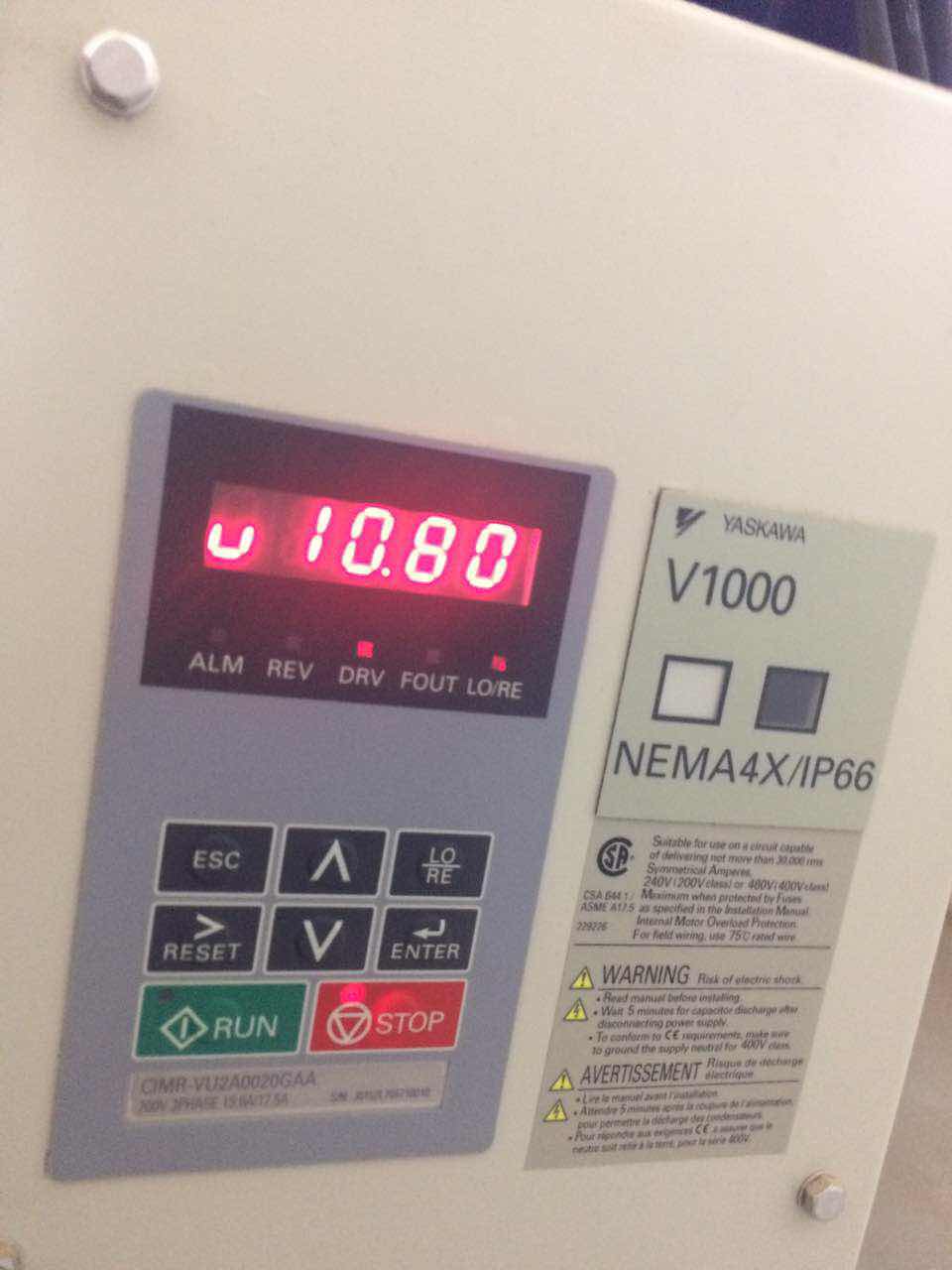

The velocity of the endmill I used is 10800 RPM

feed speed: 1800 mm/min

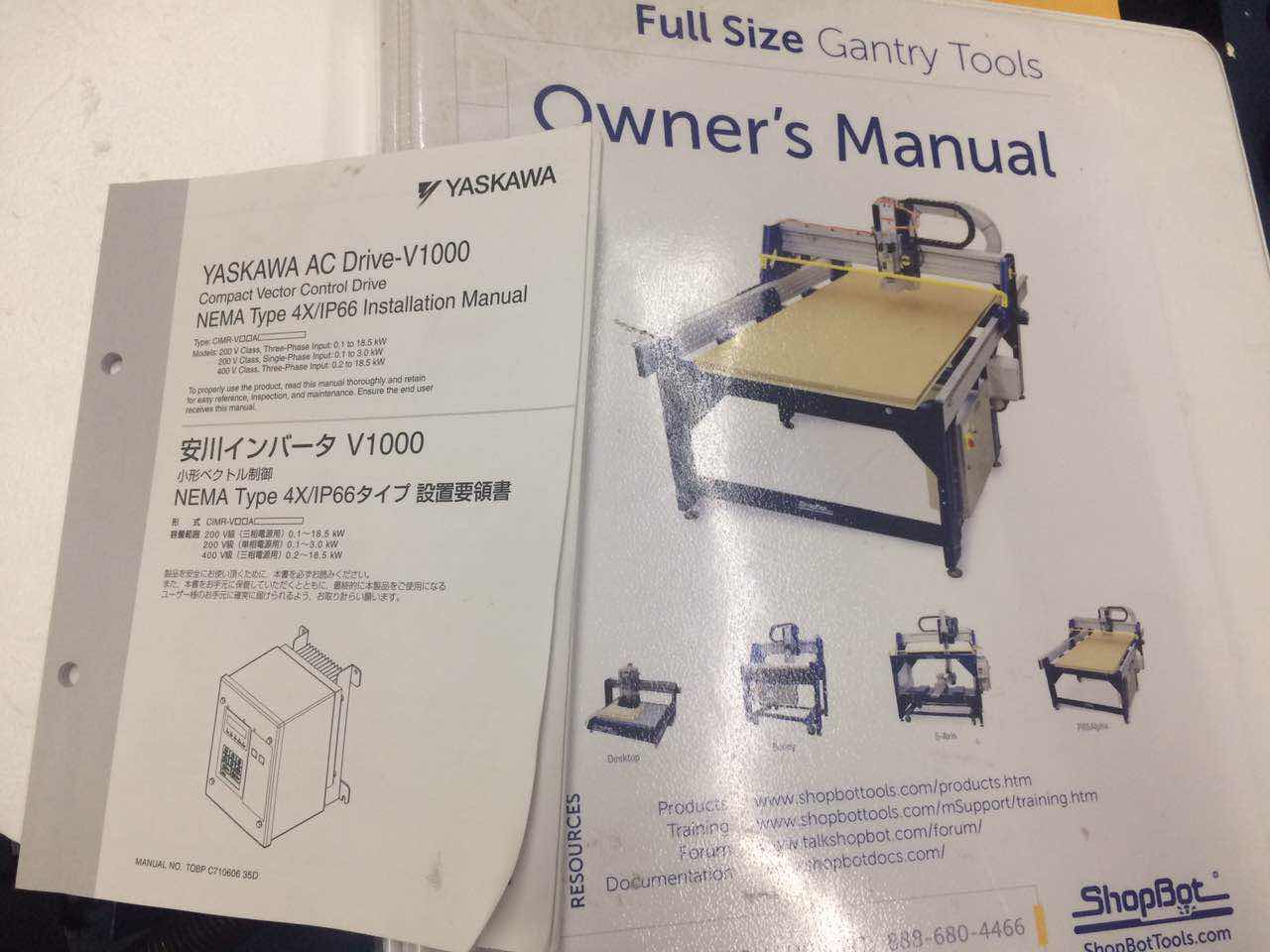

The shopbot in the szoil have some problem, my instructor said that it never worked and they didn't know how to use it.

As a result, I need to read the instruction book of the shopbot and go to the website to find the answer of running the shopbot.

