Design a 3D mold, machine it, and cast parts from it

Design a 3D mold

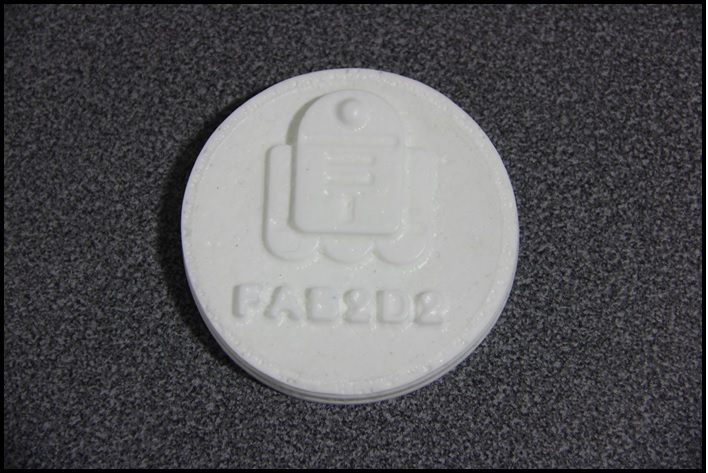

I designed the logo of my final project "FAB2D2" in SolidWorks. You can download original file here and STL file here.

Machine

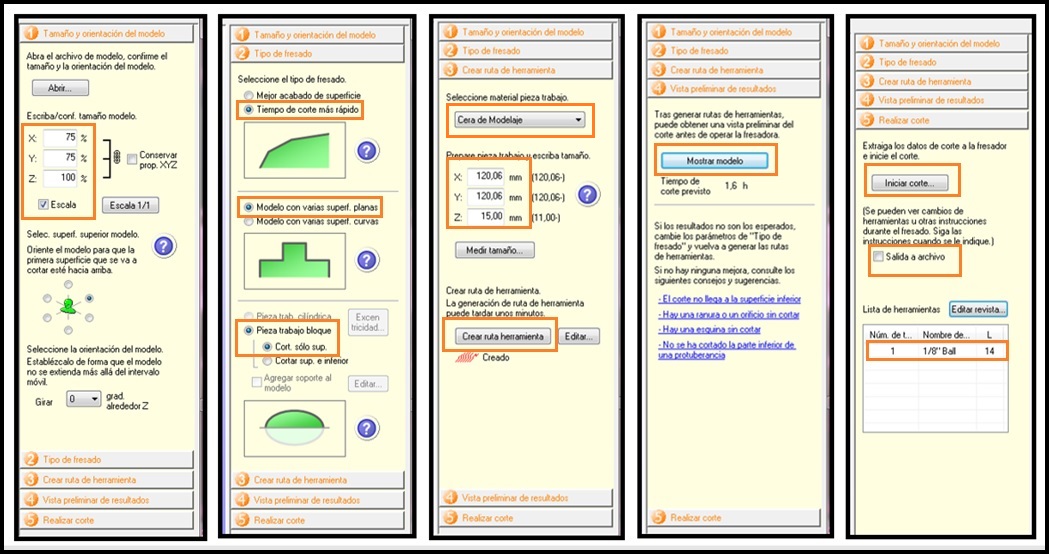

For machining I used Rolad MDX-540 and SRP Player software.

In next pictures I show the configuration to generate wax rough cut file and wax finish cut file.

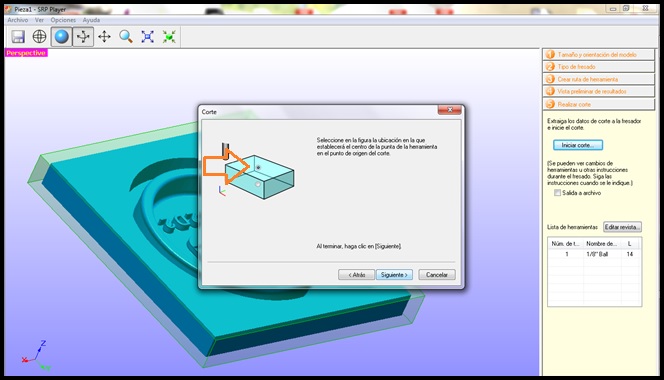

Now, it is time to machining the wax.

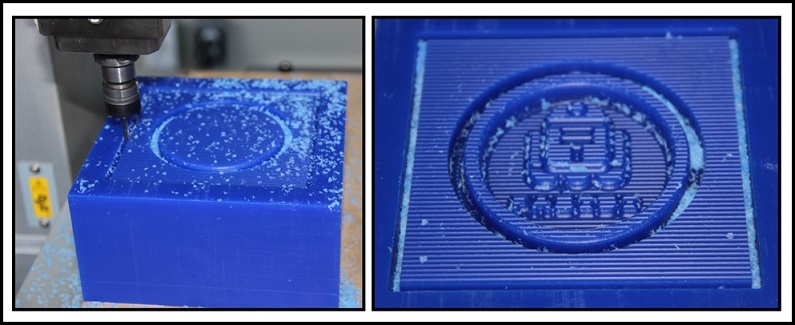

Final result of machining.

Casting

First, I fill the wax mold with water to measure the amount of material employed for casting.

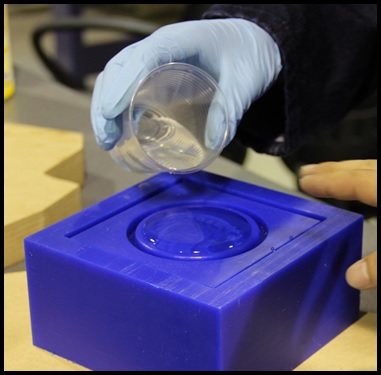

Next I mixed Silicone Rubber Compound OOMOO part A and B, put it in wax mold and after two hours I obtained the negative mold.

You can see somo holes in negative mold, I think that the mix needed more time.

Now is time to reproduce the piece. The result was good but it can improve.