For this week, the assignments to be accomplish are:

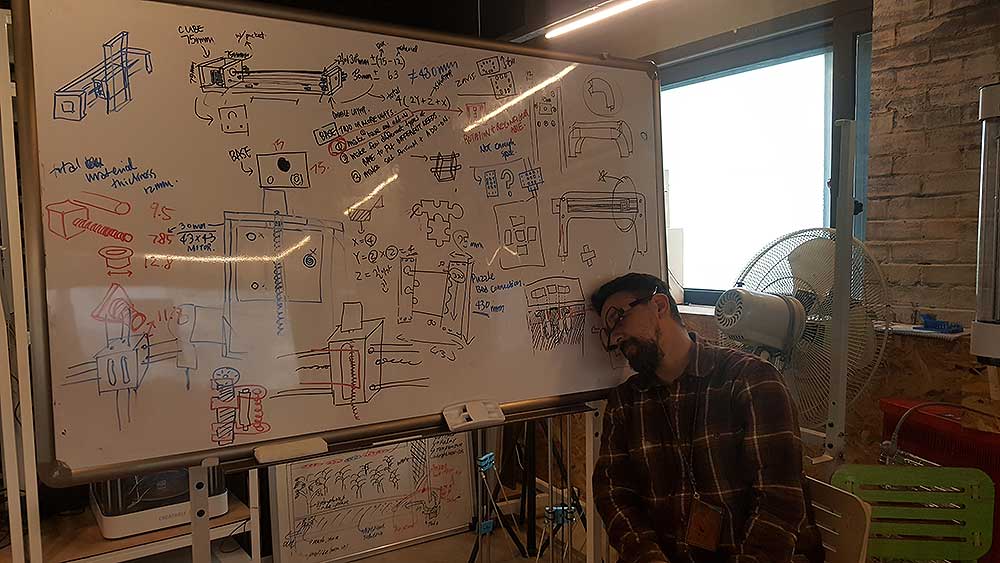

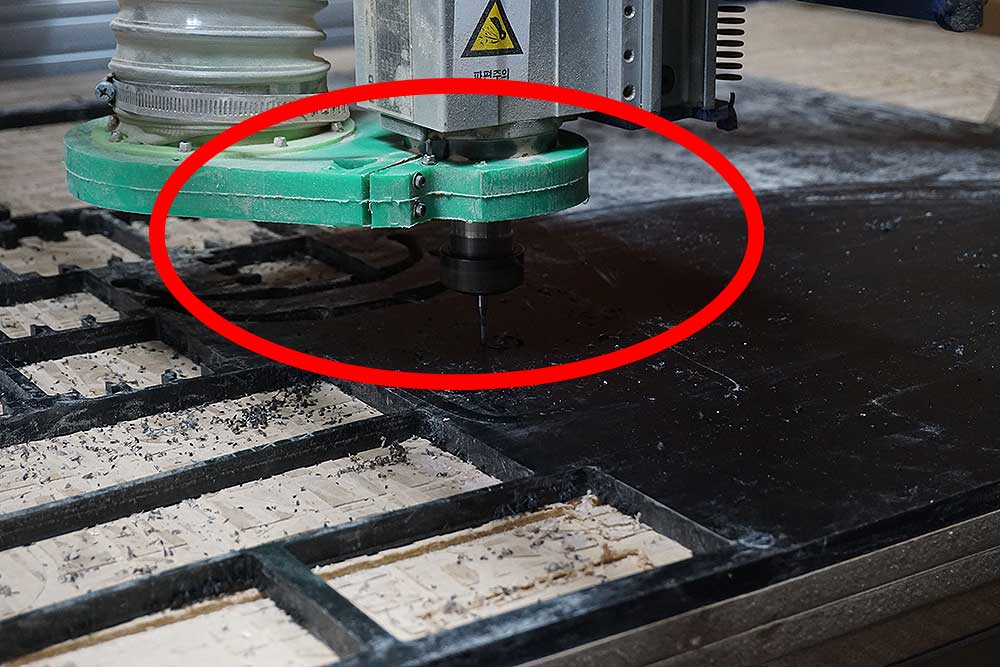

Our Group started by brainstorming how to make a Machine, and we soon realize how hard is to actually do this!! Z is the most dificult part to control!!!