Then, I follow the instruction:

1.disassemble the original board and assemble a new board for milling

2.install the endmill:

I used the 0.5 inches endmill so that I won't block easily since I need to cut the wooden board

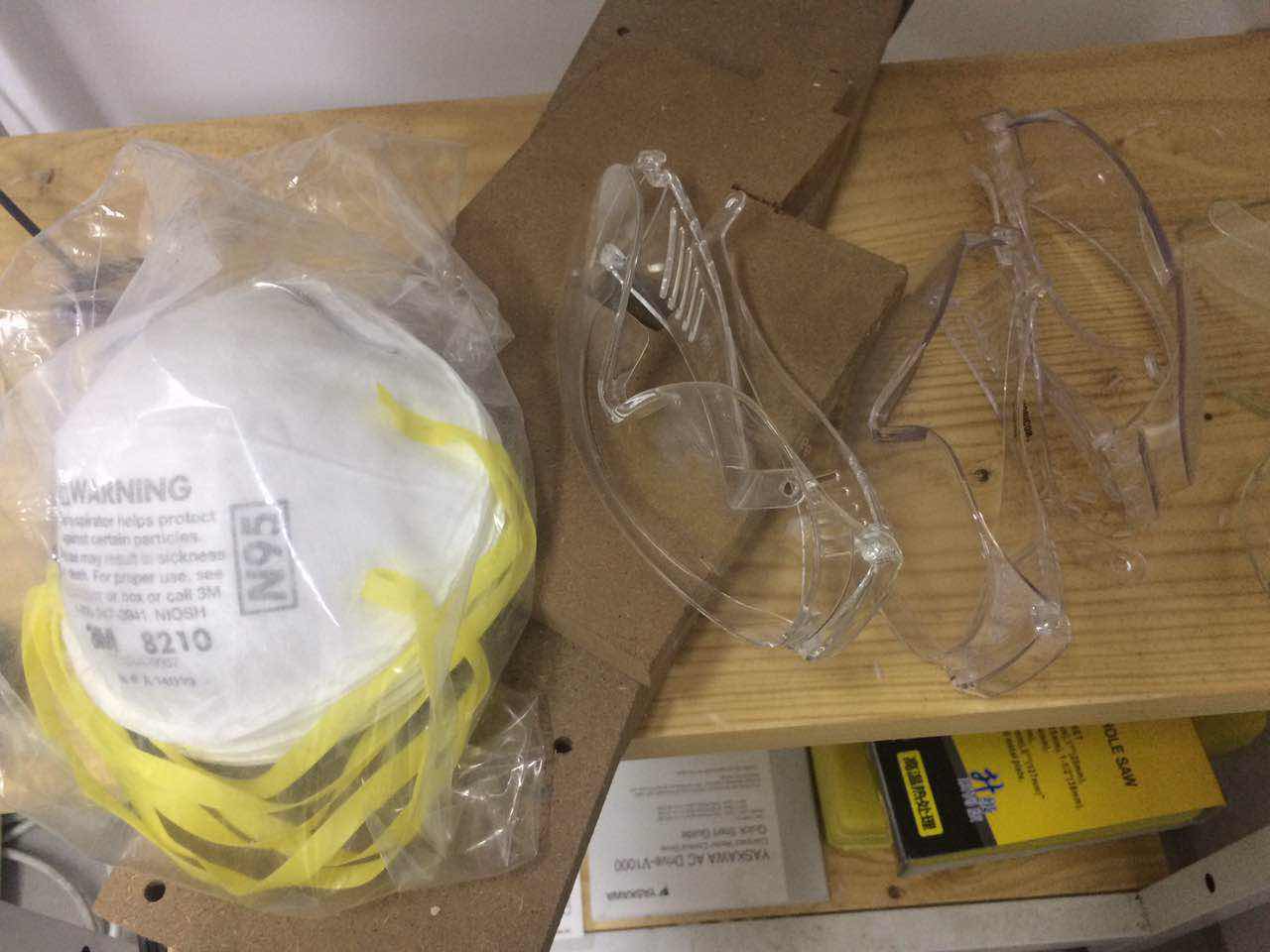

3.turn on the shopbot and the internal lock( the lock for the spindle):

