20 Feb 2017

Hello, FABRICADEMY

The Textile Academy

Contents

- Why do we need digital fabrication in the textile industry?

- Digital Fabrication + Textile = Answers?

- Hacking the fashion Industry

- Hand On Laser Cutting Techniques

Why do we need digital fabrication in the textile industry?

“In 1900, 40 percent of all US employment was on farms. Today, it's less than two percent…As automation frees our time, increases the scope of what is possible, we invent new products, new ideas, new services that command our attention, occupy our time and spur consumption. You may think some of these things are frivolous — extreme yoga, adventure tourism, Pokémon GO… A century of productivity growth in farming means that now, a couple of million farmers can feed a nation of 320 million…”

TED talk ‘Will automation take away all our jobs?’ by David Autor, Professor of Economics and Associate Head.

This statics got me thinking. What will out future job be like? How does our life style/ daily routine be like in future? 의식주 is the necessitates of life in Korean, it also means Food, Clothing, and Shelter. In the Textile Academy bootcamp lecture, explains that digital fabrication can be applied to anything, from robotic, engineering, textile and other new eras.

Textile industry has always been at the cutting edge of technology. From the silk road to the industrial revolutions, Anastasia Pistofidou pointed out about the first industrial revolution, steam power helped cotton spinning machines. Second industrial revolution allowed us to import, export and built the connectivity. Now 80 billion garments are made globally. The global textile and garment industry worths nearly $3000 trillion. However, it is second most polluted dirtiest industry, damaging all the natrual resources. Anastasia pointed out about redesign the system, correct some mistakes and errors that we been having.

* TCBL: Textile & Clothing Business Labsaims to renew the European Textile & Clothing sector.

* Dyecoo- dyeing with supercritical CO2 gas. (replacing water in dye process)

* More reading, on American Chemical Society’s Cutting Out Textile Pollution’ by Alex Scott

Hacking the fashion Industry by Zoe Romano

How does fashion industry organize?

Fashion Conglomerates: fashion is run by building desires and values and imageries of brand. Real value of the product is lost in between manufactural to consumers. Intellectual properties, copy rights, most of the garments are in grey area. Without labels or brand name, it is easy copy the garment without consequences. Fact is that every 6 months, it becomes an old collection. It is ‘un-attractive’ to customers anymore.

'Intellectual property is not technically openness.' by Zoe Romano.

Clothing Industry or garment industy goes linear economy from resource> Design> manufacturing(from ateliers to sweat shops by developing counties) > shipping > retail (shops, second-hand clothes, textile recycling, or waste) > consumption > waste.

Circular economy meaning from resource to recycling and renewing.

Alternative solution for closing the loop in fashion industry and open source projects.

Open source software, computer software with source code made available with a license.Copyright holder provides the rights to study, change, and distribute the software to anyone with any purpose.

* Valentina: pattern making software

* Blender: cloth simulation

* OpenFitLab: from scanning to trousers

* Unmade: Customisable products in an industrial scale.

Open source hardware: design that was made publicly.

* AYAB Shield: arduino shield to hack digital knitting machines.

* Circular Knitic: totally manufactured in fabled

* Smart Texiltes: empowering people with wearable and soft circuits.

Open design: the development of physical products, machines and system.

Open data: data that distributes in convenient and modifiable form.

Openwear: a collaboration community around fashion production and creation.

* The Post-Couture Collection

* Openwear

* Anothorshoe

* Comake

Digital Fabrication + Textile = Answers?

In textile bootcamp, they had few questions and maybe digital fabrication can answer those questions.

Digital Craftsmen

Crafts are getting lost because of less commercial value. Find solution to revive and empower community. Update new tools, material, processes.

Customize not Mass Production Custom digital taliors.

1. Reconfigurable Modular Systems_ replicated and assemble.

2. Seamless clothing_ problem with recycling materials, many materials and finishing.

3. New Materials_ bio-couture, bio-plastic and etc.

Different examples can be developing tools, feed with natural fiber and spray with fiber. spray on a body? or a form. Directly fabricating garments and finish on site.

