_Week14_COMPOSITES

_Introduction

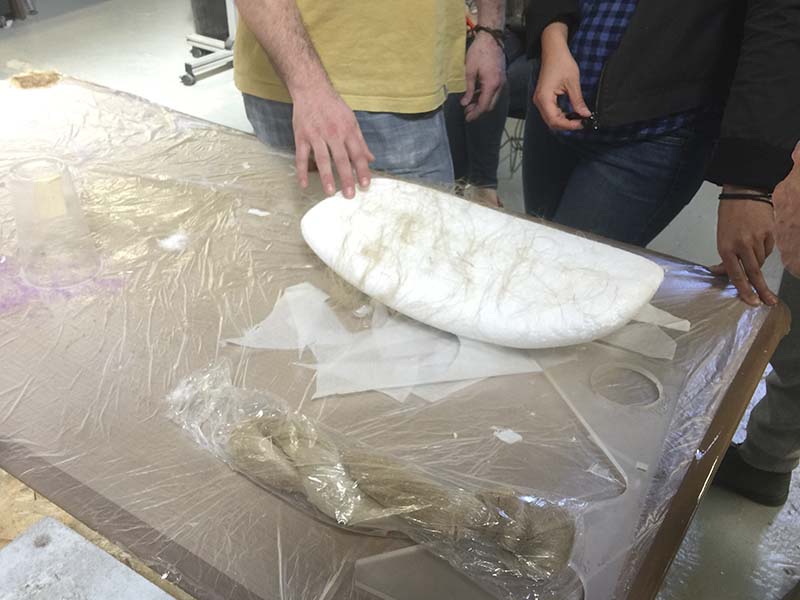

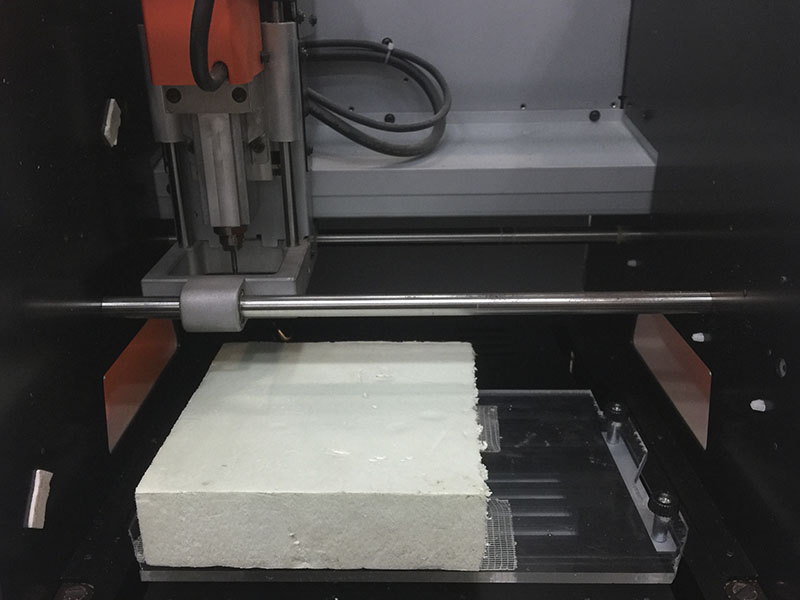

HANDS ON AGAIN! In this week we work similiar like molding and casting doing a mold from 3D milling and working with composites getting the form that we design putting layers of the material that we want and epoxy resins.

_Background

A Composite material (also called a composition material or shortened to composite, which is the common name) is a material made from two or more constituent materials with significantly different physical or chemical properties that, when combined, produce a material with characteristics different from the individual components. The individual components remain separate and distinct within the finished structure.

Useful links:

_Week Assignments

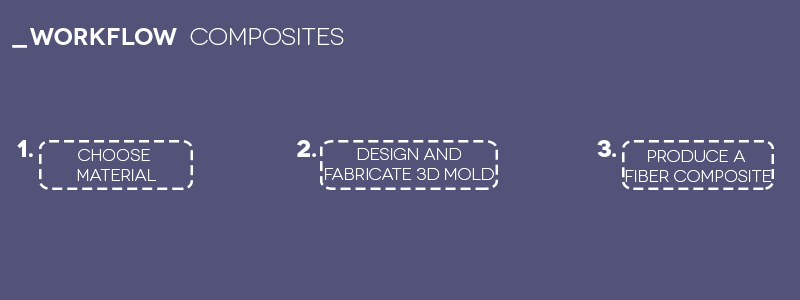

_Workflow /Step by Step

_Choose material.

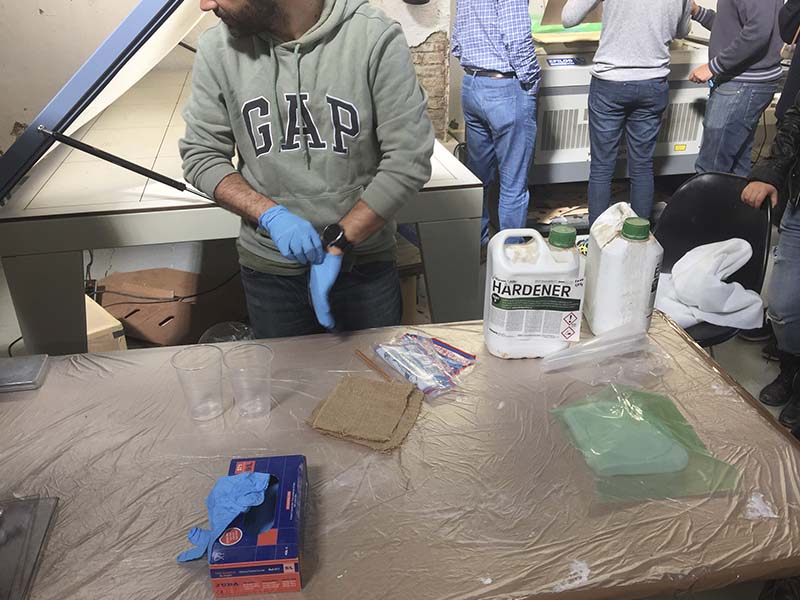

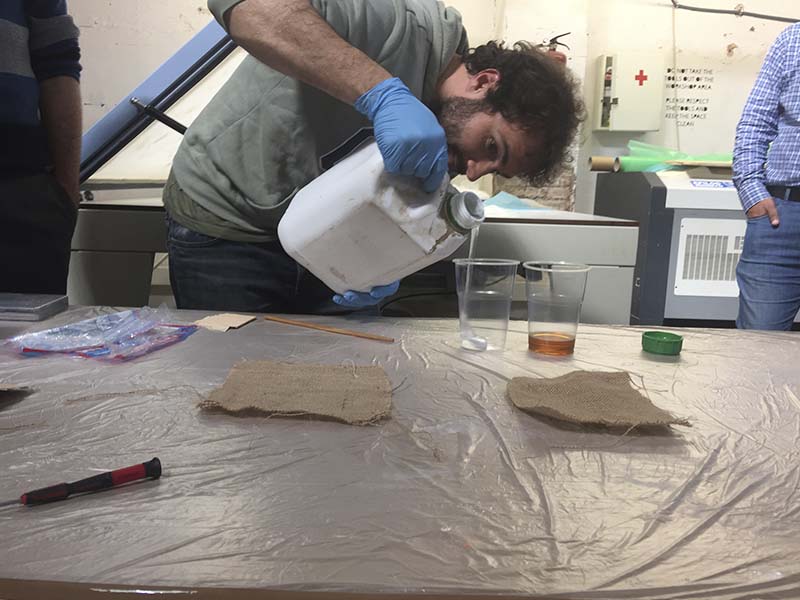

We got in the fablab some workshops for understanding the composites:

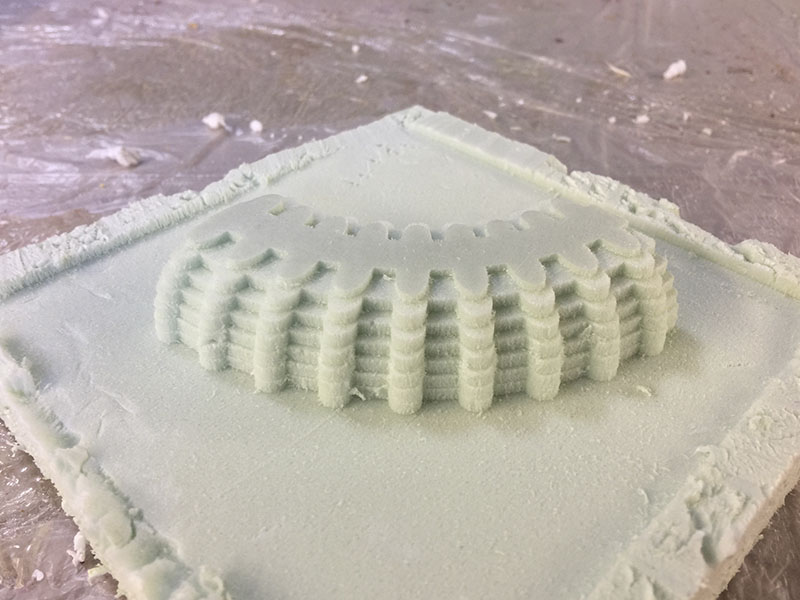

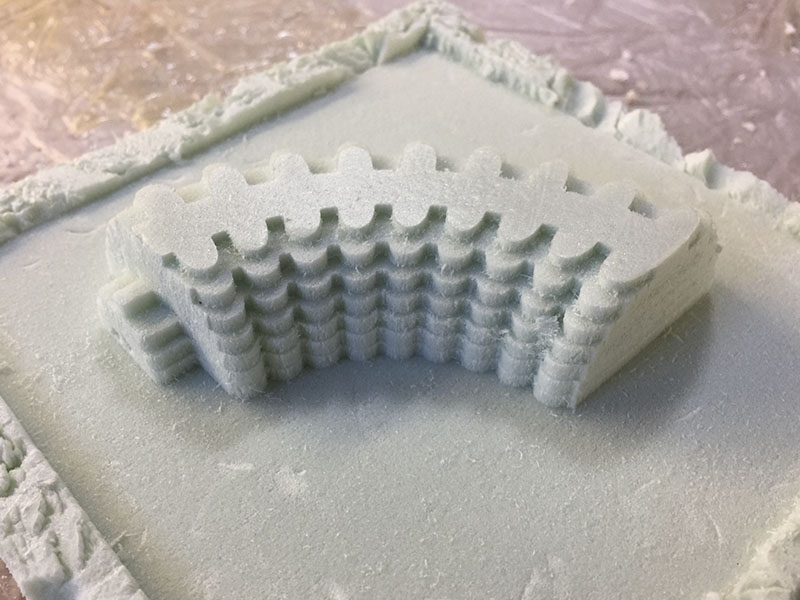

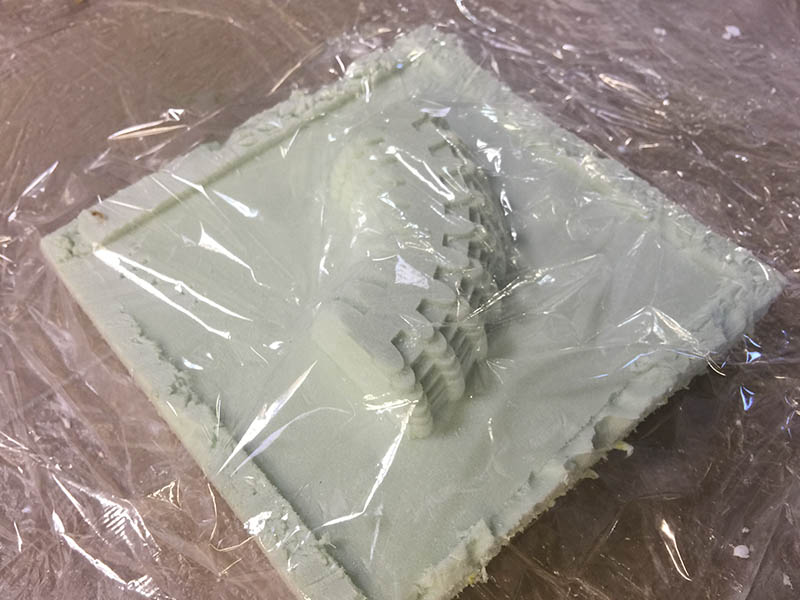

_Design and fabricate 3D mold.

