3D Scanning & Printing

This week Tasks

- A real world object to be 3D scanned (Optionally to print it out)

- An Object (Non subtractive) be 3D printed

Group assignment

link for group assignmen

I learn following things from group assignment

- Calibrating the flament diameter

- Calibrating the Calibrating the Z height and first layer

- Calibrating the extrusion multiplier

I found 3D printing and scanning so amaizing and was assigned with task very attarctive to my interest, I started to scan with following ways taking different objects.

- MDX 20 (Pneumatic scanning)

- 3D Scanning using Kinetic

- 3D printing

To play with MDX 20 I started searching for an interesting object to be scanned and I got following object

Though this object was some how large in surface area so I decided to scan this partially to come up with results quickly so it started scan as shown below in the images.

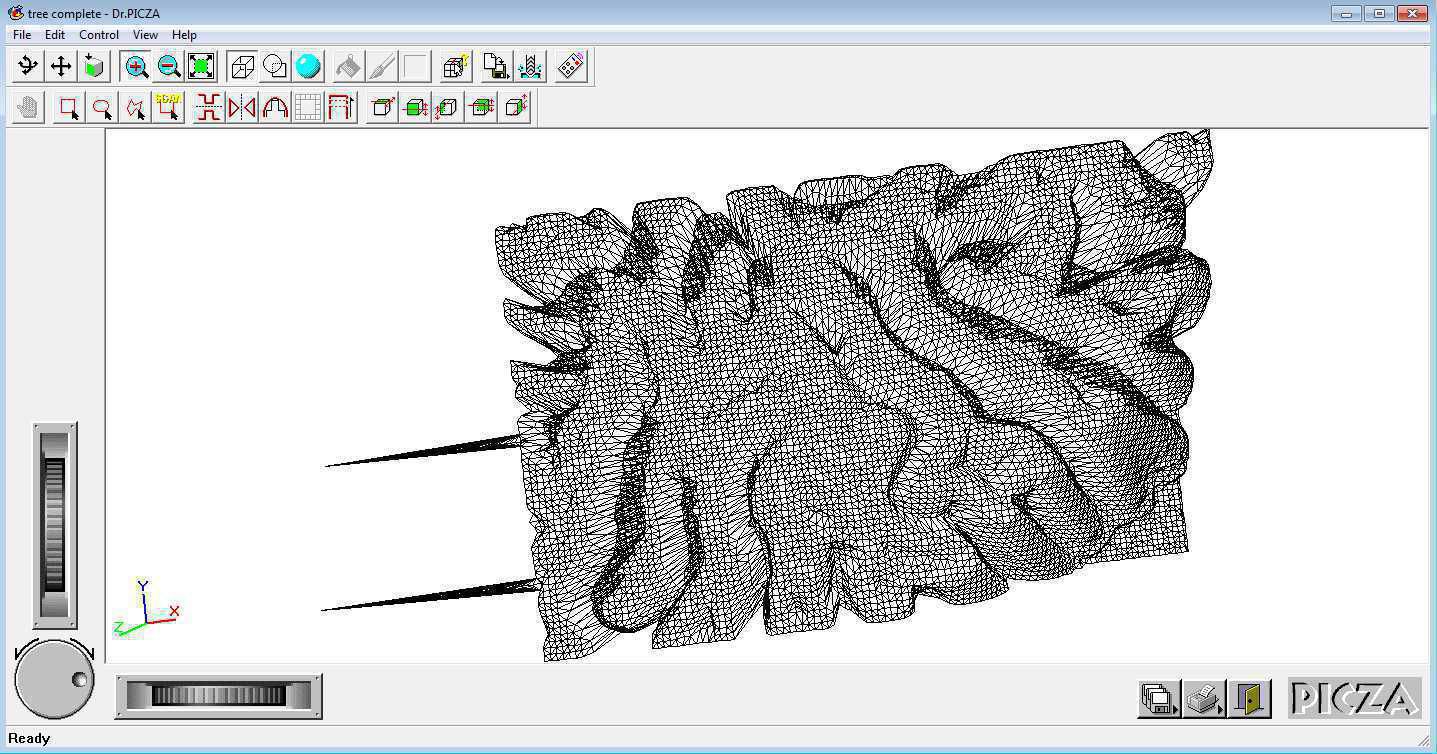

but ultimately the selected part to be scanned took almost 3 and half hour resulted in following scanned view.

An other snapshot of scanning outcome for the abject with fine tunning dimensional values.

Playing with Kinetics was quite interesting and very easy I scanned my self and got the following 3D model. hence I got to know that through this scanning process we can scan not only small objects but large objects too.

After the Scanning through kinetic I generate the stl file and import it into CURA and tried to tunned some parameters to get the 3D model ready for the printing.

So far 3D printing is concerned I was assigned in the lab to design or develop an onbject which must be non subtractive after a little thought over assigned task I came up with the idea of designing a tube which is hollow inside and folllowing a curved path. the availability of tools and software in lab was quite enough I felt very comfortable with this. I followed some tutorials and some online videos to get a little grip over commands of this tool to finalize the design following image is showing my progressive phase while working over this tool.

The object I designed is non subtractive due its bend tube shape and by the completion of the design I generated its stl file and imported that into CURA to tunned some parameters like selection of the printer and extent of the in fills and checking of net density thought layer command following image is showing the design imported in CURA.