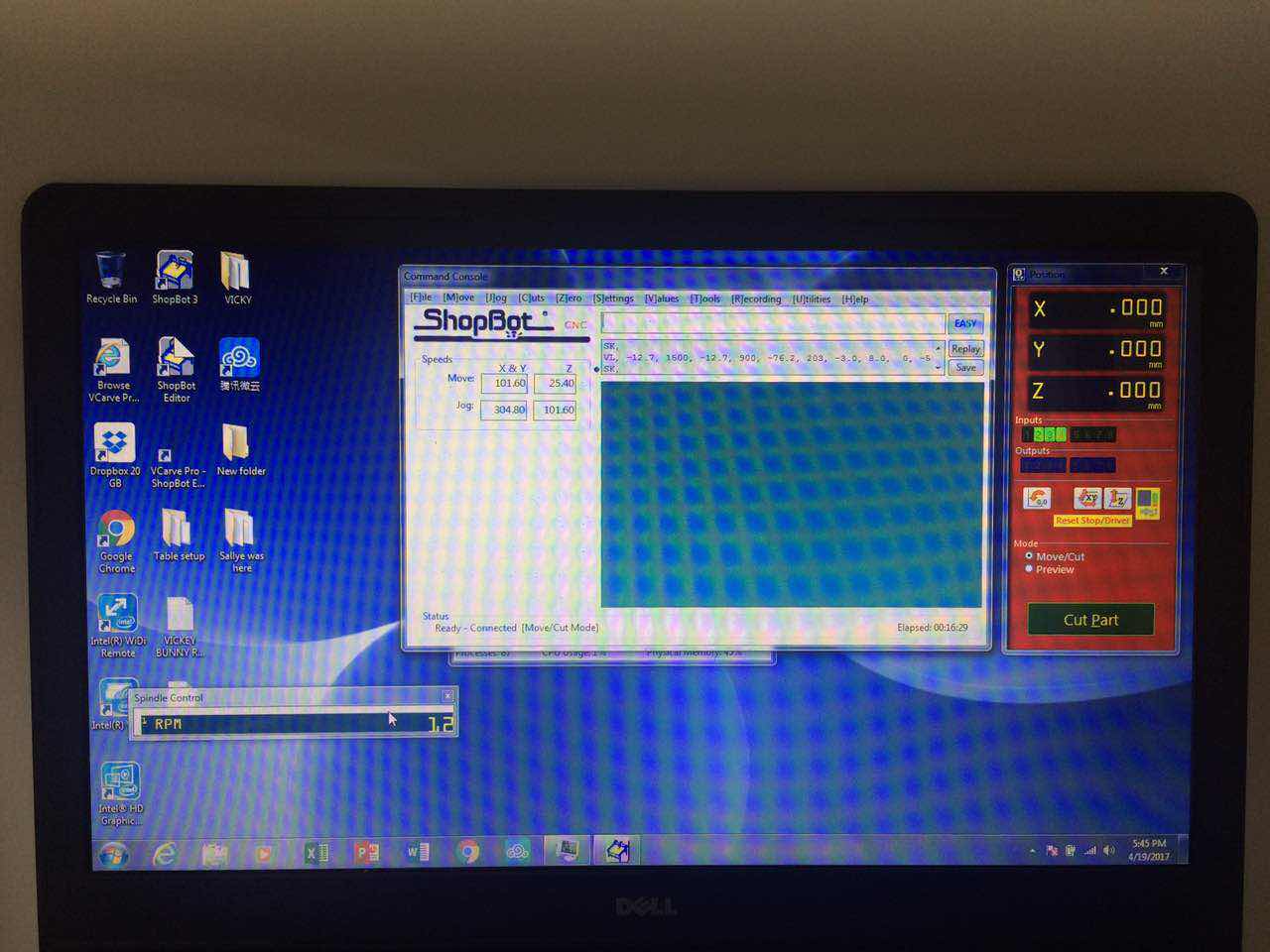

4.open the control software in the computer and reset the shopbot