After understanding the logic of the composites system and what materials I worked on, I decided to use these ones:

I didnt do the finishing this time because i wanted to see how the definition at first time its gonna work.

I didnt do the finishing this time because i wanted to see how the definition at first time its gonna work.

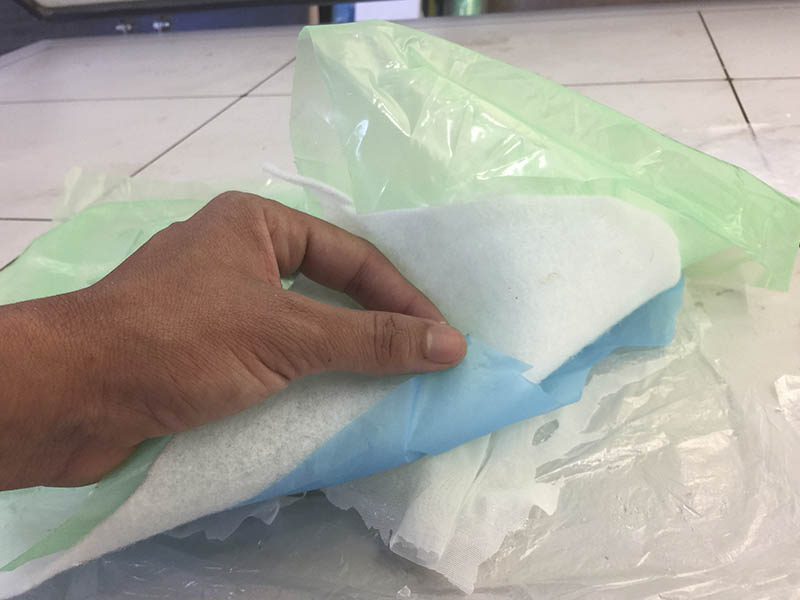

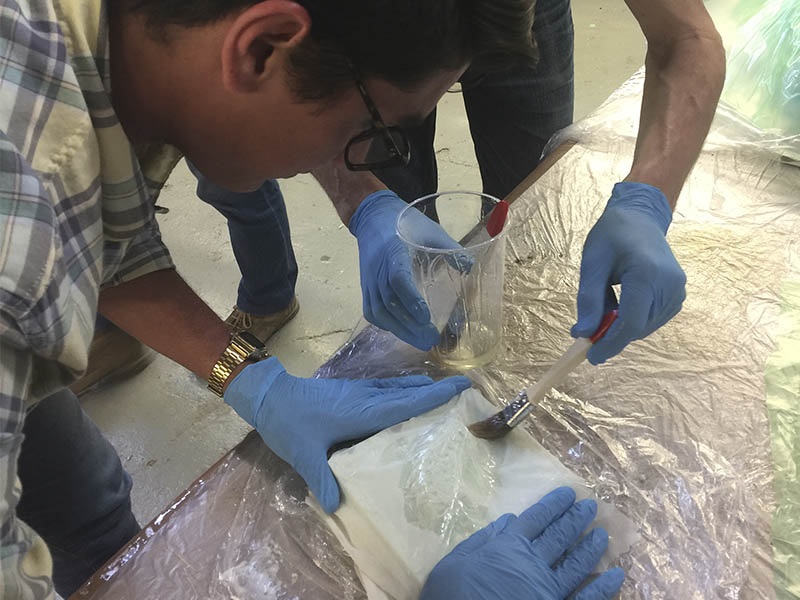

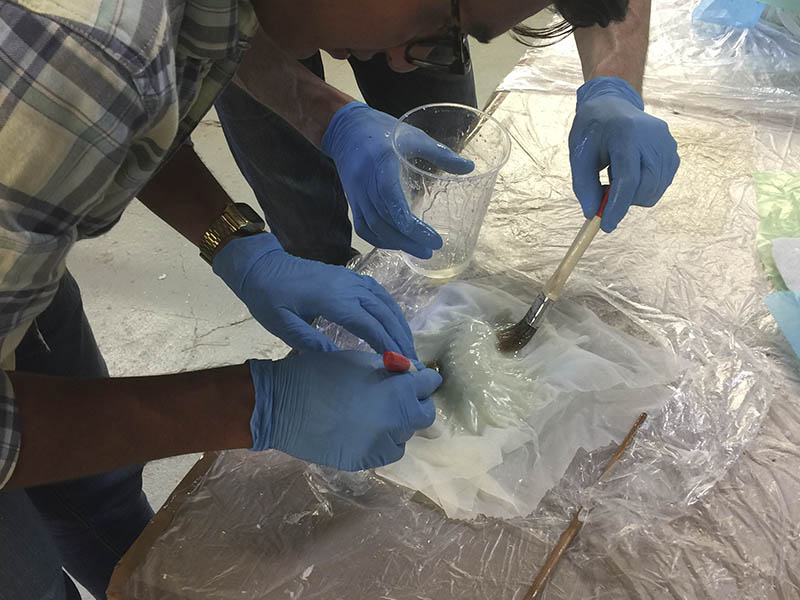

