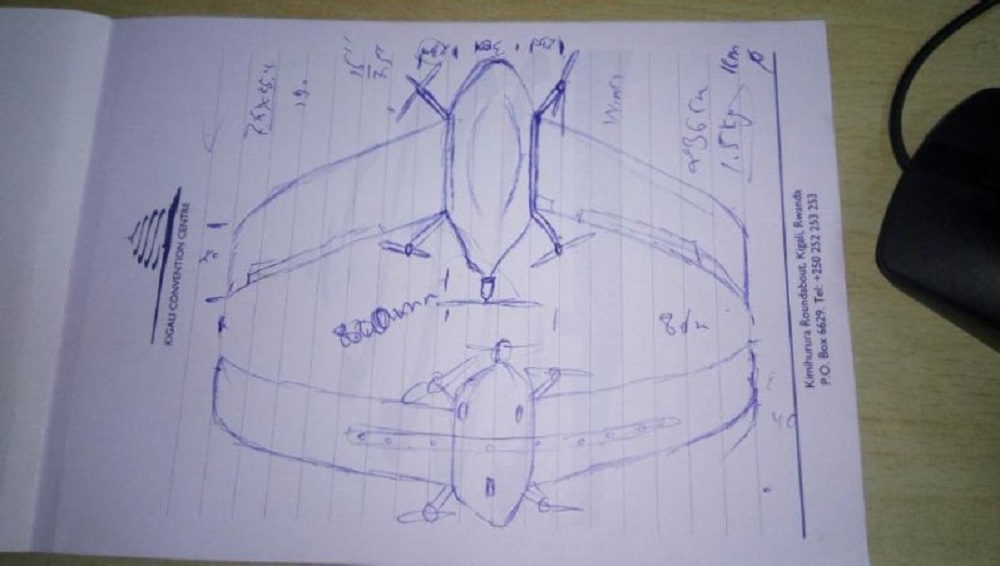

Scketch up Project

My country Rwanda is small country with Highly slope Hills country as it nickname said "Land of Thousand Hills", it's economics is based on agriculture almost more than 75% of population carries farming as main activity where they are in co-operatives depending on where their farms are, in order to boost their harvest now days we are using manpowered agriculture for spraying which is not more accurate so by comparing below technologies i like precision agriculture where we can use drones even in highly slope areas can be applied too

My country Rwanda is small country with Highly slope Hills country as it nickname said "Land of Thousand Hills", it's economics is based on agriculture almost more than 75% of population carries farming as main activity where they are in co-operatives depending on where their farms are, in order to boost their harvest now days we are using manpowered agriculture for spraying which is not more accurate so by comparing below technologies i like precision agriculture where we can use drones even in highly slope areas can be applied too