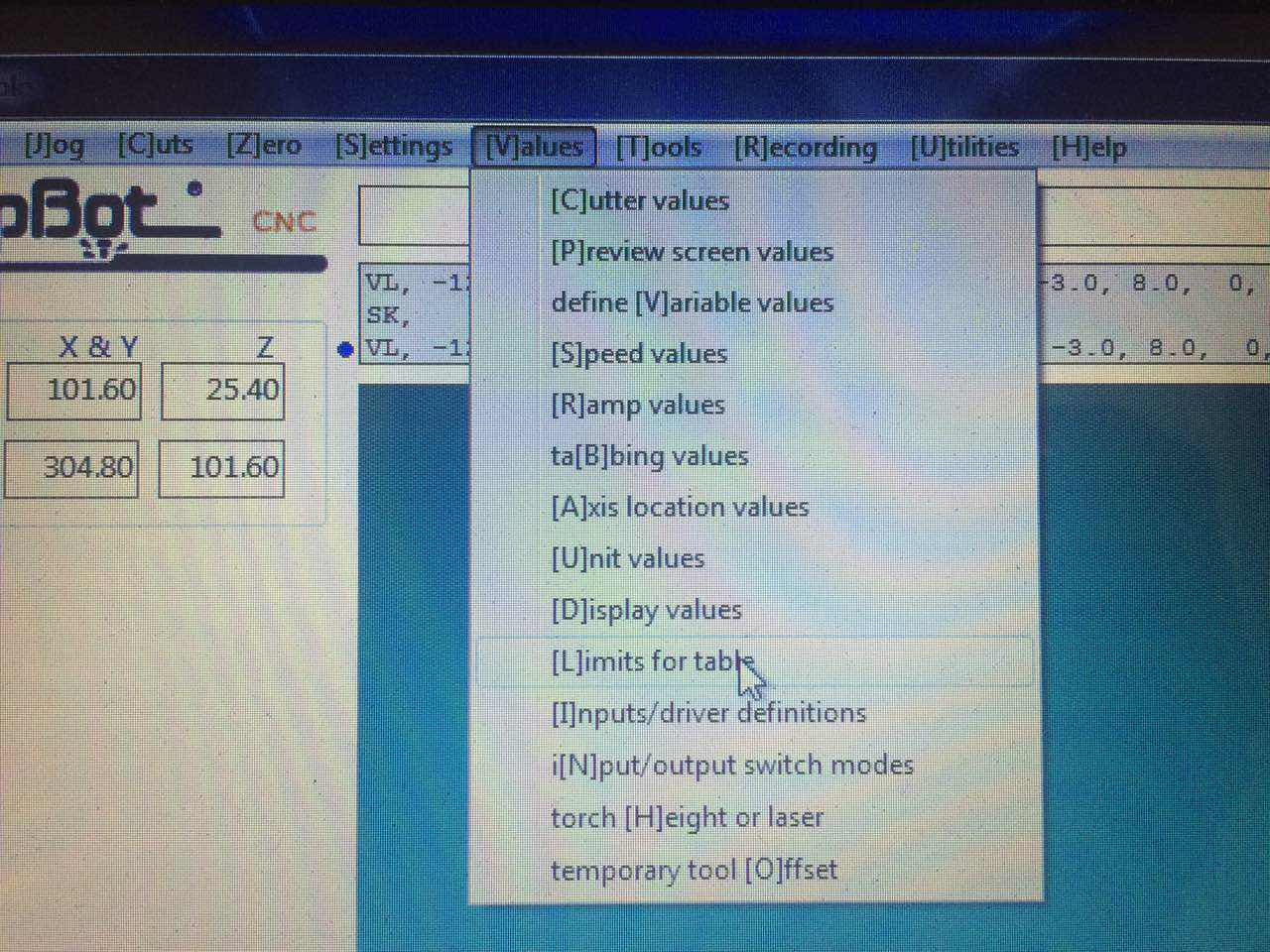

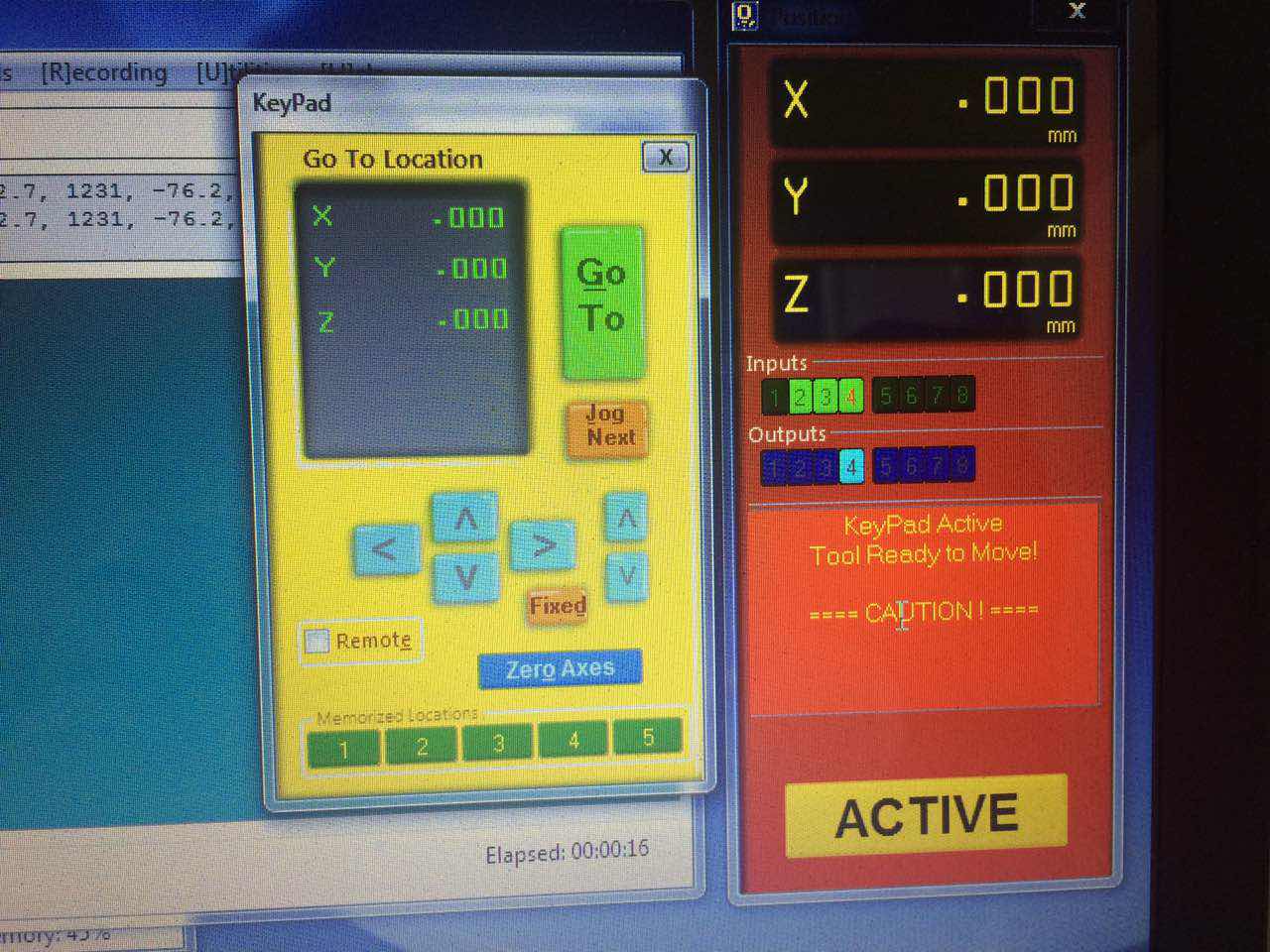

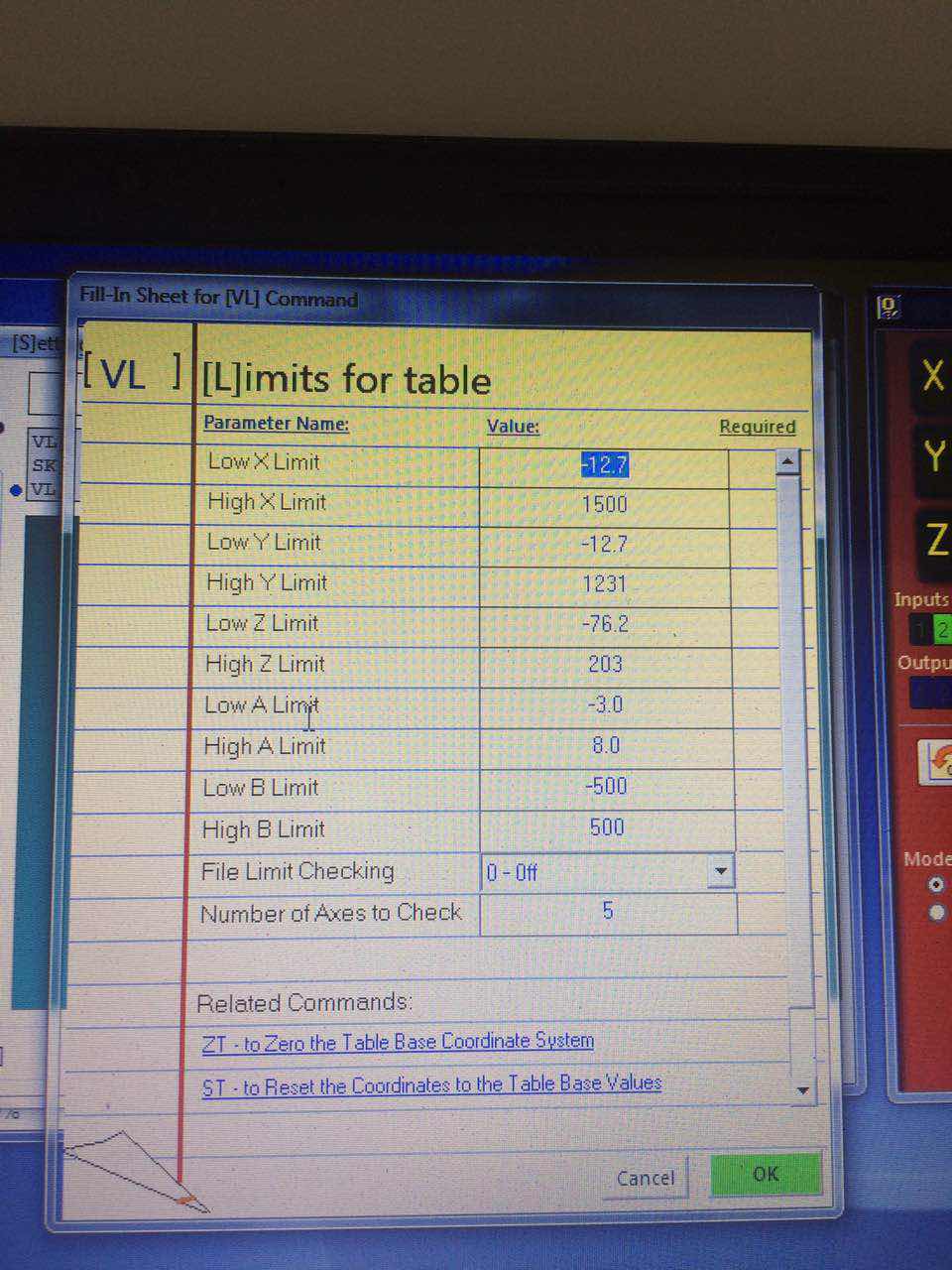

5.set the limit of the table and move to the zero axis - home the axis

Then it got some problem - I found that the endmill need to turn on manually - just set it to LO/RE > RUN

Cut the board:

assemble the boards to a desk

>

>

I can sit on it!