Machine design

Assigment objetive:

1- Make a machine, including the end effector build the passive parts and operate it manually document the group project and your individual contribution

BioPrinter

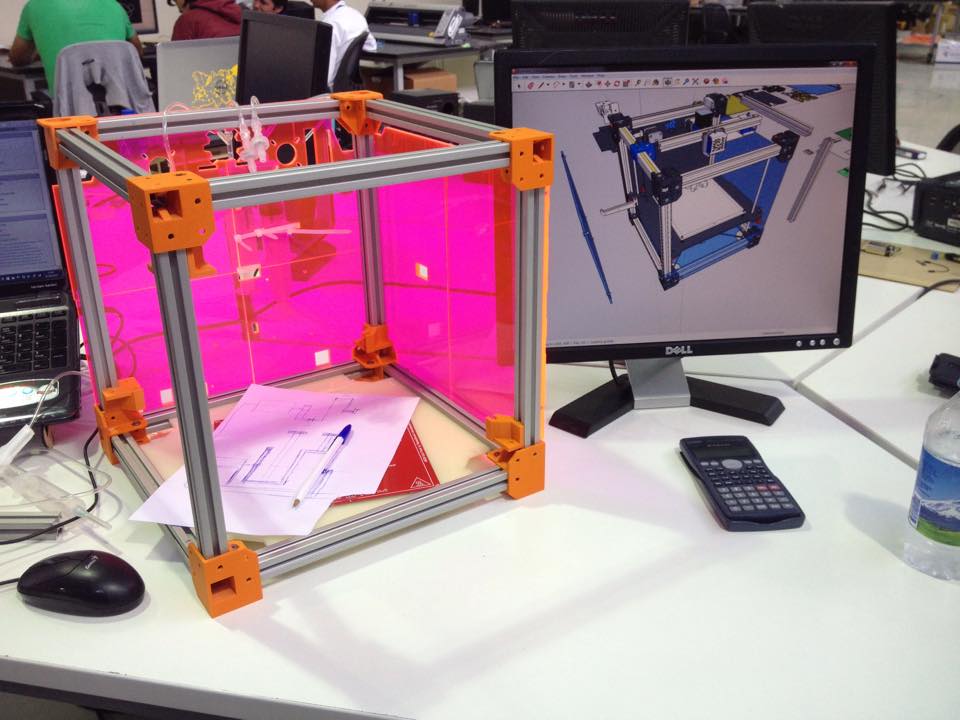

For this assignment what we are doing is a 3d Bioprinting. The focus of this machine is medical; in order to obtain prosthetics or implants.

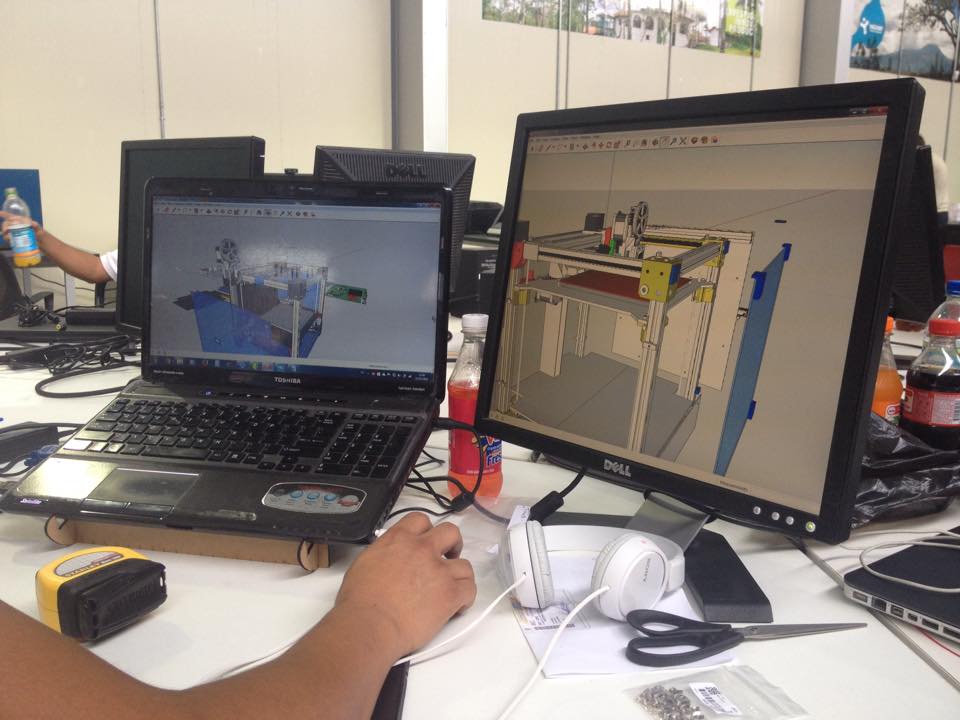

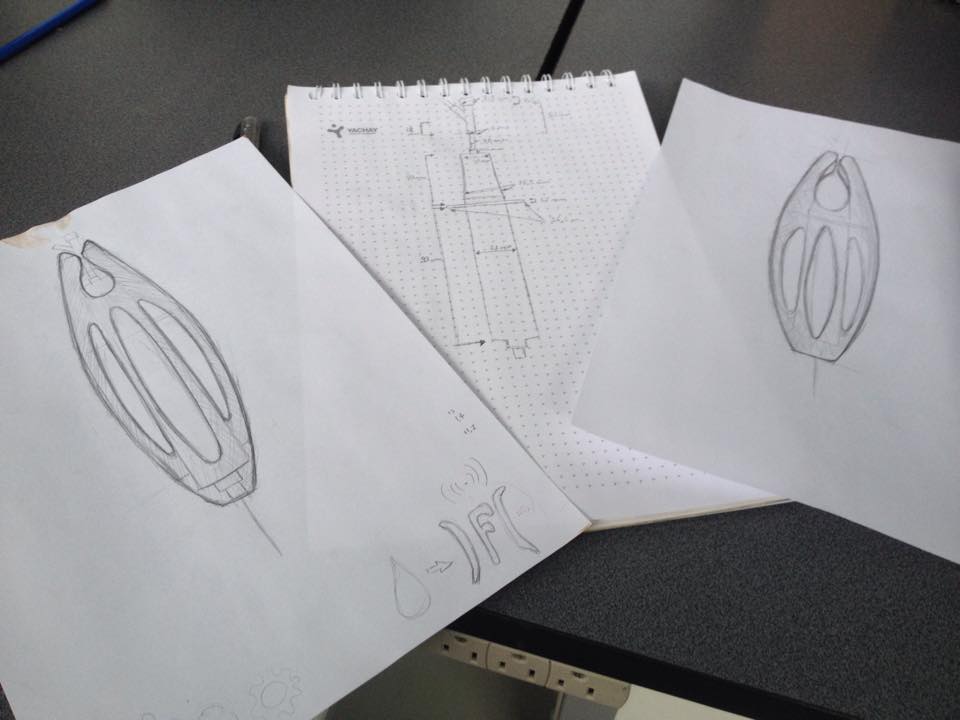

We are using a Falla 3d printer as a technological base to make this machine possible and the main innovation that it would have is the 3D Bio extruder. So we’ve been generating a brainstorm in order to find the best option to build the extruder.

As a result of the brainstorm we find 2 main issues:

1. - Build a 3D printer

1.1. - Assemble the structure1.2. – Mount mechanical system

1.3. - Install electrical system

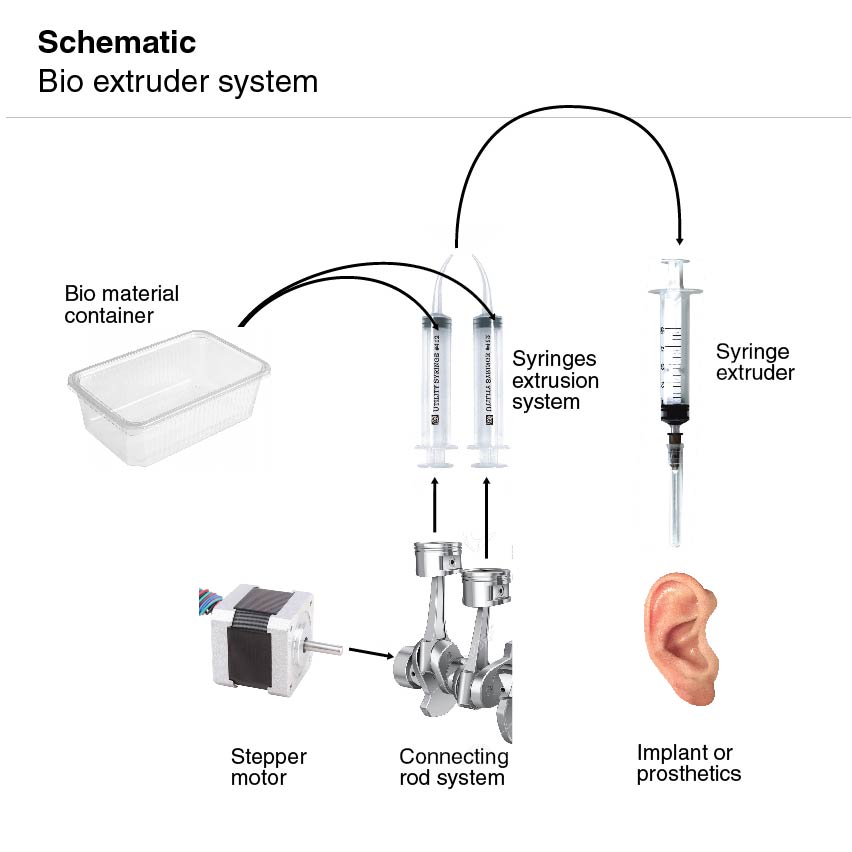

2. - Design, fabricate and taste a extruder for biomaterials

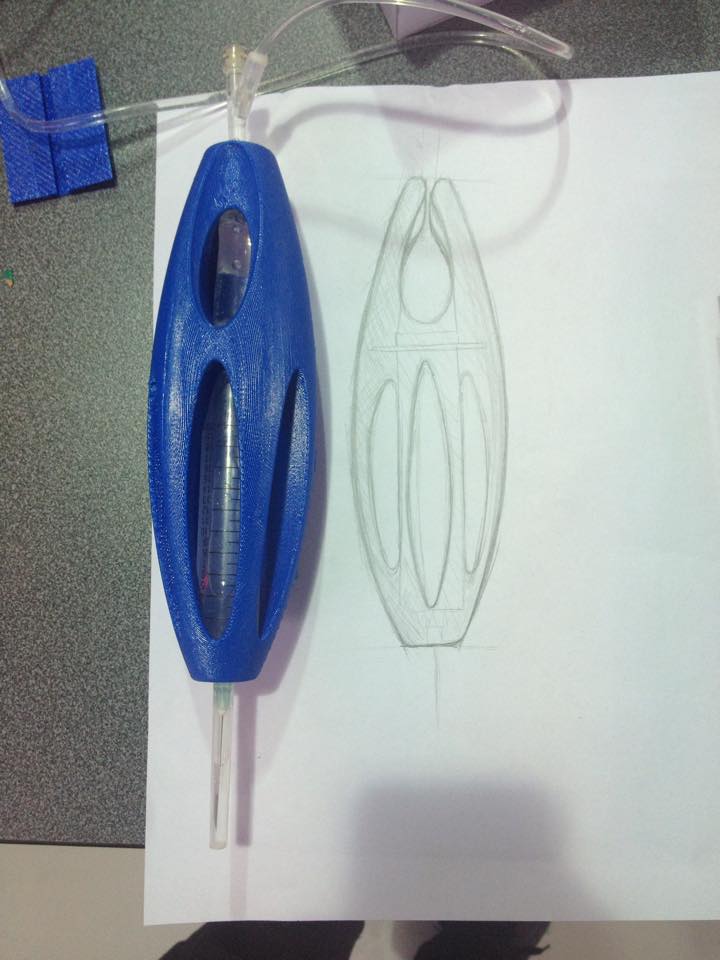

2.1. - Design schematically the extruder system2.1.1. – Identify the main issues and propose solutions

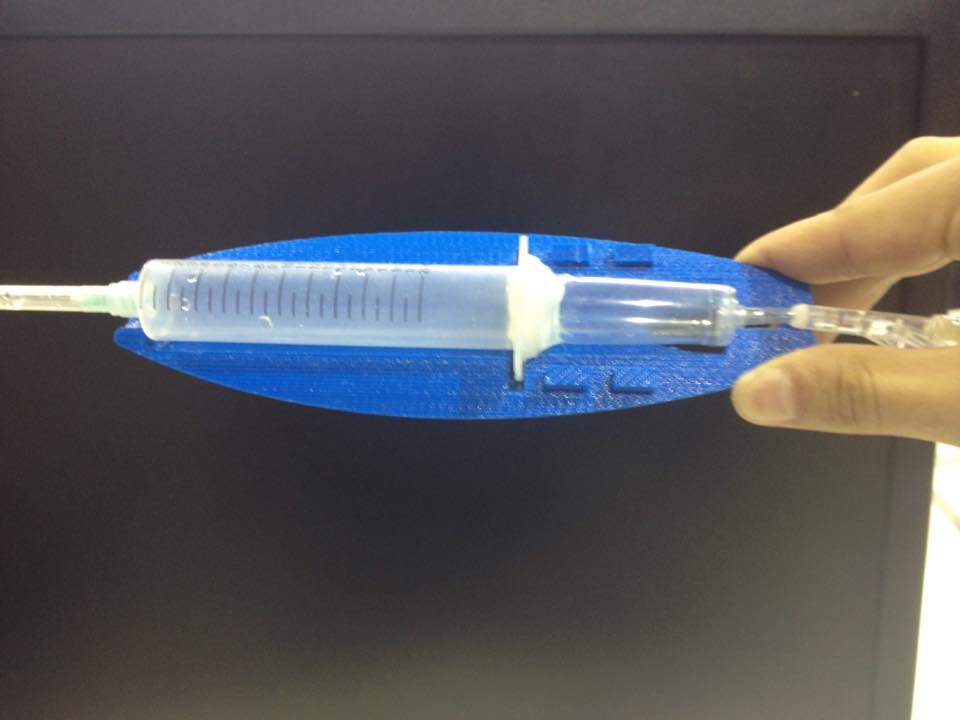

2.2. – Fabricate parts of the extruder and assemble them.

2.3. – Taste extruder system

3. - Test everything together

1. - Build a 3D printer

We started pinting 3D files, buying components and parts. And the main problem that we found is that Yachay is not closed of a city and some pieces we hadn’t find. And get everything what we needed took us some various time.

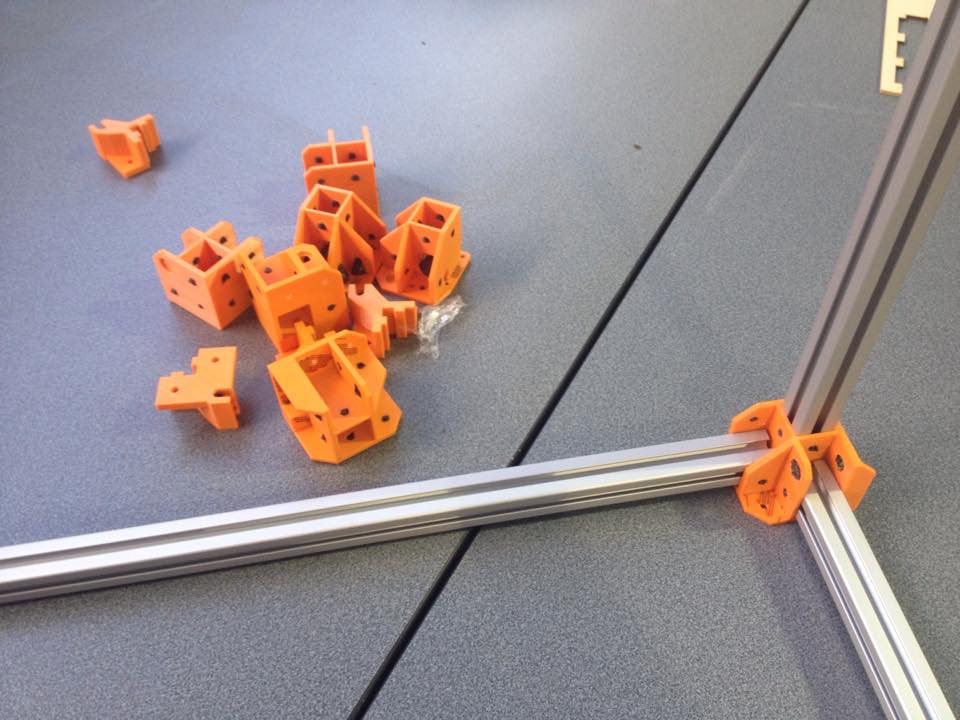

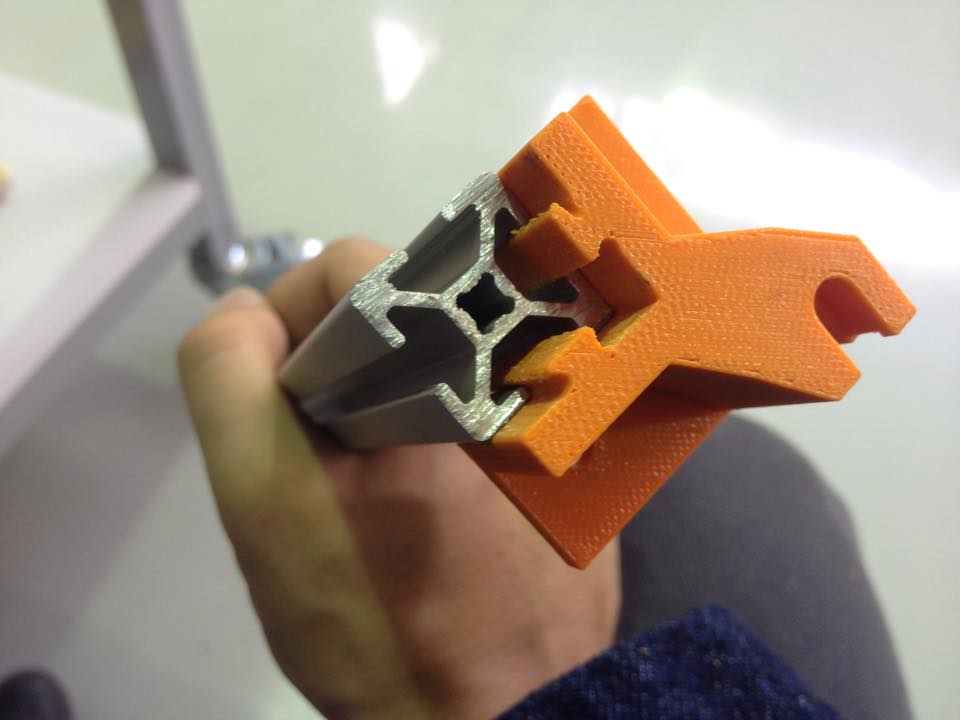

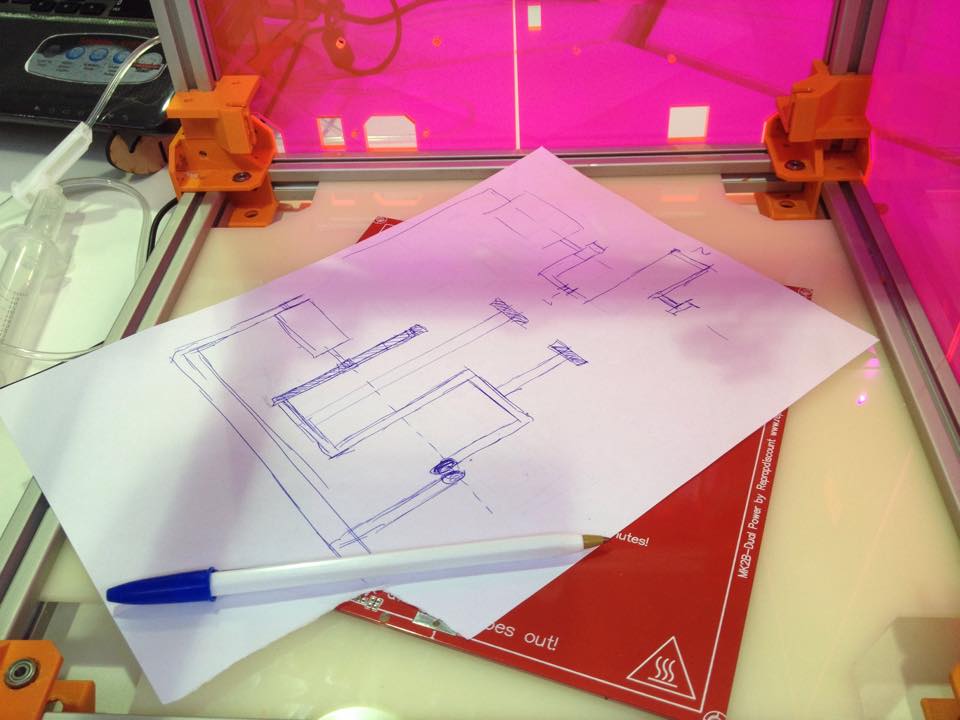

1.1. - Assemble the structure

At the same time we were cutting pieces and advancing with 3D modeling and simulating the Bioextruder system.

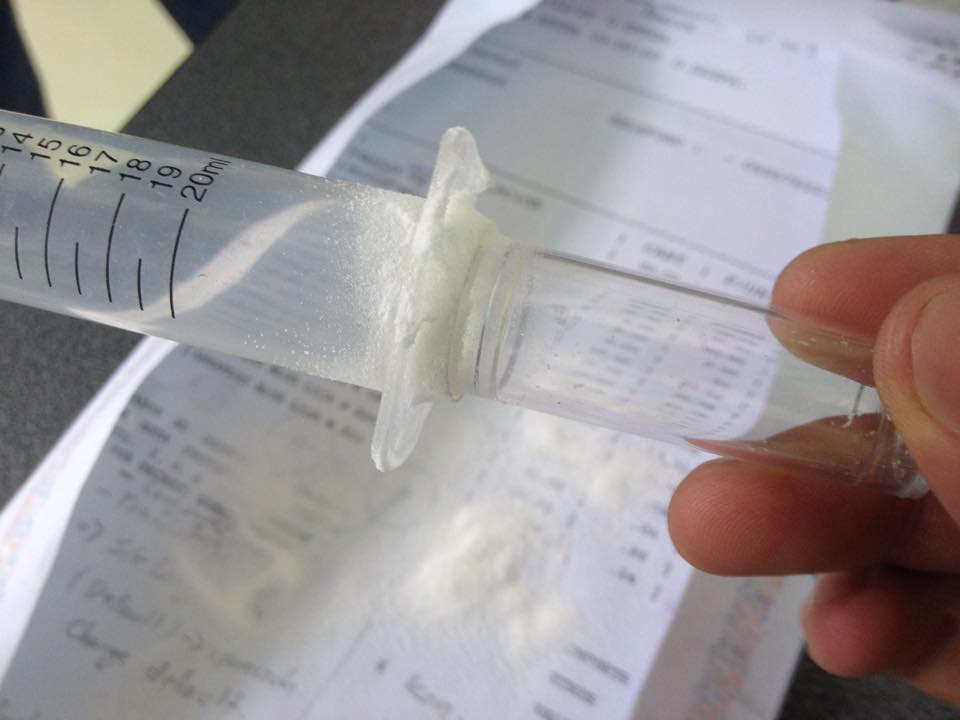

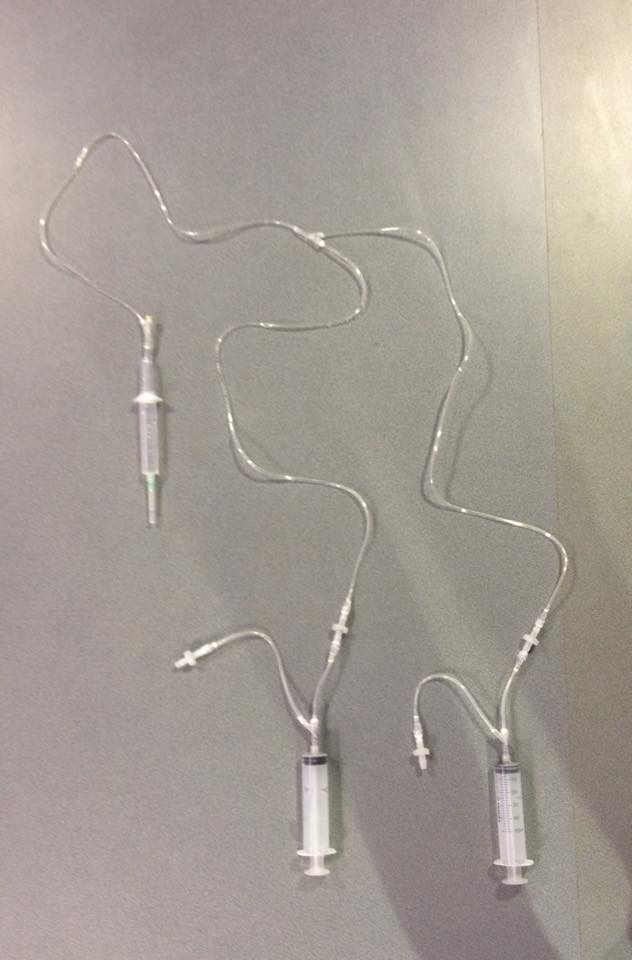

We found some details to solve in the printed files as you can see in the next images. At the same time we were developing the extruder system hacking some medial utensils.

And finally, I’ve been mixing codes and generating code in order to get different blink LED results as you can see in the video at the beginning of this page. Also I’ve been experimenting with generate code in Python and Scratch (blocks programming). I’m in love with scratch program :)

Then I found two options to define the design and I decided to use Grasshopper parametric function to cut each piece in order to get the cut lines to introduce in CNC machine.

Index

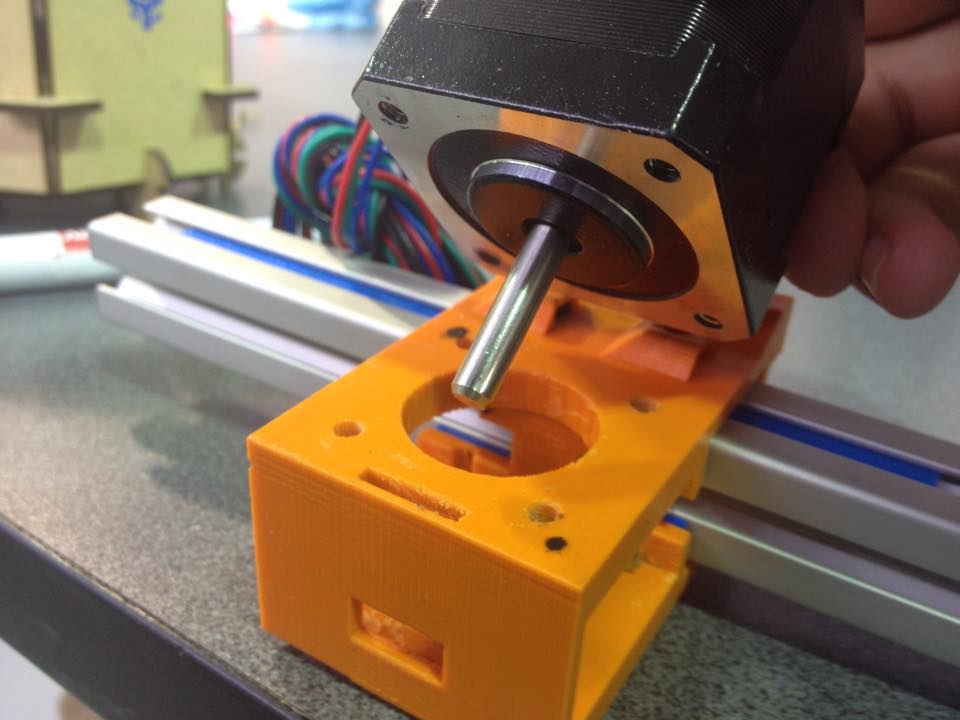

1.2. – Mount mechanical system

Index

1.3. - Install electrical system

Electrical Installation

My personal contribution was to implement all electrical installation.

In our FabLab was impossible to use the Gestalt Nodes becouse we don't have the RS-485 transceiver for develop FABNET PCB. Remember that FABNET is the physical layer and if you don't comunicate every physical node with the computer is impossible to control the cnc machine.

The electronic components of the printer are:

In our FabLab was impossible to use the Gestalt Nodes becouse we don't have the RS-485 transceiver for develop FABNET PCB. Remember that FABNET is the physical layer and if you don't comunicate every physical node with the computer is impossible to control the cnc machine.

Ramps 1.4 is a shield for Arduino Mega.

First, I connected steppers, endstops, drivers and LCD on the shield (RAMPS 1.4). Is important to connect all jumpers on each driver for maximun resolution. Next image is an schematic of connections.

Our printer is a replica of Falla 3D printer thus I downloaded firmware here.

For this printer I used Single Extruder Falla firmware. After to upload firmware on Arduino is necessary some changes:

- Check pin assignments in "pins.h" file.

- In "Configuration.h" file disable all temperature sensors and eneable End Stop Pullups becouse the printer has mecanical switches.

I used Repetier Host software to generate G-CODE.

Before starting printing a file is necessary edit G-CODE. Is important to delete the code "M109 S200" (wait for temperature to be reached) becouse the printer doesn't have sensor temperatures.

These were my personal contribution and this video is the test of the electrical installation of the printer.

Index

2. - Design, fabricate and taste a extruder for biomaterials

2.1. - Design schematically the extruder system

2.1.1. – Identify the main issues and propose solutions

Index

2.2. – Fabricate parts of the extruder and assemble them.

Index

2.3. – Taste extruder system

Index

3. - Test everything together

Index