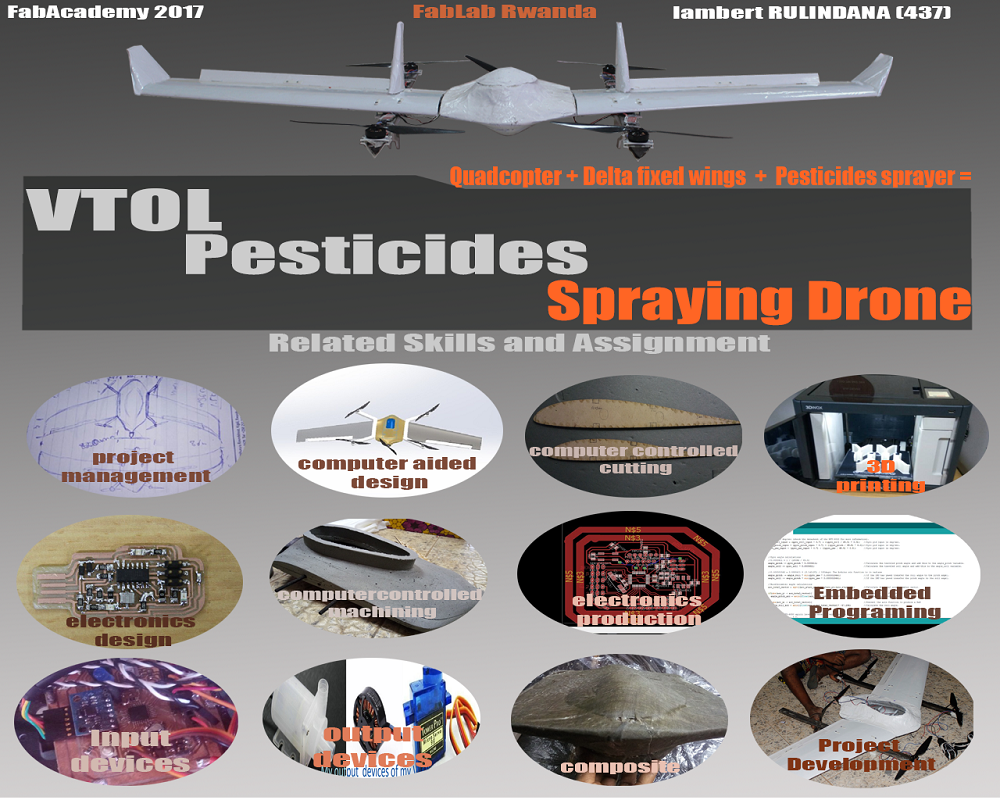

have decided to continue the project of pesticide spraying drone after each of my classmate from fablab Rwanda take his own project as my final project. At this moment I don’t know yet lift force energy are generated even i didn't do anything with related with commercial flying toys in my childhood but i like i fell happy if i saw someone fly a toy drone but i spend whole of my life with dreams of making my toy drone but final i do not what to make a toy, but i want social impact with the solution i bring, am going to make a pesticide spraying drone with hight stability in flight and as a new vision of drone configuration VTOL where it will be used in precision farming . This pesticide spraying drone will not be completed as i wish it might have complex sytem but am going to work hard as i can so that it can hover and fly with multirotor configuration and with fixed wing configuration, but I will continue to work on it until i get every thing as i planned.

How much will it cost?

An estimation price is:~$590

as shown below but the items founded in fab inventory are not listed

Download proposal budget here

Here are the links to the pages of the weeks that I worked on my final project

Computer Aided Design

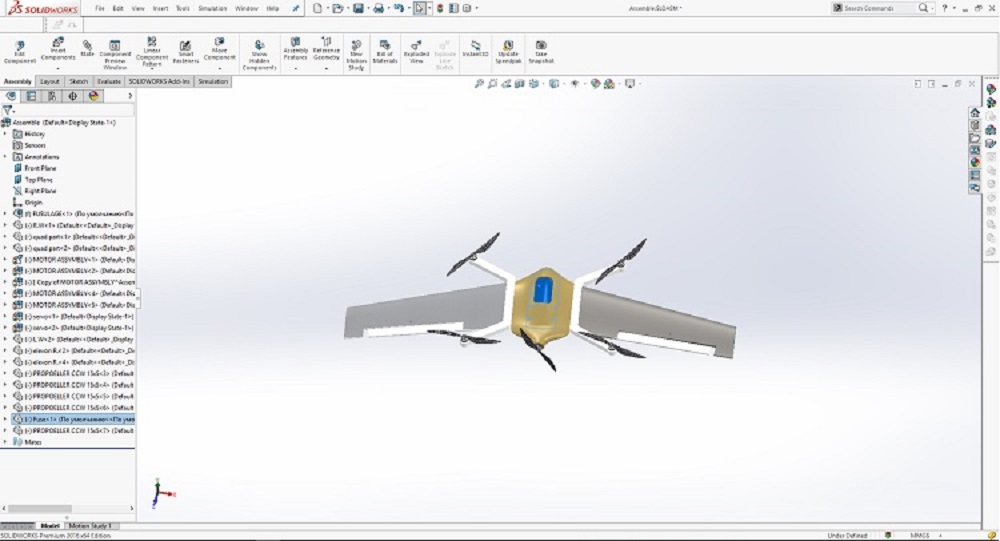

- this was my hard part to make sure which design I am going to be focused but final with my remote instructor Enrico Bassi and i based long discousion i had with a hobbyist in drone and he is comercial italian pilote from Rwandair Marco Mazzufferi i decide to make a this delta_Quad Vtol Drone

