Until 29 Mar 2017

KUROHETEX-ED MTM Mechanical & Machine Design

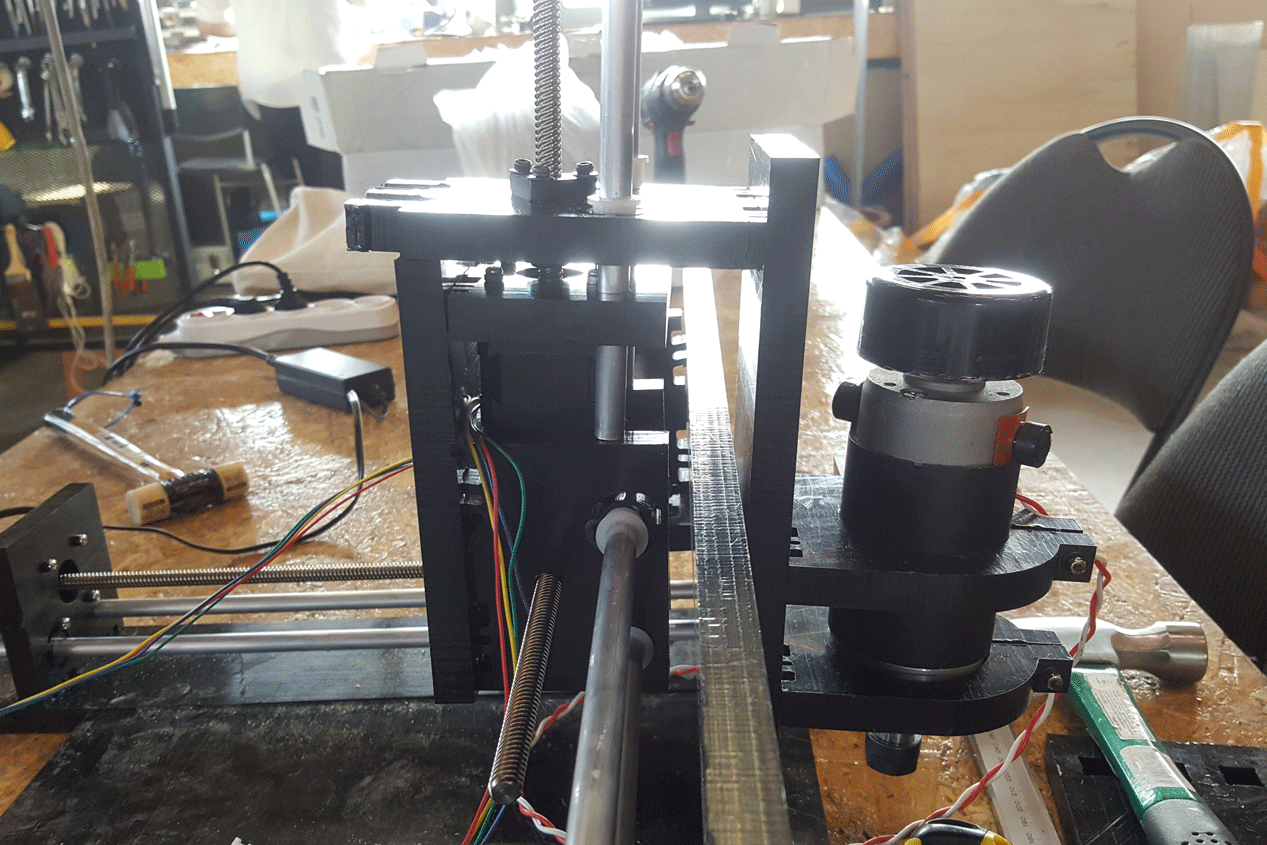

: Making CNC!!!

Contents

- Brainstorming as a group

- Designing Prototypes

- Testing HDPE, Joints and CNC.

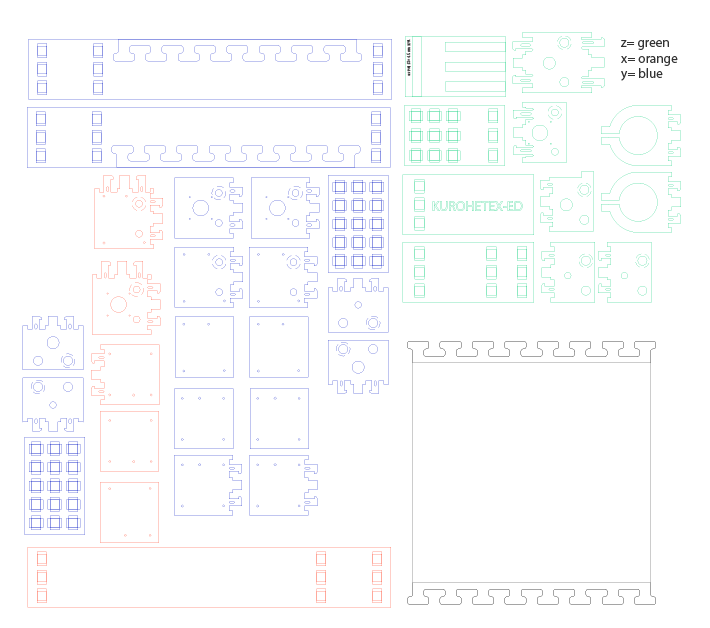

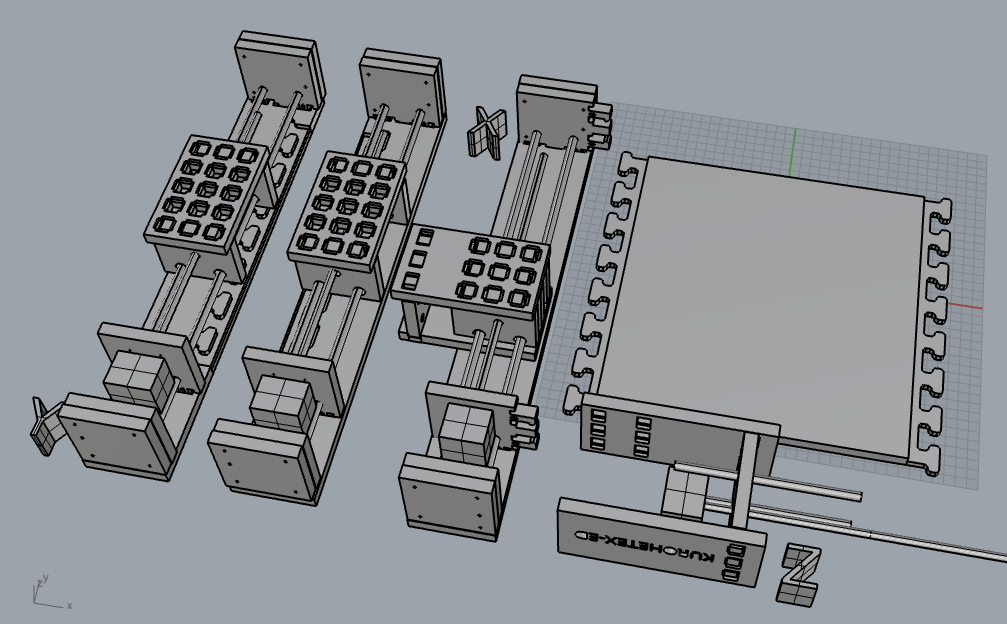

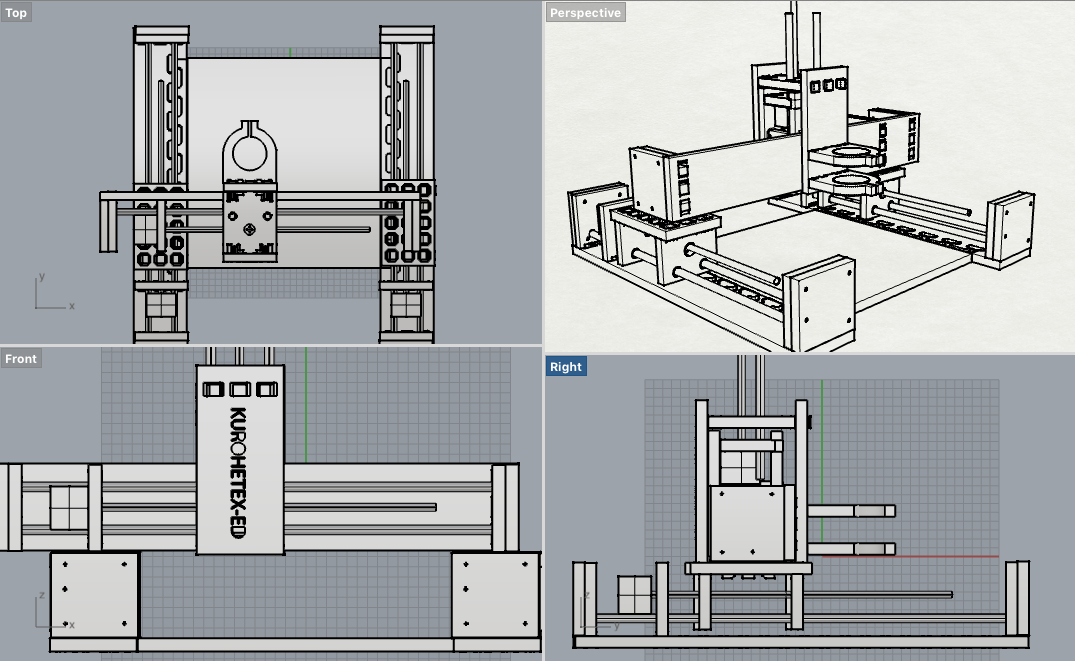

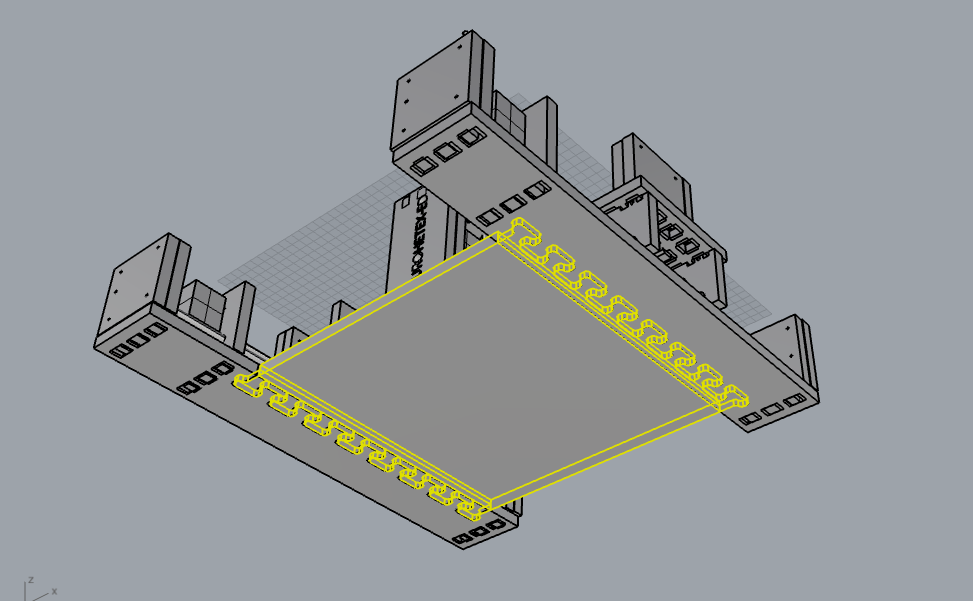

- 3D Rendering of Kurohetex MTM

- 9th ~ 11th The Fab Academy weeks

Brainstorming as a group

In Seoul, non of us have experience in machine building or programming.

We decided that we want small CNC for cutting PCBs.

Useful links:

- [m]MTM by James Coleman, Nadya Peek

- How to Make (Almost) Anything: Machine Building.

- Jonathan Ward's MTM

- James Coleman 5 Axis Timiing Belt MTM.

At the end, we referenced Fablab Seoul MTM.

