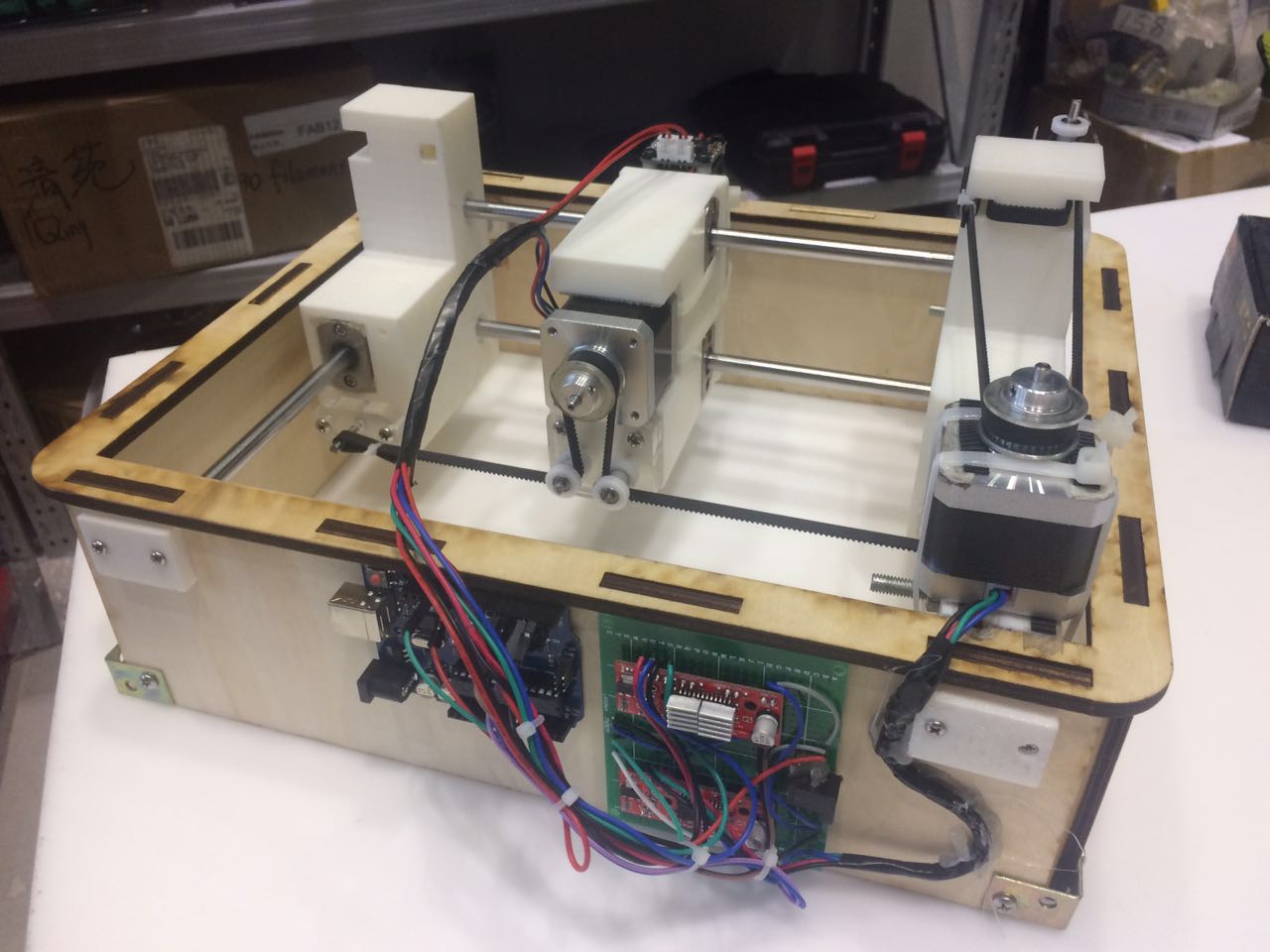

11. Machine Design

Here is a link to mechanical design

Here is the link to the group page

personal contribution

1. Find the software that will be used to control the laser engraver - grbl

And also, I read the grbl's introduction and find that there is a mode that called laser mode.

Since it can control the laser power by controling the voltage output through using the PWM. As a result, I find the laser that contained the PWM mode.

2. Make sure how the grbl work and use the inkscape to convert the gcode files and automate our machine

3. collect and make a video of our team and machine

use grbl to control the motor and laser.

I read the grbl v1.1's wiki and found there are some new features:

1. Laser mode

2. control laser's power by using PWM from voltage 0v-5v

3. Set the baud rate to 115200 as 8-N-1 (8-bits, no parity, and 1-stop bit.) when hex the board

- (We failed so many times at the beginning and then I found this wiki and after we changed the baud rate

, we just succeed to control it.) - "IMPORTANT INFO WHEN UPGRADING TO GRBL v0.9:Baudrate is now 115200 (Up from 9600)"

4. Enabling or disabling Grbl's laser mode is easy. Just alter the $32 Grbl setting.

- To Enable: Send Grbl a $32=1 command.

5. Need to use new grbl controller to send command to control the board , we used picsender.

Then, it comes to the gcode problem, after finishing the programming, we need the gcode files that can be revognized by grbl to control our laser engraver

I search lots of instructions on the internet and tried two different kinds of methods:

2 kinds os extension for inkscape

I modifies some files of the extension and successfully convert our vector image to nc files

But then I found a problem while testing it, the original setting is M03 to engraver and M05 to move, which is reversed in grbl setting.

So I modified and replace them manually by using control+H in the text.

After testing , the scope in the inscape is 500mm in width and 200mm in length and speed is 30

collect and make a video of our team and machine

I used the iMovie to make a short video - 1mins+1s - 1080p - 150m

It contains: 1. 20 pictures taken while the team members worked together 2. a 13mins video - the second time we give task to the laser engraver

The main chapter of the video are in 25x speed - 10mins -> 40s

Here is the video in youtube:

In vimeo:

opportunities for improvements in the design

1. Protection cover : The laser is very dangerous, so we could add an protection cover to against the laser injury. 2. Redesign moving joint : The moving joints were to big, we could redesign the moving joints, so the operation area would bigger than before. 3. make a software to calculate the toolpath, I find that the toolpath is actually not accurate.