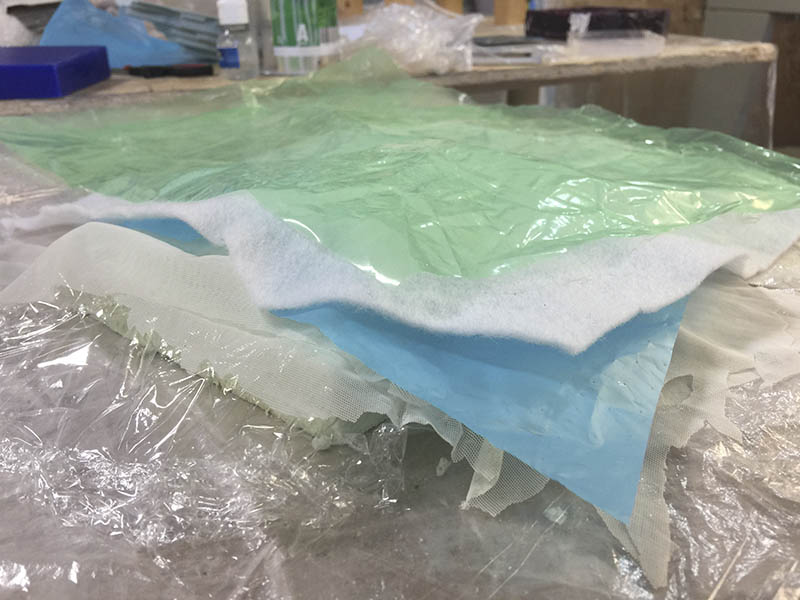

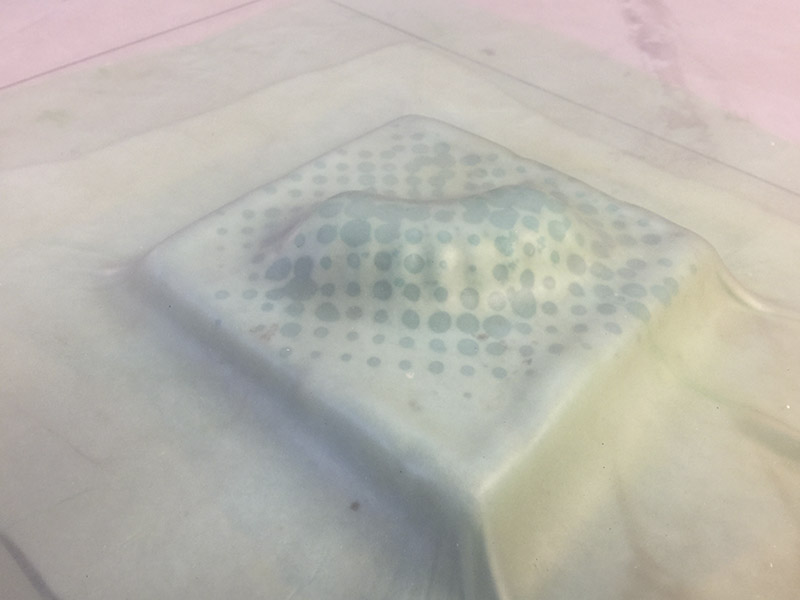

_Produce a fiber composite.

The process to create the fiber composite was having 6 layers on the top and 2 in down in order to create the composite material with the epoxy resin.

DOWN (to protect the vacuum)

UP

_Final review.

Things to correct after this exercise:

_FILES

All the files for this assignment are available to download here