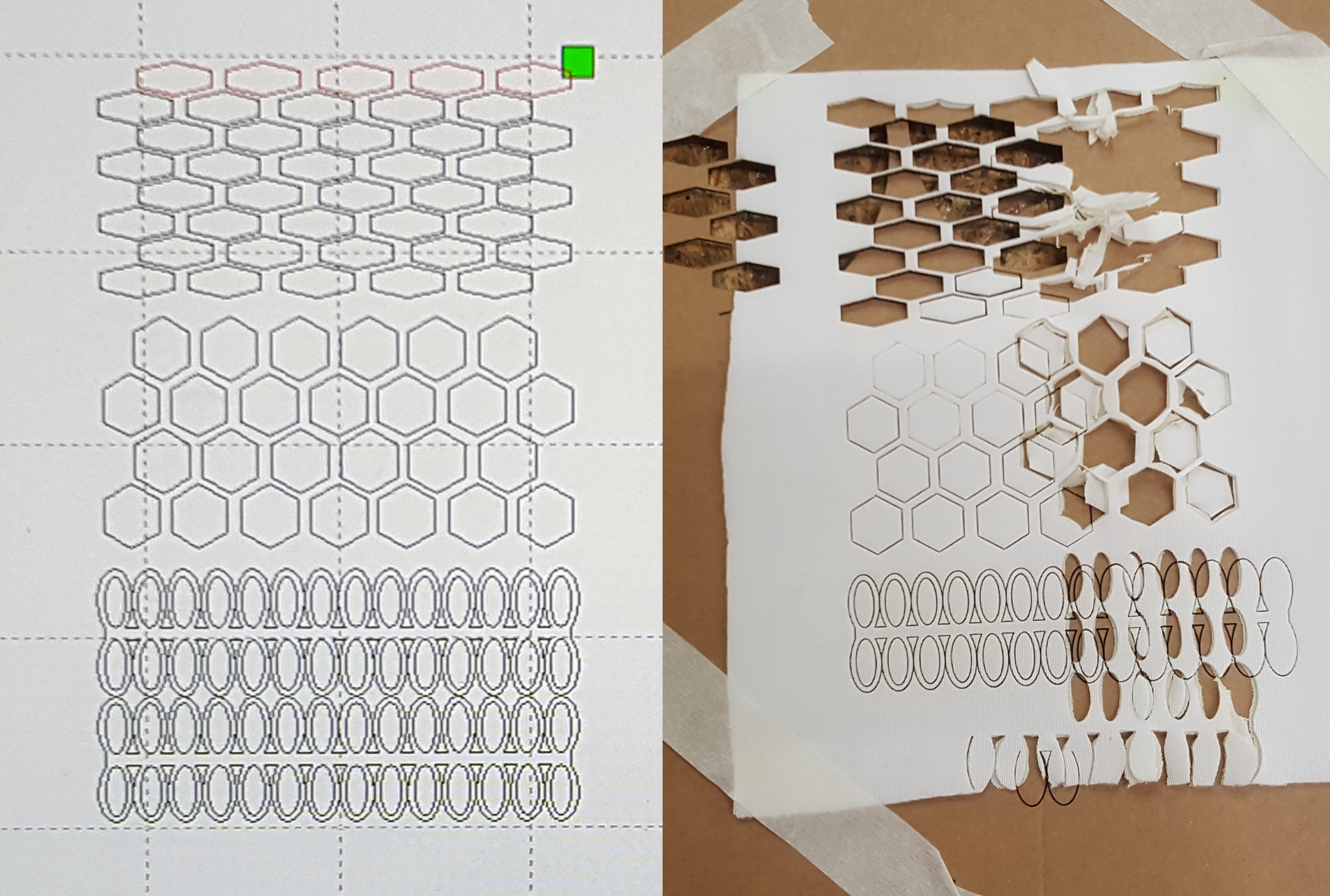

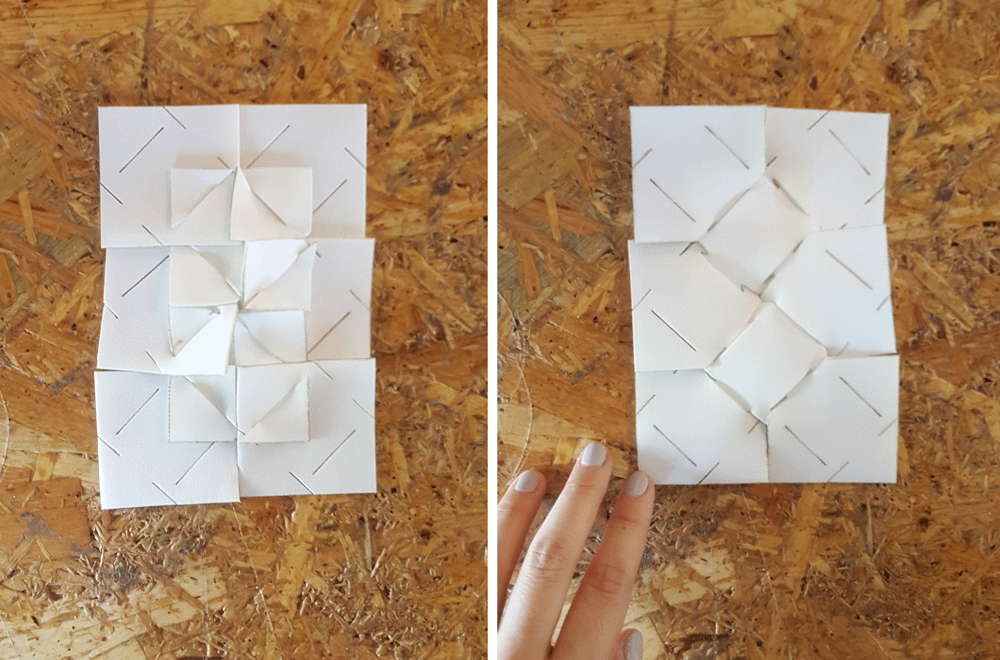

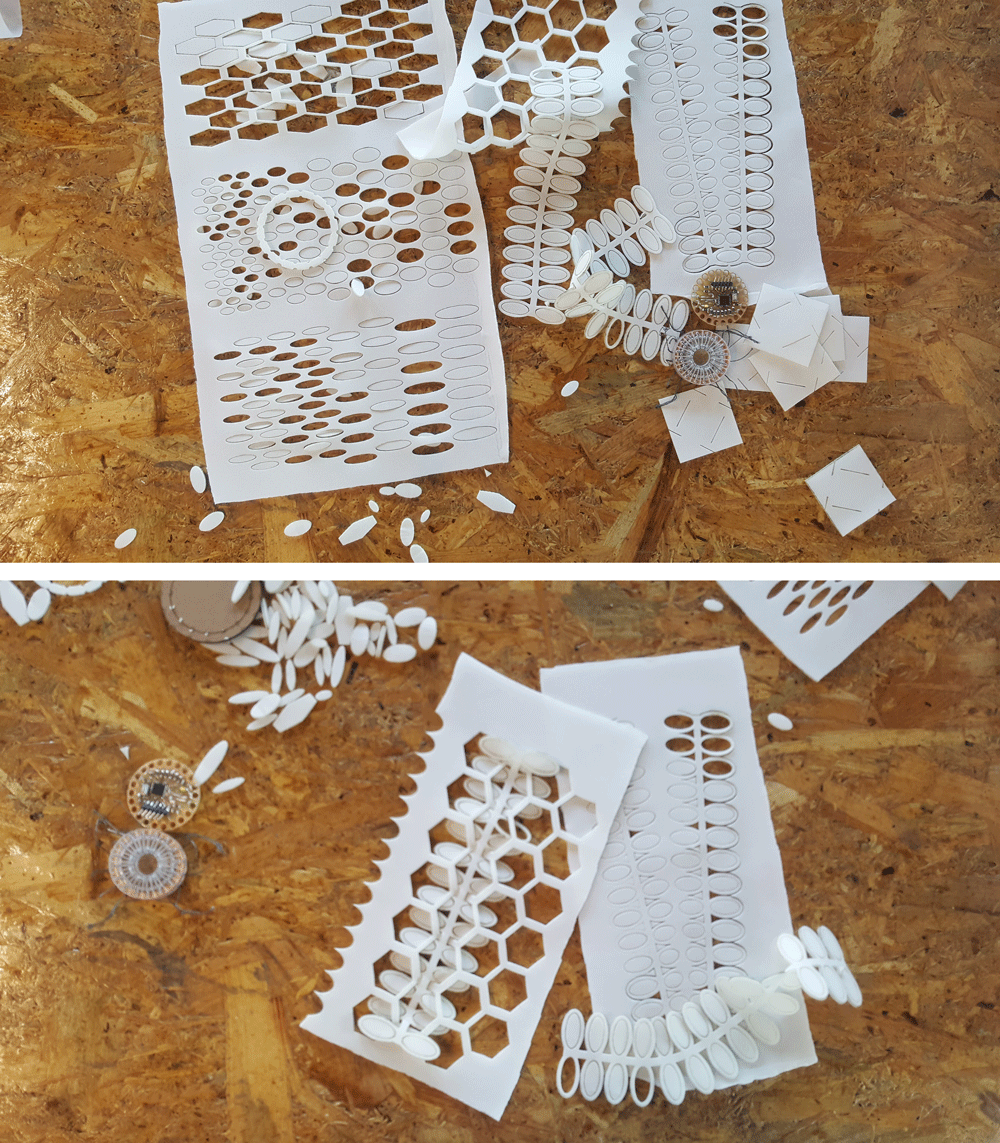

