Final Project

Experiments

Artificial Muscles

First Nitinol Experiment

I wanted to observe and get a feel of Nitinol's behavior, so I ordered some on this website. which seems to be spanish, so more local.

I received it three days after :

my Nitinol order

So I want to make a circular spring shape that the Nitinol would go back to. For this I need to "bake" it in shape.

This is called annealing.

I find metal rods lying around that is just what I need :

Metal Rods

I use some belt wheel system also lying around to make a shape support for my nitinol :

Bending the metal rod

I then get the shape I want the Nitinol to coil around :

The shape used to coil the Nitinol

The baked Nitinol

In order to bake it I used this oven at 600°C for few minutes :

The Oven used to bake the Nitinol

Alright, now that I baked or set the shape of my Nitinol, to test it, we need to modify its shape and then heat it up to see if, indeed, it returns to the shape we baked.

I first tried to throw it into boiling water and it didn't work. That was very disappointing.

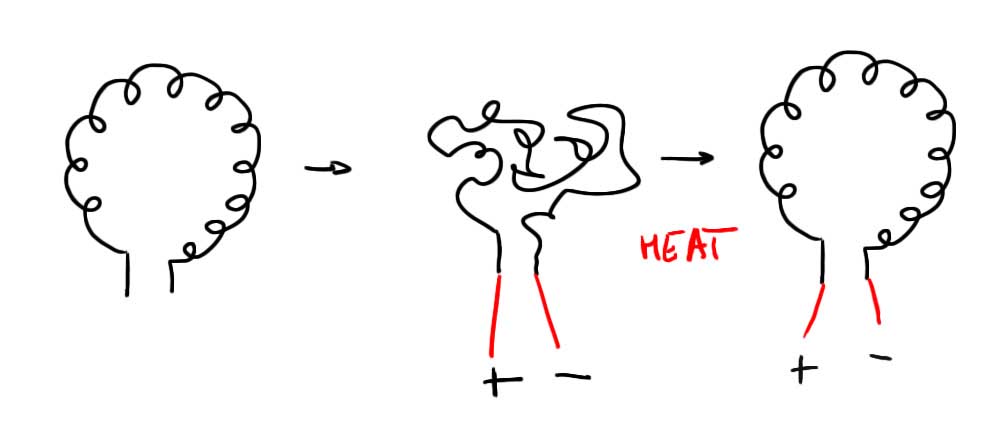

Then I decided to try the electrical method of heating by applying a direct current through it :

The electrical method of heating

Before I do that I need to know the voltage I need to apply to it.

Specs say that for this thickness of Nitinol (0.01 inch or 0.25 mm), the resistance is 0.02 Ohms per mm and that we should have a 1A current going through.

The length of my nitinol on this experiment is 45 cm

so we need to apply about 9V, I'll do 6 just to be sure I don't over heat my nitinol wire.

Nitinol experiment

Second Nitinol Experiment

I want to check how two different Nitinol springs can work together.

So I anneal two straight springs and make them alternatively contract to pull each other.

It's also a great way to test the driver board :

Legend

***