so I tried to design according to the way I want it to be looks like y using solidworks I tried to design the model and show to Marco and together we learn about aerofoil shape we may go on so I design and show to him to check if the all paramater we set if are good, we talk almost twice a week to check on progress and I really like this way because at the beggining I wasn't have any idea of they way I can turn my idea into reality again in something that may fly was like a dream but I choose this project to because I want to learn many science behind earospace engineering even am electronics engineer but from my child hood i like to fly a simple paper based plane so it was my optinuty to learn more about it and make it because it is my final project

so I tried to design according to the way I want it to be looks like y using solidworks I tried to design the model and show to Marco and together we learn about aerofoil shape we may go on so I design and show to him to check if the all paramater we set if are good, we talk almost twice a week to check on progress and I really like this way because at the beggining I wasn't have any idea of they way I can turn my idea into reality again in something that may fly was like a dream but I choose this project to because I want to learn many science behind earospace engineering even am electronics engineer but from my child hood i like to fly a simple paper based plane so it was my optinuty to learn more about it and make it because it is my final project

so am not going to talk much more about computer aided design because i talk about the way i design my motor in week 2 so clik here for the files

buying materials for use

this time is for ordering some materials for my drone i used aliexpress but the HD styrofoarm i bought it at local markert, the items ordered orderd on aliexpress are

BLDC motors

carbon fiber propellers

Electronics Speed Control(ESC)

MPU6050 sensor

6s lipo battery

hotshrinkable covering film

the styrofoarm i bought it at local market.

