Until 07 Jun 2017

Contents

- Final Slide

- Final Project Idea

- Input Device

- PCB

- 3D printing

- Molding and Casting

- Final

Final Project Development

Slide and Video

Finished device

Final Project Idea

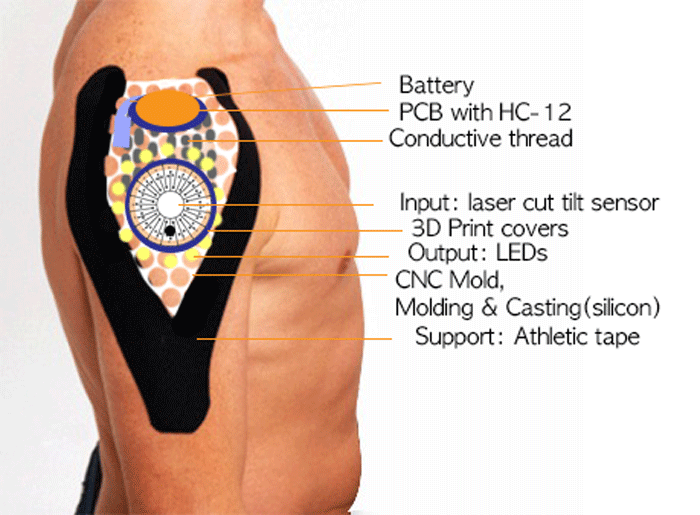

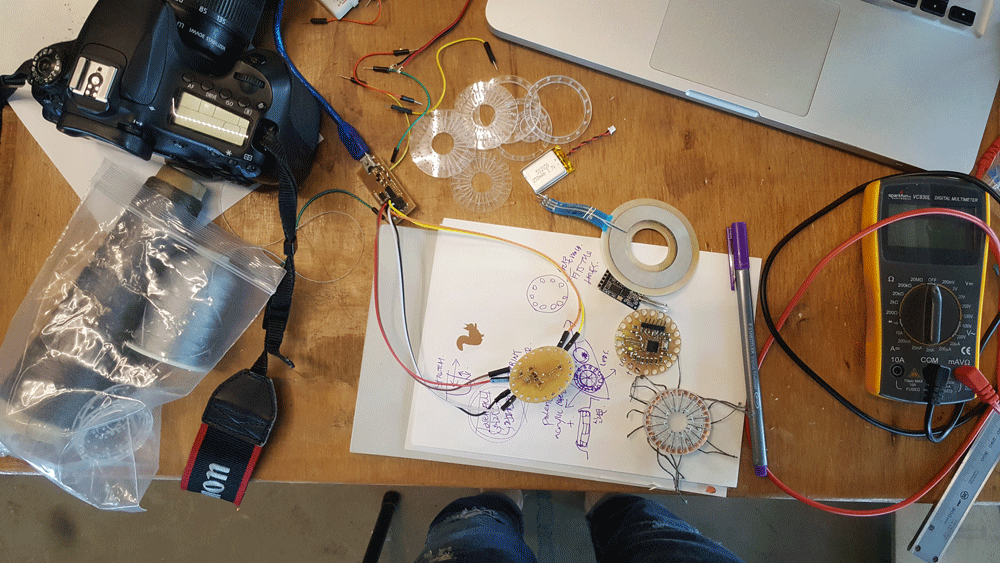

Wearable device that tracks body(shoulder, thigh or calf) movements data from bouldering, boxing and other activities. Advance climber every move is calculated, rhythmic, minimizing energy expenditure. The tilt sensor data will get collected and shown through the LEDs attached on the device. I will make this wearable sensors mostly using 3D printing, laser cutting, molding and casted silicone.

Original Ideas

Originally, I was hoping to use HC-12 and processing to have visual data sent and collected to my portable device. However, baby steps first!