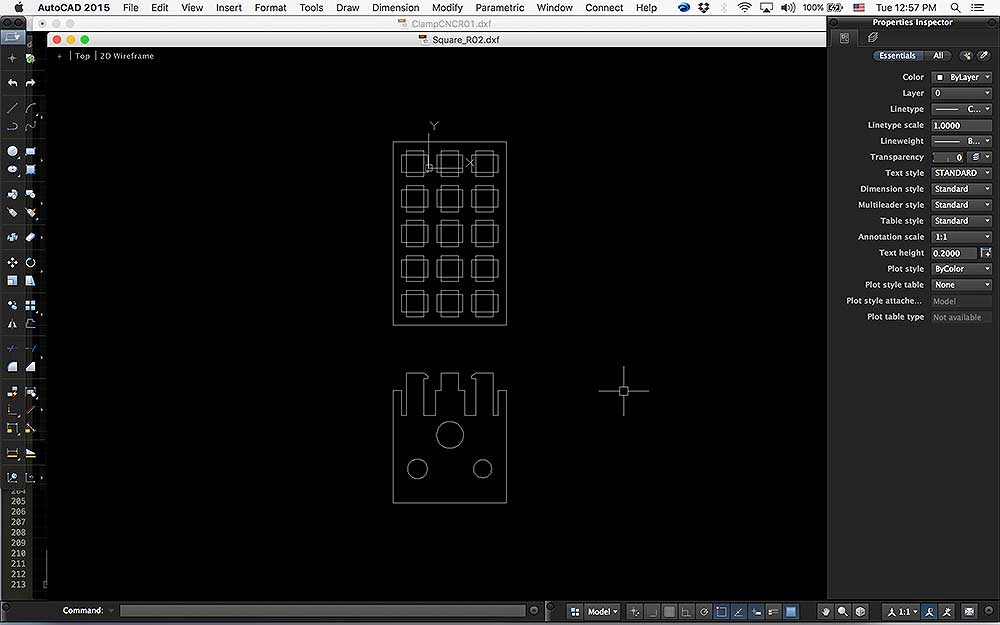

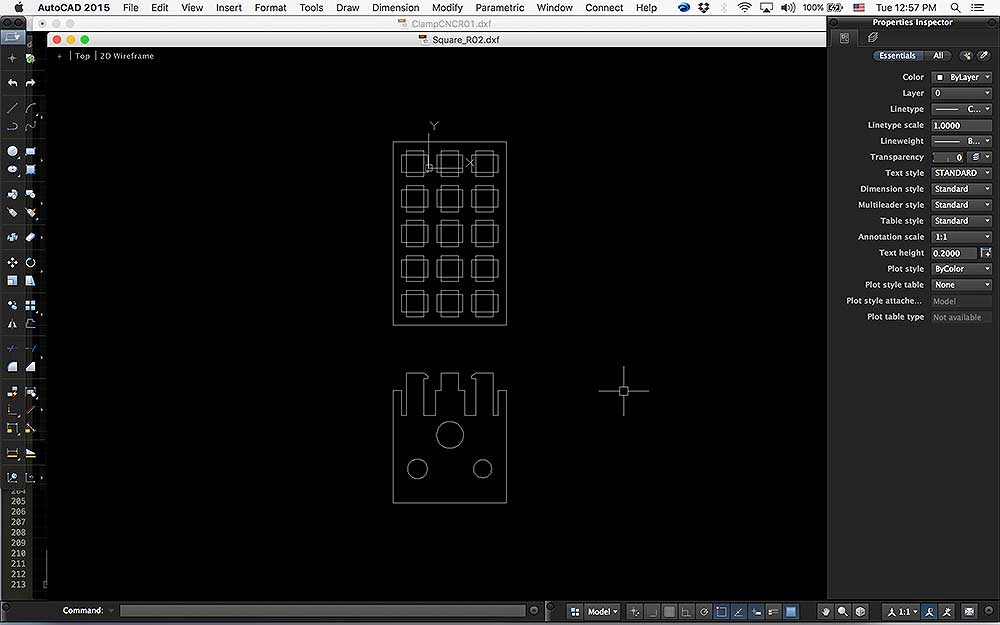

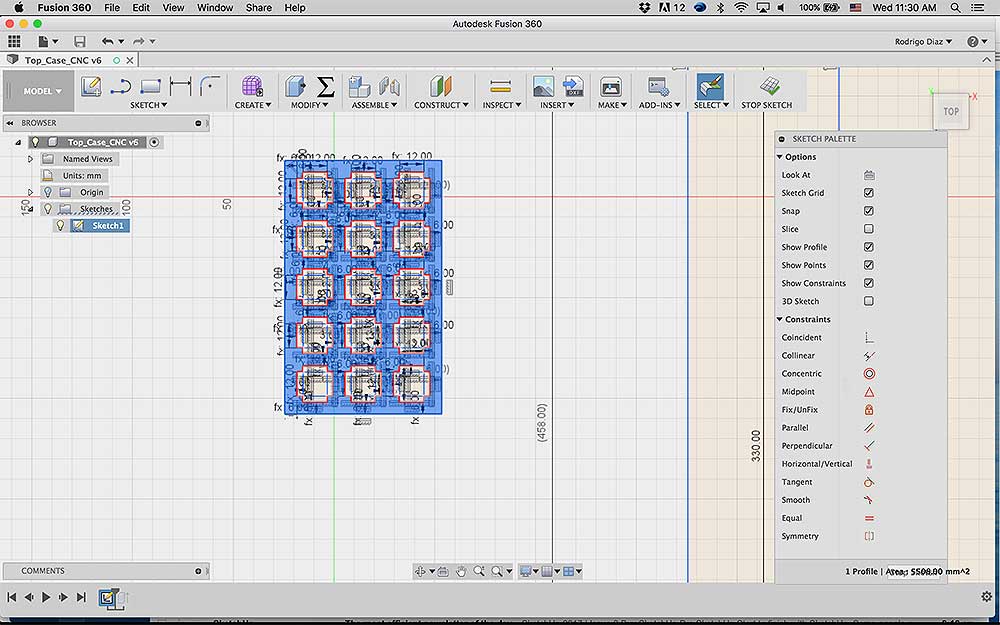

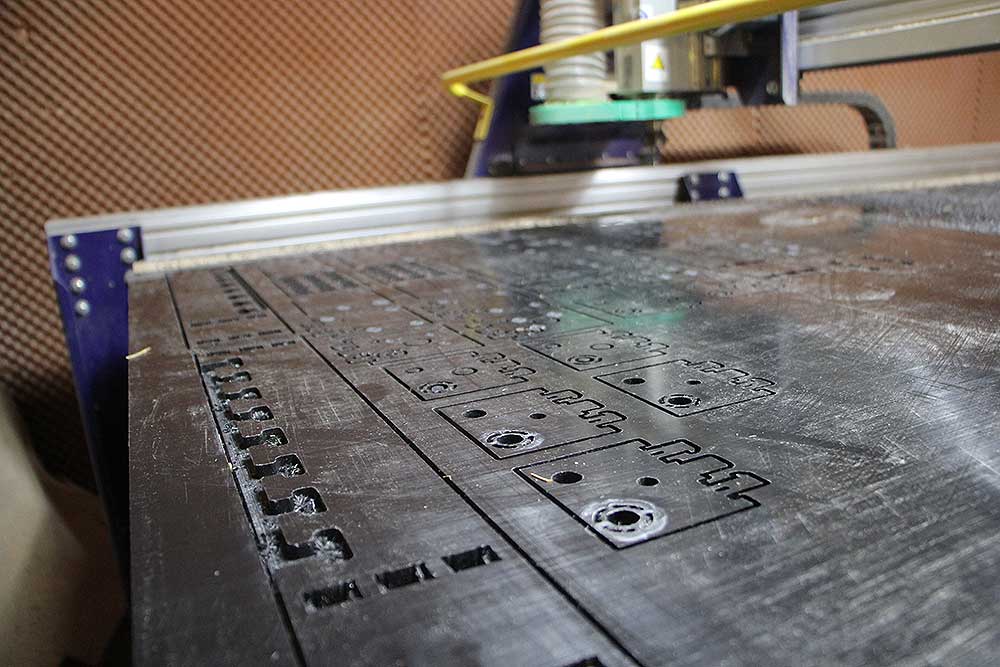