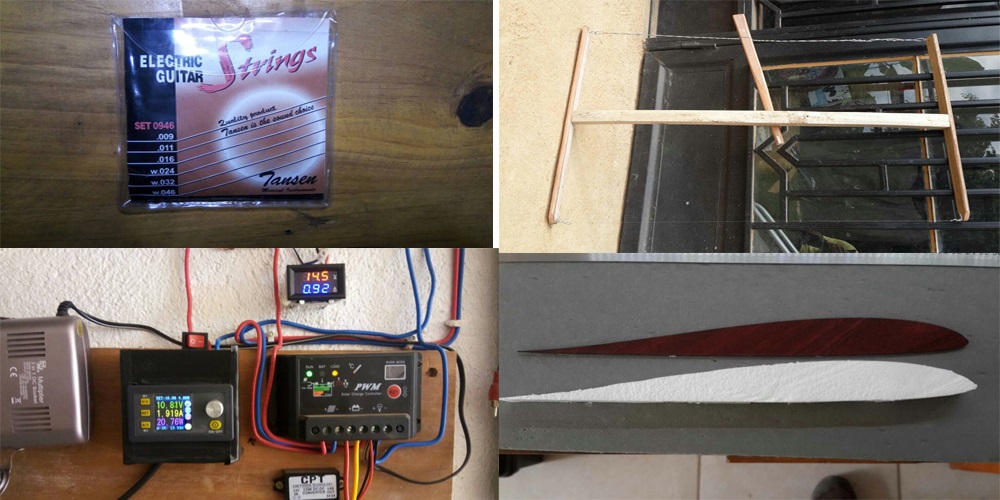

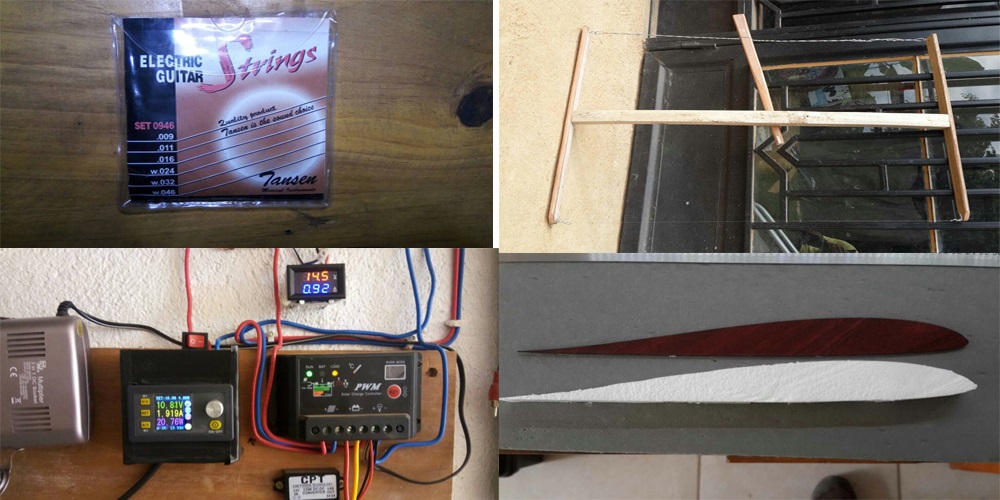

After cutting the wing profile i made a simple test on low density styrofoarm by using hotwire,NOTEwhile i am working i have to be carefull with the curent am supplying my guitar string

After cutting the wing profile i made a simple test on low density styrofoarm by using hotwire,NOTEwhile i am working i have to be carefull with the curent am supplying my guitar string

now i deside to leave small gaps for reforcement and i made the other wing profile to be used as final referencein I using hotwire i have to but on top same thing heavy on my material am working with on my side i used bricks until i completed my wings

now i deside to leave small gaps for reforcement and i made the other wing profile to be used as final referencein I using hotwire i have to but on top same thing heavy on my material am working with on my side i used bricks until i completed my wings

.jpg)

.JPG)

.JPG)

.JPG)

.JPG)

after 4days items recieved from hongkong to my fablab

the styrofoarm i bought it at local market.