Input device

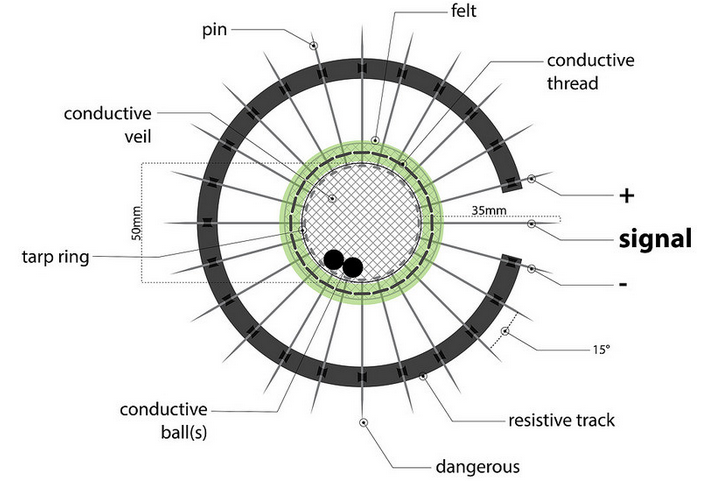

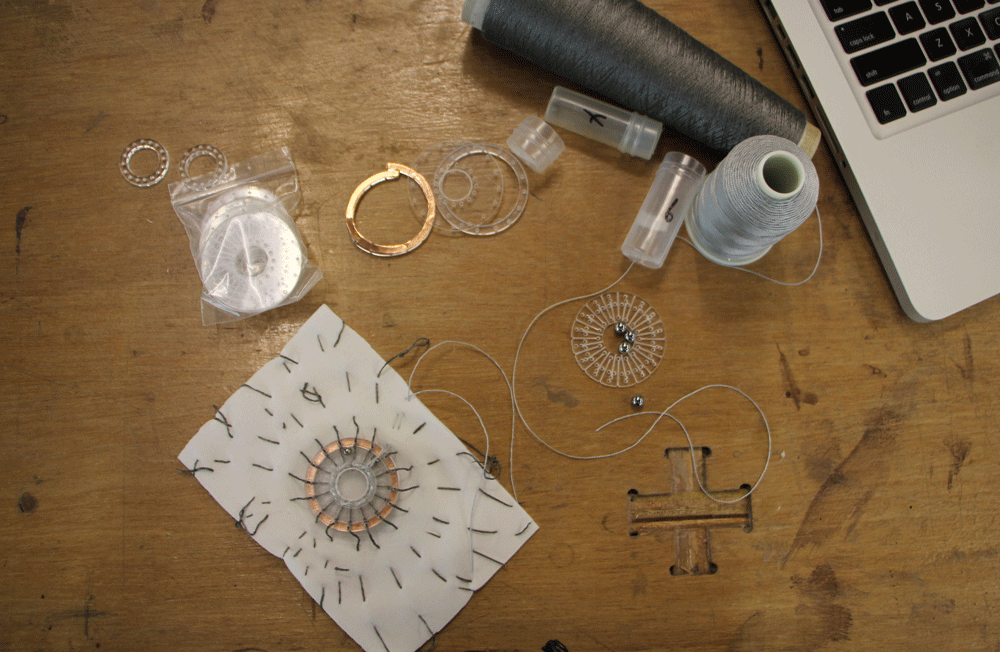

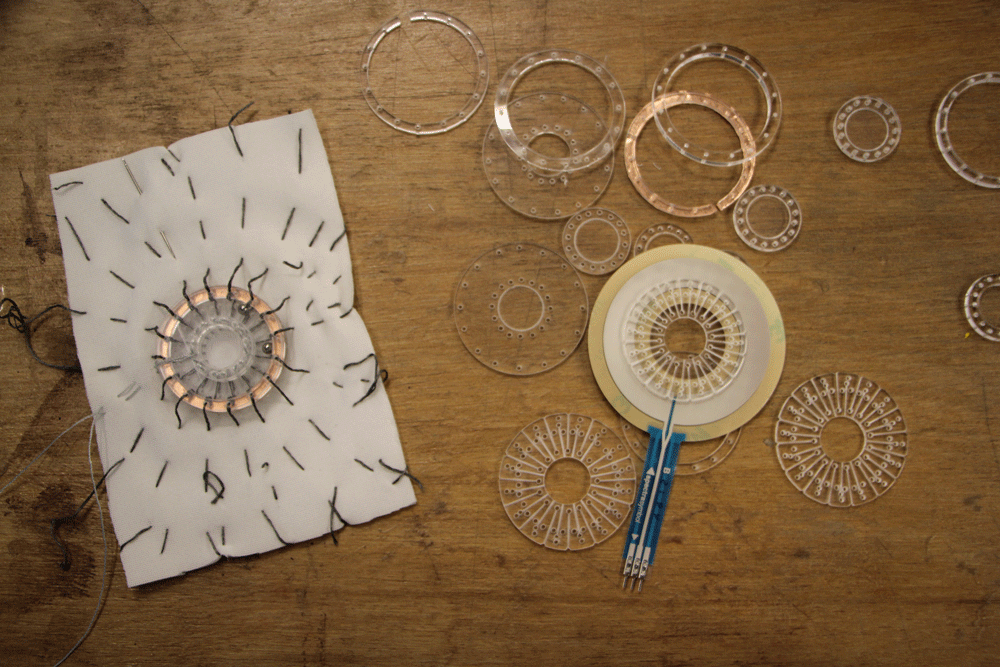

Reference: e-Textile Swatch Exchange: Dangerous Tilt

All the pieces for the tilt sensor was desinged with Adobe Illustrator.downloade .dxf file

I've used clear acrylic, conductive thread, regular thread, conductive ball from bearing store, and copper tape. Copper tape was a mistake. I should've used resistive track.

So I got circular soft potentiometer, I'm trying to decide if I want to continue with the tilt sensor idea or use Gyro sensor, because tilt sensors are bulky and on reliable at this point.

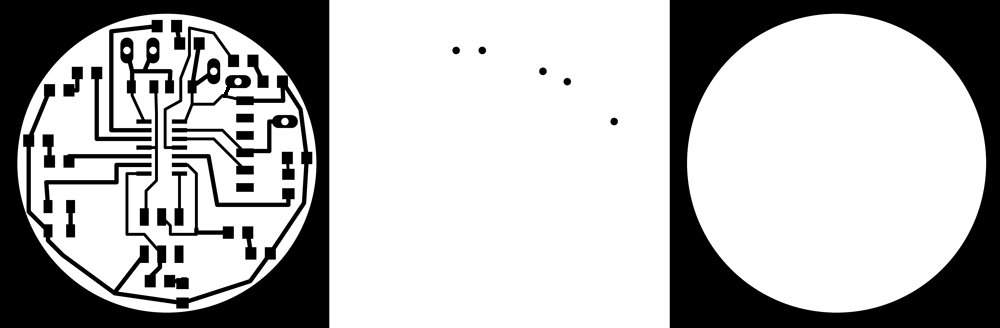

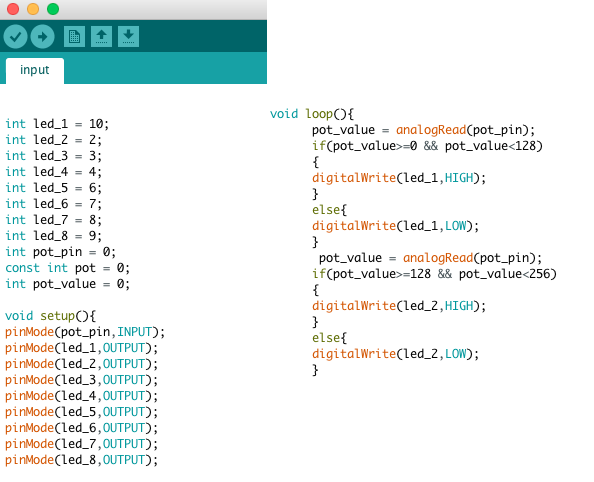

PCB

PCB board layout

Eagle downloade .brd file & .sch file