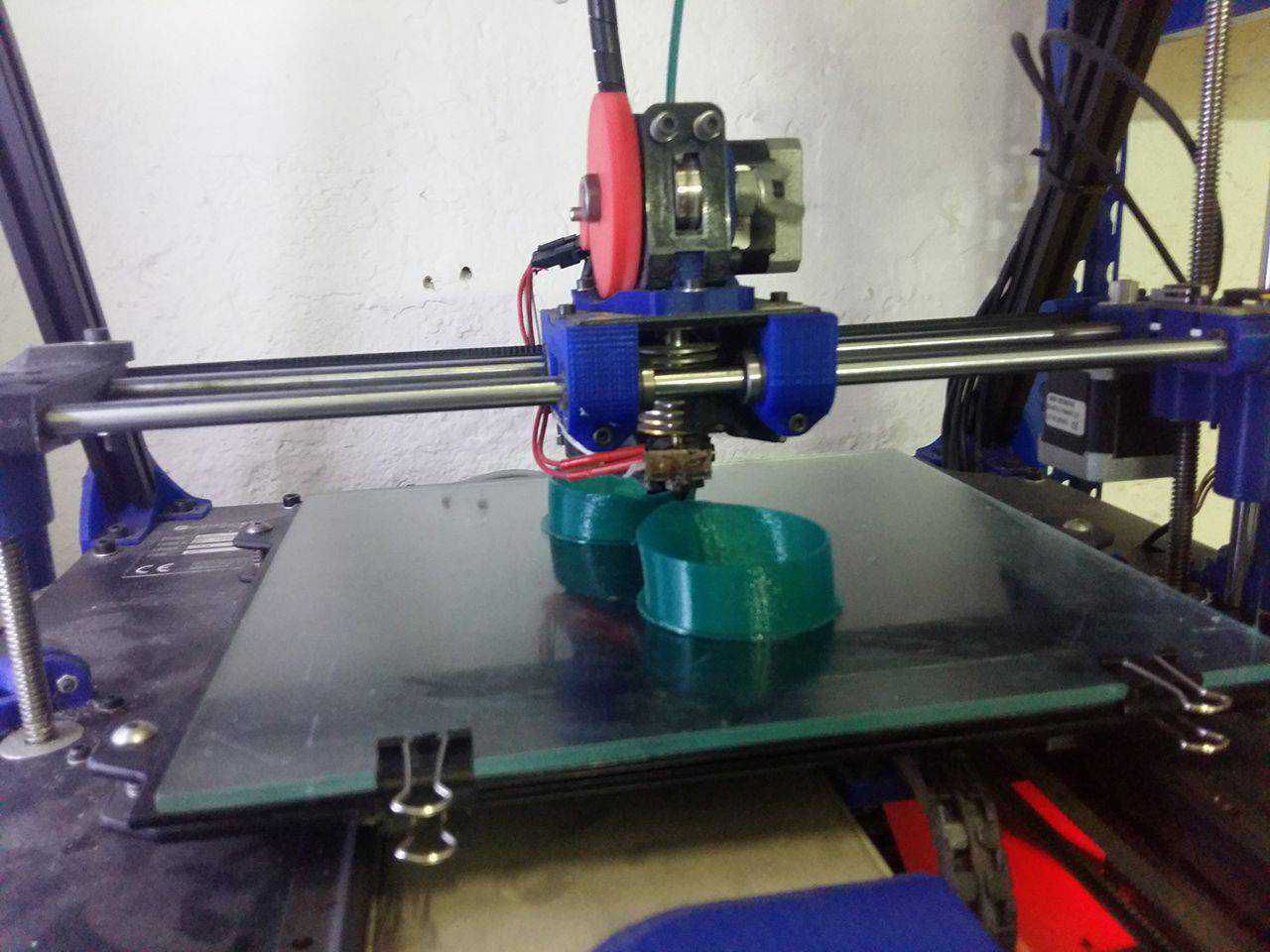

During the printing process I came up with my design some issues and printer stops the printing my design after some estimated time and I got my design printed as shown in following image.

I tried to resolve issues related to the printing of model and actually the design was dense and layers were overlapping while printing I again imported my design in rhieno and checked the issues and applied some techniques to over come this and then imported the design again in cura and tunned the parameters and processed the printing.

Finally after resolving the issues in the model by reviewing the design parameters and setting up with fine tunning I got my design ready for the final printing which is shown in image below.

My Observations

During this whole week I learned how to Scan the objects in 3D through different ways it was observed that some scanning techniques are limited to scan small objects and were also time consuming like Pnemutic MDX 20 and Dr PICZA was the softawre utility to tunned the parameteres and observing the estimated scanning time. Mean while Scanning the objects through Kinetics was quite interested because of its easy way of scanning I was just taking the frames of images by rotating th camera like scanner X-BOX Kinetic and it took less time as compared to other ways of scanning, I also came to know that I can scan large images too very quickly. Generating STL files of scanned images to get ready for the printing was quite easy done by importing the designs in Rhieno or Blender software. As for as 3d printing is concerned I observed defferent printers their properties and way of printing like PRUSA i3, Ultimaker and etc.

Download important files here