Designing Prototypes

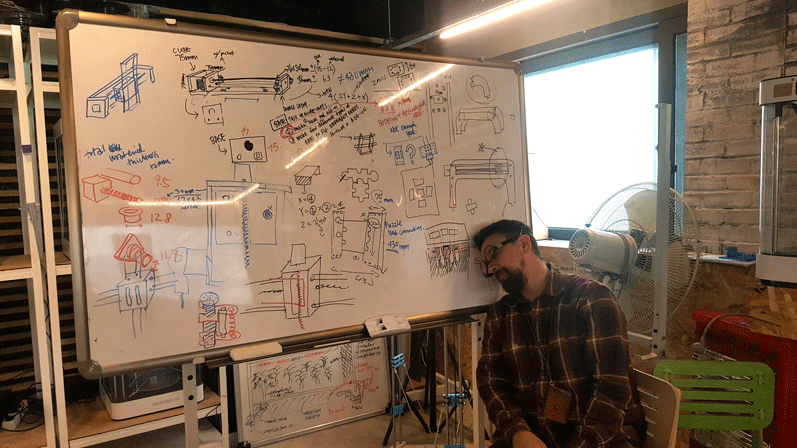

At the beginning, I had NO CLUE AT ALL! However, one thing that's great about having team with same level of understanding is that there are no stupid questions and we were there to start together.

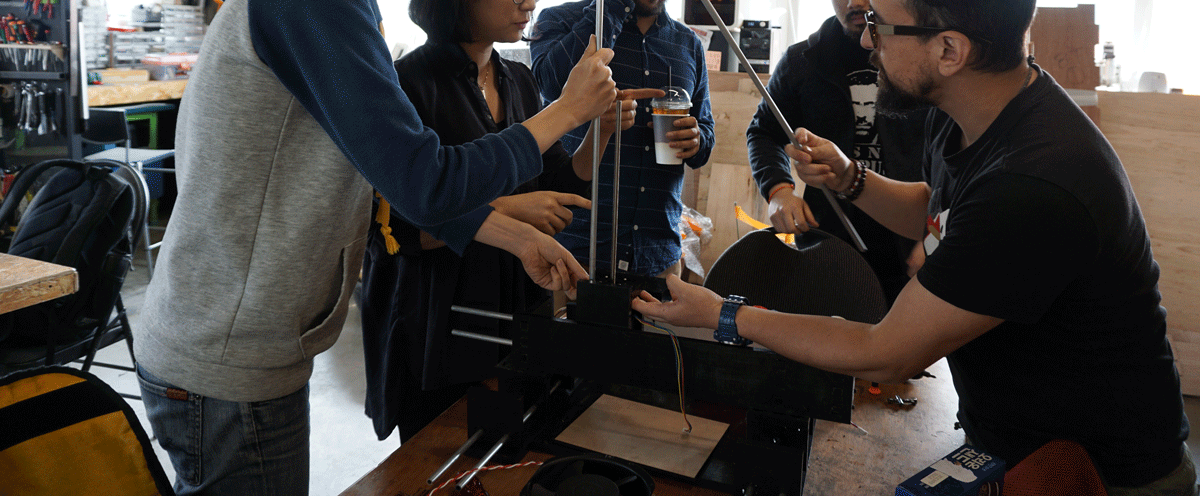

We had hard time dividing team work. We are all new to mechanical design, so we decided to make one prototypes each and evaluate our outcome and make a better version as a team. As a result, Hyejin and I designed and laser cut a model, tex did software and Rodrigo made joinerys. We had three meetings of brainstorming and attempt to understand CNC.

