Week no.2

- Computer Aided Design

- CAD Toolkit

Assigments : Develop 3D CAD skills and build a toolkit to make a parametric Design of your final project.

Softwares Used :

- PTC Creo Parametrics

- PTC Creo Advanced Framework Extension (AFX)

- Inkscape

- Fusion 360

- Onshape

CAD Toolkit

For this week assignment, we got an extensive list of CAD software and tools. As I went through, just realize that I was familiar with most of 3D Design tools (except for the gamming and video production). My background in Design project and 10 years teaching CAD classes gave me some knowledge in programs like SketchUp, AutoCAD, Inventor, SolidWorks, Catia, NX, Creo, and most recently Fusion 360.

So I decided to push things up by diving into a High-End CAD and exploring modular project and Parametric Design. For the toolkit I choose PTC Creo Parametrics as they just released 4.0 version with augmented reality support, a great PLM, Product configuration (Options Modeler), native support for 3D printing and United Technology (can work natively with a large spectrum of CAD files) for collaborative Design.

Final Project Design

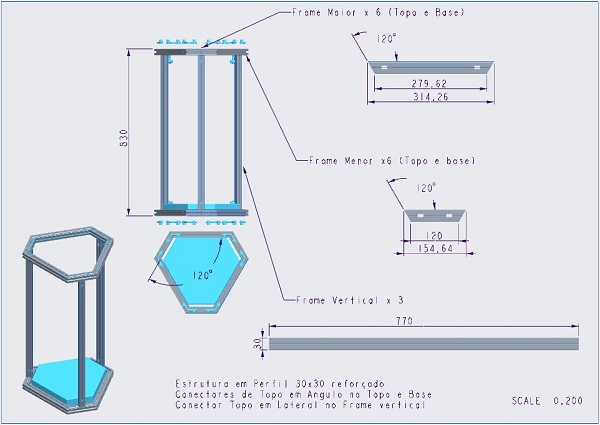

I made the initial 3D model for the 3D printer based on Kossel Delta Printer using structural aluminum profile 40x40mm, simplified version, no assembly and not a parametric model yet. However, I decided to make the first design change, since I don’t like the idea of printed parts on machine structural and Kossel models have printed joints on every corner!