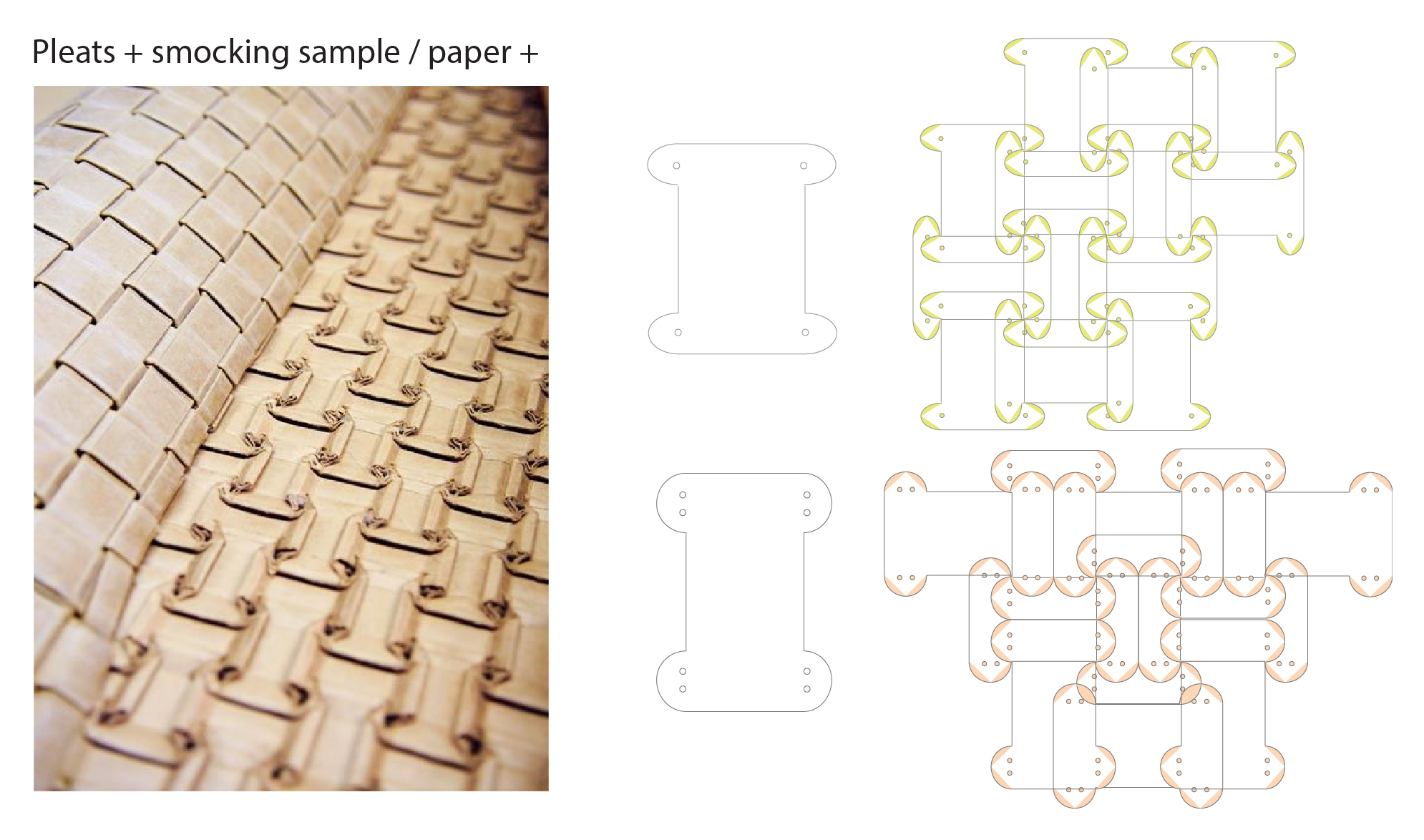

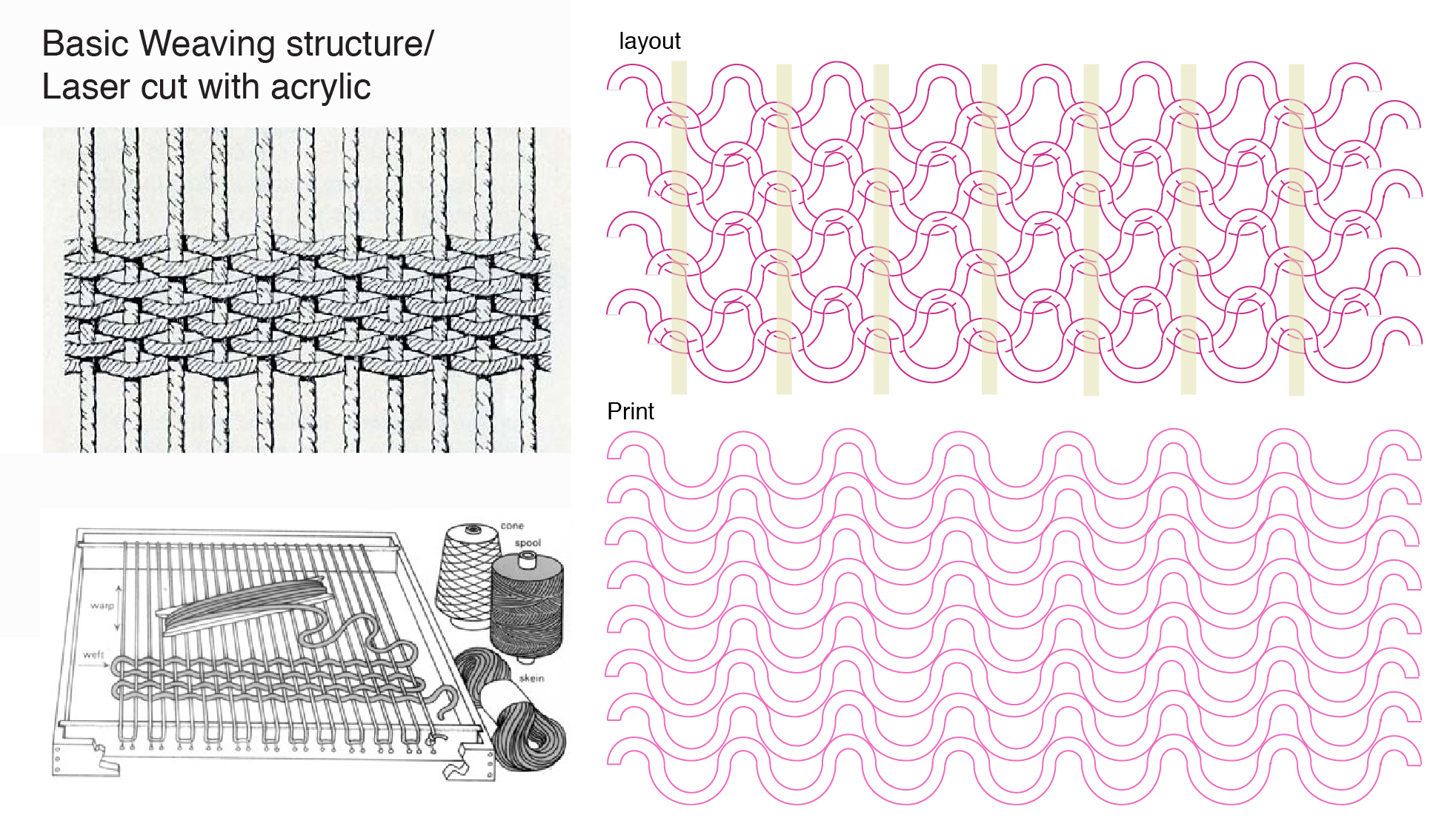

Hand On Laser Cutting Techniques

I’ve practiced laser cutting and designing textile structure in week 2(computer-aided design) and laser-cutting in week 3(computer-controlled cutting) of the Fab Academy.

More experiments with neoprene fabric.

First Test: