week 3

Computer-Controlled Cutting

ASSIGNMENTS:

- Identify and explain processes involved in a vinyl cutter machine & design something on this machine

- Design, make and document a parametric press fit construction kit.

vinyl cutting

screen printed t-shirt

weekly work

final project

To explore with vinyl cutting experiment we in FabLab CEPT decided to screen print our own T-Shirts. The workflow was something like:

Design the matter - Import in Cut studio - cut in vinyl sticker - screen print

So the first job was to design my own design that will be printed on the T shirt. For my love for Grasshopper I chose to do something related it.

contact

The design was done in Illustrator. So I exported in AI, EPS and JPEG format. The step was to load roll to the Roland GX-24 so that We get the roll dimension from the machine.

The vinyl roll had to place within the white marks over the rollers to be accepted by the machine.

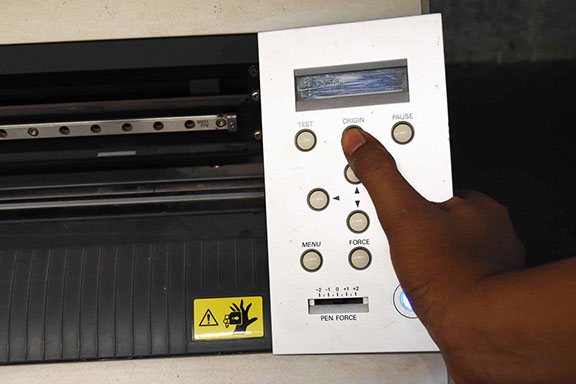

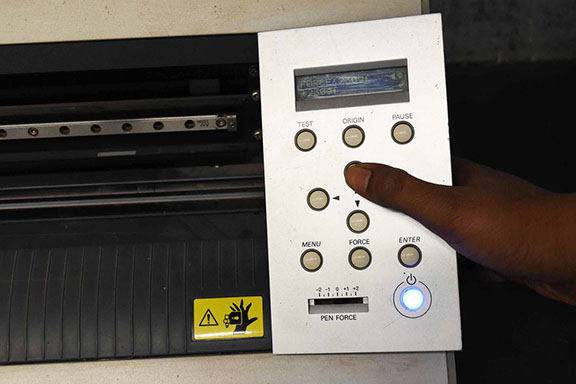

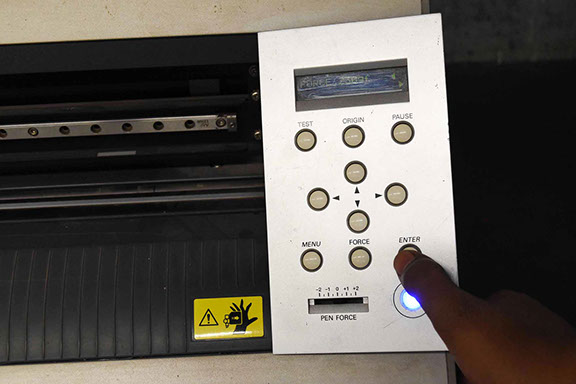

Now, the Origin button had to be hold for 3 seconds to set the origin. Next step was to set the force to perfectly cut the Vinyl. As I have worked with this machine 230 was the value that had to put.

Press the Force button.

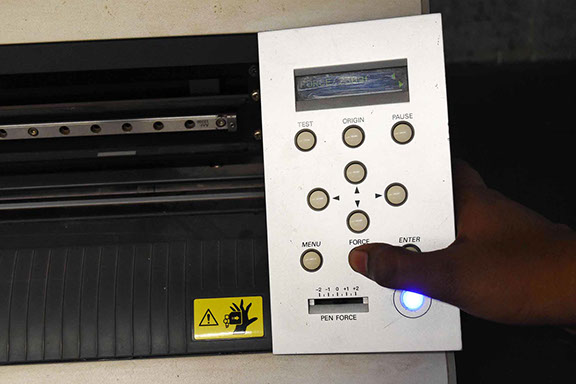

Press the Right button to go to force selection menu.

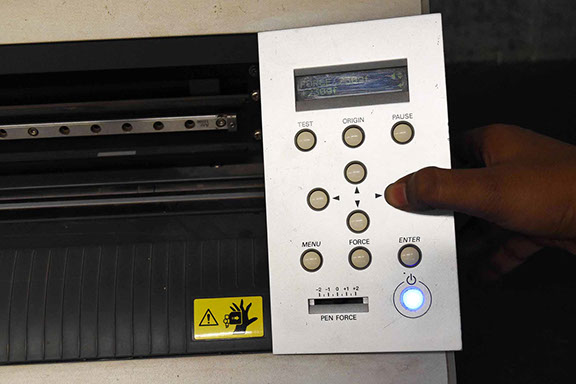

Press the Up button to go to change force Value.

Press the Enter button once the selected for is set. The machine is now all set to cut the selected Vinyl.

Fire up Cut studio.

I used the AI vector file first but got this error. "Unexpected File Format" Possibly the new version of the AI is not supported in the older CutStudio.

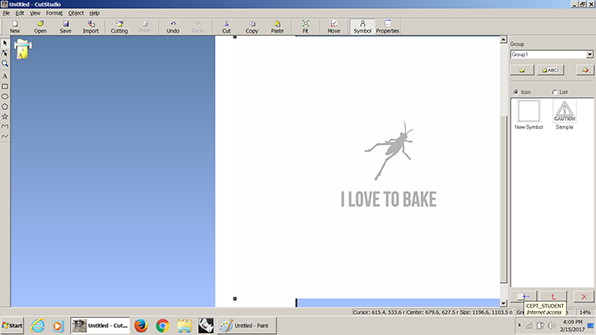

Later I tried to import th JPEG and trace the outline but it seems that there is a sizing issue with the Raster format.

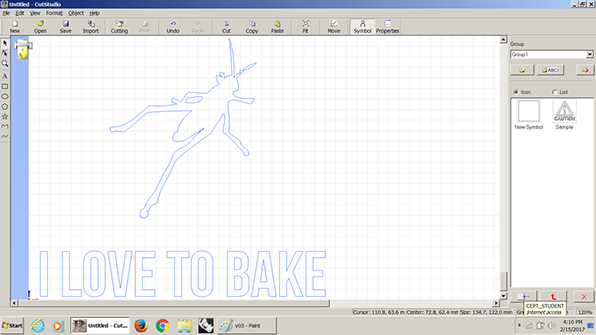

The import was successful with EPS as it came as vector path and in proper size.

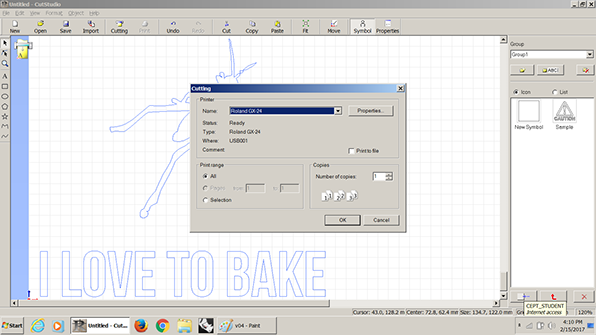

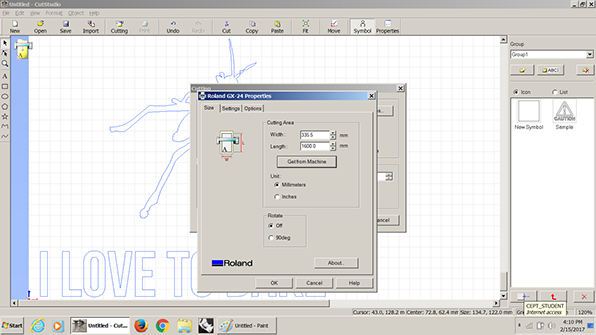

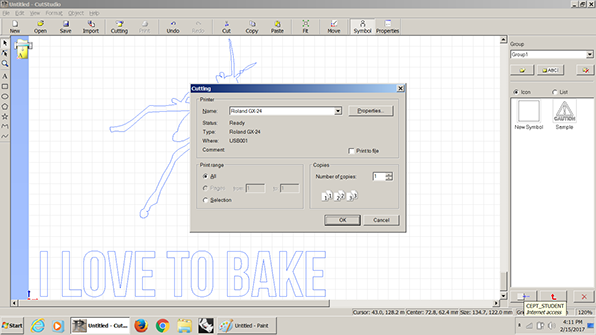

Go to Cutting and select the properties of the cutter.

The dimension is imported from the machine.

The printer is now all set to cut the vinyl

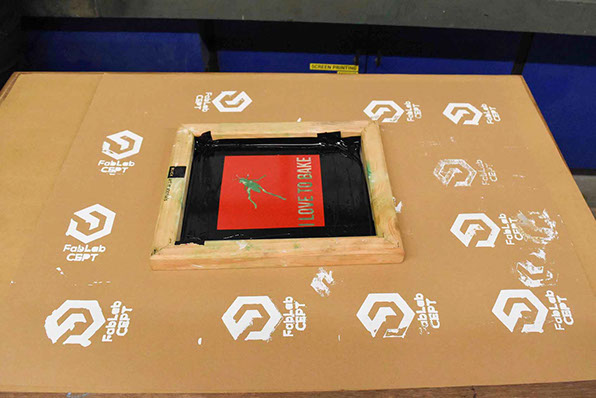

Once the printer produces the cut vinyl sheet, it was mounted onto the screen and another process of printing started from there.

First the letters are taken out. A special concentraion is needed for O, A B as they have a blank space within them,whose stencil is to be retained.

The grasshopper logo is taken out.

The rest is taped to prevent any spilled color.

A test was done on the paper to check any leakage or defect in the stencil. Next step is to print on the T-Shrit.

The frame and color is put on the T shirt.

Color is applied with squeezer,in cross direction.

The frame is safely removed.

The maker with the T shirt.

[ laser cut group work ]

Press fit

construction kit

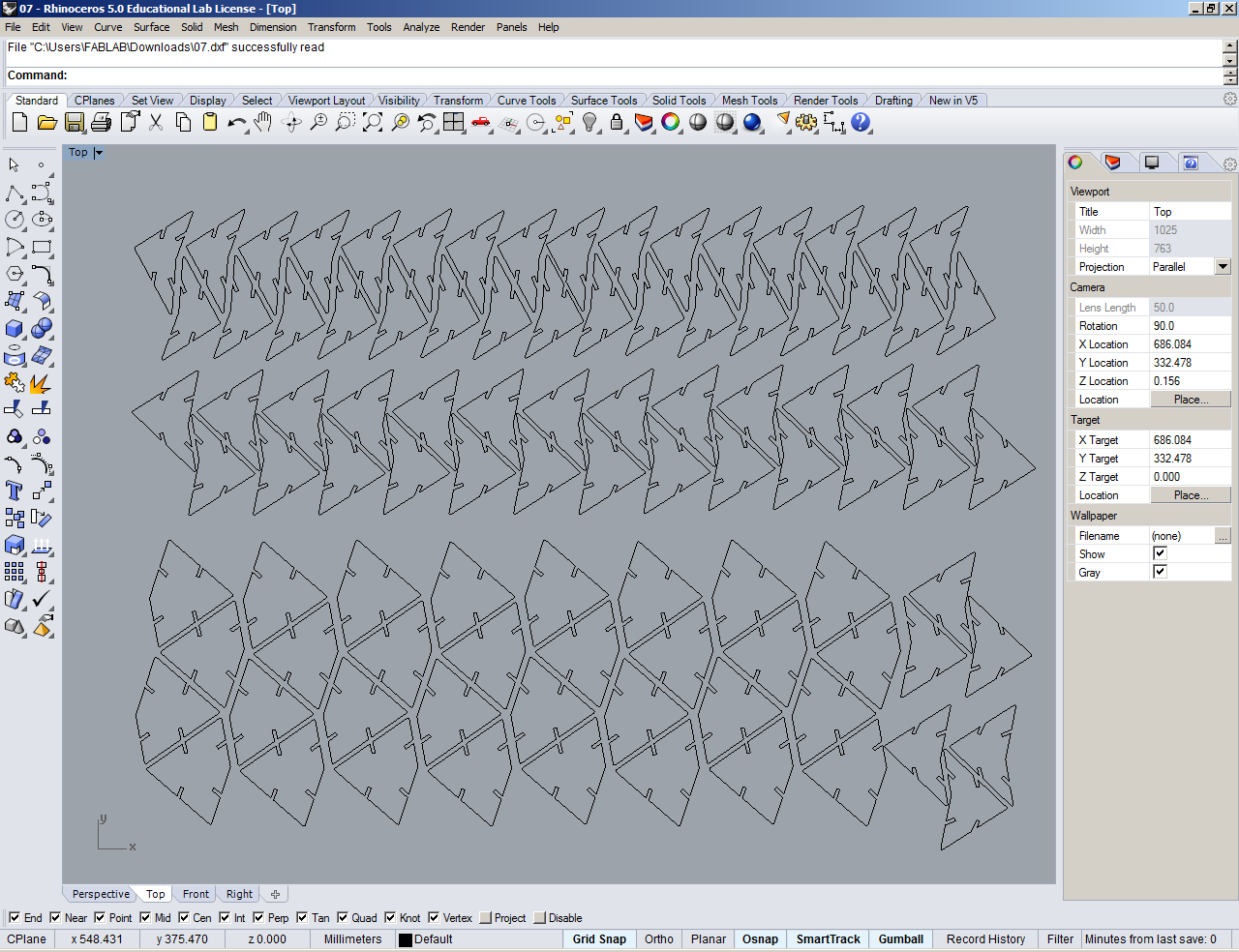

I am a lover of Suprematist paintings and works of deconstructivist architecture. I wanted to make my press-fit construction kit of similar appearance and of an installation kind. While looking for reference I saw project BLOOM by Alisa Andrasek & Jose Sanchez which I liked a lot and somehow it helped my parametric. I scripted the kit in Grasshopper and tested basic aggregation using Anemone.

I have used 3mm MDF and 40W CO2 LASER (Epilogue) to fabricate the system.

The system is designed in the grasshopper, giving the user a wide control over the pieces. The following animation can demonstrate the control on the individual piece and eventually on the whole structure.

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

<

>

Design stages

So there are 13 parameter user can control. 12 for aesthetics and one parameter will vary machine to machine "LASER Burn" to get the perfect friction the withing the pieces.

Total 3 type of module was chosen the complete the sculpture.

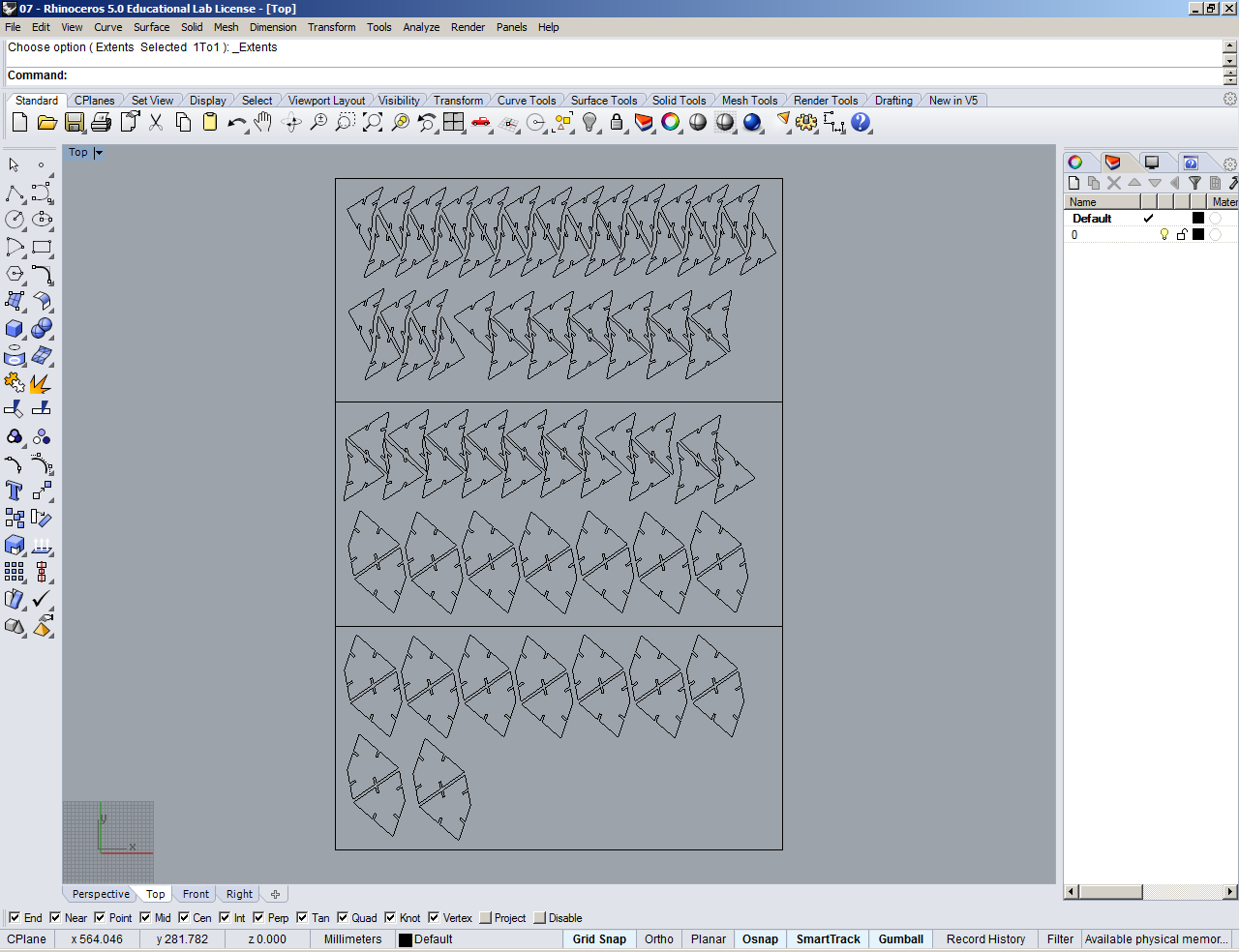

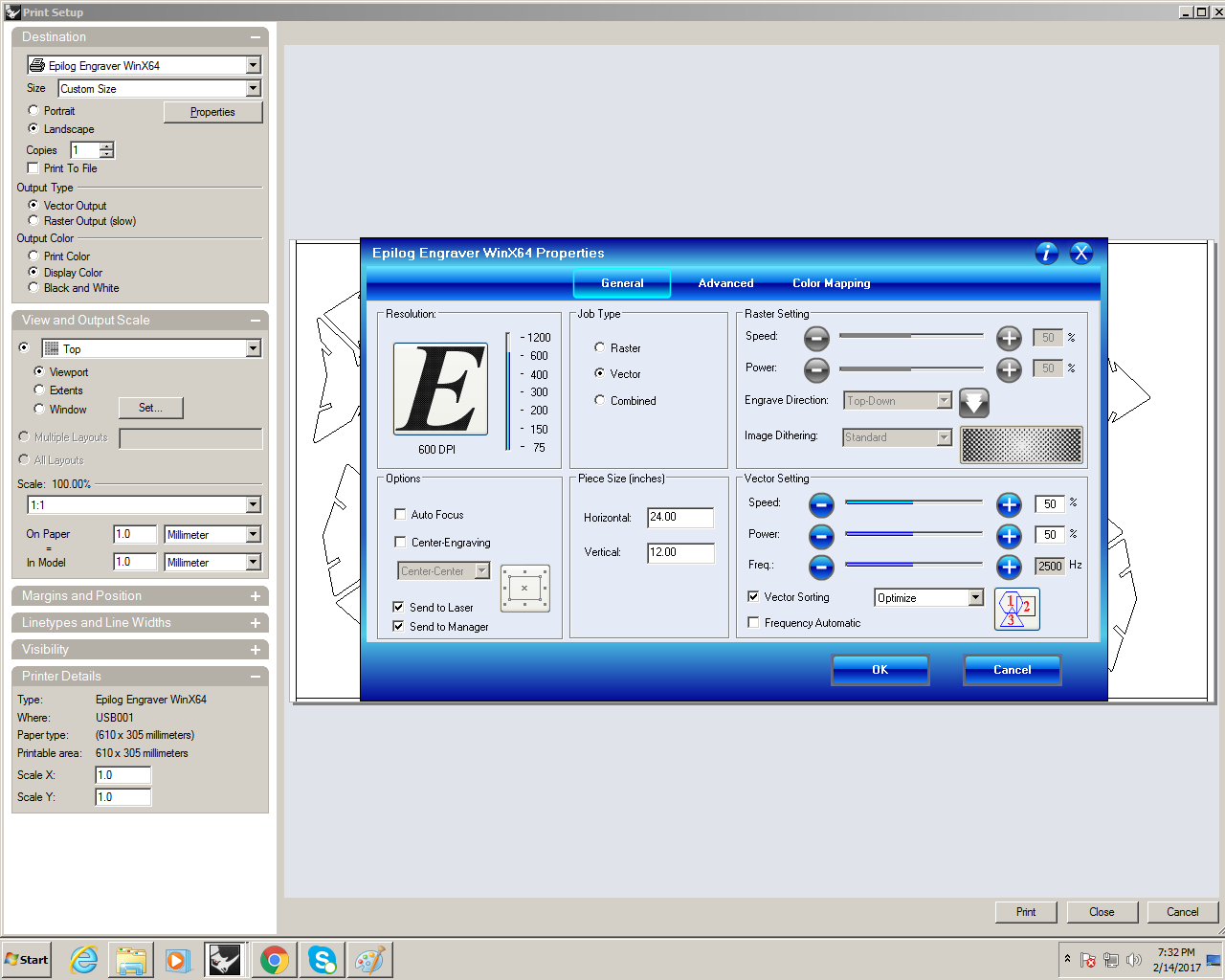

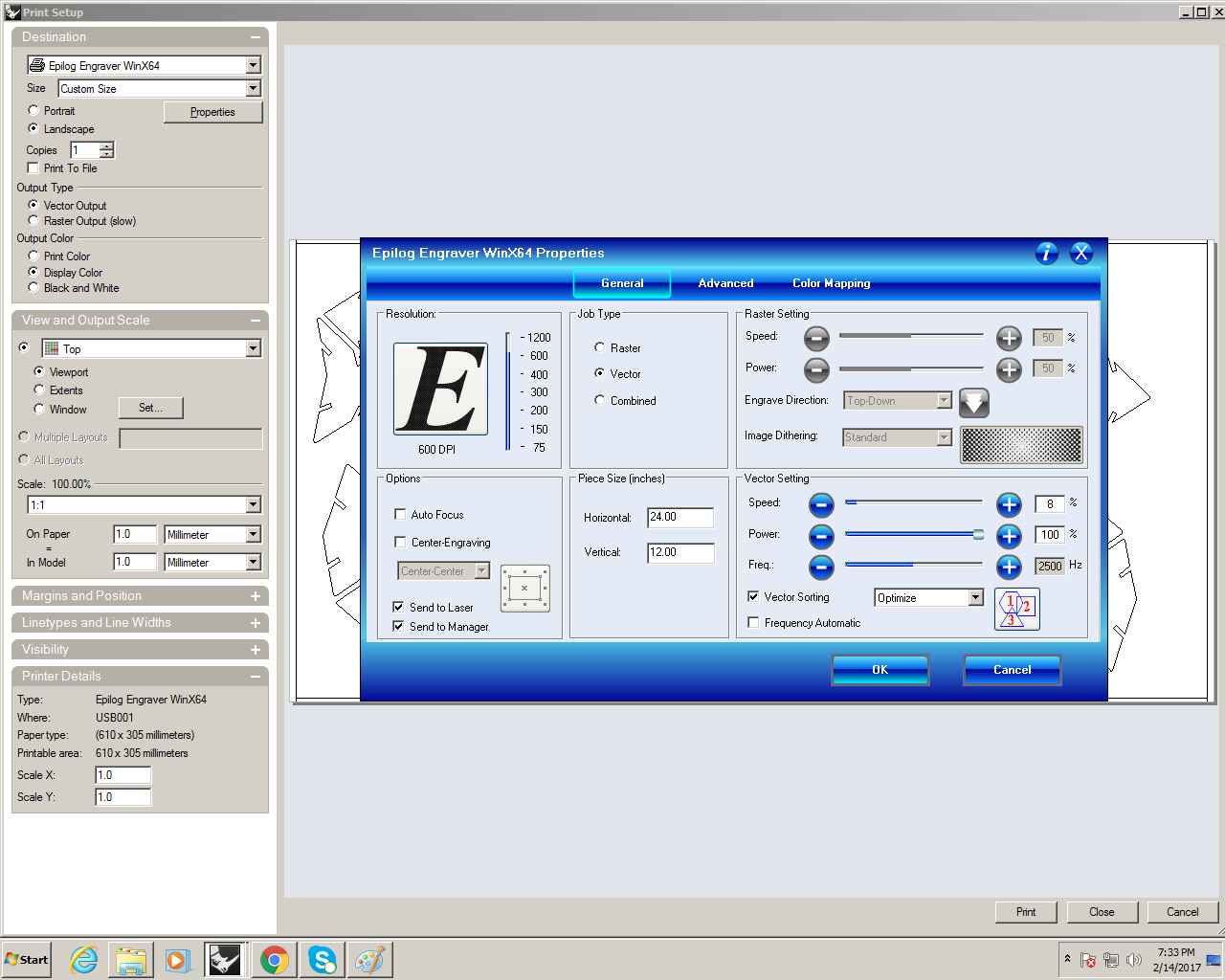

In our Lab we use an Epilogue Mini and Rhinoceros to process all the cut.

All the pieces to be cut were place in the file and arranged next according to our bed size, i.e. 24" X 12".

Nested pieces arranged in sheet.

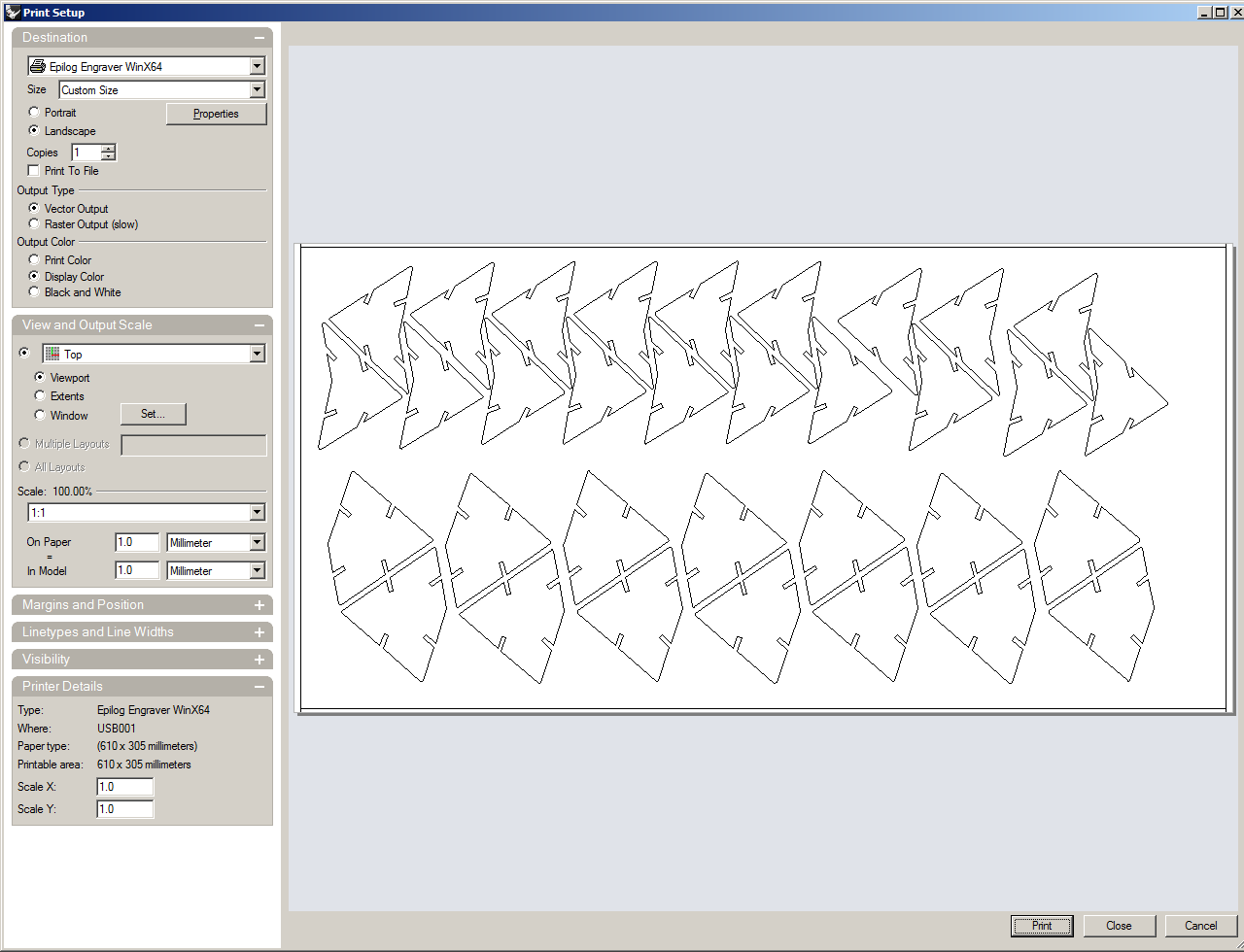

Print command and selecting vector output for the files.

Selecting only Vector as there are no rastering job in the file.

The setting for the cutting a 3 MB MDF was Speed: 6mm/ S and power at 100%.

Files for this week's assignment could be accesed from here.

go to WEEK 4 >>

Avishek Das | 2017 | FabLab CEPT