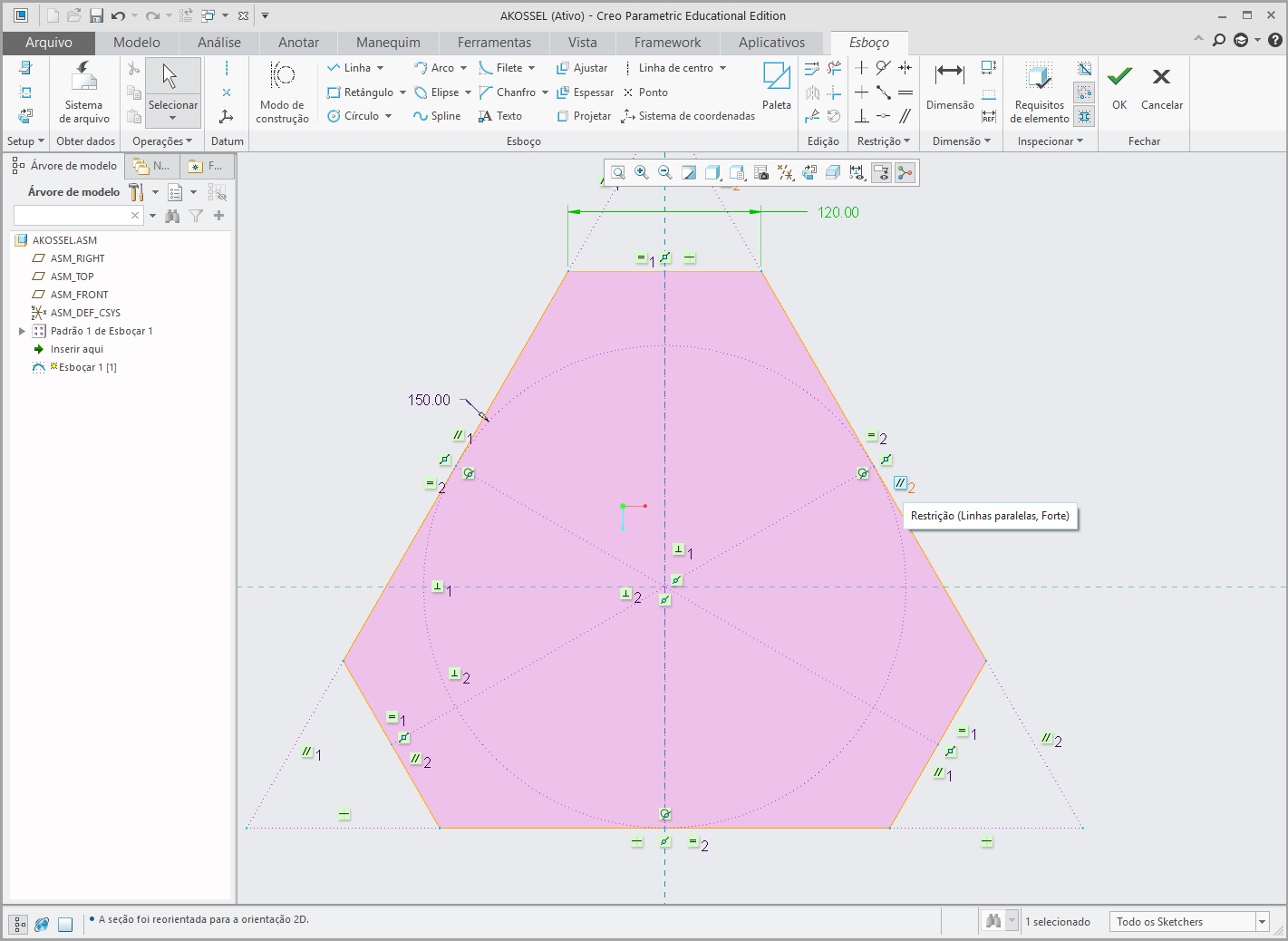

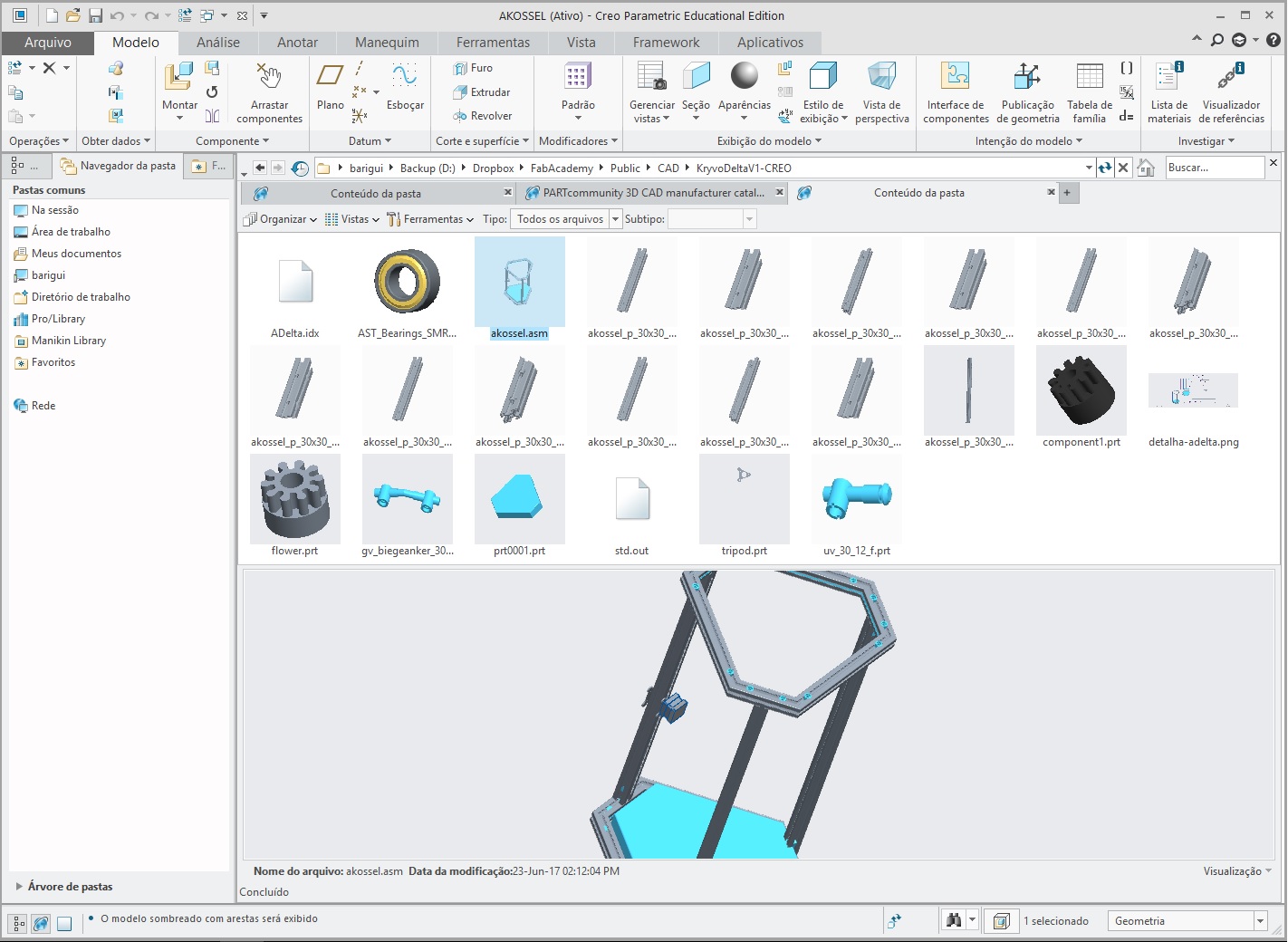

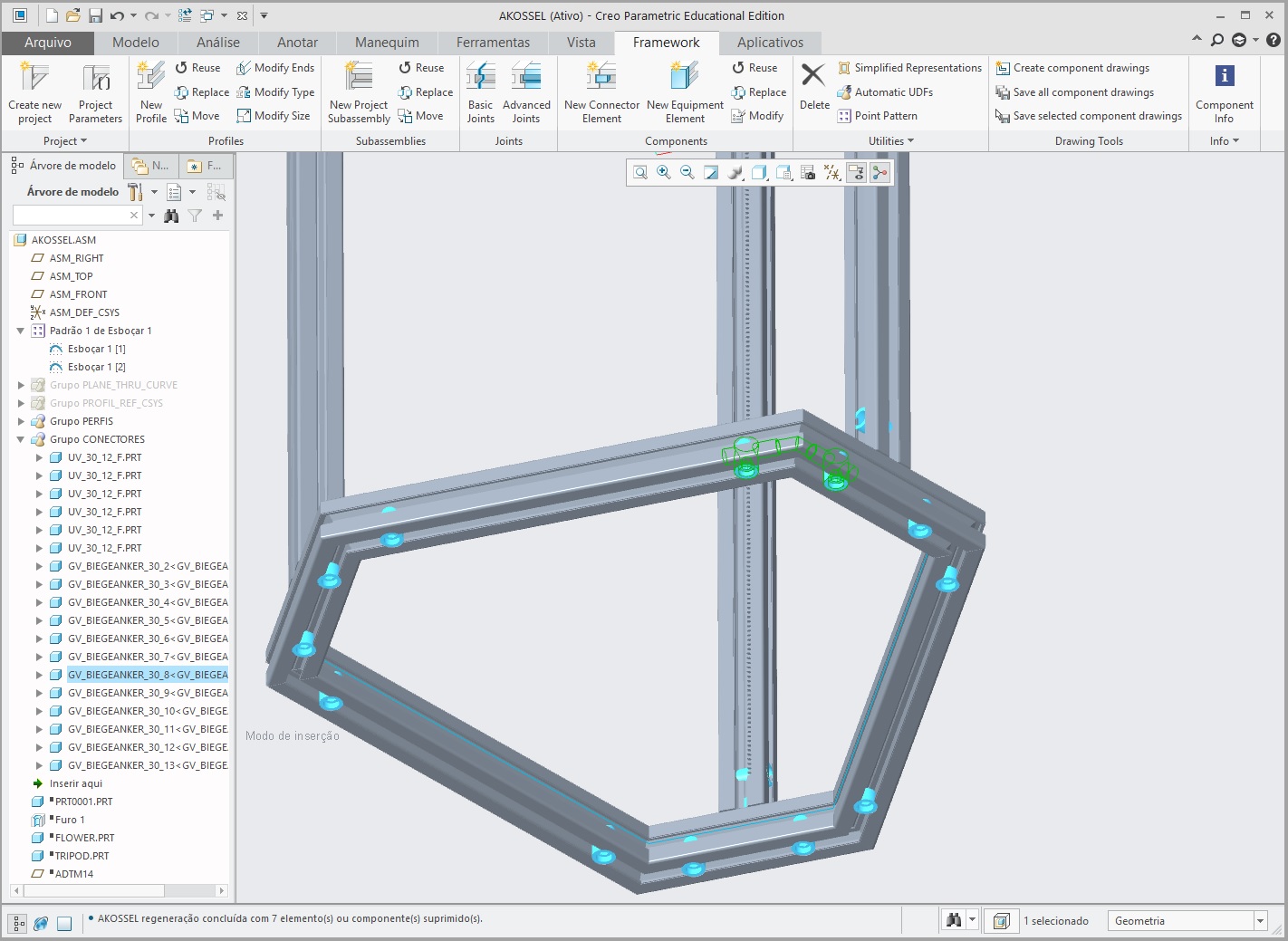

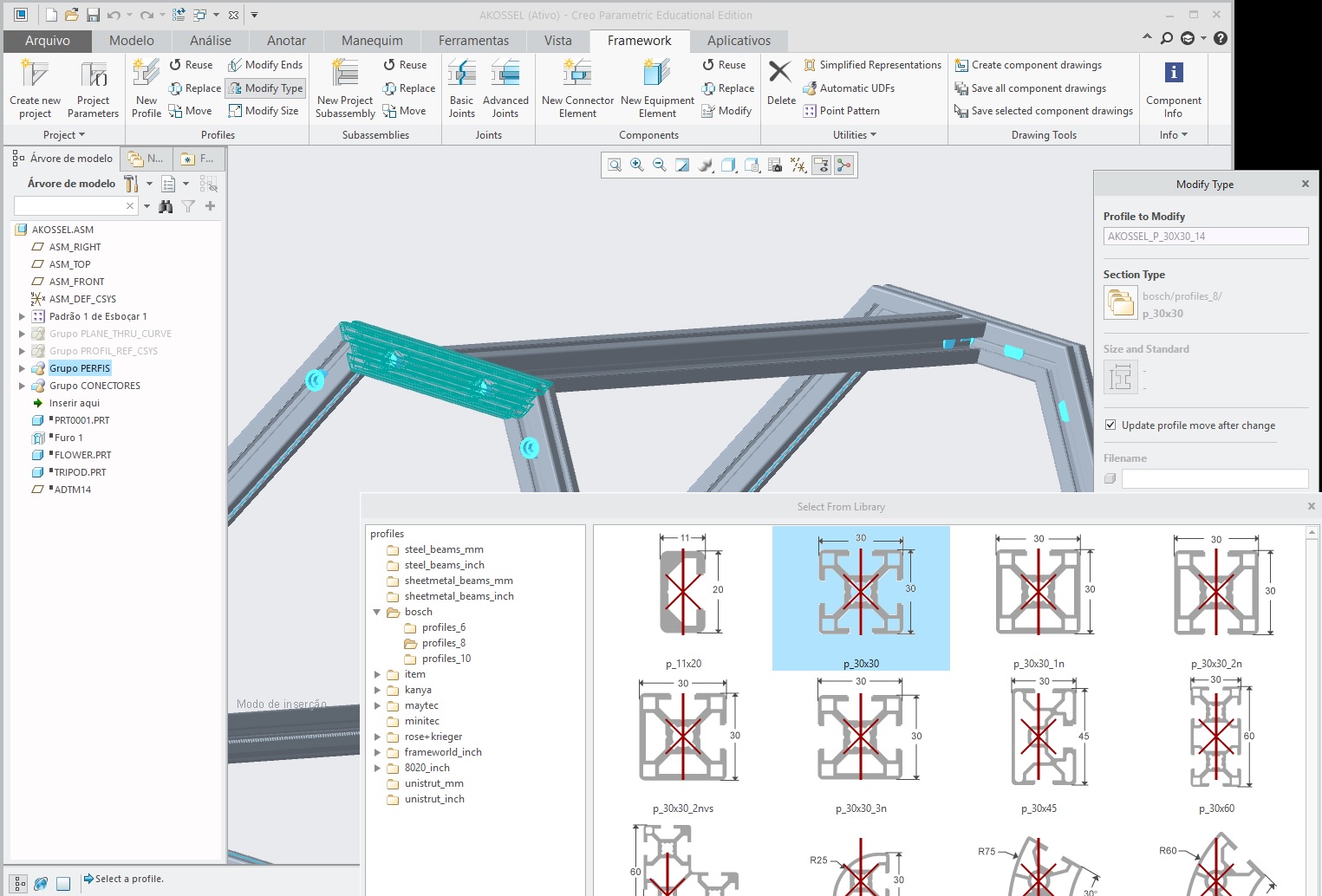

The next version came with parametric modeling, the model was drawn from a wireframe reference sketch and the dimensions were related to the maximum height and diameter of the printing bed. A new hexagonal design provides a larger volume and the possibility enclosure the bed. The resulting model is a full assembly of the structure, to keep it parametrical I used the Advanced Framework Extension (AFX). As a result, if I edit the reference volume sketch and change diameter or height, the assembly will automatically regenerate adjusting the machine proportions to the desired “printing volume”. A very cool feature !!!

Next step, I linked the 3D design to the 2D Drawings for fabrication and the parametric rule follows! As I change dimensions, it replicates thought design and regenerate the 2D Drawings. For future updates, I´ll try Creo Options Modeler to create machine configurations!

Original Project Files: Delta Printer Structure - AFX

OBS: For this part of my website documentation, I used an online model viewer toolkit based on HTML5 and Javascript : JSC3D.

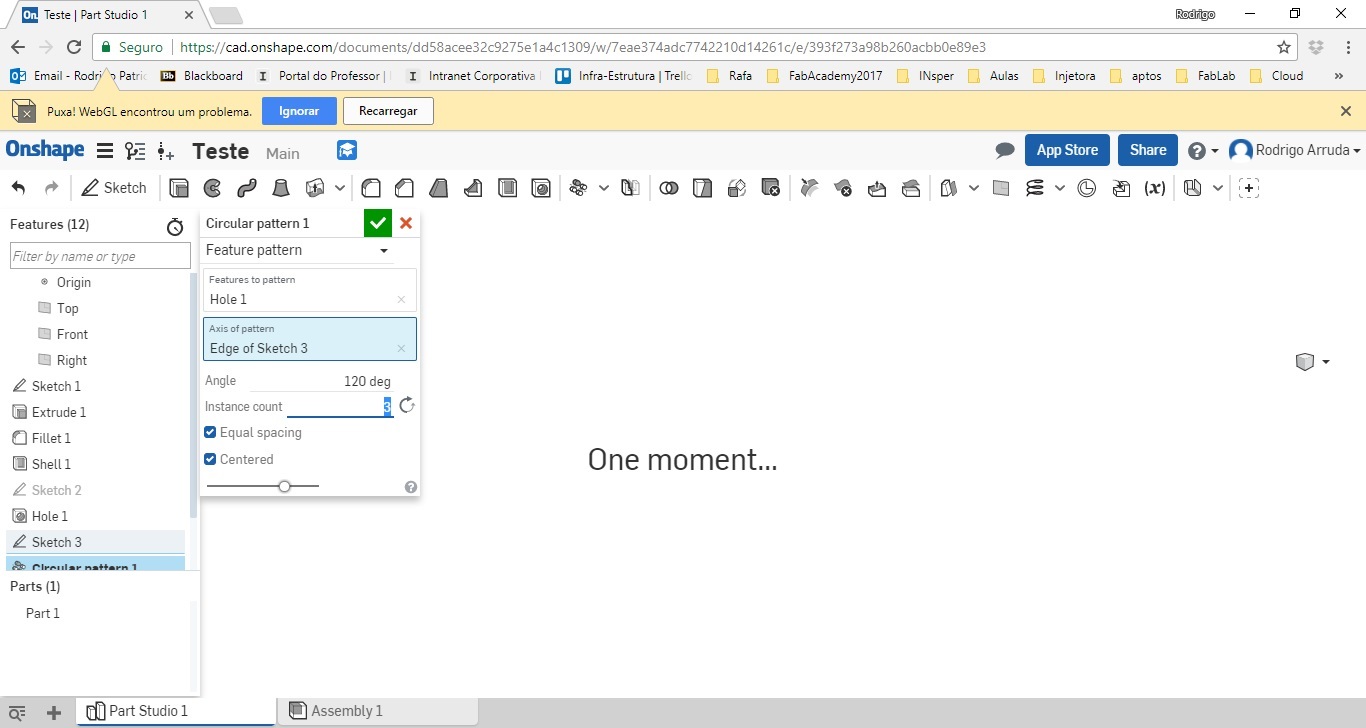

I took some time to test one CAD software that I was particularly curious about : OnShape. The concept of an online CAD that fully works from your browser is fantastic! But from my impressions are that, at this point, it is still in development. The basic Sketch and 3D features are ok, but when I tried to make a circular pattern from a simple Hole the software Freezes with an OpenGL crash warning. Also some limitations to export files Out, but you can share online with people that have already a Onshape account. Still, I was very impressed with the workspace inside the browser..

Assigments Update : Don’t rely on a printed document. Check the information for each assignment in this living document each week.

- Inkscape : Week 3 for the Vinyl Cut

- PTC Creo Parametrics : Parametric Modeling at Week 3.

- PTC Creo Parametrics : some more at Week 5 drawled the 3D printer nozzle, made a Thermal Analysis and Printed afterwards in full color.

- PTC Creo - Flexible Modeling Extension: a little more at Week 12 mould and casting a 3D model.