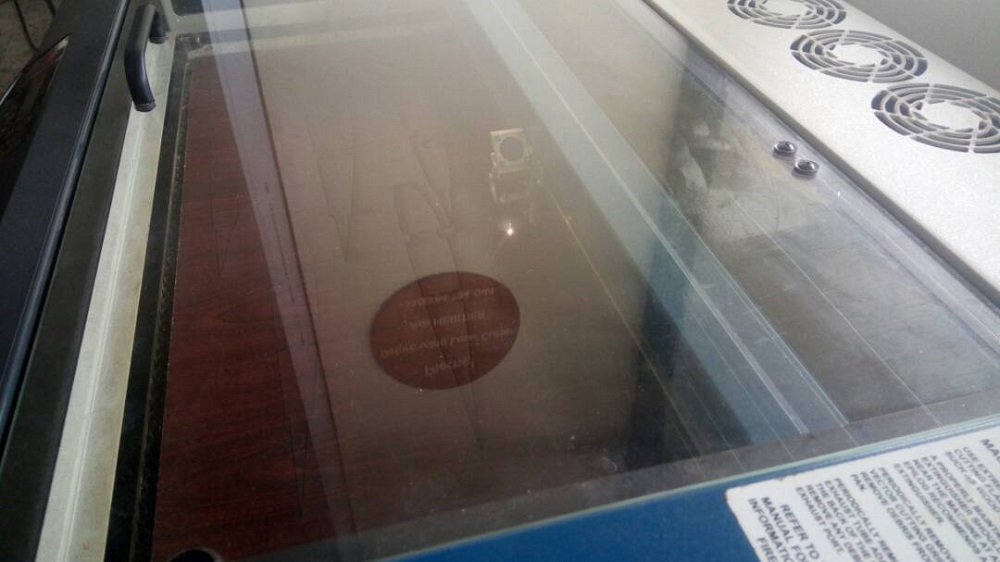

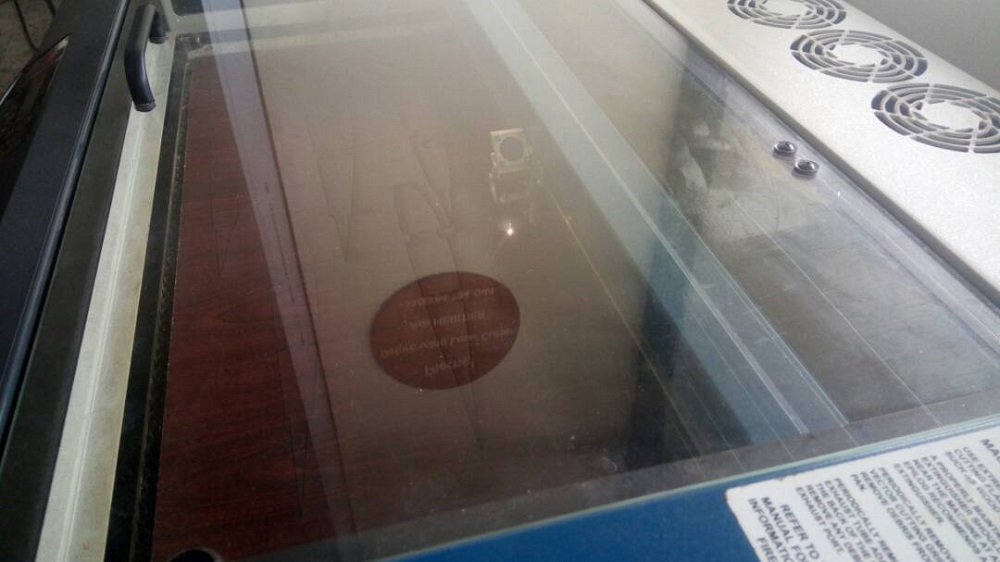

Computer Controlled cutting

at the begining i was saying that i will use Shopbot(CNC Machine for all part) but after trying my first wing i fund that it is a little bit challenging and there are many chance of lossing measurement due to flipping of the sheet, and because of the milling bit we have and due to my wing thickness is was not possible to achive my real measurement without destroying my sheet so i decide to use hotwire in this case of wings so in order to use hot wire it is recommended to have wing root and wing tip profiles that guides me in cutting my wing profile from HD styrofoarm. i used laser cutter for this task of cuting aerofoil profiles After cutting the wing profile i made a simple test on low density styrofoarm by using hotwire,NOTEwhile i am working i have to be carefull with the curent am supplying my guitar string

After cutting the wing profile i made a simple test on low density styrofoarm by using hotwire,NOTEwhile i am working i have to be carefull with the curent am supplying my guitar string

now i deside to leave small gaps for reforcement and i made the other wing profile to be used as final referencein I using hotwire i have to but on top same thing heavy on my material am working with on my side i used bricks until i completed my wings

now i deside to leave small gaps for reforcement and i made the other wing profile to be used as final referencein I using hotwire i have to but on top same thing heavy on my material am working with on my side i used bricks until i completed my wings

.jpg)

Computer Controlled machining

The fuselage of my drone is so complex so to do it with hand is not an easy way and in order to maintain aerodynamics shape is better to use CNC mashine but the propbem is the height of my fuselage is greaterthan the thikness of my sheet so i divited my fuselage into 4 equal heigh part of 32mm thick in order to use it in our CNC machine(shopbot) after fixing these part i can move to stabilizaton where i have to add vertical stabilizer and winglet

after fixing these part i can move to stabilizaton where i have to add vertical stabilizer and winglet

time for testing

now every thing is setted in it's way i was waiting for premission for testing my vtol

from that time some parts of drone had damaged like 2 propeller, charging cable for battery, remote antena, and motor mounts so i have to order other propeller form china so that i can make

from that time some parts of drone had damaged like 2 propeller, charging cable for battery, remote antena, and motor mounts so i have to order other propeller form china so that i can make

SLIDE PRESSENTATION

VIDEO PRESSENTATION

OTHER UPDATES

for future update i will post them on my repository because we have a limited time for pushing everything online ,

Download codes used

ACKNOWLEDGMENT

From the deepness of heart i want to express my special thanks and gratitude to the FabAcademy Coordination directed by Prof.Neil Gershenfeld , our supervisor Enrico Bassi who gave us useful guidance throughout this wonderful project for FabAcademy2017 on how to make almost anything. This course also encouraged me to do a lot of research and I learned about many new things. I am very thankful .Marco Mazzufferi who guided me in all about flying thing and for his motivation and inspiration he gave to me, and especially FabLab Rwanda in partenership withPSF ICT chamber