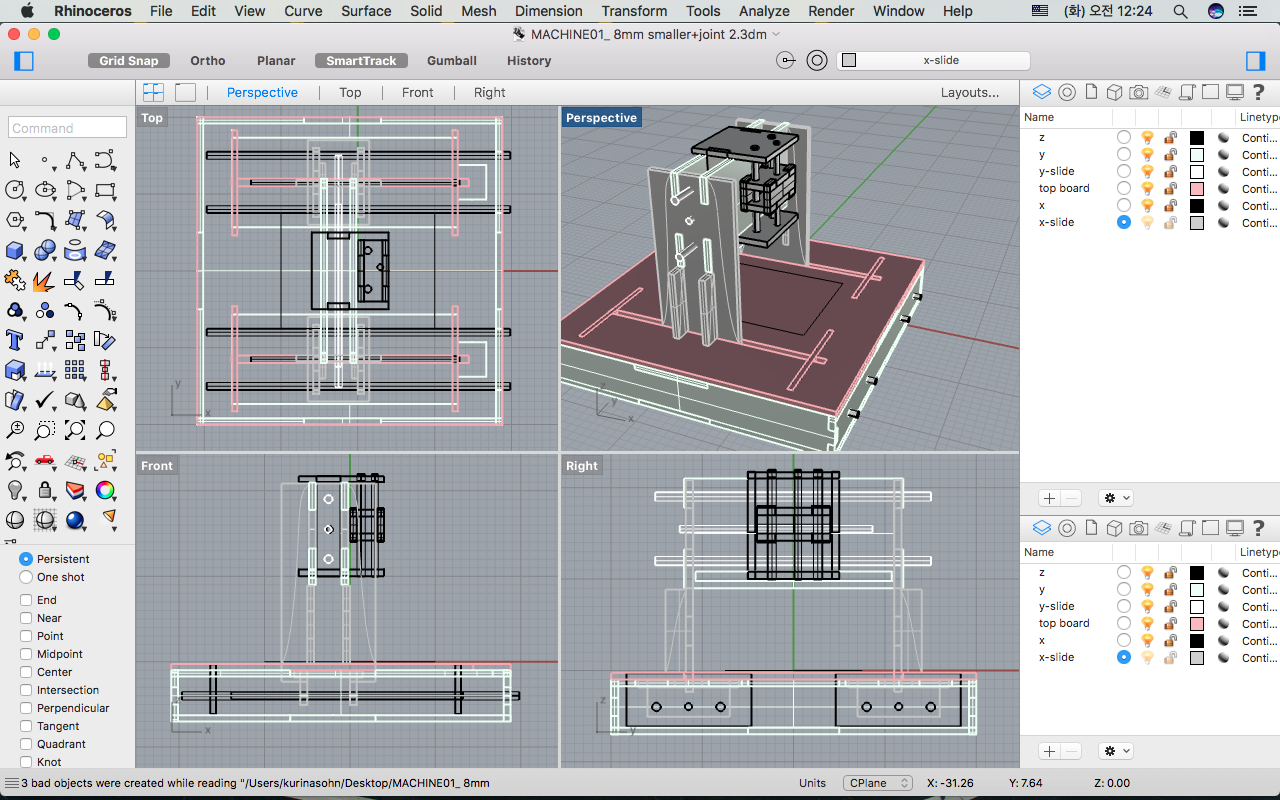

I tried to work with Fusion 360, but killed too much time just to understand the software. I went back to Rhino.

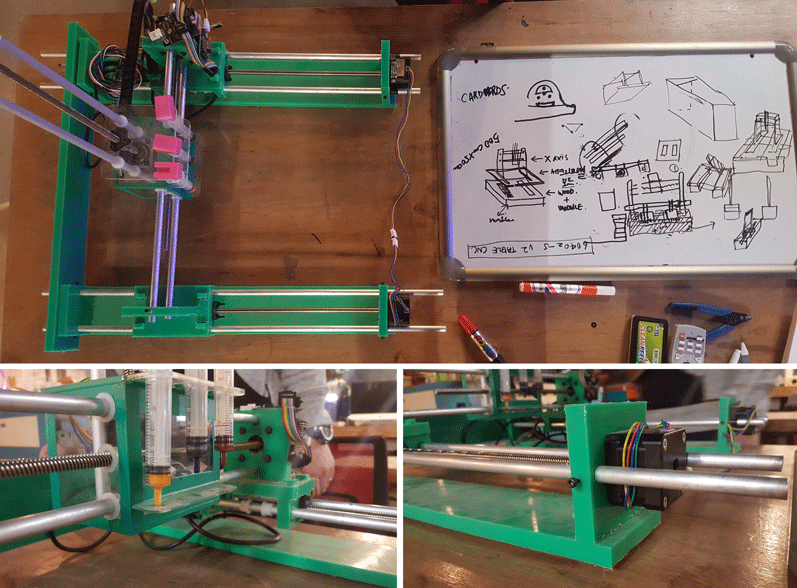

I made a CNC machine that is just for one purpose.

Measurements:

Aluminum shafts diameter: 9.5mm

Stepper Motor size: 43mmx 43mm

Leadscrew diameter: 7.85mm

Cardboard thickness: 8mm

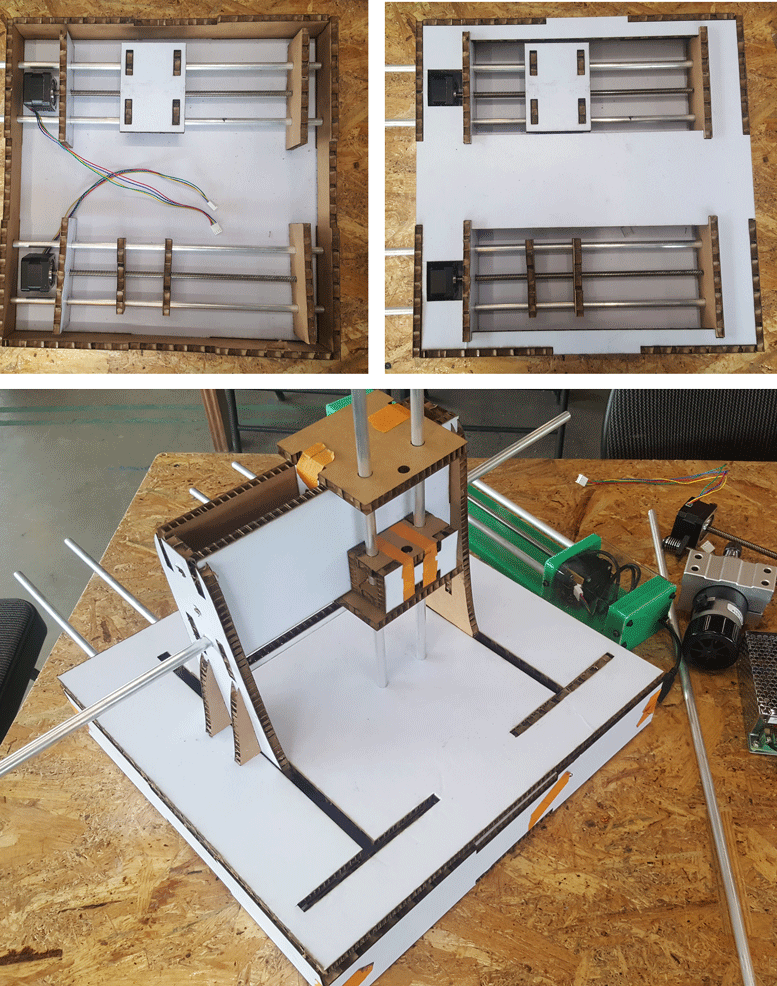

My first cardboard CNC!

Here is HyeJin's prototype

It worked nicely as cardboard prototype, but I had errors. Also, we moved on to the ideas of making it moduler. After analyzing Fablab Seoul MTMs. We added improvements.

Working as a team!

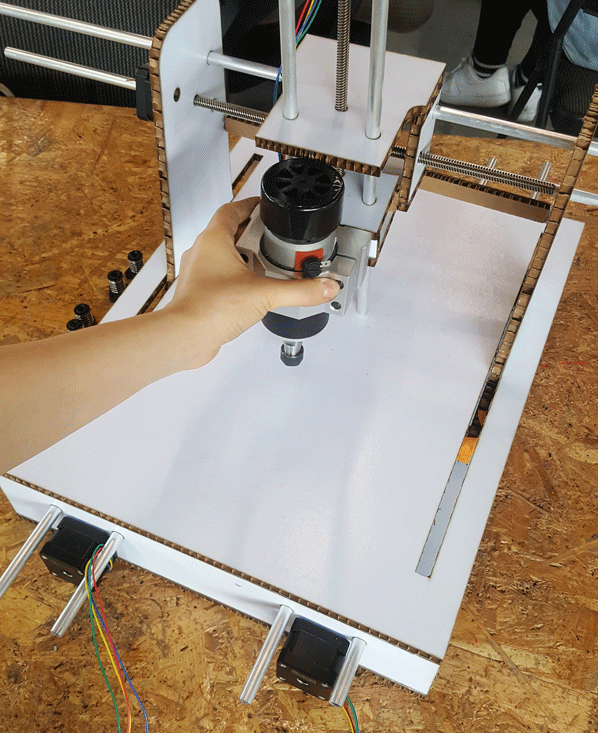

Testing HDPE, Joints and CNC.

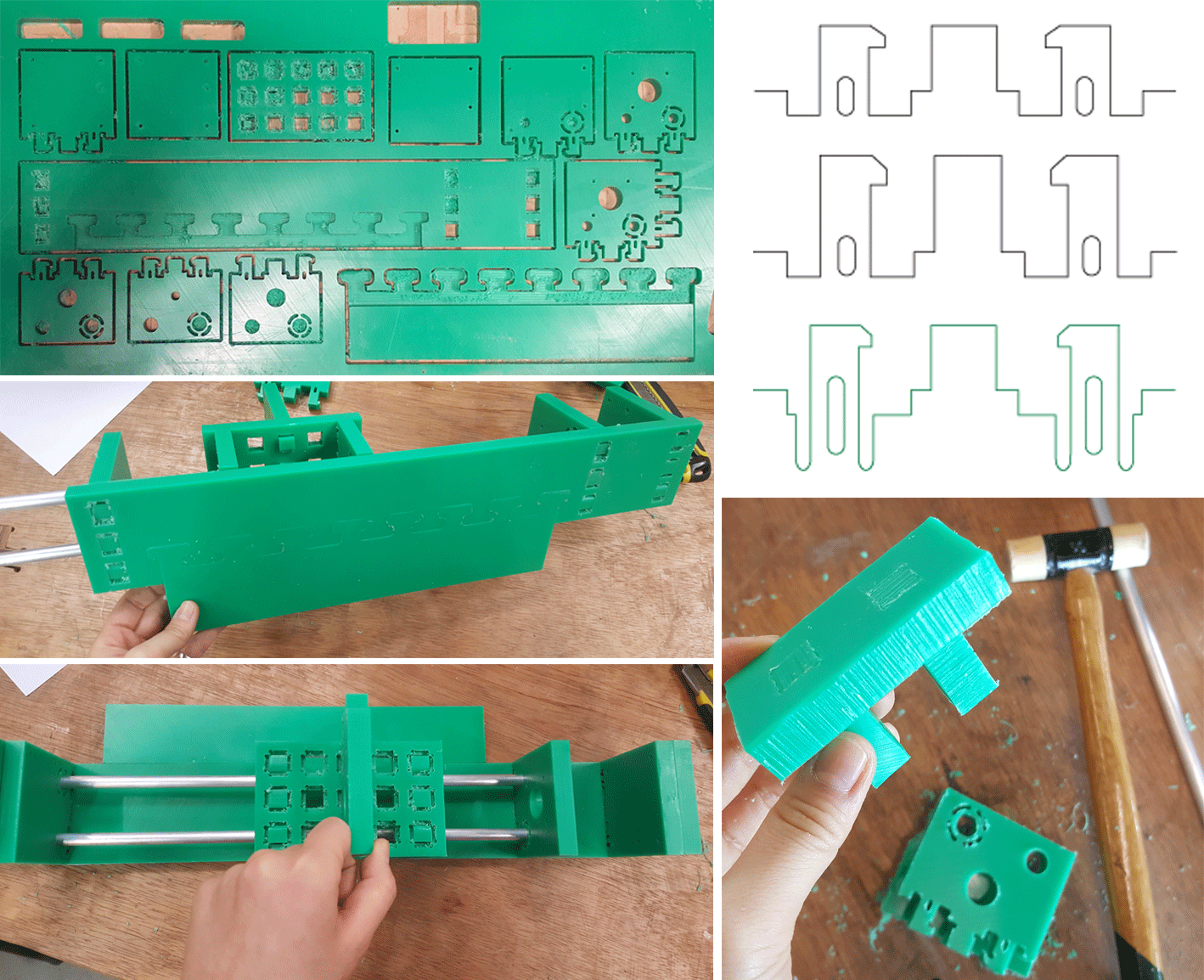

Because we had idea about all the components, I used Adobe Illustrator instead of 3D software.

3D Rendering of Kurohetex MTM

link to download, Machine .dxf file

Problems with Z axis

Presentation

I modified our website for 1 min presentation of Kurohetex-ed MTM for Fab Academy.