_Week09_MECHANICAL DESIGN

_Introduction

During the week of Mechanical Design we start to understand (or trying) how the physical part (gears, material, nuts, bolts,etc) makes a machine work correctly is conjugated with its materials and all the parts that constitute it, as part of the week the exercise will be to create our own machine starting with the principles of the mechanical design making it be automated the next week.

_Background

Mechanical Design or Machine Design is one of the important branches of engineering design, during designing various calculations are performed considering desired speeds and loads and finally the gear of particular material and specific dimensions that can take all loads and that can be manufactured at least possible cost giving optimum performance is designed.

_Week Assignments

_Workflow /Step by Step

See our group website to know the workflow of the assignment.

_Individual contribution.

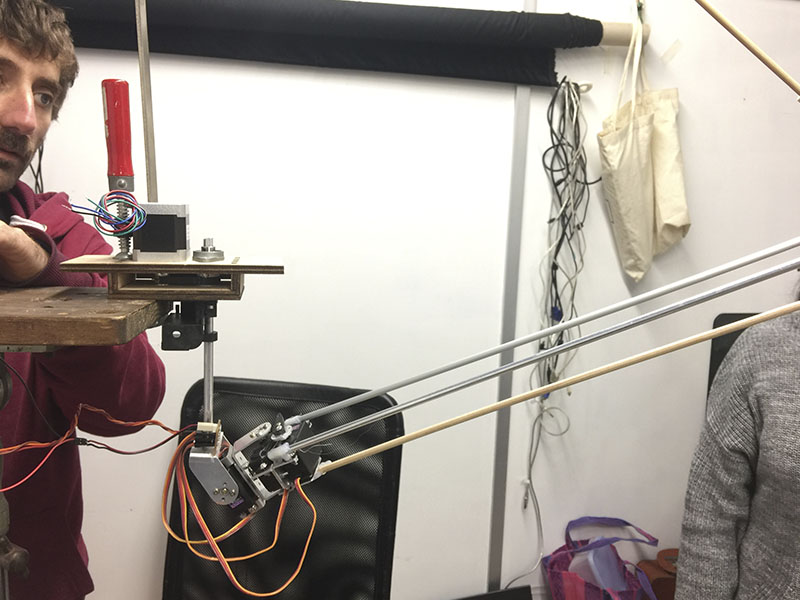

Our scope this week was to build a basic robotic arm that in the first instance helps us to understand the movement of the axes and the functioning of the system by building a primitive model. First we organize all the work seeing other small and large projects of how it has been solved this type of systems, either in the mechanical part working manually and beginning to think its development in a future automation.

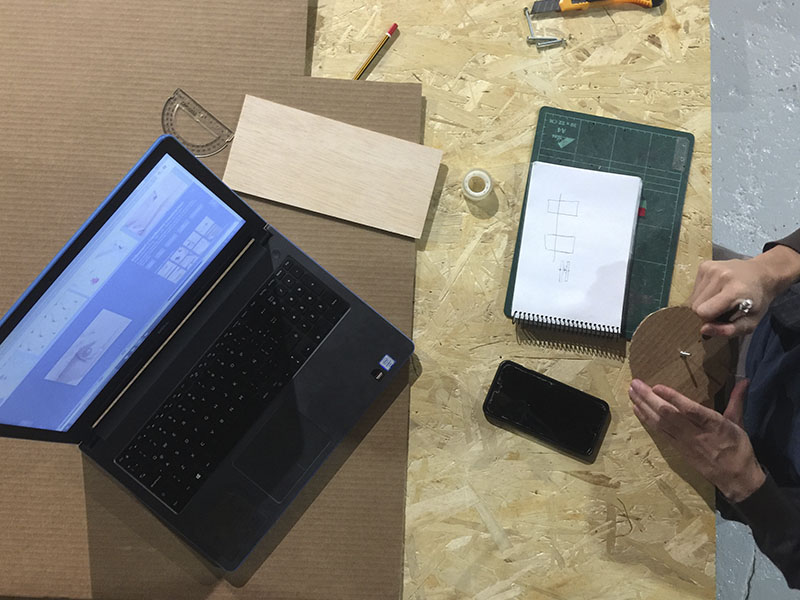

We used Trello to order the work for the development of the project with each of the things we needed, all the planning, design and development of the prototype was monitored from this platform.

We begin by seeing robotic arms in internet that have already been developed to understand first how the mechanical part works with all its parts, dimensions and joints. We visit our friend Citlali Hernández who had developed many robotic arms from scratch using Arduino and servos for a project.

Then we started to develop our first prototype cardboard to be able to create with our own hands the movement of the axes, weight and physics of each part of the robotic arm as we had seen in our searches, created just with basic nuts, bolts and cardboard of 3mm. This would work like a basic human arm: shoulder, elbow, wrist and hand.

The four axes runs like this:

_Analyse and solve technical problems.

After build the first model, we see the importance of how tight should be the joints to let the arm move correctly so we spend so much time trying to figure it out how to work good.

_Opportunities for improvements in the design.

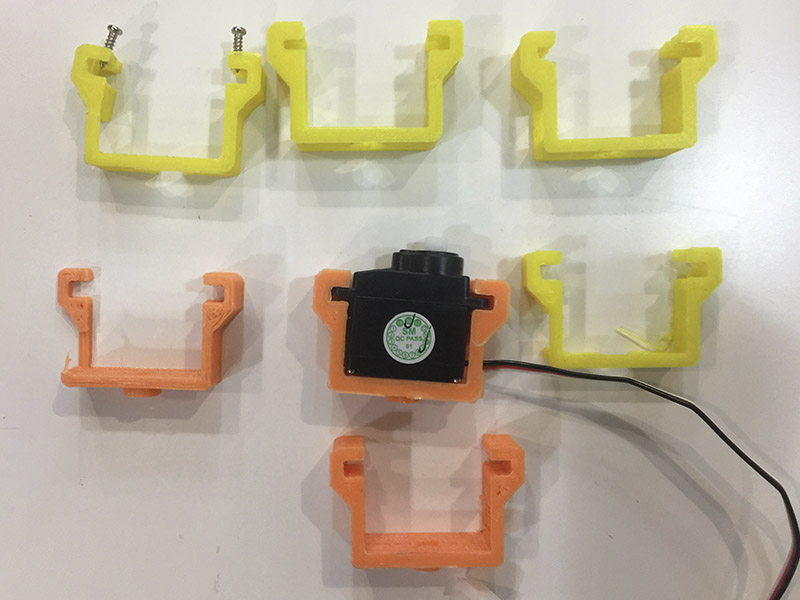

Now that we knew how to move the axes and all the mechanical thing we decided to start thinking in a modular arm that in order that one module have a microservo and works like one axis of the arm and then improve the movement and can be attached to another servo and have how many axes we want. This idea was modeled in Rhino and afterwards 3Dprinted to see how it works.

_FILES