-crop-u10329.jpg?crc=4113827574)

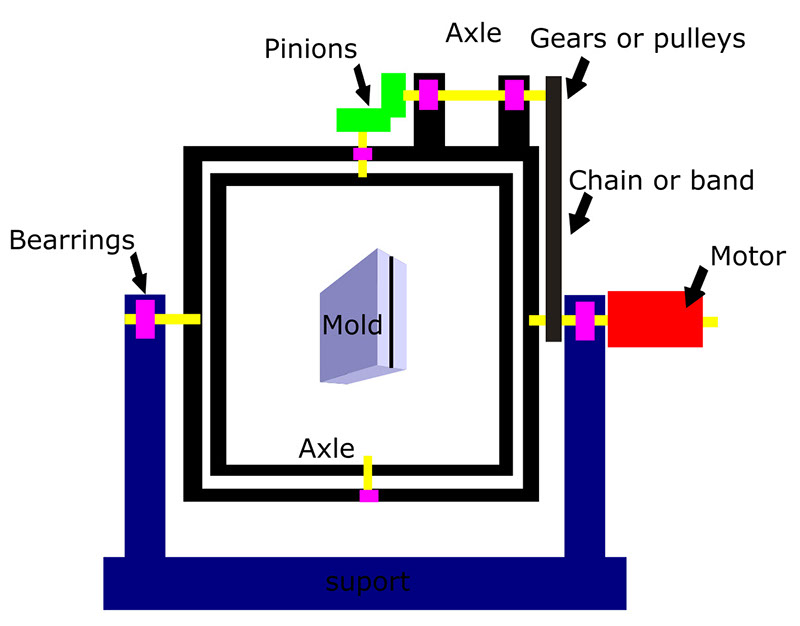

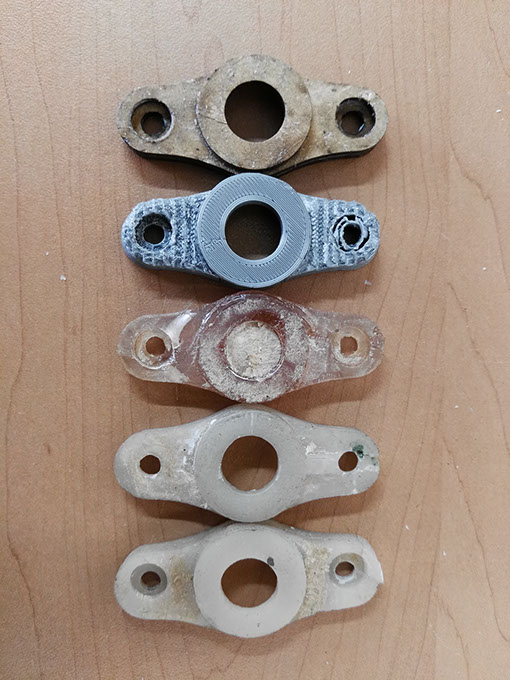

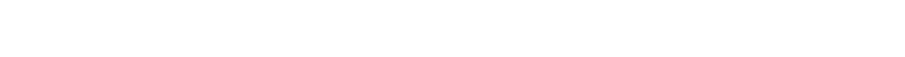

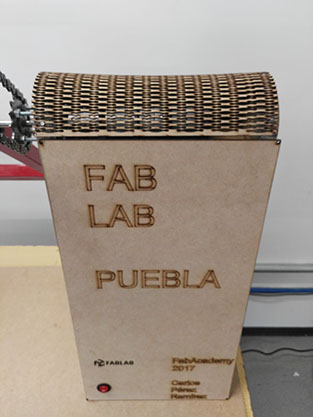

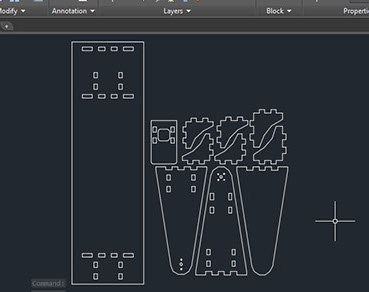

rotational moulding machine by Carlos Pérez Ramírez is licensed under a Creative Commons Reconocimiento-CompartirIgual 4.0 Internacional License.

Creado a partir de la obra en http://www.fabacademy.org/archives/2015/eu/students/silli.saverio/project07.html.

.jpg?crc=472088464)

.jpg?crc=65331275)

-crop-u10125.jpg?crc=329619673)

.jpg?crc=177575742)