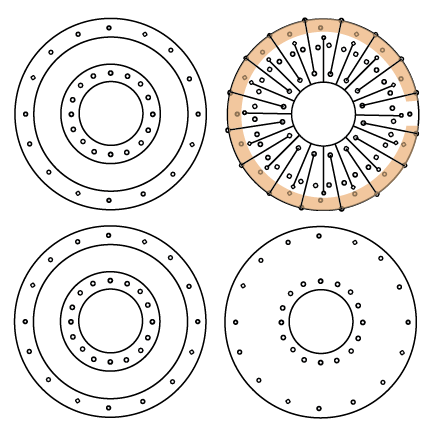

3D printing

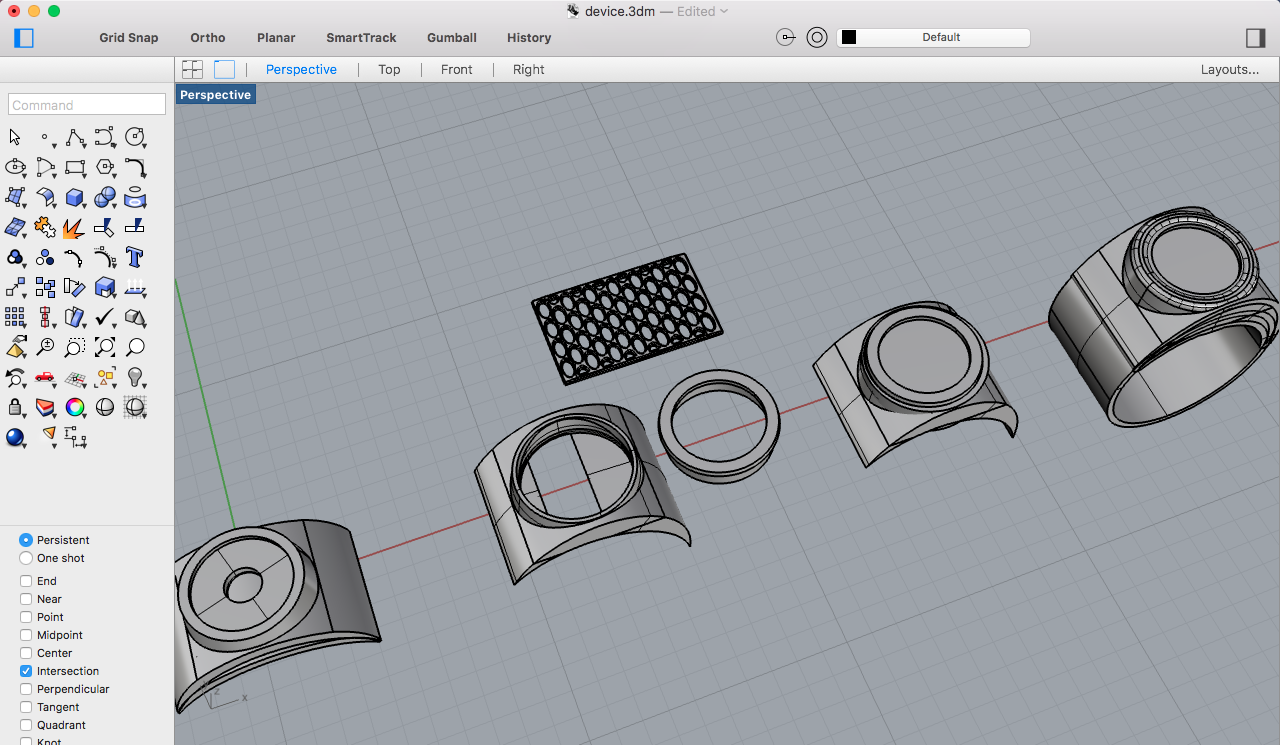

Rhino File

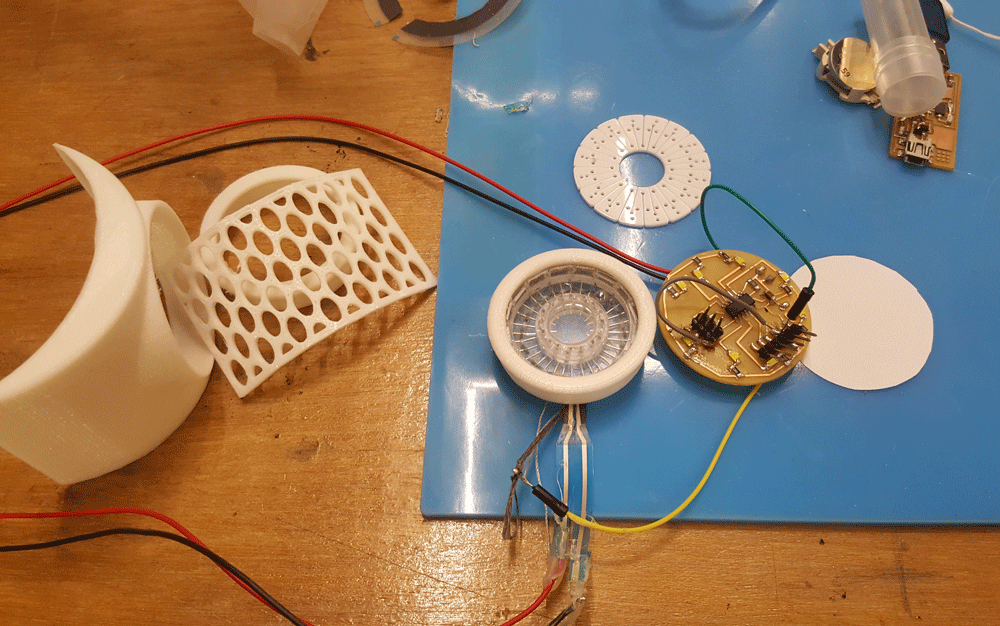

From left, first type, final 3d print, mold insert, and complete look.

Rhino design .stl file & .stl file of molding and casting design

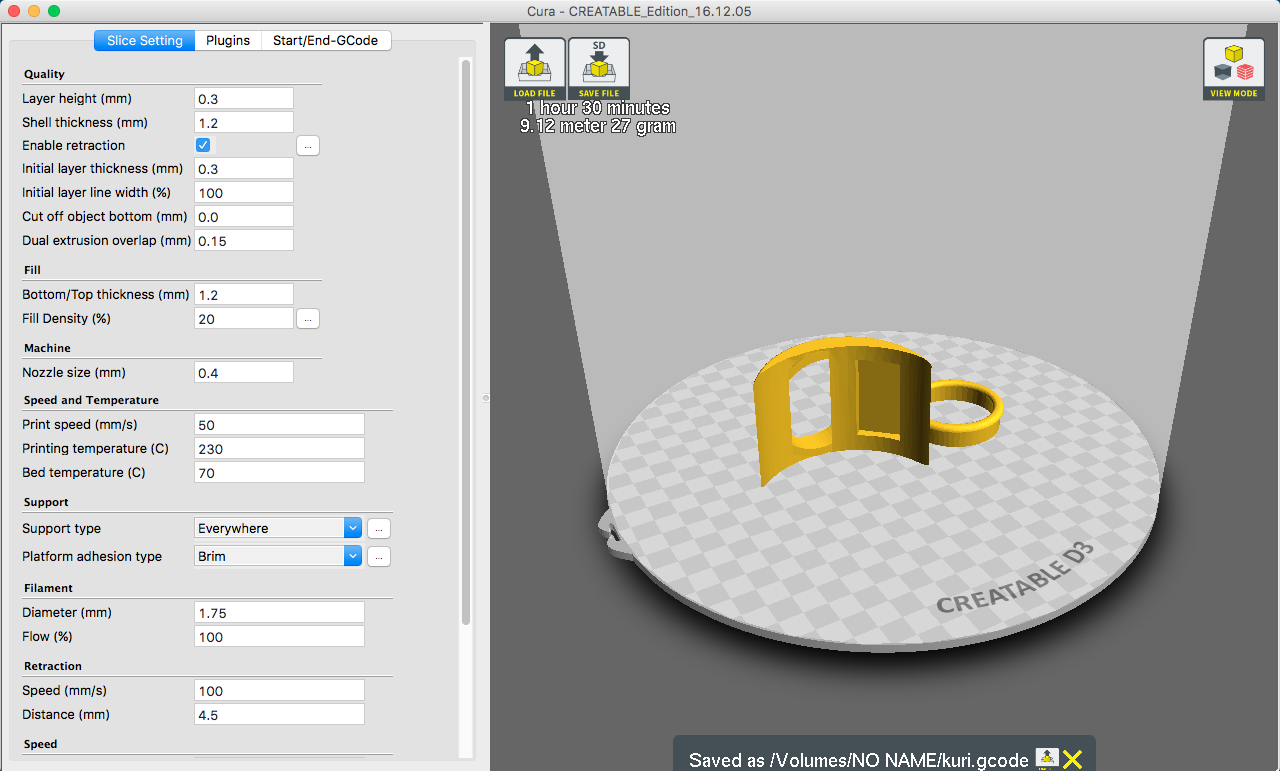

Cura, Getting started!

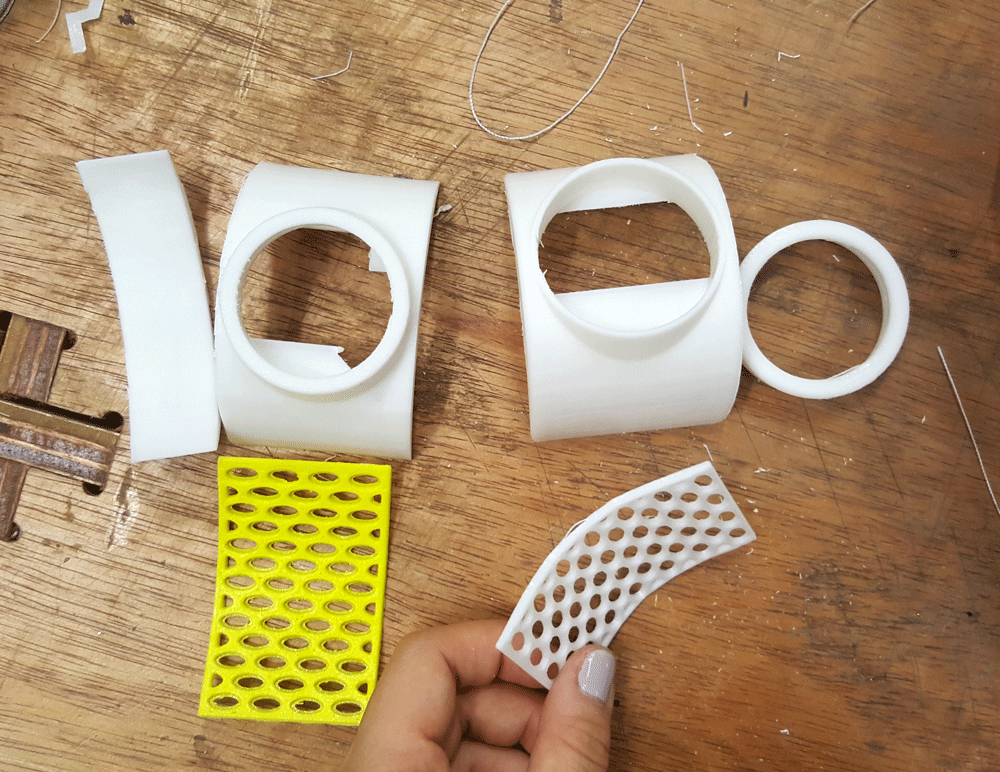

First and Final 3D print.

Putting it together!

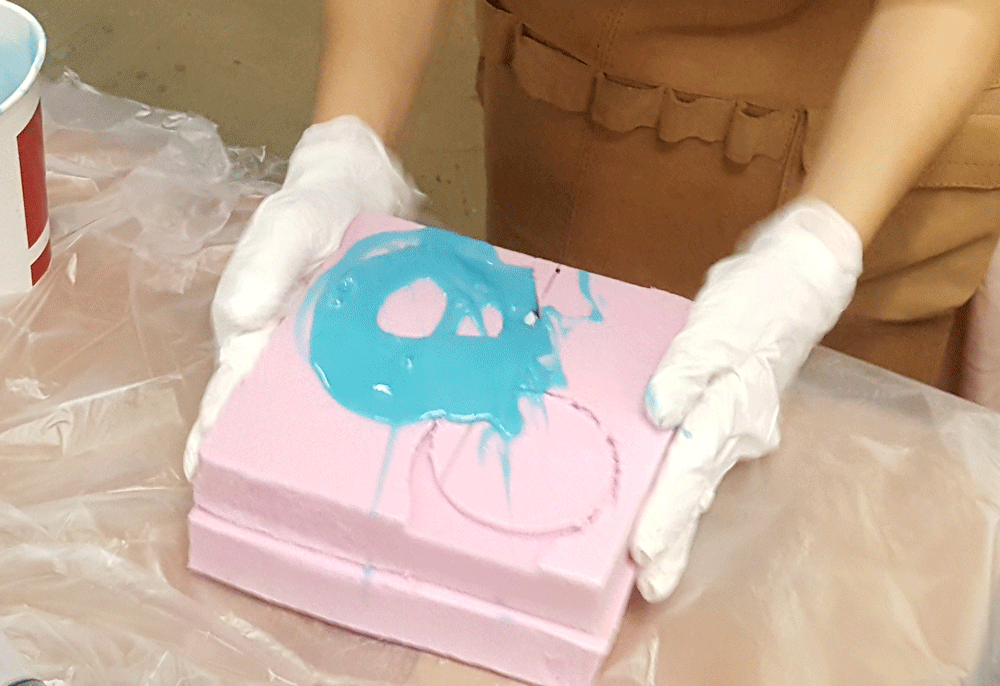

Molding and Casting

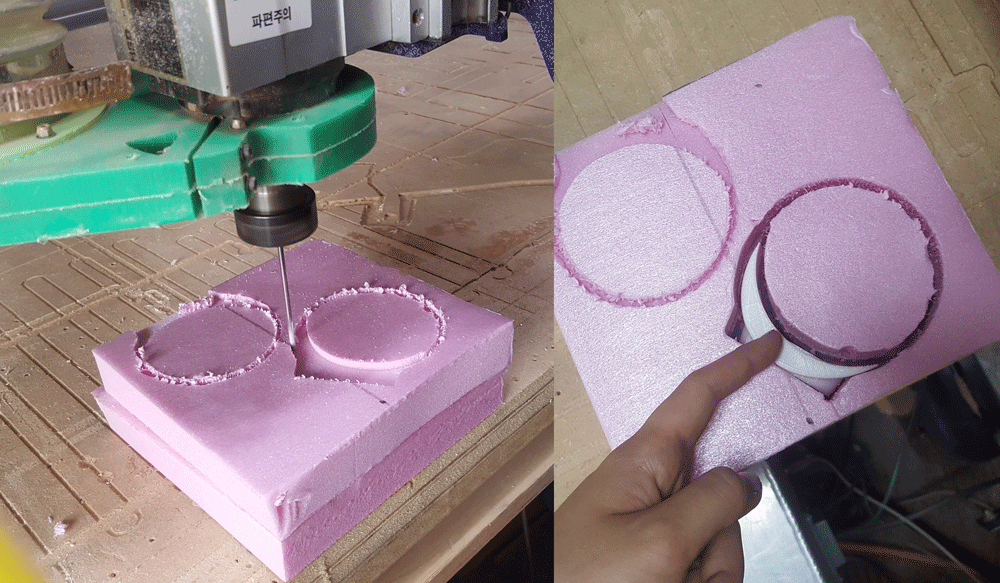

I've used construction foam and CNC for mold, than inserted 3D print in the mold.

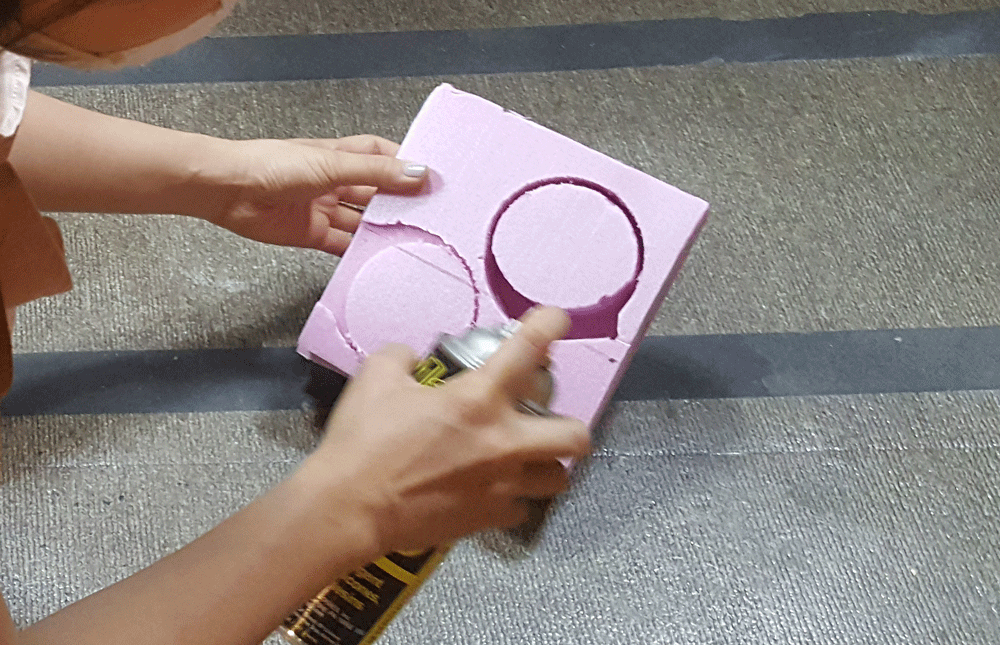

Before putting silicone, sprayed with Mann's ease release 200.

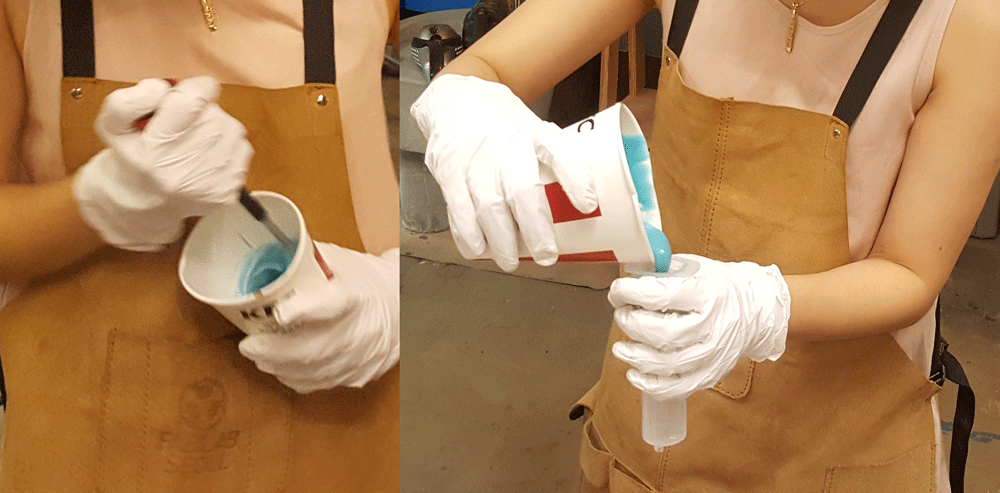

For this project, I've used injection molding, Smooth-on Mold Star 16 Fast Platinum Silicone.

After injecting, hit it to the table to release any bubble.

Time Management & Evaluation.

Time Management

Evaluation

According to Fab Academy Assignments and Assessment, I have shown different skills from different assignments by making and designing my own PCB, laser cutting, 3D printing, Molding and casting using CNC, and injuection molding. Compare to the beginning of the class, I have advanced my skills in digital fabrication.

what is the deadline? June 14, 2017

How much time do I have left? A week

what tasks have been completed, and what tasks remain? Mold is cut out using CNC, tilt sensor is made, and PCB is still in process. Debugging code, 3D printing, casting silicone is left.

how will I complete the remaining tasks in time? I have the 3d modeling ready to print, casting is only going to take 1 hour, and debugging.

what has worked? what hasn't? The first three PCB using Atmega 168 didn't work and new simplified version of Attiny 44 works.

what questions still need to be resolved? How do I made it more smoother in sensing the tilt?

what have you learned? I've learned a lot by numerous trials, failures and altherations.

Final!

Inside

Final Look