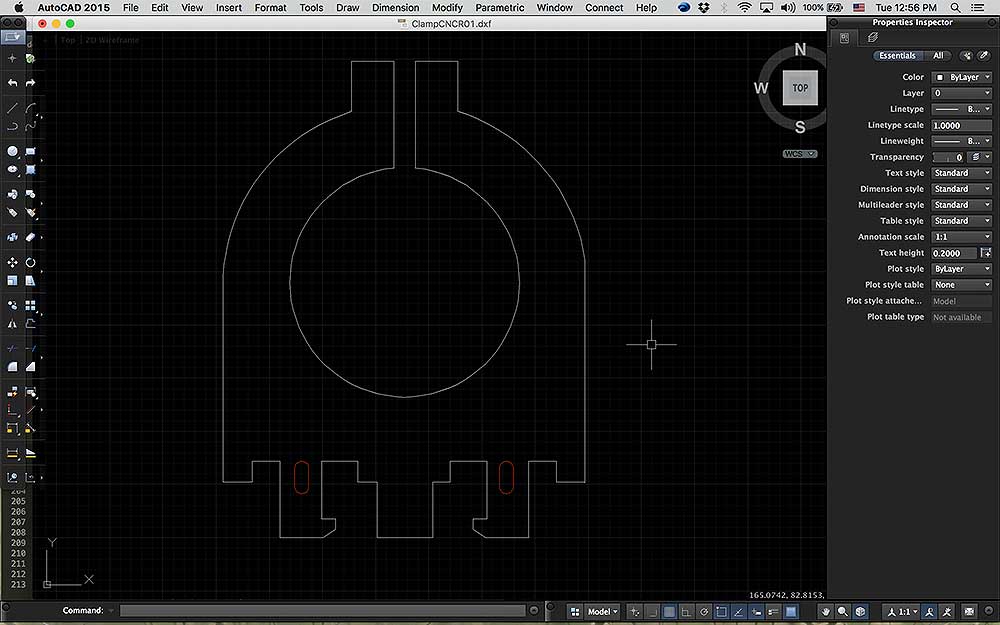

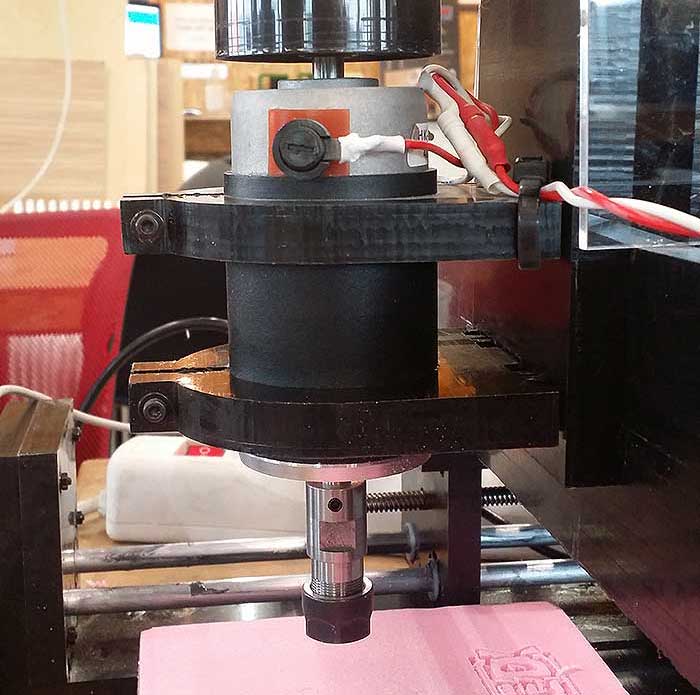

CNC has been one of the most fun machine to learn and work with

I tried to show the ordeal that our team had making the machine, but I realize all FabAcademy2017's student must have felt the same way!! chears to all!! I Hope honestly that you guys enjoy the video!!

Failures:

Take care of: